Nemotech Nautilus MK42 User manual

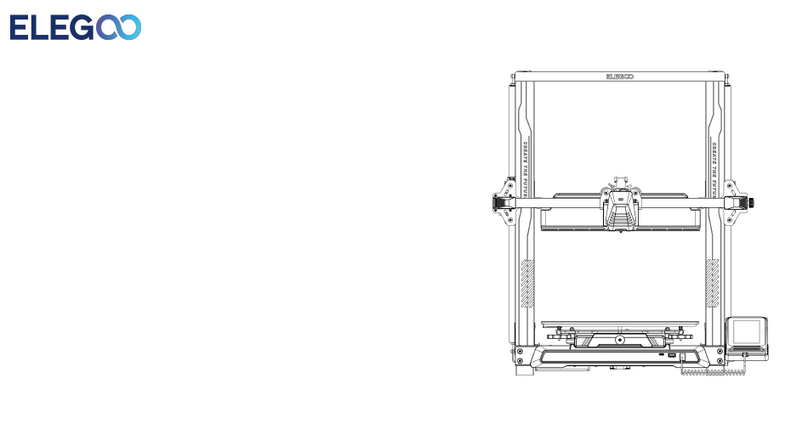

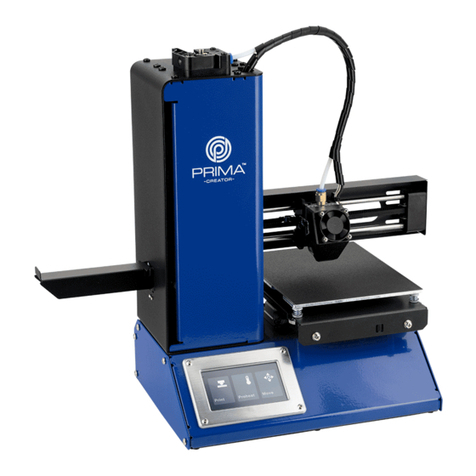

NAUTILUS 3D PRINTER MK42

Filament

Filament Holder

Printer Frame

Threaded Rod

X Axis

Z2 Stepper Motor

Z1 Stepper Motor

Heatbed

LCD Knob

LCD Panel

Reset Button

Z Axis

Extruder Stepper Motor

X Stepper Motor

X Axis Endstop Switch

SD Card Slot

Y Axis

Y Axis Endstop Switch

NAUTILUS 3D PRINTER MK42

Open the shipping box and carefully remove the printer.

Confirm the following have been included with the printer:

1 pair of Nitrile Gloves

USB Cable

Power Cable

2 Alcohol Wipes

Print Bed Pry Tool

8GB SD Card

Place the printer on a level surface in a draft-free area.

Break off the two spool holders still attached to the print bed.

Clip off the two large orange wire ties.

DO NOT CLIP ANY BLACK WIRE TIES

Attach the filament holders to the upper frame and load the filament spool. Make sure the spool

doesn’t jam and can turn freely. The filament should unwind from the top of the spool in the direction

of the LCD display.

Plug in the AC power cord, checking that the proper setting for AC voltage is selected (110V/220V), and

turn on the power using the switch located on the rear right side of the printer.

Wipe the print bed thoroughly using one of the included alcohol wipes.

DO NOT TOUCH THE PRINT BED WITHOUT WEARING NITRILE GLOVES

Check the LCD display to make sure the firmware is up to date

Main Screen displays the most important details:

A. Temperature of the nozzle (actual/desired)

B. Temperature of the heatbed (actual/desired)

C. Progress of printing in %

D. Status bar

E. Z-axis Position

F. Printing Speed

G. Elapsed printing time

Printer Statistics shows statistics for the running print. If you view the screen while the printer is idle,

you will see the lifetime statistics. Both filament usage and print time is being tracked.

Silent vs. Hi-Power Mode adjusts motor power consumption. Silent uses less current and makes the

printer quieter, but less powerful. Hi-Power is great for large (over 200 gram) prints and for freshly

assembled kits before you fine tune everything.

Factory Reset is used when troubleshooting the printer and resetting to the factory state.

Factory Reset Menu

1. Press and release the reset button (located under the LCD-Knob on the LCD panel and

marked with an X).

2. Press and hold the LCD-Knob until you hear a beep.

3. Release the LCD-Knob.

OPTIONS

1. Language

2. Statistics – erases all the recorded print time and material from the memory

3. Shipping Prep – resets only the printer language selection, but will prompt the ser once to run

the Calibrate Z function

4. All Data – resets everything including all calibration data, as well as, cleaning the whole EEPROM.

After this reset, user is expected to go through the calibration flow again, except setting the flow

height.

If you experience random glitches after firmware update or after printer upgrade, use the All

Data option.

XYZ CALIBRATION

The purpose of the XYZ calibration process is to measure the skew of the XYZ axes and to find the

position of the 9 calibration points on the print bed for the proper bed leveling.

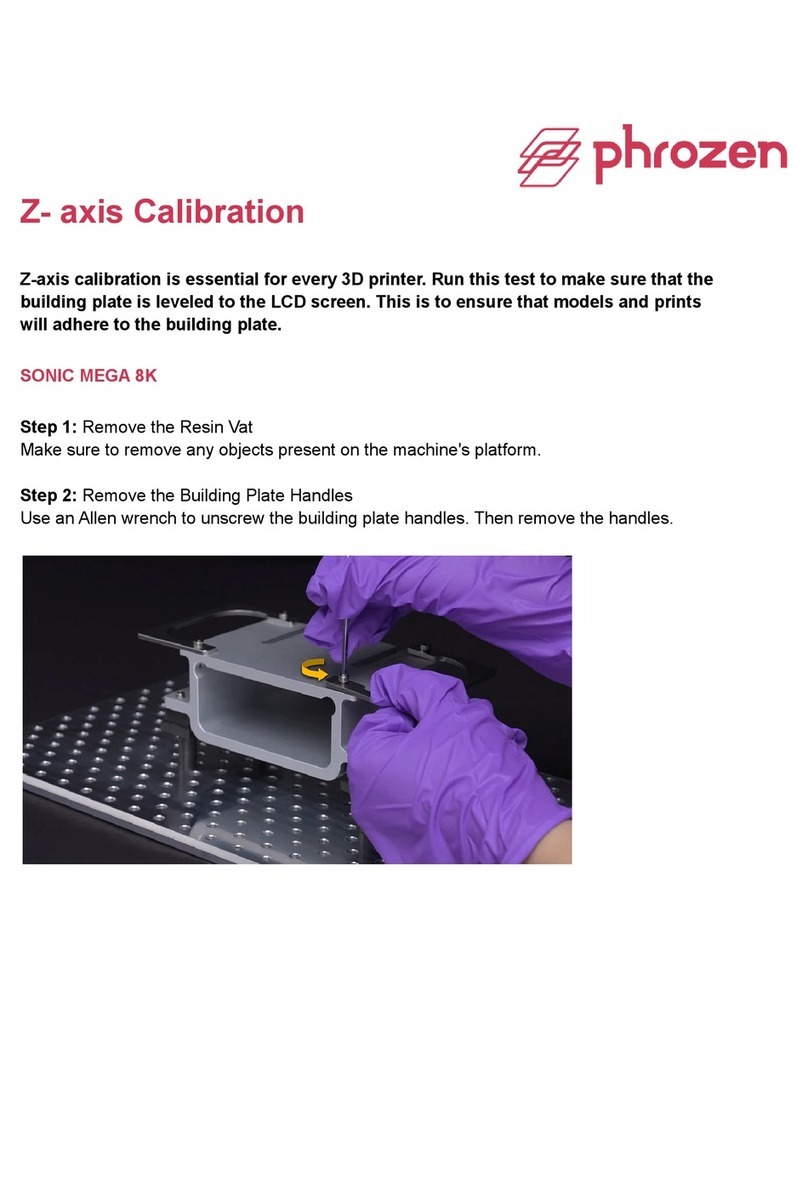

MEASURING THE DISTANCE BETWEEN THE TIP OF THE NOZZLE AND THE PROBE

1. Place a sheet of regular office paper under the nozzle and hold it there during the first round

(first four points being checked) of calibration.

If the nozzle catches on the paper during the process, power off the printer and lower the probe slightly.

Check probe height.

The paper will not affect the calibration process. The nozzle must not touch the print surface or deflect

the bed by any means. If everything went correctly, continue with the calibration process.

2. Initiating this process performs a series of measurements in three rounds. The progress and

results of each step are displayed on the LCD. In case of errors found, the XYZ calibration is

interrupted and the reason for error is shown to guide in troubleshooting

3. At the start of the XYZ calibration procedure the printer prompts you with the following

message: Calibrating XY. Move Z carriage up to the end stoppers. Click when done. The printer

then asks you to confirm this step: Are left and right Z carriages all up?

Make sure you really move the Z carriage up to the end stoppers until you hear a rattling sound as the Z

stepper motors skip steps.

The XYZ calibration procedure also prompts you to: Please clean the nozzle for calibration. Click when

done.

LOADING FILAMENT

Preheat the nozzle before inserting the filament. If printing right away, preheat the print bed, as well.

The temperature depends on the material being used.

1. Press the LCD-knob to enter the main menu on the LCD Display. Rotate the knob to choose the

preheat option and confirm by pressing the LCD-knob. Next, choose the material you will be

printing, and confirm by pressing the LCD-knob. The nozzle and print bed will heat to the

requested temperature. WARNING: DO NOT TOUCH THE HEATED NOZZLE OR THE HEATED

PRINT BED.

2. Press the LCD-Knob on the LCD panel to enter the main menu. Turn the LCD-Knob to UNLOAD

FILAMENT and press the LDC-Knob to select. The extruder will release the remaining black

filament from the factory settings.

3. Insert the filament from the filament spool into the top of the Extruder Compartment.

Look through the window on the side of the Extruder Compartment to confirm that your filament

is loading properly into the feed guide.

4. Press the LCD-Knob to enter the main menu. Turn the LCD-Knob and scroll to LOAD FILAMENT.

5. Press the LCD-Knob to select LOAD FILAMENT while simultaneously feeding he filament into the

extruder. Apply firm, even pressure. This process can take a few tries. Trimming the filament at

a sharp angle is recommended.

6. Check if the filament is flowing from the nozzle.

7. As the filament begins to flow from the nozzle, gently use the pry tool to pull the filament away

from the nozzle. Continue pulling it away until it stops flowing. The will prevent the nozzle from

clogging.

8. The LCD Screen will prompt you: Is the Color Clear. Select yes, or the process will begin again.

CHANGING THE FILAMENT

If you change the filament for a new one, do not forget to completely remove the old filament before

beginning your print.

1. Press the LCD-Knob to enter the main menu. Turn the LCD-Knob to scroll to SETTINGS. Select

MOVE AXIS – EXTRUDER until the color is completely changed.

RUNNING OUT OF FILAMENT DURING A PRINT

CHANGING FILAMENT COLOR DURING A PRINT

If your filament is running out during a print, or you want to change filament color during a print, you

can easily change it for a new spool.

1. Press the LCD-Knob to enter the main menu. Turn the LCD-Knob to scroll to TWEAK

SUBMENU, press the LCD-Knob to select CHANGE FILAMENT. The printer will pause and go

out of the print area. Follow the prompts on the LCD Screen to unload the remaining

filament and load the new spool.

FIRST LAYER CALIBRATION

Check if your printer surface is clean! See the Print Surface Preparation section of this manual.

Complete the Calibrate XYZ section of this manual first, or you can permanently damage the print

surface.

1. Preheat the nozzle for PLA. On the LCD menu, use the LCD-Knob to select Print from SD.

Run the V2calibration.gcode file from the bundled SD card.

2. The printer will probe the bed and start printing a zig zag pattern on the print surface. The

nozzle will be at the height based on the probe setting. It must not touch the print surface.

3. Observe the line which is being extruded on the print surface. Go to the LCD menu and

choose the LIVE ADJUST Z option. A new menu will show up where you can adjust the nozzle

height live during the test print.

The point is to lower the nozzle until the extruded plastic sticks nicely to the bed and you can see it is

being lightly squished. Set value should not exceed -1mm. If additional adjustments must be made,

move the probe slightly higher. Loosen the two screws on the probe holder to adjust the probe.

By rotating the probe counter clockwise, it will raise at 1mm per turn. It is very handy for precise

adjustments, but it can also be pushed in and out when the set screws are loosened completely. Then

rerun CALIBRATE Z followed by the V2Calibration.gcode again.

FINE TUNING THE FIRST LAYER

1. After finishing the calibration gcode, print a simple object. The gcode from the supplied SD

card is a great example. The Live Adjust Z function (described in the First Layer Calibration

section of this manual) works during every print, so you can fine tune at any point.

2. Calibration might be slightly different for multiple materials. It is a good practice to check the

first layer and adjust accordingly with Live Adjust Z when switching between different types

of filament.

3. If the first layer seems inconsistent between multiple prints, the probe might be too high.

Lower it slightly. Loosen the two screws on the probe holder to make adjustments.

By rotating the probe clockwise, it will lower at 1mm per turn. It is very handy for making precise

adjustments, but it can also be pushed in and out when the set screws are loosened completely. Then

rerun CALIBRATE XYZ. Keep in mind, the probe must always be higher than the nozzle tip, otherwise it

will catch on prints.

PRINTING

1. Make sure that the nozzle and the bed are heated to the desired temperature. If you forget to

preheat the printing nozzle and the bed before printing, the printer will automatically check the

temperature of the nozzle and the bed; printing will start when desired temperature is reached

– it can take several minutes. This is not recommended. Follow the procedure in the Loading

Filament section.

Do not let the preheated printer idle. When a printer is preheated and non-printing material in an

extruder degrades over time – it may cause the nozzle to clog.

2. Press the LCD-Knob and choose the Print from SD option from the menu, press to confirm and

pick the desired model model_name.gcode. Printer will start printing the object.

3. Watch the first few printed layers to be sure filament has attached to the bed properly. This

should take at least five minutes.

REMOVING OBJECTS FROM THE PRINTER

1. When printing is finished, let the nozzle and heatbed cool down before removing the printed

object. Always handle the printed objects when the temperature of the bed and nozzle drop to

room temperature. Removing the object before the heat bed has properly cooled could result in

damage to the object or the heat bed.

2. Once cooling is complete, use the Print Bed Pry Tool to gently lift the corners of the object.

Apply gentle upward pressure until the object breaks free.

PRINTING SPEED

Print times will vary depending on object size and print resolution. Printing a small object takes a few

minutes, but printing larger models can take hours. The overall printing time can be changed in

different ways.

Slic3r Print speed can be changed by adjusting the layer height in Slic3r.

In the Slic3r software, change the Print settings option (upper right corner) from 0.20 mm NORMAL (this

is the default) to 0.35mm FAST. Increasing the speed compromises the print quality. Your print will

exhibit visible layer borders and be less detailed. Lowering the speed of your print will result in greater

detail and a higher quality print model. Printing time may double. Choose 0.10mm DETAIL for better

quality.

While Printing Speed can be changed while printing. The LCD-Screen will show the FR 100% item – it’s

actual speed (feed rate). You can increase the print speed up to 999% by turning the LCD-Knob

clockwise. A speed increase of anything over 200% is not recommended. Watch the results of

increased speed on the printed object and adjust the speed accordingly.

When increasing print speed, always check that the printed object is cooled properly. Increasing the

speed of small objects printed from ABS may result in a distorted or “warped” object. This issue can be

prevented by printing more similar objects together. Layer printing interval is long enough to prevent

this issue.

If the object shows lower quality than desired, you can decrease the printing speed by turning the LCD-

Knob counterclockwise. Minimum usable print speed is around 20% of nominal speed.

NOZZLE CLEANING

Use a small wire brush to carefully clean the nozzle from the outside. Heat the nozzle before you do so.

If the filament is not extruded from the nozzle (or extruding very slowly or in very small volume), first

check the extruder fan is working properly and that the temperature is set correctly (see the Materials

List in this Manual for correct temperature settings). Also check that the filament was loaded correctly

into the extruder.

If the filament extrudes, but in a small volume, check the direction. If it swirls and goes back up toward

the nozzle, the nozzle needs to be cleaned.

To Clean the Nozzle:

1. Move the extruder to the rightmost position out of the way of the heatbed. This allows you to

reach the nozzle from below.

2. Heat the nozzle according to the filament you want to print. Load the filament. Place a small

needle (0.3 – 0.35mm) into the nozzle from below. Push the needle in 1 to 2 cm deep.

3. Remove the needle and choose LOAD FILAMENT from the LCD menu. Check for proper

extrusion. If necessary, repeat the above steps with the needle a few more times. When the

filament is extruded properly, the nozzle is clear.

PRINT MATERIALS

ABS

Materials suitable for common, robust objects.

*Nozzle temperature: 255° C

*Bed temperature: 100° C. You can set the bed between 80° to 110° C depending on the size of an

object (larger object will require a higher temperature)

PLA

Material suitable for detailed models. PLA is made of renewable sources, mostly from cornflower and

cellulose. This material is appropriate for a layer height up to 50 microns.

*Nozzle temperature: 215° C

*Bed temperature: 50° to 60° C

PET

Material suitable for large objects thanks to its minimal thermal expansion. Universal material suited

also for printable mechanical components.

*Nozzle temperature: 240° C

*Bed temperature: 80° to 100° C

NOTE Do not use isopropyl alcohol to clean the bed. Doing so may cause the adhesion to be too strong.

Windex or another window cleaner is a great option for PET. Pour a small amount on a paper towel and

wipe the print surface.

HIPS

Universal, stable material with good heat resistance suited for printable mechanical coponents.

*Nozzle temperature: 220° C

*Bed temperature: 100 ° C. You can set the bed termperaute between 80° to 110° C depending on the

size of an object (larger objects will require a higher temperature).

NYLON

Nylon is very tough material suitable for mechanical parts.

*Nozzle temperature: 240° C

*Bed temperature: 80° to 90° C

Heatbed: Requires one coat of glue stick. Call Tech Support for additional instruction.

PP

Polypropylene is a flexible and resistant material suitable for printing precise objects requiring flexibility,

firmness and persistence.

*Nozzle temperature: 254° C

*Bed temperature: 95° – 100° C

*Heatbed: The best results are obtained with common scotch tape. Attach the tape directly to the print

surface an clean it after the print is finished.

FLEX

Flex is a very strong and flexible material suitable especially for flexible prototypes, covers, etc.

NOTE – Before you start printing from Flex, clean all previous material from the nozzle. Preheat the

nozzle and load PLA to remove any other previous material. When loading Flex, loosen the extruder

(idler) screws. Keep in mind that when printing from Flex the automatic filament exchange function may

not work properly.

*Nozzle temperature: 230° C

*Bed temperature: 50° C. You can set the bed temperature up to 65° C depending the size of an object.

(Larger objects will require a higher temperature).

*Heatbed: Some very soft flex materials can bond to the bed too much and will require the use of glue

on the bed as a separator to prevent PEI damage.

DIALING IN NEW MATERIALS

Materials will vary slightly depending on the manufacturer.

*To achieve the best possible output, you should experiment with the nozzle temperature, fan speed,

print speed and flow. All of these can be changed even during a print from the TWEAK menu on the LCD

panel.

*For materials not listed above, always follow the Manufacturer’s suggested settings, but find the

closest match in the Slic3r material profiles, modify and save as NEW. Continue by printing a few simple

test pieces and continuously use the TWEAK menu.

*After each improvement, don’t forget to modify the settings in Slic3r. Reset the TWEAK values before

every print.

Slic3r

A 3D printer can print almost anything. Whether you’ve downloaded 3D models from the Internet or

created your own models, you will need to convert the .obj or .stl format into a .gcode file. Gcode is a

file format readable by a 3D printer. The file contains information for nozzle movement and the amount

of filament to extrude. The right tool for this task, and for many more, is the Slic3r program.

You set the printing material, print quality and the print speed in Slic3r. You can manipulate the object

here, vary the placement of the printbed, resize it, etc.

Table of contents