12. DISCONNECT PARTS WASHERS before servicing; when changing

13. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is

in off position before plugging in.

14. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for

recommended accessories. The use of improper accessories may cause risk of

15. CHECK DAMAGED PARTS. Before further use of the Parts Washer, a guard

or other part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function - check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

16. NEVER LEAVE PARTS WASHER RUNNING UNATTENDED. TURN

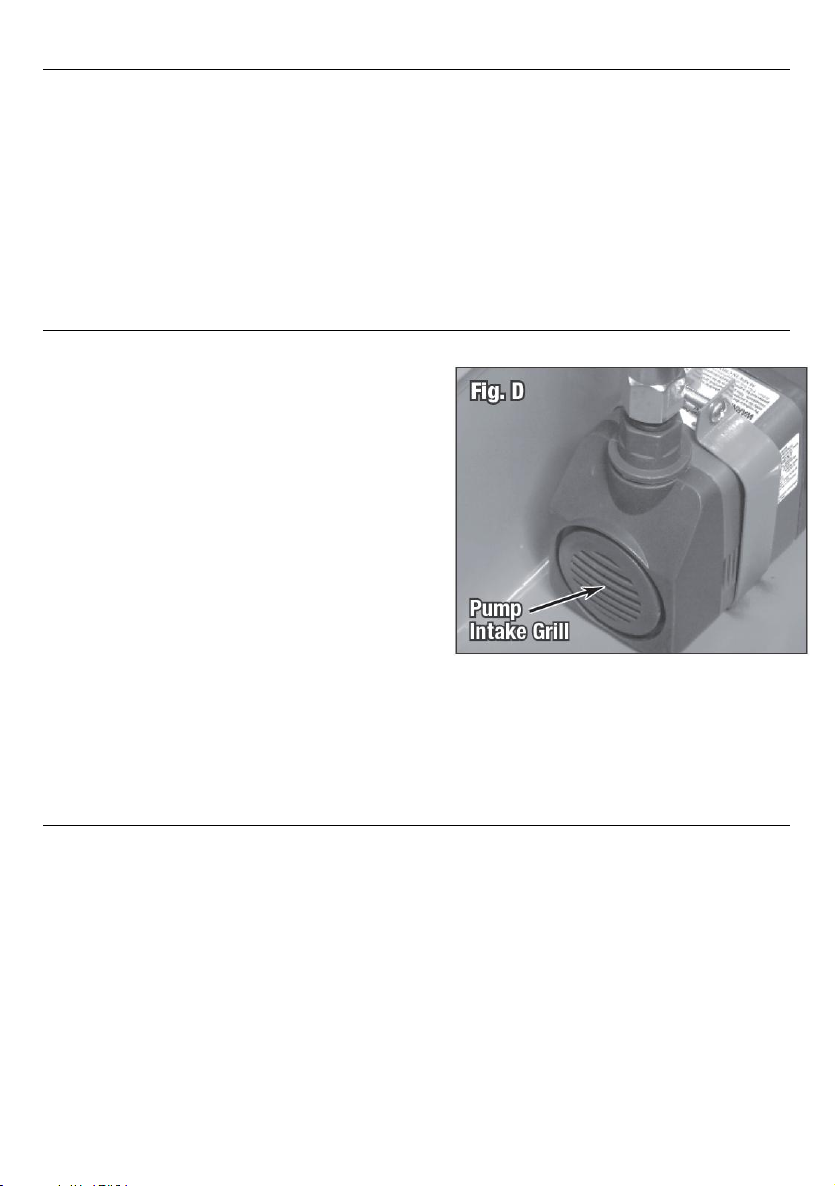

Parts Washer Safety Warnings

1. Use proper cleaning solutions.

Clean parts with water or household detergents only. Never use highly volatile

flammable solvents such as gasoline, toluene, diesel fuel, methyl ethyl ketone

(MEK), or 1,1,1-trichloroethane.

Approved cleaning solutions: Water/household detergents (PH6~8).

2. Do not use or store near open flames, pilot lights in stoves or heaters, or any

other ignition source. Solvents are highly flammable. Use in well-ventilated area.

3. Avoid intake of solvents. Materials used when cleaning and debris removed by

cleaning may be harmful or fatal if inhaled or swallowed.

4. The use of accessories or attachments not recommended by the manufacturer

may result in a risk of injury to persons.

5. When servicing use only identical replacement parts.

6. Stay alert, watch what you are doing and use common sense when operating

a Parts Washer. Do not use a Parts Washer while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating Parts Washers may result in serious personal injury.

7. Industrial applications must follow OSHA guidelines.

8. Maintain labels and nameplates on the Parts Washer. These carry important

safety information. If unreadable or missing, contact seller for a replacement.

9. Avoid unintentional starting. Prepare to begin work before turning on the Parts

10. People with pacemakers should consult their physician(s) before use.

Electromagnetic fields in close proximity to heart pacemaker could cause