FlexMotion™, National Instruments™, ni.com™, nuDrive™, and ValueMotion™are trademarks of National Instruments Corporation. Product and

company names mentioned herein are trademarks or trade names of their respective companies.

321942B-01 ©Copyright 1998, 2000 National Instruments Corp. All rights reserved. January 2000

USER GUIDE

NUDRIVE ACCESSORY

This user guide describes the electrical and mechanical aspects of the

nuDrive power amplifier accessory and describes how to use the nuDrive

with your motion controller.

Contents

Conventions ............................................................................................2

Introduction.............................................................................................2

What You Need to Get Started ...............................................................5

Safety Information ..................................................................................5

Installation and Connector Wiring..........................................................6

Front Panel Switches and Host Bus Interlock Circuit.............................6

Rear Panel Connector Wiring .................................................................7

Motor Power Terminal Blocks ........................................................7

Encoder Terminal Blocks ................................................................8

Limit Switch Terminal Blocks.........................................................11

CX and SX nuDrive Configuration ..........................................11

CF nuDrive Configuration........................................................12

I/O Terminal Blocks ........................................................................13

CX and SX nuDrive Configuration ..........................................13

CF nuDrive Configuration........................................................15

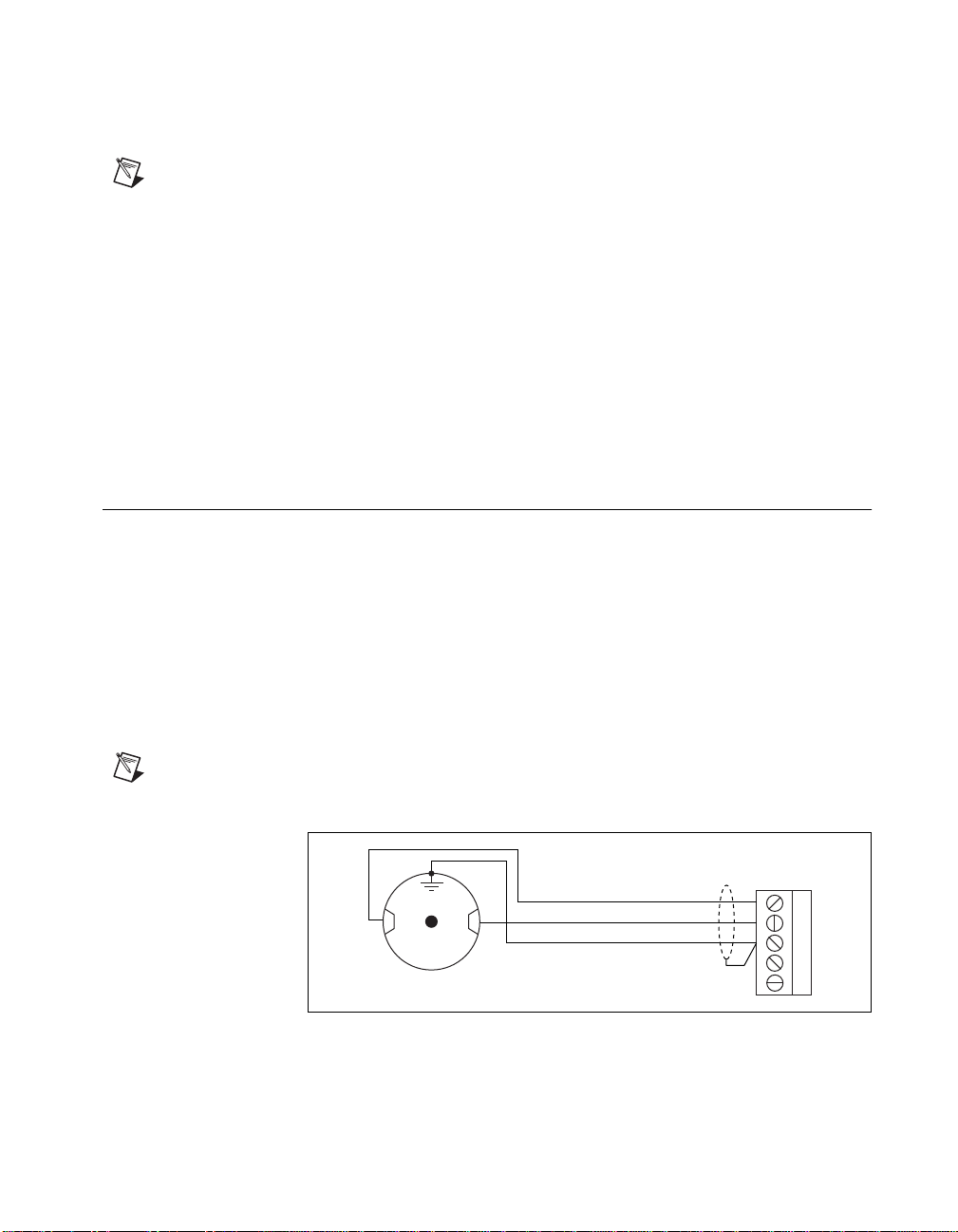

Amplifier/Driver Command Signals.......................................................16

Servo Amplifier Signals...................................................................16

Stepper Driver Signals.....................................................................16

Optional Configurations..........................................................................16

E-Stop Terminal Block....................................................................16

Servo Amplifier Configurations ......................................................17

Adjusting Current Gain and Current Limits.............................19

Balancing the Amplifier Gain...................................................21

Status LEDs..............................................................................22

Stepper Driver Configurations.........................................................23

Stepper Motor Current..............................................................24

Microstep Selection..................................................................26

Stepper Motor Configurations ................................................................26

Specifications..........................................................................................29