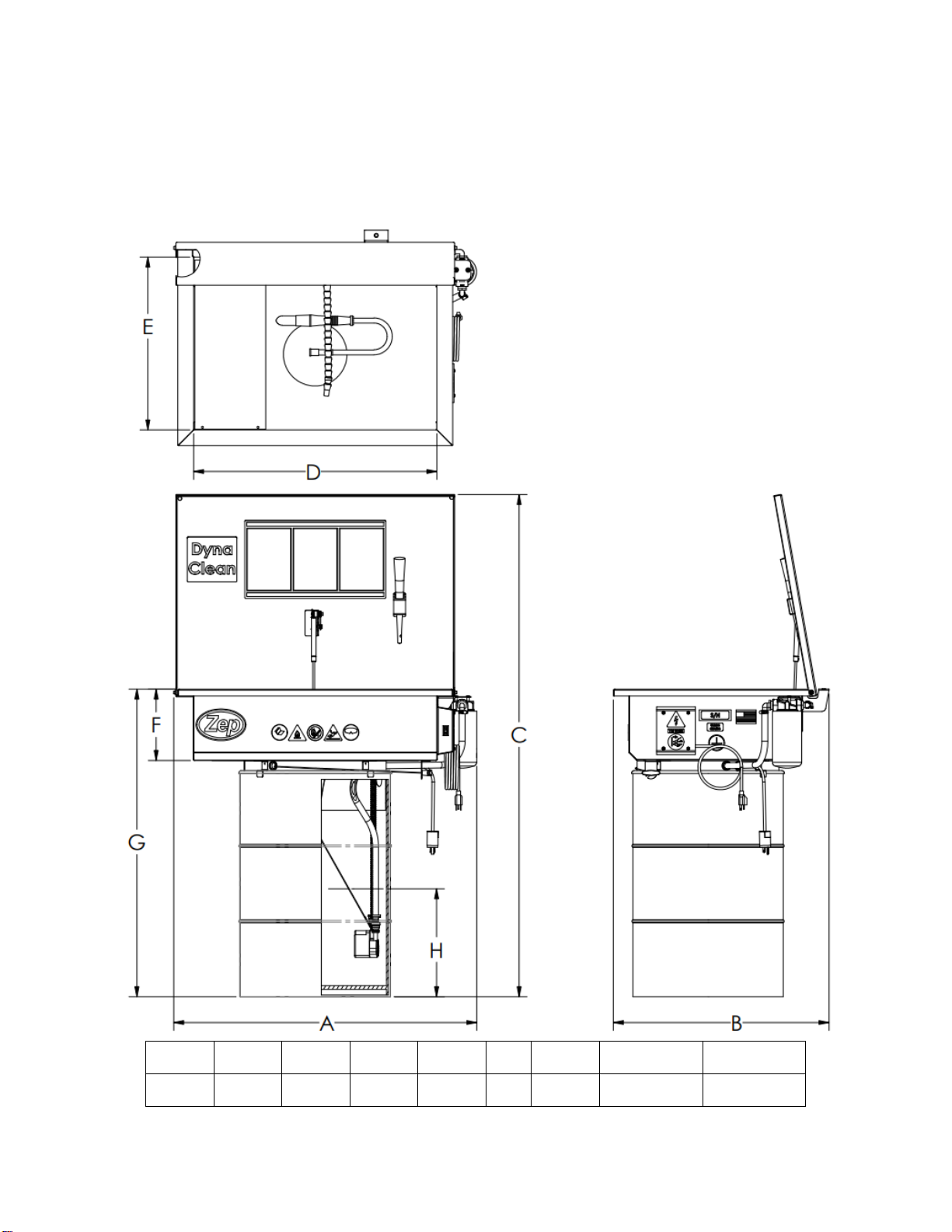

786-93885 6 of 14 6/6/22

INSTALLATION AND OPERATION

The work area should be well ventilated.

Provide adequate lighting in the work area to allow observation of the cleaning process and the floor

area around the machine. Be sure to allow adequate room to bring work to and from the machine.

Provide sufficient clearance around the machine for fluid changeovers and servicing.

Site Preparation

Before installing, careful consideration should be given to the place of operation. Place unit on a

smooth, level surface. To the extent possible avoid installing machine in areas subject to high forklift

traffic. Reasonable precautions shall be taken to avoid damaging or puncturing the drum and sink

walls.

Installation Procedure

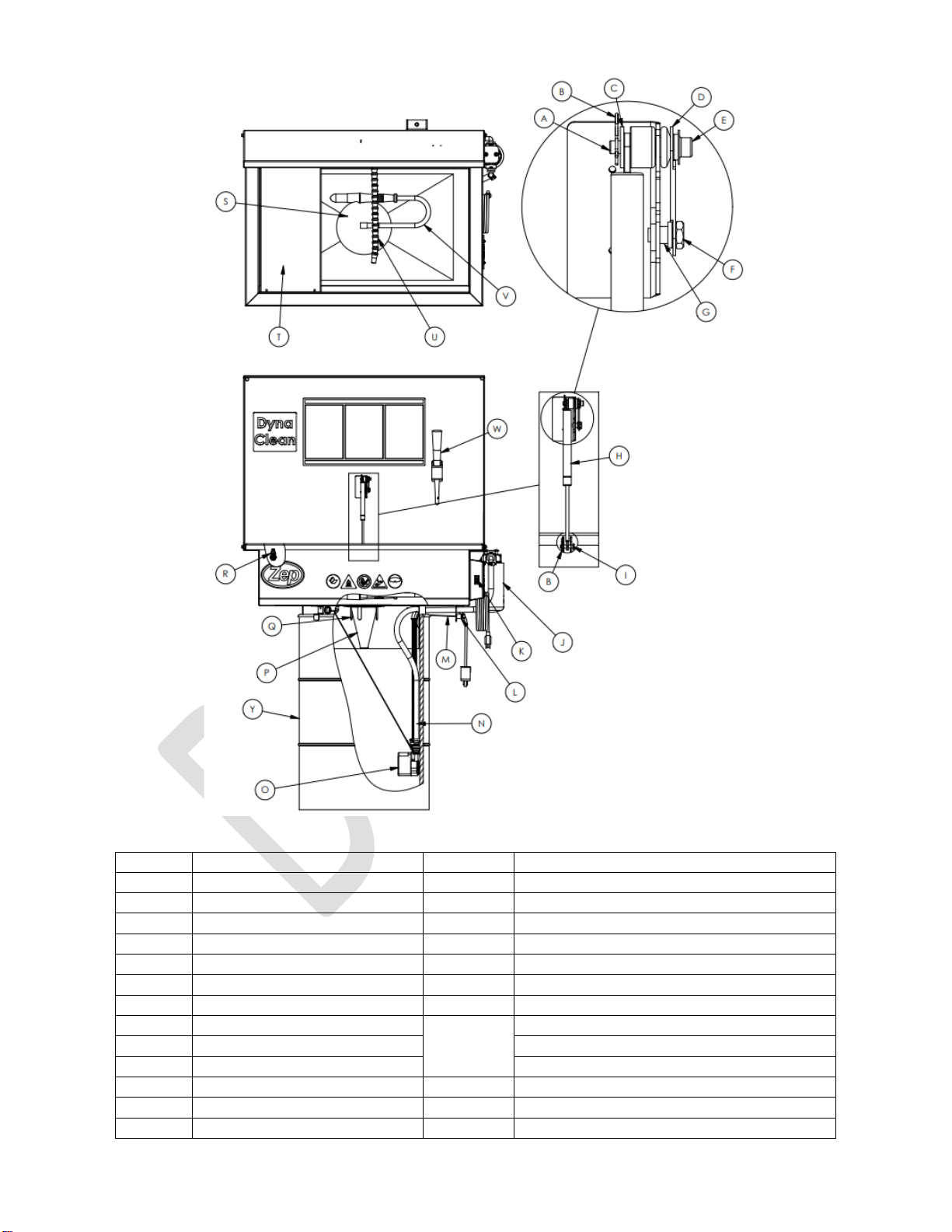

•Place cleaning tank on top of Zep 30 gallon open-head drum (Not included with machine).

Mounting ring on sink bottom should insert easily into drum and fully seat onto four mounting

brackets. If the sink does not fit into drum check drum for damage or out of roundness. If the

sink cannot be made to seat fully into the drum do not use the machine.

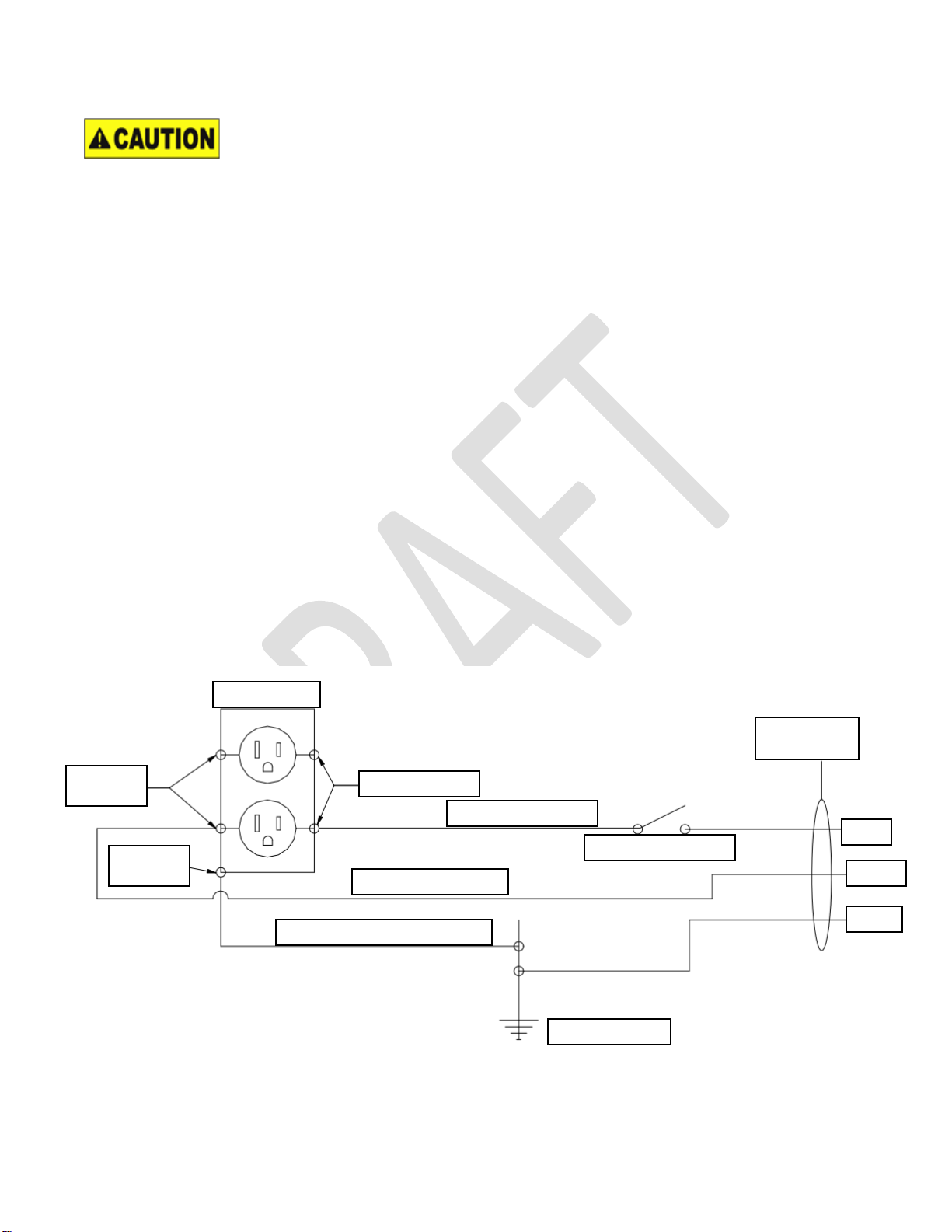

•Plug pump power cord into the receptacle on the back of electric box.

•Slip nylon filter sock onto drain cover. Position drain cover with filter bag in tank drain opening.

•Fill with appropriate cleaning fluid.

•Insert 3-prong plug into a properly grounded compatible outlet.

•Position light (If present) on rear of cleaning tank. Lift lock ring and lower light onto bracket post.

Release lock ring and check that light is secure on tank. Plug light power cord into the

receptacle on the back of electric box.

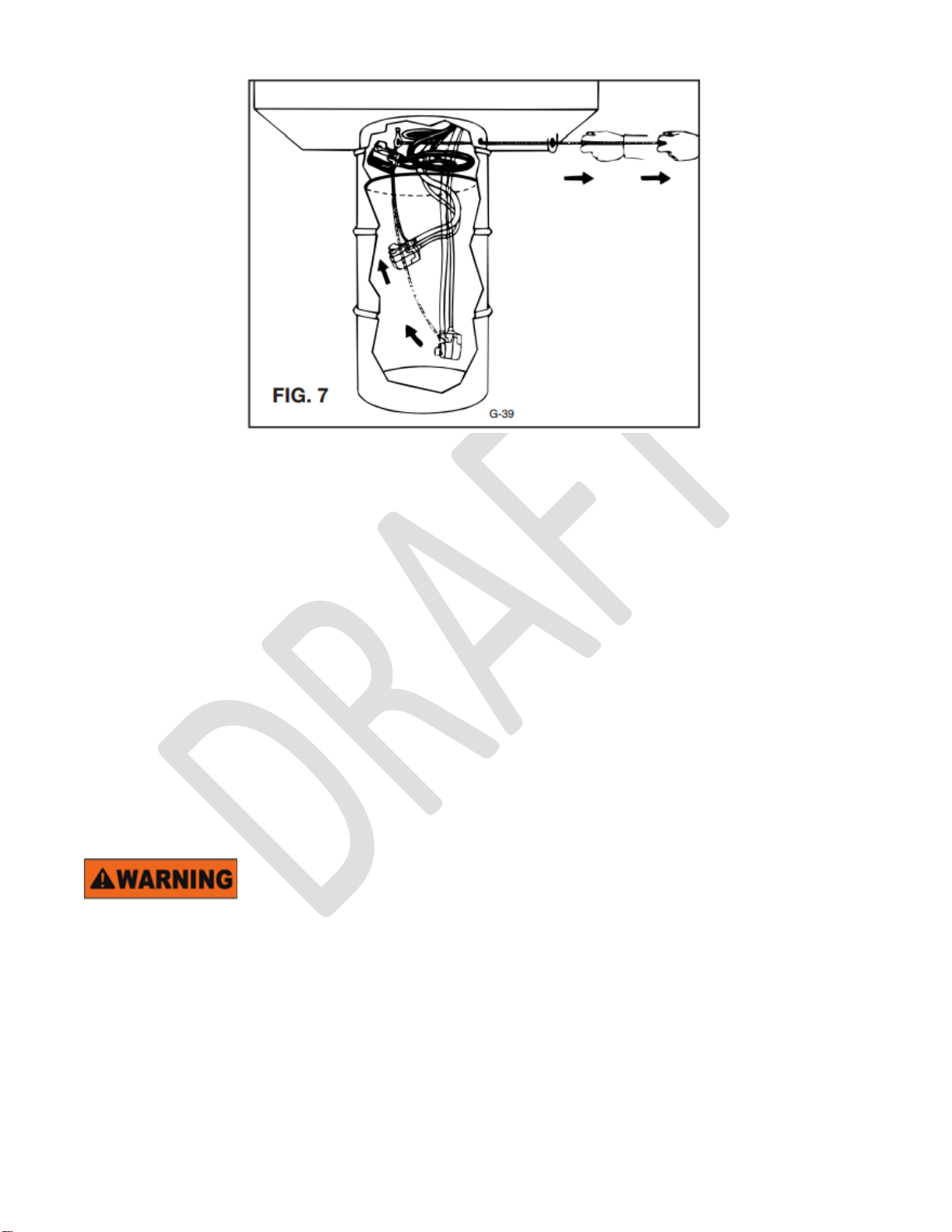

•Lower pump (Figure 2(O)) into drum by releasing the cable from bracket on right end of tank

and allow the pump to slowly pull cable into opening at left end of tank (Figure 3).

Unit is now ready for use.

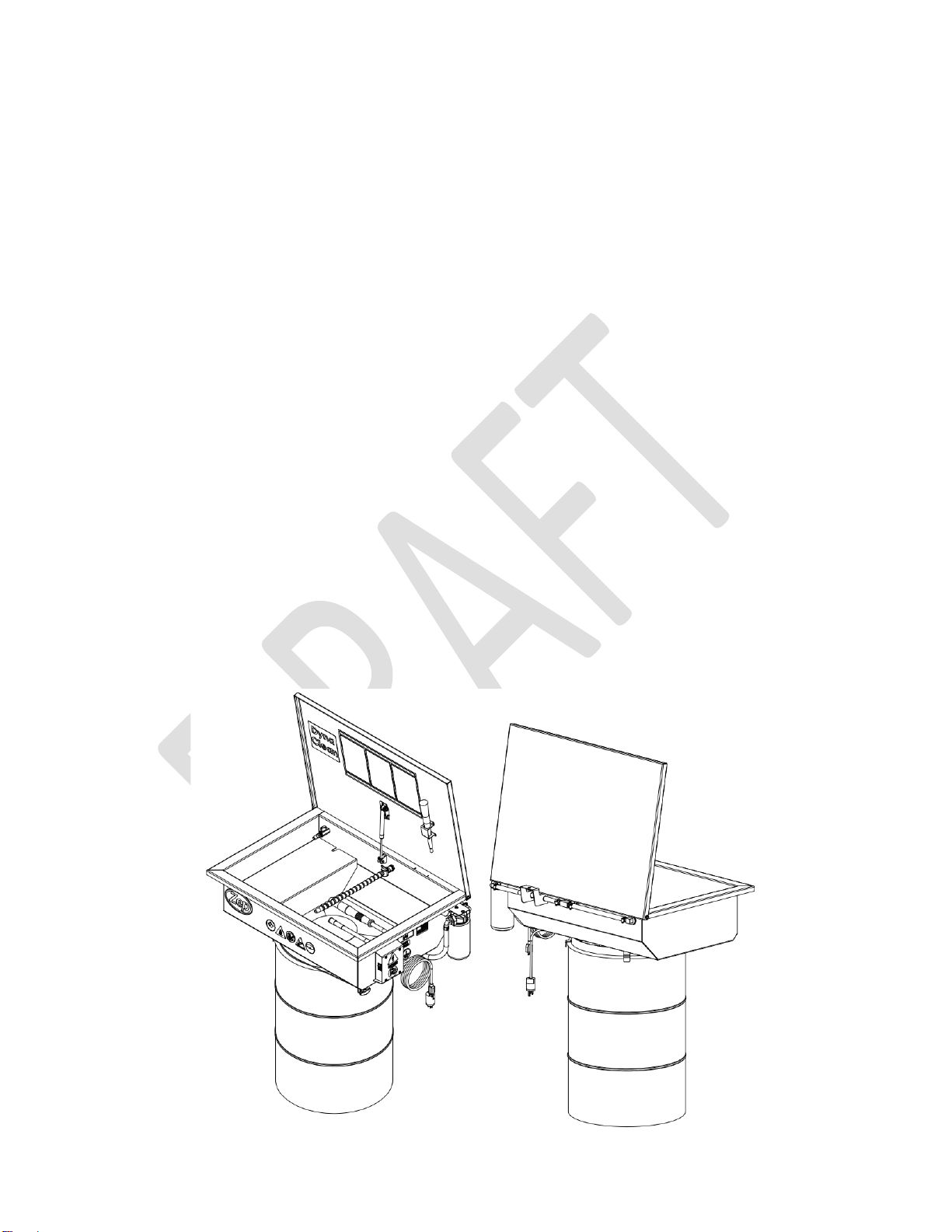

Automatic Safety Cover

Open the lid on your Dyna-Clean and you will notice that it lifts simply and easily with one hand. There

is nothing to connect or disconnect to open or close the cover.

Your Dyna-Clean lid is equipped with a two-way gas spring (FIGURE 2(H)) that also incorporates a

fusible link (FIGURE 2 (D)). When open, the cover mechanism supports the cover at a slightly forward

angle. This angle is necessary to assure the cover’s fusible link will operate in the unlikely event of fire

in the tank. In the event of a fire, the fusible link will melt at 165°F permitting the lid to slam shut,

reducing oxygen supply to the fire.

Never leave the Dyna-Clean unattended with parts in the tank which would prevent the cover from

closing completely in the event of a fire. Ensure that brush hose is stored correctly inside the unit.

Always make sure that the cover remains in its correct, slightly tilted forward position when open. Do

NOT tamper with or remove the fusible safety link. If the safety link breaks or is lost, replace

immediately. Keep the cover closed when the unit is not being used.