Safety

Environment

Avoid use in dangerous environments.

Do not use in rain, damp or wet locations, or in the presence of

explosive atmospheres (gaseous fumes, dust, or ammable mate-

rials). Remove materials or debris that may be ignited by sparks.

Keep work area tidy and well-lit - a cluttered or dark work area may

lead to accidents.

Protect others in the work area and be aware of surroundings.

Provide barriers or shields as needed to protect others from debris

and machine operation. Children and other bystanders should be

kept at a safe distance from the work area to avoid distracting the

operator and/or coming into contact with the machine. Operator

should be aware of who is around them and their proximity. Sup-

port personnel should never stand next to, in front of, or behind

the machine while the machine is running. Operator should look

behind them before backing up.

Guard against electric shock.

Ensure that machine is connected to a properly grounded outlet.

Prevent bodily contact with grounded surfaces, e.g. pipes, radia-

tors, ranges, and refrigerators. When scoring or making cuts,

always check the work area for hidden wires or pipes.

5

GENERAL RULES FOR SAFE OPERATION

Before use, anyone operating or performing maintenance on this equipment must read and understand this manual, as well as any labels pack-

aged with or attached to the machine and its components. Read the manual carefully to learn equipment applications and limitations, as well

as potential hazards associated with this type of equipment. Keep manual near machine at all times. If your manual is lost or damaged, contact

National Flooring Equipment (NFE) for a replacement.

Personal

Dress properly and use safety gear.

Do not wear loose clothing; it may be caught in moving parts.

Anyone in the work area must wear safety goggles or glasses,

hearing protection during extended use, and a dust mask for dusty

operations. Hard hats, face shields, safety shoes, etc. should be

worn when specied or necessary.

Maintain control; stay alert.

Keep proper footing and balance, and maintain a rm grip.

Observe surroundings at all times and use common sense. Do not

use when tired, distracted, or under the inuence of drugs, alcohol,

or any medication that may cause decreased control.

Keep hands away from all moving parts and tooling.

Wear gloves when changing tooling. Remove tooling when ma-

chine is not in use and/or lower cutting head to the oor.

Do not force equipment.

Equipment will perform best at the rate for which it was designed.

Excessive force only causes operator fatigue, increased wear, and

reduced control.

Equipment

Use proper parts and accessories.

Only use NFE-approved or recommended parts and accessories.

Using any that are not recommended may be hazardous.

Ensure accessories are properly installed and maintained.

Do not permanently remove a guard or other safety device when

installing an accessory or attachment.

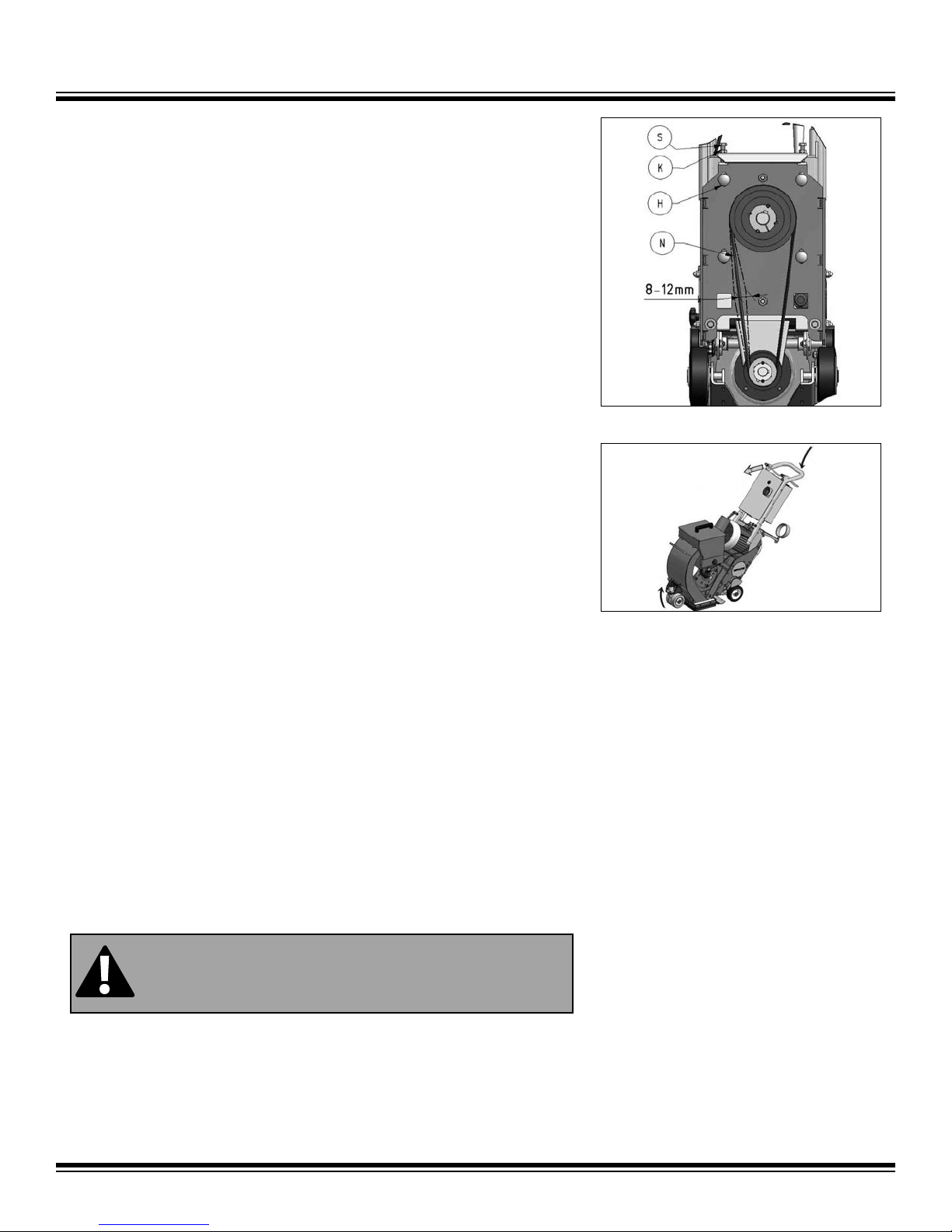

Inspect for damaged parts.

Check for misalignment, binding of moving parts, loose fasteners,

improper mounting, broken parts, and any other conditions that

may affect operation. If abnormal noise or vibration occurs, turn

the machine off immediately. Do not use damaged equipment until

repaired. Do not use if power switch does not turn machine on and

off. For all repairs, insist on only identical NFE replacement parts.

Maintain equipment and labels.

Keep handles dry, clean, and free from oil and grease. Keep cut-

ting edges sharp and clean. Follow instructions for lubricating and

changing accessories. Motor and switches should be completely

enclosed at all times with no exposed wiring. Inspect cord regu-

larly. Labels carry important information; if unreadable or missing,

contact NFE for a free replacement.

Avoid accidental starting; store idle equipment.

When not in use, ensure that the machine is unplugged; do not

turn on before plugging in. Store in a dry, secured place. Remove

tooling when storing, and keep away from children.

Maintenance & Repairs

Begin maintenance work only when the machine is shut

down, unplugged, and cooled down.

Use proper cleaning agents.

Ensure that all cleaning rags are ber-free; do not use any aggres-

sive cleaning products.

Schedule regular maintenance check-ups.

Ensure machine is properly cleaned and serviced. Remove all

traces of oil, combustible fuel, or cleaning uids from the machine

and its connections and ttings. Retighten all loose ttings found

during maintenance and repair work. Loose or damaged parts

should be replaced immediately; use only NFE parts.

Do not weld or ame-cut on the machine during repairs, or

make changes to machine without authorization from NFE.

CAUTION! ENSURE PROPER USE OF EXTENSION CORDS. IF AMP DRAW IS HIGHER THAN SHOWN ON

TABLE OR CORD IS LONGER THAN 50 FT, SEE AN ELECTRICIAN.

ASSUMPTIONS: 3% ALLOWABLE VOLTAGE DROP, COPPER CONDUCTORS RATED FOR 75OC, 1.25

SAFETY FACTOR, CORD VOLTAGE RATING OF 600VAC, PROPER CORD TYPES (STO, STOW, SOOW).

Amp Draw Gauge

0-12 14

13-16 12

14-24 10

25-40 8

5