Nelsen Corporation Aqua Classic Manual

Reverse Osmosis

Drinking Water Systems

Installation, Operation & Service Manual

Including Systems with

optional ECF Module

SECTION I. Introduction

Congratulations, you have just purchased one of the

finest Reverse Osmosis Drinking Water Appliances

available. The Aqua Classic and the Aqua Elite Reverse

Osmosis Systems have a combined engineering and

experience level of some 35 years behind them. They

were designed with a minimum of service and will

serve you for years to come.

Like any other fine product, this appliance requires

periodic maintenance in accordance with the schedule

outlined below.

Recommended Filter Change Schedule*

1) Pre-Filter, 10”, 5 Micron........................ 6 Months

2) Granulated Activated Carbon ................ 6 Months

Post-Filter

3) Reverse Osmosis Membrane ....... 24 - 36 Months

4) Pre-Carbon Filter For Chlorine ............... 6 Months

Removal (Aqua Classic II and

Aqua Elite II RO Systems Only)

5) Extended Contact Carbon...................... 6 Months

Adsorbtion Filter (ECF Module - Optional)

*Based on standard conditions.

Your new Reverse Osmosis (R.O.) Drinking Water sys-

tem uses a combination of filtration technologies to

reduce unwanted contaminants in a water supply. The

following steps combine to give you the best in clear

sparkling drinking water:

MECHANICAL FILTRATION - The sediment pre-filter

will remove the larger particles such as silt, rust and

scale. Its 5 micron (equal to 0.0002 inch) nominal rat-

ing helps to give maximum life to the R.O. Membrane

and carbon filter.

ACTIVATED CARBON PRE FILTER -

Found only on the Aqua Classic II and Aqua Elite II

(3-filter housing) RO Systems - The activated carbon

in this pre-filter will remove any chlorine that may be

present in the feed water. This pre-treatment is also

necessary for membrane protection.

REVERSE OSMOSIS MEMBRANE - The R.O. Mem-

brane is the heart of the filtration system. It is designed

to reduce the dissolved mineral content of the water.

Minerals picked up in the environment by the water

are measured as Total Dissolved Solids (T.D.S.). In

the Reverse Osmosis process, dissolved minerals are

separated from the incoming water (Feed Water) to

produce the product water (the Permeate). The excess

minerals are rinsed to drain (the Reject Water). The spi-

ral wound construction of the R.O. Membrane provides

maximum surface area for water production and is less

susceptible to fouling by particulate matter, turbidity

and colloidal materials.

TFC Membranes - Thin Film Composite (T.F.C.) Mem-

branes are specially constructed, fully aromatic poly-

amide film and are classified as a thin film composite.

These membranes are NOT chlorine resistant.

ACTIVATED CARBON POST FILTER - The Activated

Carbon Post Filter cartridge contains carbon particles

with a vast network of pores. The tremendous surface

area of these pores (typically 800-1200 square meters

per gram of carbon) gives the carbon very good ad-

sorptive sites for chlorine as well as other substances

that contribute to tastes and odors. The product water

from the membrane as well as the holding tank passes

through the Activated Carbon Post filter on the way to

the Dispensing Faucet. The Activated Carbon Post Filter

reduces tastes and odors that may pass through the

system. It adds a final “polish” to the water.

EXTENDED CONTACT CARBON ADSORPTION

FILTER (ECF Module - Optional) - This slow flow car-

bon filter is designed to reduce certain organic com-

pounds and chloramines.

AUTOMATIC SHUT-OFF VALVE - The A.S.O. Valve

senses when the product water tank is full and closes

the feed water supply to prevent excess reject water

from going to drain when the unit is not producing water.

System Recommended Operating Limits for Feed Water

Feed Water T.D.S.........................................................................................................2000 ppm max

Feed Water Temperature.............................................................................................40 - 110° F

Feed Water pH.................................................................................................................................................... 5 - 10

Feed Water Pressure......................................................................................................40 - 85 P.S.I.

Feed Water Hardness............................... Less Than 10 Grains Per Gallon

Feed Water Iron................................................................................................. Less than 0.1 ppm

Feed Water Manganese............................................................... Less than 0.05 ppm

Feed Water Hydrogen Sulfide.............................................................................................. NONE

Feed Water Supply................................................................................................................No Chlorine

Feed Water Bacteria........................................................................................ Must Be Potable

-1-

-2-

INLET (3/8" Orange)

DRAIN

(1/4" Red)

4" MIN. CARBON

Post Filter

Housing

SEDIMENT

Pre-Filter

Housing

DRAIN

(3/8" Black)

Dispensing Faucet with Air Gap

(for non-air gap installations

please see Figure 4, Page 14

Self Piercing

Saddle Valve

(cold water line only)

PRODUCT

(3/8" Blue)

DRAIN CLAMP

(locate above “P” trap)

Holding Tank

Shutoff Valve

(open position)

TANK (3/8" Yellow)

REVERSE OSMOSIS ASSEMBLY

(NOTE: Aqua Classic II and Aqua Elite II

R.O. Systems include a third filter housing;

the optional ECF Module would appear on

the top of the system. The installation

would be similar to that shown.)

Drinking Water

Holding Tank

SECTION II. Installation And Specifications

FIGURE 1 Installation Diagram

Nelsen

Corporation

-3-

SECTION III: Preparation

A. Major System Components

The following components comprise the R.O.

Drinking Water System (Refer to Fig. 1. page 2 for

general system layout.)

1) A R.O. assembly consisting of the black aluminum

bracket, filter housings, automatic shut-off and

membrane module

2) A Drinking Water Holding Tank

3) A Faucet Kit

4) A plastic tubing kit with self-piercing saddle valve

and drain clamp

5) Other items necessary for installation may include

wood screws or machine screws for mounting the

R.O. assembly, or concrete anchors for hanging

on basement wall, additional tubing or tube

connectors, plastic wire ties for organizing tubing

Optional Components

1) ECF Module - Extended Contact Carbon Adsorption

Filter located on the R.O. Assembly

2) A T.D.S. Monitor Kit (optional*) with feed water

and product water test cells

* The T.D.S. Monitor may be necessary to conform

to state or local codes, check with the local

plumbing authority.

B. Tools Recommended for Installation

The following tools will cover most of the installation

sites encountered:

1) 3/8" variable speed electric drill

2) Extension work light with outlet

3) Safety Glasses

4) 1-1/4" porcelain hole cutter kit

5) 1-1/4" Greenlee hole punch and 1/8" and 1/2"

metal drill bits for pilot hole

6) Center punch and hammer

7) 1-1/4" wood bit

8) Concrete drill bits

9) Assorted wood and metal drill bits including

7/32" metal drill bit

10) Phillips head and flat blade screwdrivers

11) 1/2", 9/16" and 5/8" open end wrench

12) 10" Crescent wrench with jaws taped to

hold faucet

13) Basin wrench or 10" pipe wrench

14) Teflon tape

15) Wide masking tape or duct tape

16) Plastic tubing cutter

17) Extra plastic tubing

18) Low range air pressure gauge

19) Bicycle hand air pump

20) Small bottle of liquid chlorine bleach

21) Graduated measuring cylinder

22) Assorted clean up materials

C. Determine System Location

The appliance can be located under a sink or in a

basement depending on space availability and the

customer’s preference. If a basement installation is

selected, additional tubing, hardware and fittings may

be needed and a hole will have to be made from inside

the cabinet, through the floor, to the basement. Never

install in an area of the home where temperature is

freezing as damage to the system will result.

The exact placement of the various components of the

appliance will vary from installation to installation. The

installer, in conjunction with the customer, must decide

on where to place the faucet, tank and purification

assembly by balancing the homeowner’s convenience

with ease of installation and servicing.

Considerations for an ice maker or other remote

hookup should be determined, including routing

and any additional tools, fittings, and tubing that

may be required.

1) Faucet - The faucet should be placed near the sink

where drinking water is normally obtained. Conve-

nience of use (filling of water pitchers and glasses),

and an open area beneath the faucet under the

sink for attaching product and drain tubing (air gap

faucets only) are considerations. A 2" diameter flat

surface is required above and below the mounting

site. The thickness of the mounting surface should

not exceed 1-1/4". Watch for strengthening

webbing on the underside of cast iron sinks.

2) Drinking Water Holding Tank - The holding tank

may be placed where it is convenient within

10 feet of the faucet, under the sink or in an

adjacent cabinet are best choices. If a longer run

of tubing is required, the tubing should be the 1/2"

diameter O.D. size to prevent a high pressure drop.

-4-

Remember, these tanks can weigh up to

30 pounds when full of water, a firm, level area

is required.

3) R.O Assembly - The R.O. Assembly may be

mounted on either the right or left side of the

under-sink area or a cabinet. Mounting in the

basement is also an option, one possible location

is near the laundry/utility sink where cold potable

water and drain access is handy. The mounting

location should allow adequate clearance and

accessibility for cartridge changes.

4) Feed Water Connection - The self-piercing

feed water shut off valve should be located as

close to the R.O. assembly as possible. USE A

POTABLE COLD WATER SUPPLY ONLY. Softened

water is preferred as it will extend the life of the

R.O. Membrane.

5) Drain Connection - The drain saddle assembly is

designed to fit around a standard 1-1/2" OD drain

pipe. The drain saddle should always be installed

above (before) the trap and on the vertical

or horizontal tailpiece. Never install the drain

saddle close to the outlet of a garbage disposal

or plugging of the RO drain line may occur. If

discharging into an utility sink or standpipe, an air

gap of greater than 1" above the flood rim must be

provided. Do NOT connect the system drain line to

the dishwasher drain or near the garbage disposal.

Back pressure from these units may cause the air

gap to overflow.

D. Prepare the Area for Installation

If a basement installation is called for, determine

where components will be located and how they will

be mounted. Special mounting brackets and hardware

may be necessary to secure the system to a wall or

ceiling joists.

Inspect cold water supply line and drain to determine

if any special fittings, in addition to what is included in

the kit, are required.

E. Prepare the Appliance for Installation

Open shipping carton and remove components. Check

that all installation parts are present which includes the

purification assembly, storage tank, faucet, installation

hardware and tubing.

Check that the air supply in the empty tank is

approximately 7 psi. Adjust if necessary.

To assure you the highest level of purity, the 5 Micron

Sediment Cartridge, GAC Cartridge and Reverse

Osmosis Membrane have been included separately in

special packaging.

The proper method of installation is outlined below.

Installation of the 5 micron Sediment Prefilter

Cartridge

Completely unscrew and remove the “PREFILTER”

housing from the appliance. Remove the protective film

from the white Sediment Cartridge. Carefully center

the cartridge in the housing before reassembling. As

you reassemble the housing to the appliance make

sure the cartridge is centered on both the filter housing

head and the housing itself. Once tight, the “PREFIL-

TER” label on the filter housing should be centered on

the “FEED WATER” label and elbow on the front of the

appliance.

Installation of the GAC Postfilter Cartridge

The GAC “POSTFILTER” Cartridge is installed in the

same manner as outlined above for the “PREFILTER”.

Installation of the Reverse Osmosis (RO) Membrane

The RO Membrane has also been shipped to you

separately. Remove the tubing from the endcap of the

membrane housing, and unscrewed the end cap, insert

the membrane as illustrated below. The O-rings on

the product water tube of the membrane MUST FULLY

SEAT in the membrane housing for proper operation.

Also make sure that the Brine Seal on the membrane

seals with no gaps or wrinkles inside the membrane

housing. Once the membrane is installed, replace the

end cap and re-connect the tubing.

To insure that all the special preservative is flushed

from the system before use, DO NOT use the first two

tankfuls of water produced by the system.

Nelsen

Corporation

MEMBRANE HOUSING

INSERT BRINE SEAL

MEMBRANE

-5-

SECTION IV: Installation Steps

All plumbing should be done in accordance with state

and local plumbing codes.

NOTE: Some codes may require installation by

a licensed plumber; check with the local

plumbing authority prior to installation.

In restricted under-sink areas, it may be easier to

install the faucet first. Allow adequate tubing lengths

for any final component position.

A. Install The Faucet

NOTE: For Faucet Assembly Diagram,

please see Figure 2, below.

Under counter installations generally require that the

faucet is installed with the built in air gap connected.

In basement installations, the built in air gap does not

have to be used only if one is provided elsewhere in

the drain line.

A non air gap faucet, which requires a smaller 9/16"

mounting hole, is available from the factory to make

basement installations easier.

If the sink already has a hole provided that can accom-

modate the RO faucet, then no drilling is required and

you can proceed to the section on mounting the faucet.

NOTE: Sprayers can be disconnected to provide

a suitable hole for the RO faucet. A pipe

cap or plug will be required to seal the

sprayer connection.

1. Make The Faucet Mounting Hole

IMPORTANT:

It is mandatory that safety glasses

be worn during sink hole drilling

operations to prevent eye injury.

Before starting the hole making operation, always

check below the sink so that nothing interferes with

mounting the faucet such as reinforcing ribs, support

brackets or cabinet construction.

Stainless Steel Sink, Air Gap or Non Air Gap Faucet:

Recommended tools:

•Centerpunch

•Variablespeeddrillandhighspeeddrillbits.

•Greenleechassispunch7/8"holesize(alternate

9/16" size may be used for non air gap faucet)

•Protectivegloves

Procedure:

a) Center punch a small indent at the desired

faucet location.

Nelsen

Corporation

NON-AIR GAP FAUCETAIR GAP FAUCET

1/4" Standard

Red Tubing

Air Gap Hole

Black 3/8"

Reject

Tubing to

Drain

Blue 3/8" Product

Water Tubing

Chrome Base Plate

Rubber Washer

Plastic Bottom Washer

Flat Washer

Star Washer

Hex Nut

3/8" Faucet Adaptor

Blue 3/8" Product

Water Tubing

Threaded Nipple

CL

Chrome Base Plate

Rubber Washer

Slotted Washer

Spacer

Flat Washer

Threaded Nipple

Hex Nut

3/8" Faucet Adapter

Blue 3/8" Product

Water Tubing

FIGURE 2 Faucet Installation Diagram

b) Slowly drill the required pilot hole for the

chassis punch.

c) Set up the chassis punch per instructions and

tighten nut to cut the desired hole size.

d) Clean up sharp edges with a file if necessary.

Porcelain/Enamel/Ceramic on Sheet Metal or Cast Iron

Base; Faucet with or without Air Gap Module:

Recommended tools:

•Variablespeeddrill

•Reltonporcelaincuttertoolset7/8"size

(alternate 9/16" size may be used for air gap or non

air gap faucet)

•Plumber’sputty

It is important to understand what is involved in this

procedure. First, the glassy layer of porcelain must be

penetrated through to the base metal. Second, a center

disc of porcelain must be removed while protecting the

surrounding porcelain against chipping or fracturing.

Third, the base metal must be drilled through to com-

plete the hole.

Procedure:

a) Mark the center for the 7/8" hole

b) Form a shallow putty dam around hole area

and fill with enough water to lubricate carbide drill

bit.

c) Carefully drill pilot hole through porcelain/enamel

and base metal using carbide type pilot drill.

IMPORTANT:

Always operate drill with light

pressure at slow speed (300-400 rpm)

d) Insert pilot tip of spring-loaded porcelain cutter

into pilot hole.

e) Drill porcelain/enamel using spring-loaded por-

celain cutter, making certain a complete ring has

been cut through the porcelain/enamel to the

metal base.

f) Change to the metal cutter. With slow speed and

light pressure, cut away the inner porcelain/enam-

el disc down to base metal. Make certain that the

cutter does not touch outer rim of the cut porce-

lain/enamel. Continue with this bit to cut through

metal until sink has been completely penetrated.

IMPORTANT:

When using a porcelain cutter it is

critical to take precautions that it

is always in a sharpened condition.

Dull cutters are known to chip sinks.

2. Mount The Faucet:

NOTE: For Basement Installation Without Air

Gap Module See Figure 6, Page 16.

Under Counter Installation with Air Gap Faucet:

a) Familiarize yourself with all components shown

in the air gap faucet diagram.

b) Disassemble hardware from the threaded nipple,

except for chrome base plate and rubber washer.

NOTE: Rubber washer may be replaced with bead

of plumber’s putty for neater appearance.

c) Connect length of standard red 1/4" tubing to

smaller barb on air gap faucet. Push on firmly until

it seats.

d) Connect length of black 3/8" tubing to larger barb

on air gap faucet. Push on firmly until it seats.

e) Feed the air gap tubing and threaded nipple

through sink/counter mounting hole and orient

the faucet as discussed with the customer.

f) From below sink/counter assemble the white

spacer (open end up, open side toward air gap),

flat washer and hex nut on threaded nipple and

tighten by hand.

g) Back off on hex nut just enough to slide slotted

washer between white spacer and underside of

sink/counter (with open side of slotted washer

closest to air gap tubes)

h) After rechecking faucet orientation, tighten hex

nut (9/16" wrench or deep socket) until faucet

feels secure.

i) From above the sink make any minor orientation

corrections by turning the faucet with a padded

adjustable wrench.

Note: Flats on chrome faucet may be used for

tightening with an adjustable wrench. Use

care not to mar chrome finish.

-6-

Nelsen

Corporation

-7-

B. Install the Feed Water Valve and Tubing

The saddle tapping valve supplied is designed for use

with 3/8" to 1/2" OD soft copper supply tubing (plain or

chrome) and rigid metal pipe (see below). Do not use

with flexible ribbed supply tubing which has too thin a

wall thickness and requires special hardware. If neces-

sary, refer to the diagrams on page 19 for the correct

use of the “John Guest” fittings.

Soft Copper Tubing Installations:

1) Turn off cold water valve under the sink, or main

valve for the house.

2) Before installing saddle tapping valve, make

sure piercing lance does not protrude beyond

rubber gasket.

3 Assemble saddle tapping valve on copper tubing.

See Figure 3.

4) To pierce soft copper tube, turn handle

clockwise until it is firmly seated. The valve is

closed in this position.

5) Turn on main supply valve to pressurize cold water

line. Check for leaks. With a wrench snug nut/seal

around valve stem.

NOTE: For basement installations the existing

orange feed water tubing may have to be

longer to reach feed valve.

6) Connect one end of the orange tubing to the feed

water valve using brass compression nut, insert

and plastic sleeve.

Rigid Metal Pipe Installations:

1) Turn off cold water supply valve and drain the line

to prevent spillage.

2) Drill 3/16" hole at the desired location. To prevent

shock hazard, use a battery operated drill.

3) Before installing saddle tapping valve, make

sure piercing lance does not protrude beyond

rubber gasket.

4) Assemble saddle tapping valve on copper tubing.

See Figure 3.

5) Turn saddle valve handle clockwise to close valve.

With a wrench tighten nut/seal around valve stem.

6) When you wish to open valve and supply

cold water to the unit, turn valve handle

counterclockwise.

7) Connect one end of the orange tubing to the feed

water valve using brass compression nut, insert,

and plastic sleeve.

NOTE: For basement installations the existing

orange feed water tubing may have to be

longer to reach feed valve.

C. Prefill and Sanitize the Storage Tank

Prefilling the tank is always recommended so there

is pressure to check for leaks and several gallons of

water to flush carbon post filter. Tanks are furnished

with a special disinfectant and only require filling with

water for 15 minutes to be completely sanitized. An

instruction tag will accompany the tank. It is important

to use a sanitizer when prefilling tank so the solution

can sanitize the tubing, fittings, and faucet at the time

of installation and startup.

1) Insert free end of orange feed water tubing into the

“John Guest” fitting on the storage tank.

2) Open feed water valve and tank valve and allow

tank to fill (about 3 minutes).

Tightening

Screw

Reversible

Backplate

Valve Handle

Tubing to

RO Inlet

“John Guest”

Fitting

FIGURE 3 Feed Valve Installation

Nelsen

Corporation

-8-

3) Turn off feed water valve and tank valve and set

tank aside (15 minutes min).

D. Install the Drain Connection

NOTE: For Basement Installation See Figure 6,

Page 16.

Under counter Installations:

IMPORTANT: Before starting this procedure,

inspect the condition of the drain

piping, especially in older homes

where the traps and tailpieces can

be deceptively thin and frail. If in

poor condition, the condition

should be remedied.

The drain saddle assembly is designed to fit around a

standard 1-1/2" OD drain pipe.

The drain saddle should always be installed above

(before) the trap and on the vertical or horizontal

tailpiece. Never install the drain saddle close to the

outlet of a garbage disposal or plugging of the RO drain

line may occur. See Figure 4.

1) Position threaded half of drain saddle at selected

location and mark the spot through the opening.

See diagram.

2) Drill a 1/4" hole at the marked spot through one

side of drain tailpiece.

3) Position both halves of drain saddle on drain pipe

so threaded opening lines up with the hole in

drain pipe.

4) Use bolts and nuts to clamp drain saddle onto

drain pipe. Do not over tighten and make sure

there is equal space between saddle halves on

each side. See diagram.

5) Wrap teflon tape on thread of “John Guest” fitting

and tighten into drain saddle.

E. Make Initial Tubing Connections

NOTE: For Basement Installation See Figure 6,

Page 16.

Under counter Installation:

1) It is advantageous to make some of the tubing

connections at this time, since the under-sink

work area is not so cramped and access to the

components is easier. If necessary, refer to the

enclosed diagram on use of the “John Guest”

plastic fittings.

2) The orange 3/8" tubing should already have been

connected to the feed water valve with a 3/8"

brass compression nut, insert and plastic sleeve.

3) Tighten 3/8" plastic “John Guest” fitting onto

threaded faucet nipple. No Teflon tape is required

to make an effective seal. It may be necessary to

hold faucet from turning while tightening fitting.

4) Route black 3/8" tubing from faucet air gap to

drain saddle so that it slopes continuously down-

ward without loops or low spots. Cut to proper

length and connect to “John Guest” drain fitting.

F. Install the Purification Assembly &

Storage Assembly

NOTE: For Basement Installation See Figure 6,

Page 16.

Under counter Installation:

The purification assembly is usually mounted to the

right or left sink cabinet sidewall, taking into consider-

ation the space available and the tank location. Gener-

ally, the tank is placed in the rear of the cabinet while

Drain Pipe

Drain Clamp

Front Plate

“John Guest”

Locking Clip

1/4" Screw 1/4" Nut

“John Guest”

Fitting

1/4" Drilled Hole

FIGURE 4 Feed Valve Installation

Nelsen

Corporation

-9-

the purification assembly is positioned toward the front

for cartridge accessibility.

To mount the purification assembly elevate at least

2" off the cabinet floor and, while keeping level, mark

the location of the mounting holes on cabinet sidewall.

Make small pilot holes with an awl or drill and screw in

the two mounting screws, leaving just enough protrud-

ing to allow bracket mounting slots to slide over them.

NOTE: If the cabinet sidewalls are not of solid

construction, the purification assembly can

be set on the cabinet floor and held against

the sidewall with the mounting screws.

The tank may be oriented either vertically or

horizontally. It is generally placed to the rear of the

cabinet but can be set in the front center (between the

sink basins) for ease of access if space permits.

G. Make Final Tubing Connections

NOTE: For Basement Installation See Figure 6,

Page 16.

With all of the components in place, the final tubing

connections can be made. When routing tubing

between components, several guidelines should

be observed.

• Tubingrunsshouldgenerallyfollowthecontour

of the cabinets rather than interfere with the

cabinet storage area.

• Striveforneatnessandanorderlytubing“ow”

using fasteners (e.g. insulated staples) to secure

the tubing. Cut tubing to the desired length.

• Arrangethetubingsotherearenosharpbends

and leave some “play” in the tubing for ease

of servicing.

• Trytokeepthetubingfromthepuricationassem

bly to the tank and faucet as short as practical

for good flow. If necessary, refer to the enclosed

diagram on use of the “John Guest” plastic fittings.

Undersink Installation

1) Connect orange 3/8" tubing from feed water valve

to the “Feed” connection on purification assembly.

2) Connect yellow 3/8" tubing from purification as-

sembly to tank.

3) Remove “RED” plug from drain elbow, insert end

of red 1/4" tubing leading from faucet into drain

elbow. See figure 1, page 2.

4) Connect blue 3/8" tubing from purification assem-

bly to “John Guest” fitting on faucet.

H. Install Ice Maker Hookup (optional)

The RO drinking water appliance can be connected to

any standard refrigerator ice maker or ice maker/water

dispenser. It should never be connected to a commer-

cial type bar ice maker.

Hooking up an ice maker involves connecting a tee

with shut off valve into the blue 3/8" faucet tubing and

routing tubing over to the refrigerator. Hooking up to

existing copper tubing is generally not recommended

unless it is less than six months old. If copper tubing

must be used, then installation of a small in-line carbon

filter at the refrigerator connections is recommended.

Before turning off the existing tap water supply to a

refrigerator ice maker, always shut off the ice maker

first (usually by lifting the lever arm above the bin to

the uppermost position). The ice maker should only be

turned on again after the RO system has been drained

several times and the tank has a full supply of water.

NOTE: Before any service is performed on the RO

system, always turn off ice maker valve

and the ice maker unit. Only turn on when

system is operating and tank is full.

I. Start Up The System

1) Double check that all connections are secure.

2) Turn on feed water valve and check for leaks. If

any leaks are noted, turn off valve and correct

before proceeding.

NOTE: If a leak occurs at a “John Guest” fitting

refer to Page 19 for correct usage.

3) Turn on storage tank valve and open faucet until a

steady stream of water flows. Close faucet, wait

at least 5 minutes and carefully check for leaks.

Correct as necessary.

-10-

NOTE: When the system is first turned on, water

may intermittently “spurt” from the air

gap opening at side of air gap faucet. This

is perfectly normal, and is caused by air

trapped in the system. This will usually

disappear within a short time.

J. Flush System of Preservative &

Check Operation.

1) Lift faucet handle and allow tank to drain com-

pletely of sanitizing solution. Do Not Use This

Water. When tank is empty, the faucet will steadi-

ly drip. This is the rate water is processed by the

RO system.

2) With faucet handle in “up” position, measure the

rate of the steady drip from spout. Use a grad-

uated cylinder (in milliliters) and watch with a

second hand to calculate approximate production

in gallons per day (milliliters per minute X 0.38 =

gpd). Proceed to check reject flow rate by discon-

necting tubing at drain connection and measure as

per above. The ratio should be a minimum of 2.5

(reject) to 1 (product).

3) Close faucet and re-inspect system for leaks.

Instruct customer (or use special faucet tag

supplied) to wait at least 4 hours and drain tank

again. The water should be discarded as it may

contain some preservative/disinfectant solution.

4) System should be ready to use as soon as the tank

refills. If any objectionable taste is noticed after

second tank draining, wait and drain tank the fol-

lowing day. Only at this time should an ice maker

be turned on if one is connected to the system.

NOTE: If optional percent rejection is used and

indicates service is required, several

tankfulls of water may have to be used

to completely flush excess TDS from the

new Carbon Post Filter before the green

light will show.

K. Clean Up & Paperwork

1) Clean up the work thoroughly.

2)

Affix any special decals or stickers. Be sure to

record the house pressure and TDS for service files.

3) Familiarize family members with the general oper-

ation of their new RO drinking water appliance. In

particular, note the following on standard faucet:

•Thefaucethandlepositions,downfor

momentary flow, and up for continuous flow.

Also note the moveable spout.

•Thelocationofthefeedvalveandtankshutoff

valve as well as the procedure for turning them

off.

•Reviewthemanyusesofthewater(cooking,

soups, juices, ice cubes, baby formula, pets,

plants, etc.)

•Reviewtherecommendedmaintenancesched

ule as determined by local water conditions.

Section V: Appendix for

Basement Installations

The following variations are generally required for

basement installations:

A. Installing The Drain Connection

For basement installations, the drain saddle is generally

not used. Instead, the RO reject line is routed so that

it drains into a laundry sink, floor drain, or standpipe

through an approved air gap. See Figure 6 on Page 15.

B. Mounting The Faucet

Air Gap Faucet

Follow the installation instructions given earlier in this

manual. Do not hook up any air gap tubing to the fau-

cet since an alternate air gap will be used elsewhere in

the drain line.

Non Air Gap Faucet

1) Familiarize yourself with all components shown in

the diagram of the non-air gap faucet.

2) Assemble only the chrome base plate and rubber

sealing washer onto the threaded nipple. (Plumb-

er’s putty may be used in place of sealing washer

for neater appearance)

3) Feed threaded nipple through sink/counter mount-

ing hole (9/16" hole is adequate).

-11-

4) From below the sink/counter assemble plastic

bottom washer, flat washer, star washer, and hex

nut onto the threaded nipple. Hand tighten hex nut

until faucet feels snug.

5) After rechecking faucet orientation, tighten hex nut

(9/16" wrench or deep socket) until faucet feels

secure.

C. Making Initial Tubing Connections

1) A proper length of orange 3/8" feed water tubing

should already have been connected to feed water

valve with a brass compression nut, insert and

plastic sleeve.

2) Tighten 3/8" “John Guest” fitting onto the threaded

nipple. It may be necessary to hold faucet from

turning while tightening fitting.

3) Connect proper length of blue 3/8" tubing to faucet

fitting (See “John Guest” fitting instructions).

Route tubing through the floor to the vicinity of the

purification assembly location.

4) Route standard red 1/4" tubing from an appropriate

drain connection (e.g. laundry sink, floor drain,

stand pipe) to intended location of purification

assembly. An air gap must be installed between

outlet and drain connection.

D. Installing the Purification Assembly

& Storage Tank

The purification assembly is generally mounted to the

basement wall (using wall anchors) or to wood ceiling

supports. To mount the purification assembly, keep

bracket level and mark the location of the mounting

holes. Install wall anchors and/or mounting screws

as required. Leave screw heads protruding to allow

bracket mounting slots to slide over them.

The tank may be oriented either vertically or horizontal-

ly and can be placed on a shelf, on the floor or

suspended with sturdy brackets to the ceiling supports.

An effort should be made to minimize the distance

between the tank and purification assembly to assure

an adequate flow rate to the faucet.

E. Making Final Tubing Connections

1) Connect orange 3/8" tubing from feed water valve

to “Feed” connection on purification assembly.

2) Connect blue 3/8" tubing from faucet to the

“Faucet” connection on purification assembly.

3) Locate the yellow “plug” on the back of the puri-

fication assembly. Remove the yellow “plug” and

connect the yellow 3/8" tubing. Connect the other

end of the yellow 3/8" tubing to the storage tank.

4) Locate the red “plug” on the purification assembly.

Remove the red “plug” and connect the red 1/4"

drain tubing to the drain fitting on the purification

assembly.

SECTION VI: Operation &

Maintenance

A. Normal Operation

1) It is normal for the Total Dissolved Solids (T.D.S.) of

the water to be higher than normal during the first

5 gallons of operation, this is due to the sanitizing

solution and the new Post Filter. After this water is

rinsed to drain, the removal rate should stabilize at

a value greater than 75%. Water pressure affects

the production rate and quality.

2) R.O. systems produce drinking water at relatively

slow rates, it can take up to 8 hours or more to

fill the holding tank. Normal operation is to let the

Holding Tank fill with water and then draw water

as is needed. When the pressure in the Holding

Tank falls to a given pressure( as the water is

being used) the Automatic Shut Off Valve (A.S.O.

Valve) will start water production and the system

will refill the Holding Tank. When the Holding Tank

is full and no water is being used, the A.S.O. Valve

will automatically shut off the feed water to con-

serve water.

The more water that is used (up to the capacity of the

system) the better the R.O. system will function. Utilize

other uses for the water, such as flowers, pets and

rinsing glassware.

After periods of non-use, such as a week’s vacation,

it is better to empty the holding tank and allow the

system to produce fresh water for use. If the system

is not used for 3-4 weeks or longer, it is a good idea

to re sanitize the system and to change the Activated

Carbon and Sediment Filters.

-12-

B. Changing Filters

NOTE: This R.O. System contains filters which

must be replaced at regular intervals to

maintain proper performance. Use only fac-

tory approved filters.

Please see Page 1 for the recommended interval for

changing the filters. Local conditions may dictate more

frequent changes.

Use a drip pan to catch any water that may spill when

the Filter Housing are removed.

1) Close the Saddle Tapping Valve by turning fully

clockwise and open the Dispensing Faucet by lift-

ing the handle. Allow the Holding Tank to empty.

2) Loosen and remove the appropriate Filter Housing.

Discard the cartridge(s).

3) Wash the inside of the Housing(s) using a mild

detergent and a soft cloth. Do not use abrasive

cleaners or pads. Thoroughly rinse all soap from

the housing before reassembly.

4) To sanitize the system and replace the filter

cartridge(s):

NOTE: The system should be sanitized before

installing the Activated Carbon Post

Filter Cartridge.

a) Use a good quality unscented 5-1/4% liquid bleach

such as Clorox.

b) Add one cap full of bleach (this is 2 tsp. or 10 ml)

to the Sediment Filter Housing. Install the Sedi-

ment Prefilter only. Check the Housing O-ring for

proper position in its groove, replace Sediment

Filter Housing on R.O. assembly.

c) If your R.O. system has a Pre Carbon Filter Hous-

ing, add one cap full of bleach. Carefully fill the

housing with tap water and temporarily install the

housing, without the Activated Carbon Pre Filter.

d) Add one cap full of bleach to the Activated Carbon

Post Filter Housing. Carefully fill the housing with

tap water and temporarily install the housing,

without the Activated Carbon Post Filter.

e) The Dispensing Faucet should be open, slowly

open the Saddle Tapping Valve on the Feed

Water Line.

f) As soon as water begins to drip out of the

Dispensing Faucet, close the Faucet.

g) Let the system stand for 15 minutes.

h) At the end of 15 minutes, in the following order,

close the Saddle Tapping Valve, close the Hold-

ing Tank Valve and open the Dispensing Faucet to

release the pressure.

i) Remove the Post Carbon Filter Housing and empty

(Repeat procedure if your system has a Pre Carbon

Filter Housing). Remove any wrapping/packaging

from carbon cartridge (s) and install in housings.

Check the O-ring to insure that it is positioned

properly in its groove and replace Housing(s) on

R.O. unit.

j) Disconnect the yellow product water tubing that

runs from the Holding Tank. Put 50 drops of bleach

(this is 1/2 tsp. or 3 ml) into the tubing and recon-

nect it.

k) Slowly open the Saddle Tapping Valve. When wa-

ter begins dripping out of the Dispensing Faucet,

in the following order, close the Faucet and then

open the Holding Tank Valve.

l) Do not open the Faucet for at least 8 hours.

m) Discard the first two full tanks of water produced,

they will contain chlorine.

n) When the Faucet is first opened, expect air and

carbon fines (very fine black powder), from the

new carbon filter (s) to be rinsed out. This is nor-

mal for the first tank of water.

SECTION VII: Technical Data

A. Water Quality

1) Water quality is normally measured with a special

meter that measures the water ability to conduct

electricity. The more dissolved solids in the water,

the higher the conductivity. The results are usually

reported in Parts per Million (ppm) or Milligrams

per Liter (mg/l) of Total Dissolved Solids (T.D.S.).

(Although technically they are not exactly equal, in

most discussions ppm = mg/l.)

2) R.O. Membranes are rated by the amount of

dissolved solids that are rejected. This rating is

a ratio of the T.D.S. in the product water and is

-13-

reported as Percent Rejection. If the feed water

contained 100 ppm of T.D.S. and the product water

contained 10 ppm of T.D.S., 90 ppm have been

rejected and the reject ratio is 90%.

Percent =Feed T.D.S. - Product T.D.S. x 100%

Rejection Feed T.D.S.

B. Water Quantity

1) Water quantity is termed Flux or Product Water

Rate and is measured as the amount of water pro-

duced in one day. It is reported as Gallons per Day

(gpd) or as Milliliters per Minute (ml/min).

2) The flow of water to drain is the Reject Water Rate

and is measured as Gallons per day (gpd) or

Milliliters per Minute (ml/min).

Milliliters per minute x .38 = gallons per day

EXAMPLE: The drain flow will fill a graduated cylin-

der to the 105 ml mark in one minute.

105 ml/min. x .38 = 40 gpd

If the container available measures ounces, use the

following conversion:

Ounces per minute x 11.2 = gallons per day

3) The Reject Ratio is the amount of water produced

compared to the amount of water flowing to drain.

Reject Ratio = Reject Rate

Product Rate

4) The Percent Recovery is another way to measure

the amount of water produced as compared to the

amount actually used.

% Recovery = Product Rate x 100%

Feed Rate

NOTE: The total flow or feed water rate into

the system is the sum of the product

flow and the drain flow.

C. Water Pressure and Temperature

Most R.O. Membranes are rated at a standardized

condition of 77°F (25°C) and 60 psi (414 kPa) discharg-

ing to atmospheric pressure.

Product water quality and quantity greatly depend

upon the Net Pressure Differential (∆p) across the R.O.

Membrane. This pressure differential is a summation of

the feed water pressure at the Membrane, which tries

to push the water through, the pressure in the Hold-

ing Tanks, which tries to push the water backwards

and the osmotic pressure, which also tries to push the

water backwards.

The Osmotic Pressure is in proportion to the dissolved

minerals in the water and can be approximated by 1

psi for each 100 ppm of T.D.S.

The higher the net pressure differential, the higher the

quantity and quality of water produced.

Some loss of production when using a pressurized

Holding Tank is normal.

Feed Water Temperature also has an affect on water

production. The lower the temperature, the lower the

quantity of water produced (see Table 3, page 13)

Water Production Rate = Rated Flow

x Pressure Correction

x Temperature Correction

TABLE 1: Pressure Correction factors for Thin Film Composite

(T.F.C.) Membrane Production Rate

Pressure Correction Percent

∆psi ∆kPa Factor Rejection*

10 69 .17 84

15 103 .25 88

20 138 .33 90

25 172 .42 92

30 207 .50 93

35 241 .58 93

40 276 .67 94

45 310 .75 94

50 345 .83 94

55 379 .92 94

60 414 1.00 94

65 448 1.08 94

70 483 1.17 95

75 517 1.25 95

80 552 1.33 95

85 586 1.42 95

90 621 1.50 96

95 655 1.58 96

100 689 1.67 96

To adjust form 60 psi (414)kPa) to another pressure multiply the pro-

duction rate by the correction factor. To adjust from given pressure

to standard conditions divide by the factor.

*Percent rejection of Total Dissolved Solids

-14-

Drinking Water

Holding Tank

INLET

(3/8" Orange)

2" Min.

DRAIN

(1/4" Red)

Dispensing

Faucet

Self Piercing

Saddle Valve

(cold water line only)

PRODUCT

(3/8" Blue)

Drain Clamp

Booster Pump

24 Volt AC

Transformer

(locate above “P” trap)

Holding Tank

Shutoff Valve

(open position)

TANK

(3/8" Yellow)

Tank

Shut-off

Valve

Reverse Osmosis

Assembly Equipped with

Booster Pump

CARBON

Post Filter

Housing

SEDIMENT

Pre-Filter

Housing

Optional Angle Stop Adapter Valve

Connects to your stop valve, riser, and

water supply line, eliminating the need for a

saddle valve. Features include Push-In

Tube Connection, 90 degree

Shut-Off, will swivel for

better positioning.

FIGURE 5 Booster Pump Installation Diagram

-15-

SECTION VIII: Booster Pump

Appendix

The booster pump consists of the pump, transformer

unit and the tank shut-off switch. The tank shut-off

switch will shut down the pump when continuous

water production is not necessary, as when the tank is

full, so as not to prematurely burn out the pump. The

AC transformer steps down the primary household 110

voltage to a safe 24 volts.

NOTE: For typical Booster Pump Installation

See Figure 5, Page 14.

Installation of the Tank Shut-Off Valve

•Turnoffthewaterattheneedlevalveifon.

•Cuttheyellow3/8”O.D.exibletubingwithaclean

square cut to insure proper seal and to avoid mis-

alignment of the compression fitting connectors.

•

Insert tubing into pump ports and tighten the fittings.

•Openthefeedwatervalve.

•Checkttingsforleaks.

•Checkthetransformervoltageandpluginto

appropriate receptacle.

•Allowwatertocirculatetorelieveentrappedair.

The pump will now build pressure. Operating pressure

will vary with membrane flow rate, flow restrictor flow

rate, feed-water pressure and line voltage. Typical oper-

ating pressure is constant, between 80 - 110 psi.

If the flow restrictor is too small, or the R.O. system is

clogged, an internal pump by-pass mechanism limits

the output pressure to “feed water pressure plus 80

psi”. As pump output pressure approaches “feed-water

pressure plus 80 psi”, a slight squeaking sound may be

heard. This “sound” can be avoided by eliminating the

system clogging.

Technical Notes

Membrane production rate is rated at 60 psi; the same

membrane operating at 90 psi or 100 psi will increase

production rate by 30% - 40%.

Membrane rejection rate is rated at 60 psi; the same

membrane operating at 90 psi - 100 psi will increase

reject rate by 5% - 10% depending on the system

“back-pressure”.

Pump orientation is recommended to be in any position

except with the pump head pointed down.

TABLE 2: Temperature Correction Factors for Thin Film

Composite (T.F.C.) Membrane Production Rate

Temperature Correction

°F (°C) Factor

50.0 (10.0) 1.711

50.5 (10.3) 1.692

51.1 (10.6) 1.673

51.6 (10.9) 1.654

52.2 (11.2) 1.636

52.7 (11.5) 1.618

53.2 (11.8) 1.600

53.8 (12.1) 1.582

54.3 (12.4) 1.564

54.9 (12.7) 1.547

55.4 (13.0) 1.530

55.9 (13.3) 1.513

56.5 (13.6) 1.496

57.0 (13.9) 1.480

57.6 (14.2) 1.464

58.1 (14.5) 1.448

58.6 (14.8) 1.432

59.2 (15.1) 1.417

59.7 (15.4) 1.401

60.3 (15.7) 1.386

60.8 (16.0) 1.371

61.3 (16.3) 1.356

61.9 (16.6) 1.342

62.4 (16.9) 1.327

63.0 (17.2) 1.313

63.5 (17.5) 1.299

64.0 (17.8) 1.285

64.6 (18.1) 1.272

65.1 (18.4) 1.258

65.7 (18.7) 1.245

66.2 (19.0) 1.232

66.7 (19.3) 1.219

67.3 (19.6) 1.206

67.8 (19.9) 1.193

Temperature Correction

°F (°C) Factor

68.4 (20.2) 1.180

68.9 (20.5) 1.168

69.4 (20.8) 1.156

70.0 (21.1) 1.144

70.5 (21.4) 1.132

71.1 (21.7) 1.120

71.6 (22.0) 1.109

72.1 (22.3) 1.097

72.7 (22.6) 1.086

73.2 (22.9) 1.075

73.8 (23.2) 1.064

74.3 (23.5) 1.053

74.8 (23.8) 1.042

75.4 (24.1) 1.031

75.9 (24.4) 1.021

76.5 (24.7) 1.010

77.0 (25.0) 1.000

77.5 (25.3) 0.991

78.1 (25.6) 0.982

78.6 (25.9) 0.974

79.2 (26.2) 0.965

79.7 (26.5) 0.957

80.2 (26.8) 0.948

80.8 (27.1) 0.940

81.3 (27.4) 0.932

81.9 (27.7) 0.924

82.4 (28.0) 0.915

82.9 (28.3) 0.908

83.5 (28.6) 0.900

84.0 (28.9) 0.892

84.6 (29.2) 0.884

85.1 (29.5) 0.877

85.6 (29.8) 0.869

To Adjust from 77° F (25° C) to another temperature, multiply

the production rate by the correction factor. To adjust from a

temperature to standard conditions divide by the factor.

-16-

INLET

(3/8" Orange)

DRAIN (1/4" Red)

Carbon

Post Filter

Housing

Sediment

Pre-Filter

Housing

Dispensing Faucet without Air Gap

REVERSE OSMOSIS ASSEMBLY

(NOTE: Aqua Classic II and Aqua Elite II

R.O. Systems include a third filter housing;

the optional ECF Module would appear on

the top of the system. The installation

would be similar to that shown.)

Self Piercing

Saddle Valve

(cold water line only)

PRODUCT

(3/8" Blue)

Holding Tank

Shutoff Valve

(Open Position)

Drinking Water

Holding Tank

TANK (3/8" Yellow)

Undersink Area

FLOOR

For best flow, keep tubing

from tank to RO Assembly

as short as possible.

Air Gap Devise

(eg. GAP-A-FLOW)

To Laundry Sink Standpipe

or Floor Drain

FIGURE 6 General Basement Installation Diagram

-17-

How to use the “Quick Connect” fittings.

Your new Reverse Osmosis Drinking Water Appliance

is outfitted with the new generation of user-friendly

“Quick Connect” push-in fittings. Proper use of the

fittings is shown in the diagrams. It is important that

the tubing selected for use with these connectors be

of high quality, exact size and roundness, and with no

surface nicks or scratches. If it is necessary to cut the

tubing, use a plastic tubing cutter or sharp razor knife.

Make a clean, square cut. An optional red locking clip

is installed in certain fittings to provide extra security.

Remove this clip first before trying to remove tubing

by sliding away from fitting. Should a leak occur at a

fitting, the cause is usually defective tubing.

To fix:

•Relievepressure

•Releasetubing

•Cutoffatleast1/4”fromend

•Reattachtubing

•Conrmconnectionisleakfree

To Attach Tubing

To Release Tubing Optional Locking Clip

Push tubing straight in as far as

it will go.

Collet

Tubing

Push in collet to release tubing.

Tubing is secured in position.

Optional Red Locking clip slides

between collet and fitting.

Nominal Rejection Characteristics of

Thin Film Composite Polyamide Membrane*

* The above percent of rejection is for reference only and not

to be construed as chemistry, temperature, and TDS are not

constant in each water supply.

Ion Symbol % Rejection

Aluminum Al+3 97 – 98

Ammonium NH4+ 85 – 95

Borate B4O2-2 30 – 50

Boron B 60 – 70

Bromide Br - 93 – 96

Cadmium Cd+2 93 – 97

Calcium Ca+2 95 – 98

Chloride CI - 92 – 98

Chromate CrO4-2 85 – 95

Copper Cu+2 96 – 98

Fluoride F - 93 – 95

Iron Fe+2 96 – 98

Lead Pb+2 95 – 98

Manganese Mn+2 97 – 98

Ion Symbol % Rejection

Magnesium Mg+2 95 – 98

Mercury Hg+2 95 – 97

Nickel Ni+2 97 – 98

Nitrate NO3- 90 – 95

Phosphate PO4-3 95 – 98

Polyphosphate 96 – 98

Potassium K+ 92 – 96

Silica Si 85 – 90

Silicate SiO2-2 92 – 95

Silver Ag+ 95 – 97

Sodium Na+ 92 – 98

Sulfate SO4-2 96 – 98

Thiosulfate S2O3-2 97 – 98

Zinc Zn+2 97 – 99

Feed Channel Space

r

Perforated Central

Brine Seal

Membrane

Feed Solution

Permeate Collection Material

Permeate

Concentrate

Membrane

Feed Channel Spacer

Outer Wrap

Reverse Osmosis – How Does it Work

Reverse osmosis (RO) is a separation process that

uses pressure to force a solvent through a membrane

that retains the solute on one side and allows the pure

solvent to pass to the other side. More formally, it is the

process of forcing a solvent from a region of high solute

concentration through a membrane to a region of low

solute concentration by applying a pressure in excess of

the osmotic pressure. This is the reverse of the normal

osmosis process, which is the natural movement

of solvent from an area of low solute concentration,

through a membrane, to an area of high solute

concentration when no external pressure is applied. The

membrane here is semipermeable, meaning it allows

the passage of solvent but not of solute.

Reverse Osmosis

Drinking Water System

One Year Limited Warranty

Nelsen Corporation warrants its Reverse Osmosis Drinking Water System to be free from defects

in materials and workmanship for a period of one year from the date of manufacture when

installed and operated within recommended parameters.

Nelsen Corporation will repair or replace at its discretion any defective component. This

warranty does not cover the disposable sediment and carbon cartridges whose service life

depends on feed water conditions. The Reverse Osmosis Membrane is warranted for one year.

If the required pre-filter conditions to the membrane are not followed the membrane will not be

warranted.

Conditions of Warranty

The above warranty shall not apply to any part of the Reverse Osmosis Drinking Water System

that is damaged because of occurrences including but not limited to neglect, misuse, alteration,

accident, misapplication, physical damage, or damage caused fire, act of God, freezing or hot

water. If the unit is altered by anyone other than Nelsen Corporation the warranty is void.

To obtain service: (A) contact your local dealer who supplied the unit, or (B) contact the factory

for the dealer nearest you. It is the obligation of the owner to pay for shipping or travel charges

to return the defective part.

This is the sole warranty made by Nelsen Corporation with respect to the Reverse Osmosis

Drinking Water System. No other warranties, expressed or implied, are given including

merchantability or fitness for a particular purpose, incidental or consequential damages, or

other losses.

This exclusion applies to the extent exclusion is permitted by law.

No person or representative is authorized to assume for Nelsen Corporation any liability on its

behalf, or in its name, except to refer the purchaser to this warranty.

This Warranty gives you specific legal rights; you may also have other rights which vary from

state to state.

Nelsen Corporation • 3250 Barber Rd. • Norton, OH 44203

© 2013 Nelsen Corporation Part# RO SVC MANUAL

This manual suits for next models

3

Table of contents

Popular Water Filtration System manuals by other brands

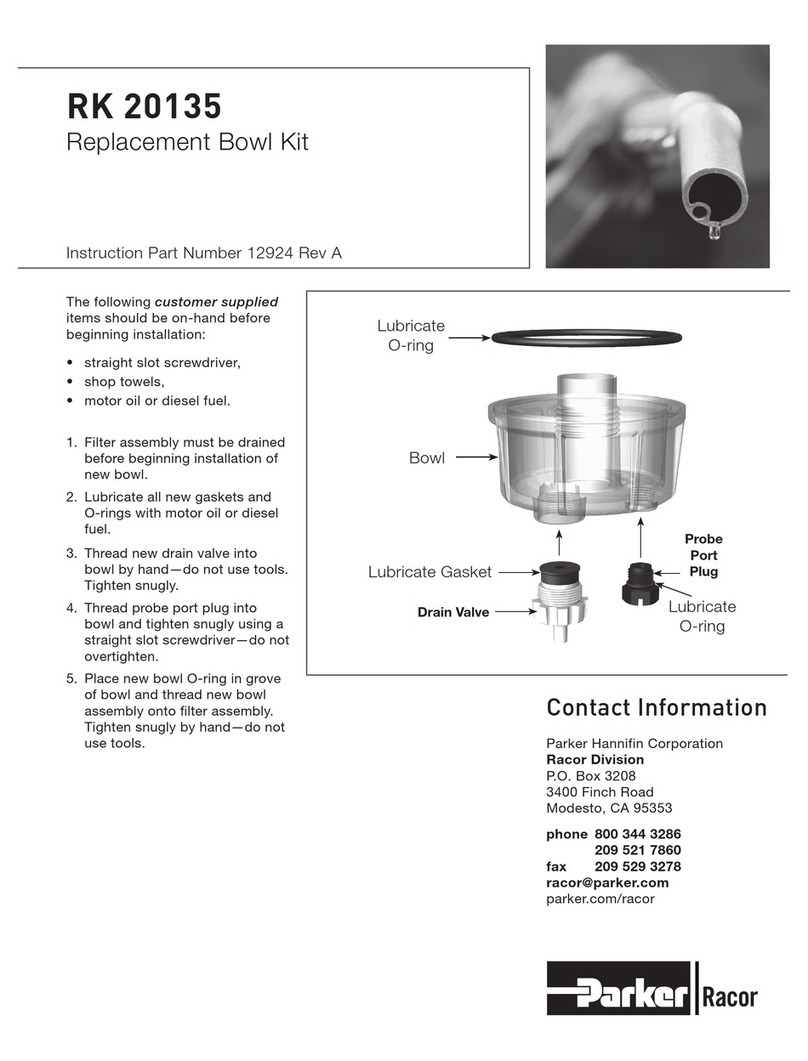

Parker

Parker Racor RK 20135 instructions

amiad

amiad TEQUATIC PLUS F-150 Installation, operation and maintenance manual

SpectraPure

SpectraPure CSPDI-90-MF Installation and operating manual

Aqualife

Aqualife AquaClave P5 user manual

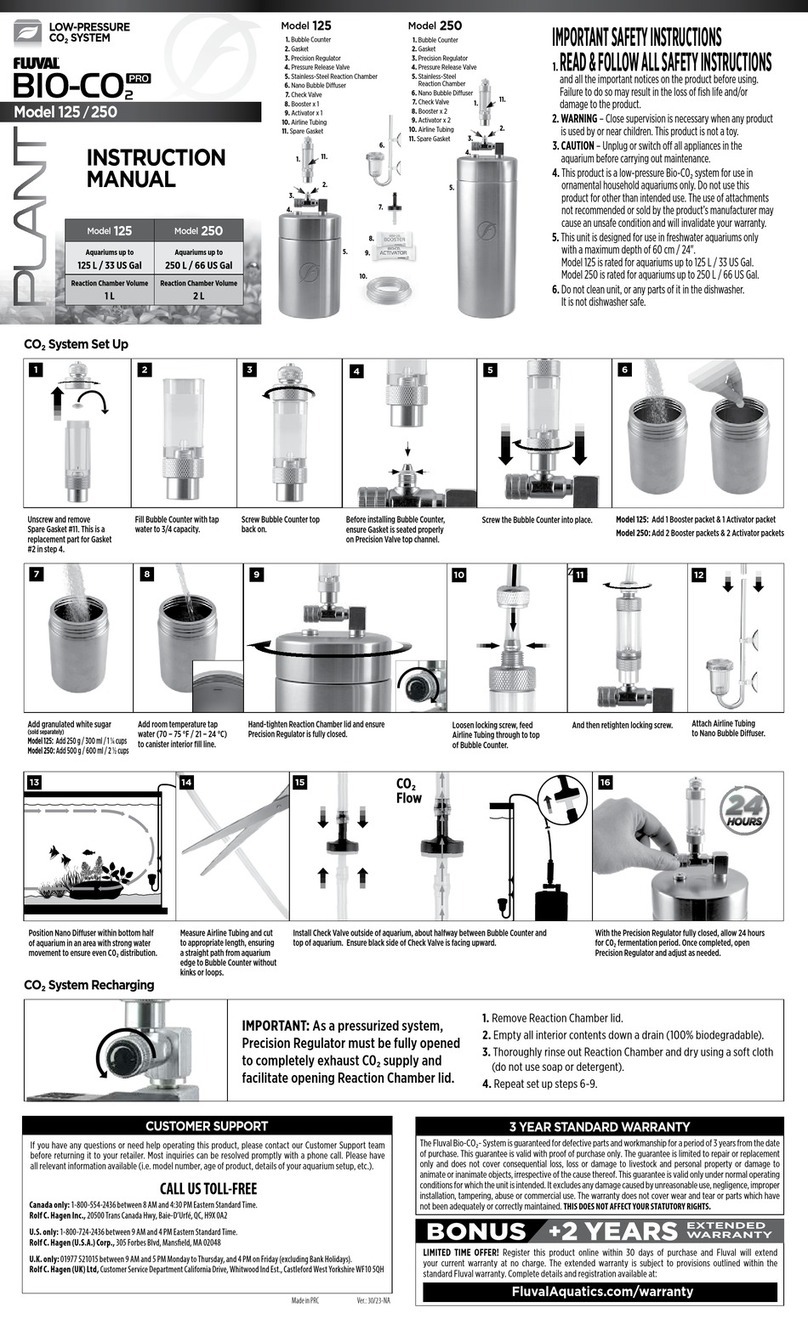

Fluval

Fluval BIO-CO2 PRO 125 instruction manual

Sulaco A.I.R Works

Sulaco A.I.R Works DUST COMMANDER Installation, operation and maintenance manual