Negele FMI User manual

Operating Manual FMI

Magnetic-inductive Flowmeter FMI

FMI-C (compact Version)

FMI-R (remote Version)

Negele Messtechnik GmbH

Raiffeisenweg 7

D-87743 Egg an der Günz

You can reach our technical service department at:

Tel.: 0049 8333 9204 720

E-Mail: support@anderson-negele.com

Operating Manual FMI

Negele Messtechnik GmbH

1

Raiffeisenweg 7

87743 Egg a. d. Günz

Table of contents

1. General description ..................................................................................................5

1.1. Structure and Identification of the device...............................................................5

1.2. Function ....................................................................................................................5

1.3. Technical data...........................................................................................................6

1.3.1. Converter......................................................................................................6

1.3.2. Transmitter in compact design ......................................................................6

1.3.3. Transmitter in remote design.........................................................................7

1.3.4. Measuring ranges and error limits.................................................................7

2. Safety instructions....................................................................................................8

2.1. General remarks .......................................................................................................8

2.1.1. Special diligence of the user..........................................................................8

2.1.2. General safety instructions............................................................................9

2.2. Intended use............................................................................................................10

2.3. Special safety instructions and devices ...............................................................10

2.4. Explanation of the safety symbols used...............................................................11

3. Transport .................................................................................................................12

3.1. General information................................................................................................12

3.2. Dimensions and weight..........................................................................................13

3.2.1. Remote version...........................................................................................13

3.2.2. Compact version.........................................................................................13

3.2.3. Converter with wall bracket .........................................................................14

3.2.4. Dimensions of the process connections ......................................................14

4. Application...............................................................................................................15

4.1. Conditions required for the transmitter ................................................................15

4.1.1. Measuring of air and gas.............................................................................15

4.1.2. Solids..........................................................................................................15

4.1.3. Mounting position – electrode axis ..............................................................16

4.1.4. Inlet and outlet pipe sections.......................................................................19

4.1.5. Conductivity conditions................................................................................19

4.1.6. Interference fields........................................................................................19

4.1.7. Earthing/grounding conditions.....................................................................19

4.1.8. Meter tube lining..........................................................................................20

4.2. Flow direction .........................................................................................................20

4.3. Conditions required for the converter...................................................................21

4.4. Display turned by 90°.......................... ...................................................................21

4.5. Alignment of the converter ....................................................................................22

4.6. Cable lengths for the remote version....................................................................22

4.7. Welding work........................................................................................................... 23

4.8. Wire end ferrule........................................................................................................23

5. Installation...............................................................................................................24

5.1. Installation instructions for the transmitter..........................................................24

5.2. Installation instructions for the converter.............................................................25

5.2.1. Installation of the electrical power supply ....................................................25

5.2.2. Connection of the transmitter ......................................................................28

Operating Manual FMI

Negele Messtechnik GmbH

2

Raiffeisenweg 7

87743 Egg a. d. Günz

5.2.3. Connection scheme for the remote design ..................................................29

5.2.4. Screwed EMC cable gland..........................................................................30

5.3. Electrical connection of peripherals......................................................................31

5.3.1. Digital output...............................................................................................32

5.3.2. Digital input .................................................................................................33

5.3.3. Analog output - current output.....................................................................33

5.3.4. CS3-Bus......................................................................................................34

6. Commissioning........................................................................................................35

6.1. General information................................................................................................35

6.2. Advice for starting-up the FMI ...............................................................................36

6.3. Basic settings upon delivery................................................................................336

6.3.1. System structure and operating elements ...................................................37

6.4. Flow direction .........................................................................................................38

6.5. Zero point adjustment (“ZERO adjust”) ................................................................38

6.6. Metering interruption (assignment of the digital input) .......................................38

6.7. Metering with an empty meter tube.......................................................................38

6.7.1. Internal "EMPTY pipe detection" .................................................................39

6.8. Metering at low conductivities...............................................................................39

6.9. Optical operating elements....................................................................................39

7. Operation..................................................................................................................40

7.1. Basic keypad functions..........................................................................................41

7.2. Image navigator ......................................................................................................41

7.2.1. Zero reset of the volume counter.................................................................44

7.2.2. How to delete malfunction messages..........................................................44

7.2.3. Parameter change.......................................................................................44

7.2.4. How to release a parameter change:...........................................................45

7.2.5. How to release the service functions:..........................................................45

7.3. Image level: Measured values................................................................................46

7.3.1. Measured value: Volume...........................................................................446

7.3.2. Measured value: Flow rate........................................................................446

7.3.3. Measured value: Flow rate and volume.....................................................446

7.3.4. Measured value: Total quantity....................................................................46

7.3.5 Error message: Transmitter not connected.................................................. 47

7.4. Image level: Base parameters................................................................................47

7.4.1. Language....................................................................................................47

7.4.2. CS3Bus address .........................................................................................47

7.4.3. Dimension...................................................................................................48

7.4.4. Profibus address .........................................................................................48

7.4.5 Q-type 48

7.5. Image level: Pulse output.......................................................................................49

7.5.1. Pulse mode.................................................................................................49

7.5.2. PV1.............................................................................................................50

7.5.3. TP1.............................................................................................................50

7.5.4. PV2.............................................................................................................50

7.5.5. TP2.............................................................................................................50

7.6. Image level: Digital input........................................................................................51

7.6.1. Function: Digital input..................................................................................51

7.6.2. IT1...............................................................................................................51

7.7. Image level: Current output....................................................................................51

Operating Manual FMI

Negele Messtechnik GmbH

3

Raiffeisenweg 7

87743 Egg a. d. Günz

7.7.1. Current output mode ...................................................................................52

7.7.2. Qmax ..........................................................................................................52

7.7.3. TP3.............................................................................................................52

7.8. Image level: Metering parameters .........................................................................52

7.8.1. LFS.............................................................................................................53

7.8.2. MSPE..........................................................................................................53

7.8.3. BSPE ..........................................................................................................53

7.8.4. Average.......................................................................................................53

7.8.5. Offset..........................................................................................................54

7.8.6. SPAN..........................................................................................................54

7.8.7. Pipe Detect (recognition of an empty meter tube)........................................54

7.8.8. Nominal width..............................................................................................54

7.9. Image level: Special functions...............................................................................54

7.9.1. Zero adjust..................................................................................................55

7.9.2. Factory setting.............................................................................................55

7.10. Image level: Service level.......................................................................................55

7.10.1. Error register: Metering ...............................................................................55

7.10.2. Error register: Operating system................................................................556

7.10.3. Simulation of the current output.................................................................556

7.10.4. Simulation of the pulse outputs .................................................................556

7.10.5. Simulation of the flow rate...........................................................................57

7.11. Image level: Info......................................................................................................57

7.11.1. Info1............................................................................................................57

7.11.2. Info2............................................................................................................57

7.11.3 Info3 58

8. Parameterization.....................................................................................................59

8.1. Adjustments............................................................................................................62

8.1.1. Adjustment by calibration factor "m spe" ...................................................622

8.2. Measuring accuracy: ............................................................................................633

9. Troubleshooting....................................................................................................644

9.1. Error diagnosis.....................................................................................................644

9.1.1. Error diagnosis via the display...................................................................644

9.1.2. Error list.....................................................................................................655

9.2. Typical effects or error sources...........................................................................666

9.2.1. Flow without flow rate indication:...............................................................666

9.2.2. No pulse transmission despite displayed flow............................................666

9.2.3. No analog signal available.........................................................................666

9.2.4. Deviations of measured values .................................................................677

9.3. Error reset .............................................................................................................688

9.4. Transmitter tests...................................................................................................688

9.4.1. Insulation test............................................................................................688

9.4.2. Symmetry test...........................................................................................699

9.4.3. Visual check..............................................................................................699

10. Maintenance ............................................................................................................70

10.1. Safety instructions for maintenance work............................................................70

10.2. Routine maintenance..............................................................................................70

10.2.1. Preventive maintenance steps ....................................................................71

10.3. Repairs ....................................................................................................................72

Operating Manual FMI

Negele Messtechnik GmbH

4

Raiffeisenweg 7

87743 Egg a. d. Günz

10.3.1. Sending-in the flow meter to the manufacturer............................................72

10.3.2. Repair Work................................................................................................73

10.3.2.1. Replacement of the sealing cover of the operating unit ...............73

10.3.2.2. Replacement of the transmitter....................................................73

10.4. Special program functions.....................................................................................73

10.4.1. Flow simulation ...........................................................................................73

10.4.2. Simulation via the display unit .....................................................................74

10.5. Spare parts to be kept available on stock.............................................................74

11. Decommissioning....................................................................................................74

11.1. Temporary decommissioning................................................................................74

11.2. Final decommissioning / disposal.........................................................................74

12. Contact details.........................................................................................................75

Operating Manual FMI

Negele Messtechnik GmbH

5

Raiffeisenweg 7

87743 Egg a. d. Günz

1. General description

1.1.

Structure and Identification of the device

This instruction manual refers to both the compact all-in-one design and for the remote version of

the electromagnetic flow meter.

The FMI is available in the following versions:

operated by DC power supply, compact version

operated by AC power supply, compact version

operated by DC power supply, remote version

operated by AC power supply, remote version

compact version:

Transmitter and converter form a single unit.

Remote version:

The transmitter is installed in the pipeline. The converter is fixed to the wall. Both

components are connected by means of a connection cable for coil current supply and

electrode signals.

This instruction manual does not deal with the Weights and Measures-approved versions of the flow

meter.

1.2.

Function

The electromagnetic flow meter, type FMI, measures both the flow rate and the volume of liquid

flows at a high precision.

The measuring device is suitable for measuring conductive liquids.

The FMI converter is a microprocessor based device that supplies the transmitter with a switched

and regulated coil current.

The signal generated at the electrodes is amplified in the converter, conditioned and shown in the

internal measuring registers both as flow rate and volume information.

Volume pulses (pulses per volume unit) are output for controlling and measuring uses.

The instantaneous flow rate is output as an analog signal of 0 or 4...20 mA according to the

desired range of 0...100 %.

Operating Manual FMI

Negele Messtechnik GmbH

6

Raiffeisenweg 7

87743 Egg a. d. Günz

1.3.

Technical data

1.3.1. Converter

Supply voltage: FMI DC: 9 - 32 V DC

FMI AC: 100 - 240 V AC, 50/60 Hz

Power consumption: 10 VA max. / 8 watts

Electrical fuse connection: AC power supply: T 500 mA

DC power supply: T 1.5 A

Digital pulse output: 3 x galvanically isolated optocoupler output

Maximum load: 32 V / 20 mA / pulse sequence: 1 kHz max.

Analog output: 0 or 4 - 20 mA (active or passive), maximum load 500 Ω

(optional) 4-20 mA passive output with Hart communication

Max.500 Ωload

Digital input: 1 x galvanically isolated optocoupler input;

9 - 32 V, Ri < 3.2 kΩ, activation: 9 - 32V DC,

1 kHz max.

Serial interface: RS485, CS3-Bus protocol

Ambient temperature: -20°C ... +55°C DC power supply

-20°C ... +45°C AC power supply

For further technical data please refer to item 5.3.

1.3.2. Transmitter in compact design

Transmitter compact version

Process connection:

Aseptic flange

Nominal widths:

DN 10, 15, 25, 32, 40, 50, 65, 80, 100, 125, 150

Optional product connections:

Tri-Clamp, Cherry I-line, ANSI Flange

Meter tube: Material no.: 1.4404 / AISI 316 L

Liner: PFA

Electrodes: Material no.: 1.4404 / AISI 316 L

Materials:

Housing: Material no.: 1.4301 / AISI 304 (micro blasted)

Protection class:

IP67

Electrical connection:

Internal cable connection

Calibration data included in the associated converter

Product temperature:

100°C max.

Cleaning temperature:

130°C for a maximum period of 30 minutes

Product conductivity:

5 µS/cm at a minimum

Admissible pressure:

0.5 bar absolute at a maximum at 20 °C; max. 16 bar (DN 10 – DN100)

Max. 10 bar (DN125 – DN150)

Flow velocities:

0.1 - 10 m/s

Operating Manual FMI

Negele Messtechnik GmbH

7

Raiffeisenweg 7

87743 Egg a. d. Günz

1.3.3. Transmitter in remote design

Transmitter Remote version

Process connection:

Aseptic flange

Nominal widths:

DN 10, 15, 25, 32, 40, 50, 65, 80, 100, 125, 150

Optional product connections:

Clamp, milk pipe, small flange, etc.

Meter tube: Material no.: 1.4404 / AISI 316 L

Liner: PFA

Electrodes: Material no.: 1.4404 / AISI 316 L

Materials:

Housing: Material no.: 1.4301 / AISI 304 (micro blasted)

Protection class:

IP 67

Inductive resistance:

100 Ω, calibrating data included in the appropriate converter

Electrode cable:

LIYCY-0; 4 x 0.5 mm², shielded

Coil cable:

F-CY-OZ; 2 x 0.5 mm², shielded

Product temperature:

165°C max.

Cleaning temperature:

-

Product conductivity:

15 µS/cm min.

Admissible pressure:

0.5 bar absolute at a maximum at 20 °C; max. 16 bar (DN 10 – DN100)

Max. 10 bar (DN125 – DN150)

Flow velocities:

0.1 - 10 m/s

* The pressure rating depends on the process connection and the seals and gaskets used.

1.3.4. Measuring ranges and error limits

Measuring

tolerance Unit

DN

Total measuring range

[ L/h ]

Flow rate at a

flow velocity of

1 m/s

[ L ] ± 0.2 % *

10

30 - 3,000 300 > 60 L/h

15

70 - 7,000 700 > 130 L/h

25

180 - 18,000 1,800 > 300 L/h

32

300 - 30,000 3,000 > 600 L/h

40

450 - 45,000 4,500 > 1,000 L/h

50

700 - 70,000 7,000 > 1,400 L/h

65

1,200 - 120,000 12,000 > 2,400 L/h

80

1,800 - 180,000 18,000 > 3,600 L/h

100

2,800 - 280,000 28,000 > 5,600 L/h

125

4,400 - 440,000 44,000 > 22,000 L/h

150

6,400 - 640,000 64,000 > 32,000 L/h

* see measuring accuracy 8.2

Operating Manual FMI

Negele Messtechnik GmbH

8

Raiffeisenweg 7

87743 Egg a. d. Günz

2. Safety instructions

Due to the great variety of possible uses, this instruction manual addresses the general application

conditions.

Special cases such as extraordinary ambient conditions or special safety instructions require

coordination with the manufacturer.

2.1.

General remarks

2.1.1. Special diligence of the user

This measuring instrument has been designed and built in consideration of a risk analysis and after

a careful choice of the harmonized standards and further technical specifications to be kept. It

corresponds to the state of the art and offers an optimum safety.

In practical use, however, that degree of safety can only be obtained when all measures required

in this respect will be really taken. It belongs to the diligence of the user of the flow meter to plan

such measures and to check and survey if they are really fulfilled.

In particular, the user has to ensure that:

- The measuring instrument is only used for the intended application as directed (also

see the following chapter “Intended use”).

- The measuring instrument is operated in a perfect and functioning condition and that

especially the safety devices are regularly checked for their proper operation.

- The personal protective equipment required for the operating, maintenance, and repair

staff is kept available and really used.

- The complete instruction manual in a legible condition is permanently available at the

location of the measuring device.

- The device is operated, serviced, and repaired by sufficiently qualified and authorized

personnel only.

- The personnel concerned is regularly trained for all applicable questions of the

protection of labour and environment and familiarized with the instruction manual and

especially the safety precautions included therein.

- All the safety and warning instructions attached to the measuring instrument are not

removed and kept in a legible condition.

In case of problems that cannot be resolved by the user, contact the service department of Negele

Messtechnik GmbH

Operating Manual FMI

Negele Messtechnik GmbH

9

Raiffeisenweg 7

87743 Egg a. d. Günz

2.1.2. General safety instructions

These safety instructions have to be strictly observed in order:

•To not endanger the safety of persons and environment

•To avoid any damages to the measuring instrument

•To prevent any faulty batches upon the production

The electric connection may only be carried out by persons who have got the necessary expert

knowledge (e.g. trained electrical fitters or persons instructed in electrical engineering) and the

necessary authorization from the user.

Unauthorized persons are not allowed to

open a housing that shows this symbol!

The wiring of the voltage supply and the inputs and outputs of the control

circuits has to be carried out professionally in consideration of the up-to-date

state of the art. Also refer to chapter 5 “Installation”/”Electrical Connection”.

In particular, the following references have to be observed:

•Safety instructions

•Electrical connection data

1. All persons who are involved in the installation, commissioning, operation, service, and

maintenance of the flow meter have to be qualified accordingly.

2. This instruction manual has to be strictly observed. The user of the flow meter has to

guarantee that the personnel concerned has read and fully understood the instruction

manual.

3. All kinds of work have to be done with utmost care and may be carried out by

accordingly authorized and trained personnel only. At any rate the directives of the

respective country for opening and repairing the devices have to be considered.

4. The instruction manual has to be available close to the flow meter, easily accessible to

the operating staff.

5. Before starting any cleaning, conversion, service or maintenance work, the measuring

device has to be switched off and disconnected from the mains power. This requires a

device for separating all live wires, e.g. a 2-pole main switch in the control cabinet. The

associated device has to be protected against unauthorized switching-on.

6. Before starting any service and maintenance work, the system has to be flushed with

water and emptied. If the flow meter has to be removed from the pipe system, all

pipelines will have to be previously emptied and protected by means of some

appropriate emptying and shut-off measures.

Warning of

dangerous voltage!

Important

information

Operating Manual FMI

Negele Messtechnik GmbH

10

Raiffeisenweg 7

87743 Egg a. d. Günz

7. The flow meter fulfils the general safety requirements according to EN 61010.

8. Never remove or put out of action any safety devices by modifications to the flow

meter!

9. Do not touch any part of the flow tube while the measuring instrument is cleaned.

Otherwise, you run the risk of getting burnt!

10. To minimize the danger of injury, the working area of the operator has to allow

sufficiently free space.

11. The technical data according to the instruction manual, nameplate and, if available, the

performance specification has to be considered.

If damage is done to the meter all warranties are void.

Dangers not resulting from the functionality of the device, but from the ambient and

operating conditions prevailing at the place of application, have to be referred to in

appropriate instructions to the operators and by the attachment of some danger signs!

The user of the device is exclusively responsible for the compliance with these

instructions!

2.2.

Intended use

The measuring instrument is only allowed to be used for the application that it has been designed,

dimensioned and built for:

-

the connection to an earthed monophase network or a direct current network (see the

nameplate)

-

in industrial areas according to EN 61000-6-2/4 for reasons of EMC

The intended purpose of the electromagnetic flow meter is the measurement of conductive liquids

in the food processing industry and in the cosmetic, pharmaceutical and chemical industries.

This flow meter is not suitable for the measurement of hazardous, explosive, and

combustible liquids of PED group 1.

Any modifications to the measuring device that might have an influence on the function and the

safety devices of the flow meter are only allowed to be carried out by the engineering specialists or

authorized persons of Negele.

Possible misuse

Any utilisation being in contradiction to the above-mentioned application means an inadmissible

misuse of the measuring instrument! In such a case Negele does not assume any responsibility for

the safety.

Negele has to be contacted before the flow meter will be used for any different application, and

after a careful investigation of all facts Negele could possibly release the flow meter for the

intended new application.

2.3.

Special safety instructions and devices

The following dangers could be directly or indirectly caused by the flow meter, type FMI, during

operation or commissioning:

•Electric shock if the electronic housing is opened improperly

Operating Manual FMI

Negele Messtechnik GmbH

11

Raiffeisenweg 7

87743 Egg a. d. Günz

•Burns by touching hot pipe sections

•Scalds and/or chemical burns by hot liquids or gas coming out through leaking flange

connections or because of an inexpert opening of the pipe system

2.4.

Explanation of the safety symbols used

The FMI flow meters are reliable in operation and meet the highest technical specifications. They

leave our factory at a safety-related flawless condition. The devices correspond to the relevant

standards and directives according to EN 61010 “Electrical safety testing for measurement and

laboratory devices”. However, a hazard can originate from the devices, if they are used inexpertly

and not for their intended purpose. Therefore, strictly observe the safety instructions of this

instruction manual which are marked by the following symbols:

Hot caustic solution can cause

serious chemical burns

Es besteht erhöhte

Rutschgefahr im Nassbereich!

Important

information

Warning of dangerous

voltage

Warning against an

increased risk of skidding

in wet areas

Endangered

electrostatic component

part

Attention!

Beware of hot surface

Beware of hand

injuries

Warning of harmful or

irritating substances It increased slip risk in wet

areas

Operating Manual FMI

Negele Messtechnik GmbH

12

Raiffeisenweg 7

87743 Egg a. d. Günz

3. Transport

3.1.

General information

The following points have to be respected in order to avoid damages to the measuring instrument

or injuries during the transport of the device:

Transport work is only allowed to be carried out:

- By accordingly qualified and authorized persons

- By the aid of appropriate load suspension and fastening devices

- If any risk can be fully excluded while the device is lifted or conveyed

The packing of the measuring instruments is subject to the following labelling:

Fragile goods Keep dry!

Check the added packing list before you will start opening the packing!

Compare by means of the packing list if all parts are really available or not!

Treat sensitive parts with special care!

Please do not fail to dispose of the packing material according to the appropriate regulations.

Caution

Operating Manual FMI

Negele Messtechnik GmbH

13

Raiffeisenweg 7

87743 Egg a. d. Günz

3.2.

Dimensions and weight

3.2.1. Remote version

Type DN W

[mm]

D

[mm]

H

[mm]

Weight

[kg]

10 104 90 200 4

15 104 90 200 4

25 104 90 200 4

32 104 105 220 5

40 104 105 220 5

50 104 130 240 6

65 104 130 240 6

80 105 155 270 10

100 110 170 280 15

125 110 220 335 20

G1

150 140 220 335 23

3.2.2. compact version

DN W

[mm] D

[mm] H

[mm]

Weight

[kg]

10

104 90 225 6

15

104 90 225 6

25

104 90 225 6

32

104 105 240 7

40

104 105 240 7

50

104 130 265 8

65

104 130 265 8

80

105 155 290 12

100

110 170 305 17

125

110 220 355 22

150

110 220 355 25

D

H

B

Ø90

DB

H

Ø90 200

Operating Manual FMI

Negele Messtechnik GmbH

14

Raiffeisenweg 7

87743 Egg a. d. Günz

3.2.3. Converter with wall bracket

3.2.4. Dimensions of the process connections

Please refer to the FMI product-information for further details.

Operating Manual FMI

Negele Messtechnik GmbH

15

Raiffeisenweg 7

87743 Egg a. d. Günz

4. Application

4.1.

Conditions required for the transmitter

The installation of the measuring instrument depends on the version delivered: “remote” or

“compact”.

In any case the transmitter has to be installed in the product line and the converter has to be

supplied with voltage.

When selecting the place for the installation of the measuring instrument you should in any rate

ensure that the housing can be opened for service work whenever desired and that the flow meter

can be simply removed, if necessary.

Cross-flows should be absolutely avoided, as they could cause some damages to the electronic

part.

In order to protect the transmitter against damages, select the place of

installation so that:

•the process pressure is always kept below the admissible operating pressure

•the product temperature is always kept below the admissible temperature

•the transmitter is mechanically levelled out (e.g. to avoid vibration)

•the meter tube can be emptied in case of the danger of frost

•the measuring instrument is not arranged straight above a gully or sink hole

•the connection housing is not permanently exposed to drip water

4.1.1. Measuring of air and gas

The electromagnetic measuring instrument can supply perfect measuring results in case of gas-

free liquids only. Air locks or deaeration in a liquid will lead to faulty measurements.

Thus, make sure that air locks or other possible parts of gas are safely remote before the

measuring device e.g. by gas separators or that deaeration can be excluded by a sufficient working

pressure.

The measuring device is not damaged e.g. by air locks.

4.1.2. Solids

Normally, solids do not have any negative influence on the volume measurement.

The pipe diameter should always be chosen sufficiently large in order to prevent the meter tube

from being clogged in case of products including solid particles.

Due to the fact that the flow velocity of solid matters is relatively lower than that of the liquid part of

the product, a higher flow fluctuation could be caused while the flow rate is determined.

The measurement of abrasive materials can cause a drifting of the measuring accuracies and, in

the end, a deterioration of the transmitter.

Caution

Operating Manual FMI

Negele Messtechnik GmbH

16

Raiffeisenweg 7

87743 Egg a. d. Günz

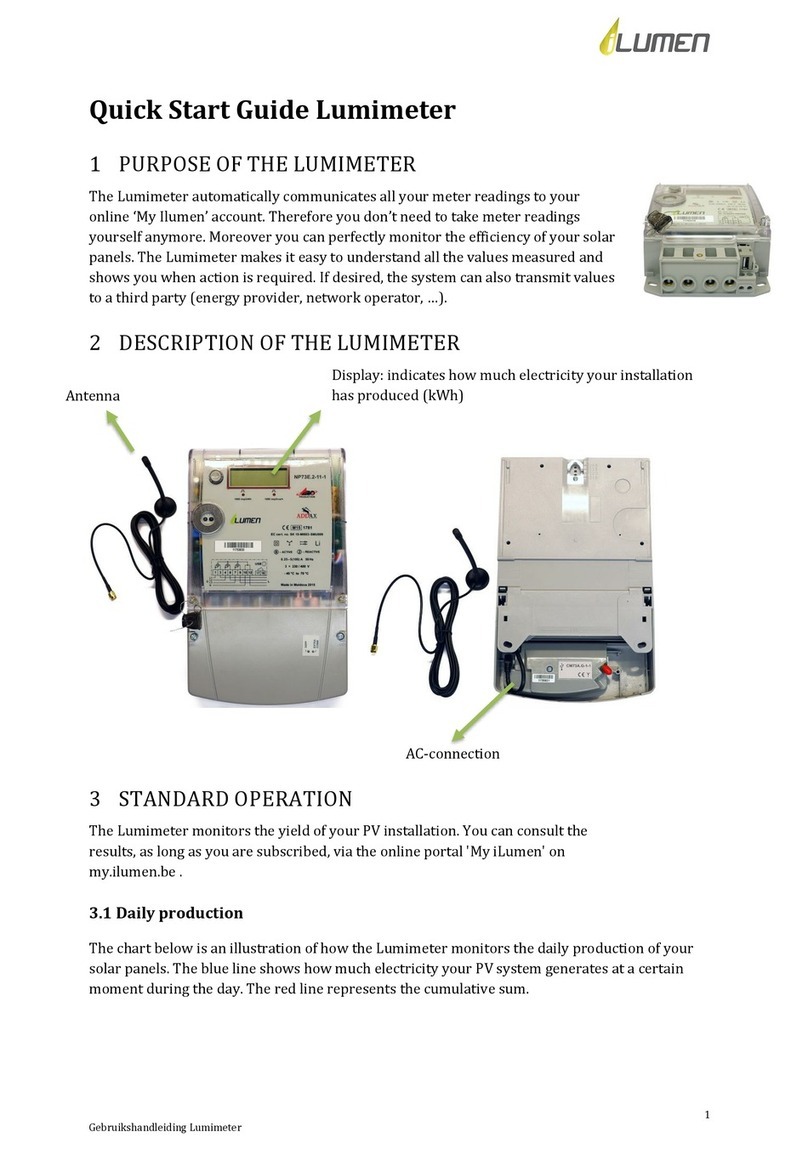

4.1.3. Mounting position – electrode axis

Due to the principle described, the fitting position – to a certain extent – can be selected any way

desired. The basic condition for accurate measuring results is, however, a full and gas-free meter

tube.

If possible, the electrode axis should be horizontally arranged, in order to avoid a deposition of gas

bubbles or solid particles on the surface of the electrodes. Therefore, a slightly ascending pipeline

is advisable, preferably with a deaerating possibility at its highest position.

The fitting position should be chosen in such a way that a good readability and handling of the

operating unit is guaranteed.

The pipelines within the inlet and outlet pipe sections must not show any unevenness, e.g. welding

beads.

max. 45°

Electrode axis

Operating Manual FMI

Negele Messtechnik GmbH

17

Raiffeisenweg 7

87743 Egg a. d. Günz

Suggestions for installation

freier Auslauf

<5m

freier Auslauf

Wrong

At the highest point of the pipeline. Gas bubbles

accumulate in the transmitter.

→

Faulty measurement!

Wrong

Descending pipe:

At the end of the conveyance of the metered product

the pipe runs empty.

→

Measuring errors!

Correct

Preferred mounting position:

Rising pipeline and horizontal pipe section before an

ascending pipeline

Descending pipelines of a length of more than 5 m

have to be equipped with a deaeration valve after the

flow meter.

Correct

In case of a horizontal pipe conduct the mounting

position is placed in slowly increasing sections of the

pipe.

Correct

Provide a culvert for free inlet or outlet. The transmitter

is permanently filled with liquid as demanded.

Free outlet

Free outlet

Operating Manual FMI

Negele Messtechnik GmbH

18

Raiffeisenweg 7

87743 Egg a. d. Günz

5xDN 3xDN

Long lines

after

the flow meter always have to be

equipped with a shut-off device. If it is placed before the

flow meter, a vacuum will be caused in the metering pipe

by the big kinetic energy in the liquid column when

shutting off. This can damage the lining of the tube!

Do not place the flow meter on the suction side of the

pump!

→

Danger of negative pressure!

Keep the recommended inlet and outlet sections!

Avoid curvatures of space before the flow meter!

Operating Manual FMI

Negele Messtechnik GmbH

19

Raiffeisenweg 7

87743 Egg a. d. Günz

4.1.4. Inlet and outlet pipe sections

For the installation of electromagnetic transmitters DIN 1944 recommends an inlet pipe

section of 5 x DN and, accordingly, an outlet pipe section of 3 x DN in case of an

undisturbed flow. For an irregular flow (e.g. distorted rotational flow profile) the inlet and

outlet pipe sections have to be extended accordingly or a rectifying device for the flow has

to be installed in order to guarantee the specified measuring accuracy.

4.1.5. Conductivity conditions

Compact design

The liquid to be measured has to show a minimum conductivity of ≥5 µS/cm.

Demineralised water requires a conductivity of ≥20 µS/cm.

A count suppressor for empty meter tubes belongs to the standard equipment of the converter.

That function will have to be switched off at conductivities below 50 µS/cm.

Separated design

The liquid to be measured has to show a minimum conductivity of ≥15 µS/cm.

Demineralised water requires a conductivity of ≥30 µS/cm.

A count suppressor for empty meter tubes belongs to the standard equipment of the converter.

That function will have to be switched off at conductivities below 50 µS/cm.

4.1.6. Interference fields

Straight at the transmitter masses of iron or strong permanent or electromagnetic fields must

absolutely not exist, as they could influence the defined exciting magnetic field, thus falsifying the

signal.

4.1.7. Earthing/grounding conditions

A perfect earthing/grounding of the transmitter is an essential requirement for a reliable and

accurate measurement.

“Inductive measuring method” means that the metered liquid itself acts as an electric conductor,

i.e. a correct and careful earthing/grounding ensures that no additional potentials will falsify the

extremely low metering signal.

For that reason, the earthing/grounding resistance has to be definitely smaller than 10 Ω. The

earth/ground wire used must not transfer any interference voltages, i.e. no other electric devices

must be connected to that line.

If in case of a plastic pipe system no equipotential bonding is available between the inlet and outlet

sides, it will be necessary to take some appropriate measures for a potential equalisation.

In case of the remote design, the earthing/grounding between transmitter and converter is

achieved by means of the shielding braid of the electrode cables and the coil supply cables with

the metal cable gland provided for that purpose.

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

Extech Instruments

Extech Instruments SL250W quick start

PCB Piezotronics

PCB Piezotronics 3651A122KG Installation and operating manual

ProMinent

ProMinent DULCOTEST DT4B operating manual

sauter

sauter SAUTER TE SERIES instruction manual

Fungilab

Fungilab EVO Series instruction manual

Tektronix

Tektronix ATECTekRanger user manual