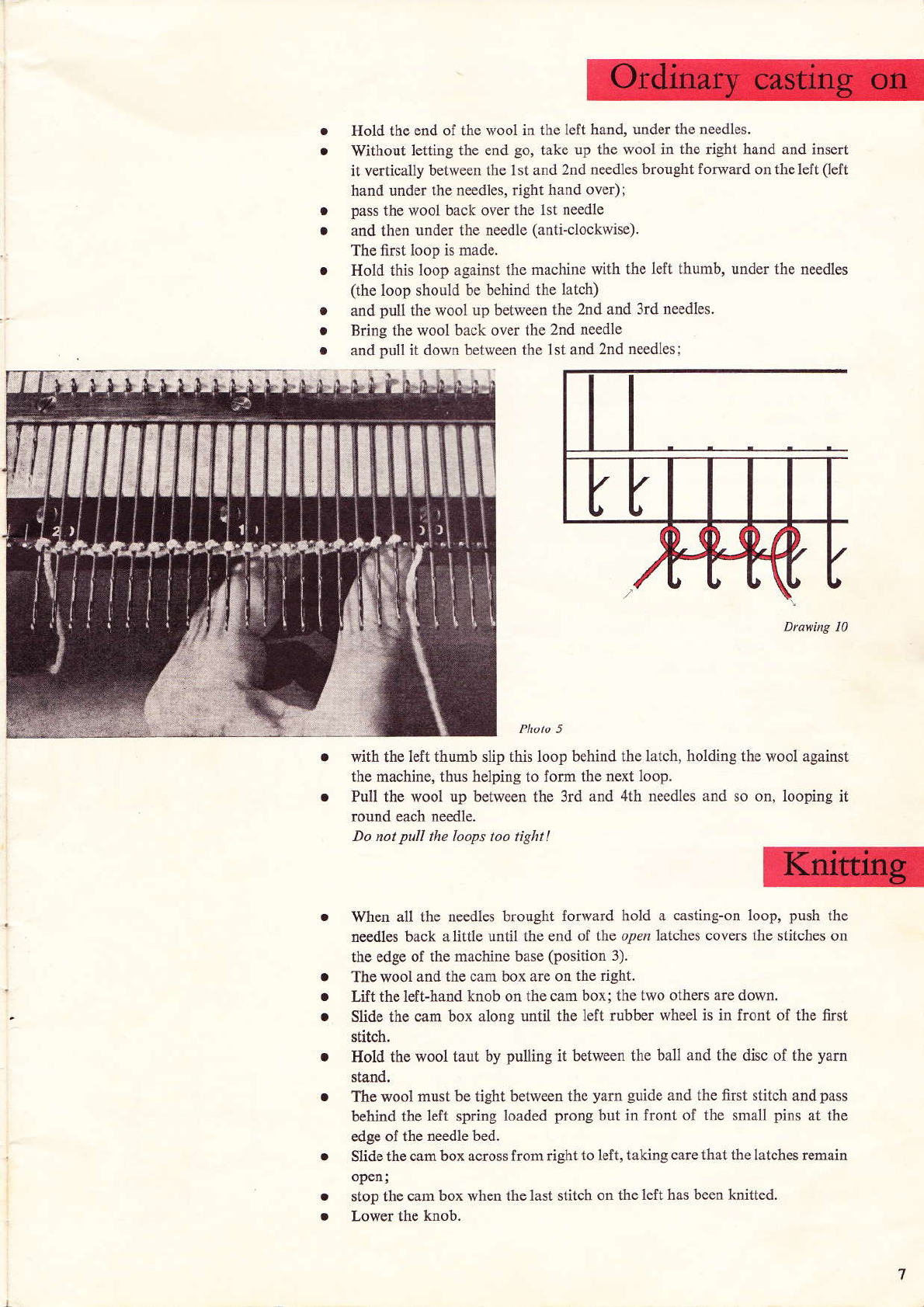

Slide the cam box across from left to Iight, taking care ihat the stitches

remain right against the machine, slipping behind the latches when the

needles come lorward (a nd nol coming forward wjlh the needles on to the

the upper cross bar).

Contirue slidiog the cam box smoothly accross the needles, laking it in

e{ch row only far enough to knit the last stilch.

One row is knilled each lime the cam box passes over lhc wotk. Slocking

rtitch is bcing formed-purl side lacing you.

fmportant !

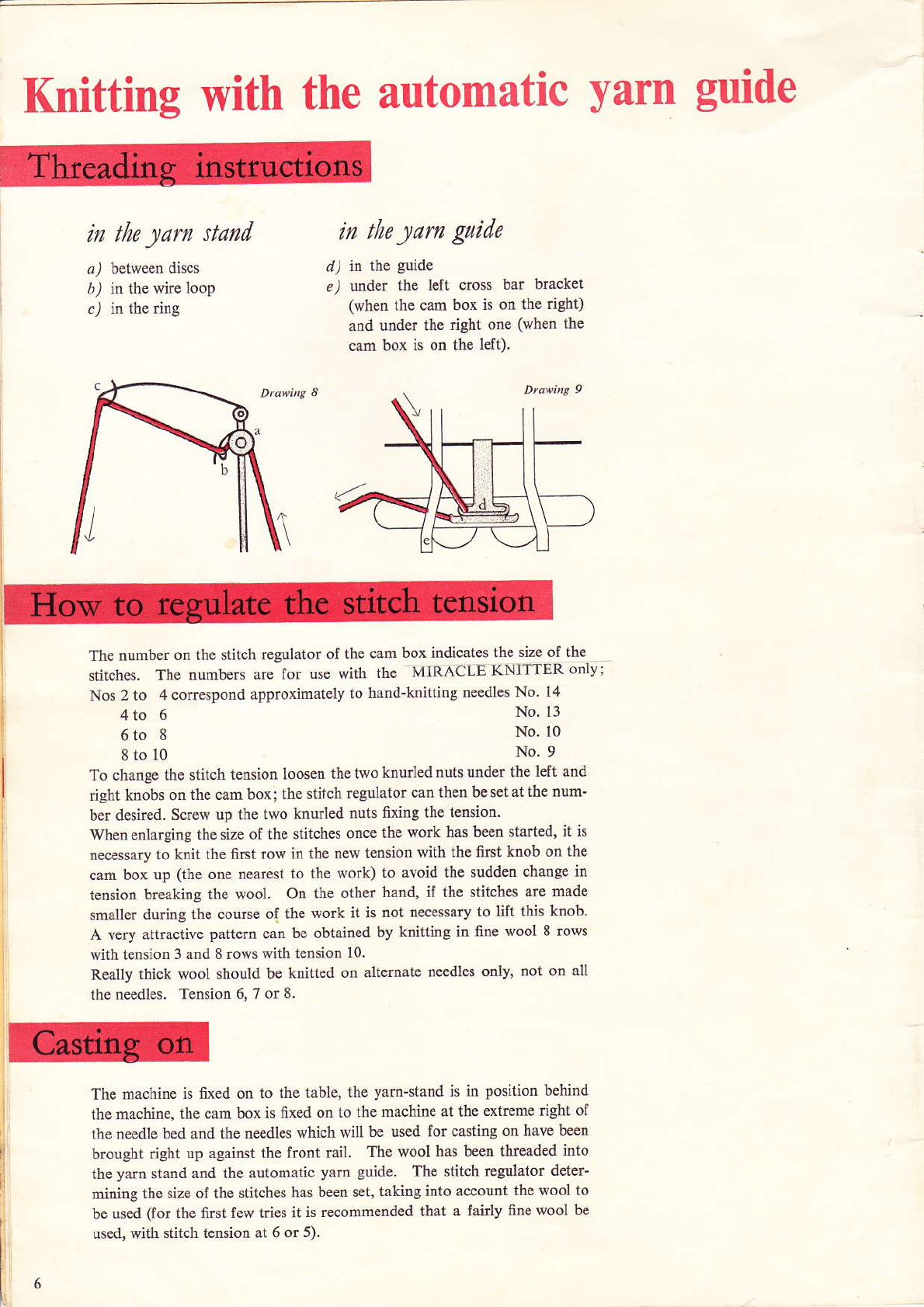

Thc wool must be threaded correcrly in the yarn stand and the aulomalic

yarn guide.

The ball should unwind easiiy.

The stitch tension mLrst correspond to the thickness ol the wool used.

The cam box should nol be laken further than is necessary to knil Ihe last

stitch. Should it be n€cessary to go beyond this poinl the wool should be

given morc play and pulled taul again when bringing thecam boxback on lo

lhc selvedge.

Do not turn brck once r row has been startcd.

Do not Iift the work up to look at the other side: itmight become unhooked.

The lhree knobs should be down (except during the first row, when the lst

knob should be up).

Never lower a knob when the corresponding part oi the cam box is on lhe

worki the leet o[theneedles would prevent ihe cam lrom descending properly.

Please note

How the selvedge stitch is formed:

At the beginning oi a row the yarn should come from underneath the

needle; rhe stitch should slip behind rhe latch Nheo the needle come! for'

ward and ahewool should be stretched tautly on to the needle in tront of the

llLtch.

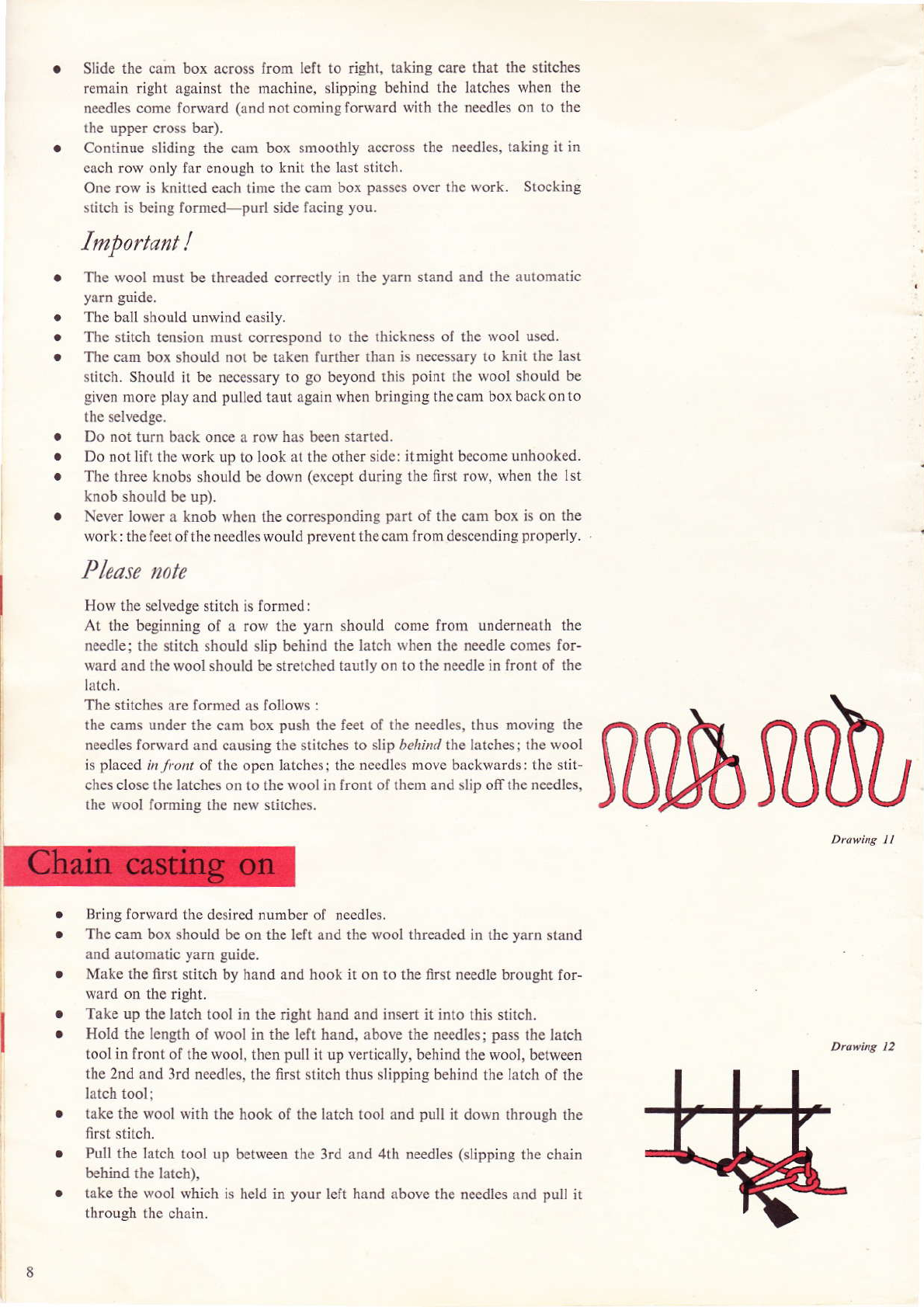

The stitches rre formed as lollows :

the cams under the cam box push rhe leet ol lhe needles, thus moving the

needles forward and causing the st;tches to slip relxrLl the latches; lhe wool

is placed rr l.orr oi the open latchest the needles move brckwards: the stit-

ches close the latches on to the wool in fronl of them and slip offthe needles,

rhe wool lorming the new stitches.

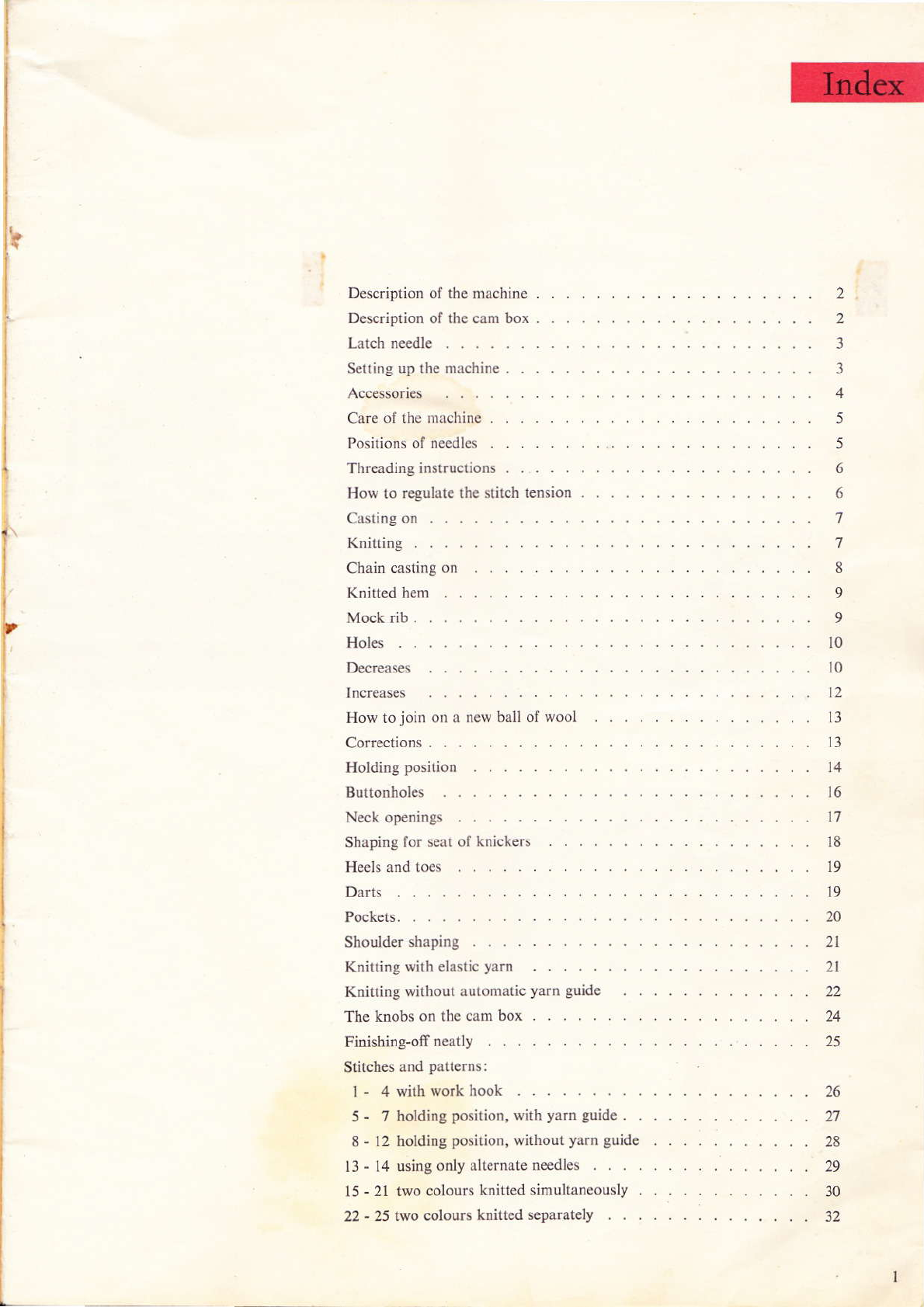

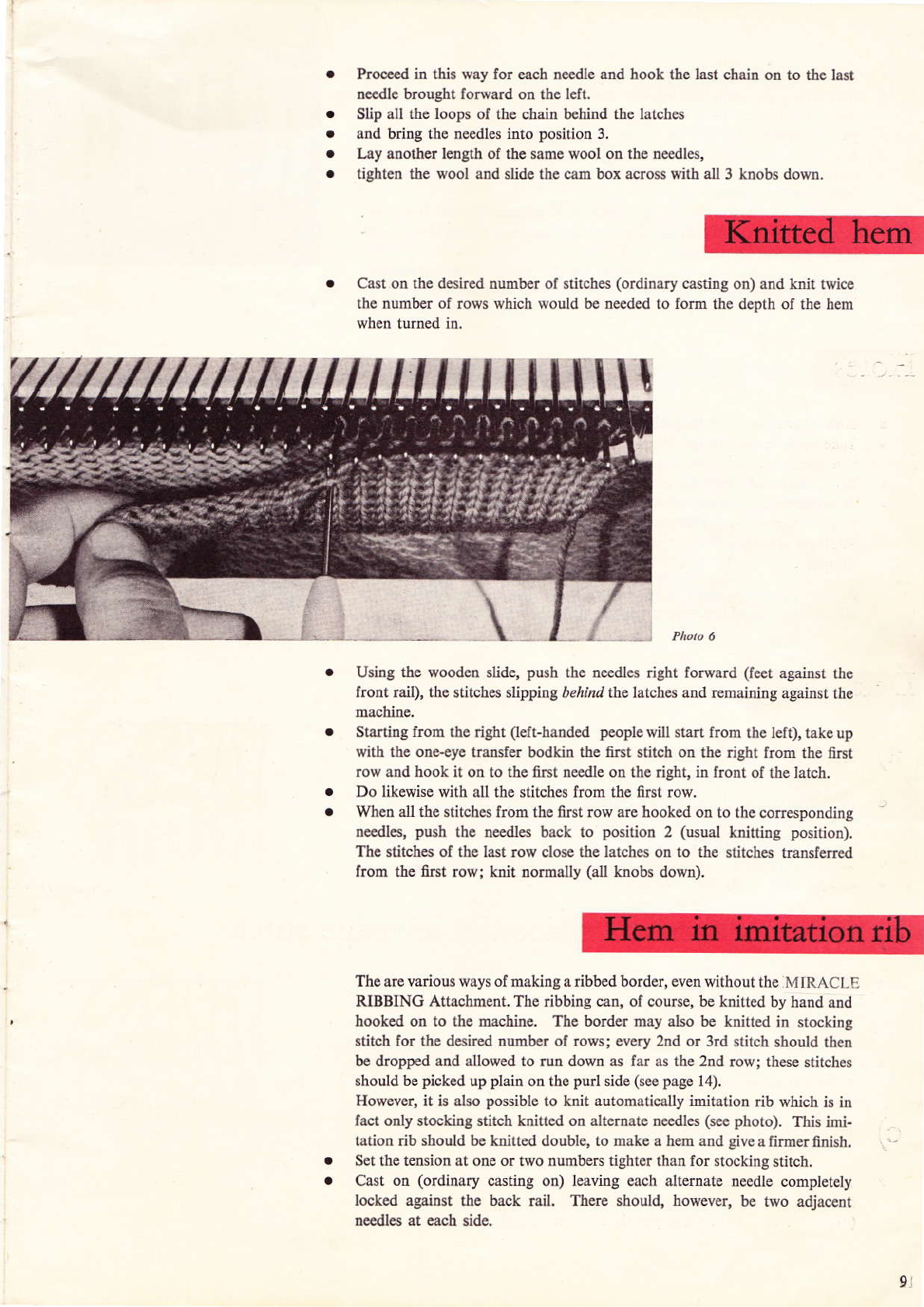

Bring forward the desired number ot n€edles.

The cam box should be on the left and the wool threaded in rhe yarn stand

and automatic yarn guide.

Make the first sritch by hrnd and hook it on to the first needle brought for-

ward on the right.

Take up the latch tool in rhe right hand and irsert it into this slilch.

Hold the length ot wool in the lelt hafld, above the needles; pass the Iatch

tool in front of the wool, then pull it up vertically, brhind Ih€ wool, betw€en

the 2nd and 3rd needlcs, the firsr slitch thus slipping behind the Iatch of the

Iatch tooli

lake the wool with thc hook o[ lhe latch tool nnd puU ir down lhrough rhe

first stilch.

Pull the latch tool up between thc 3rd and 41h ne€dles (slipping the chain

behind the latch),

take the \yool which is held in your left hand nbove the ne€dles.rnd pull it

through the chain.