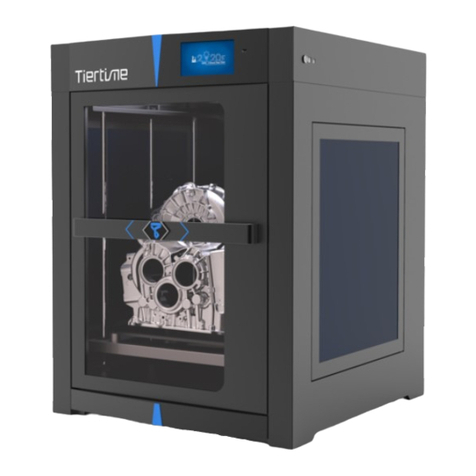

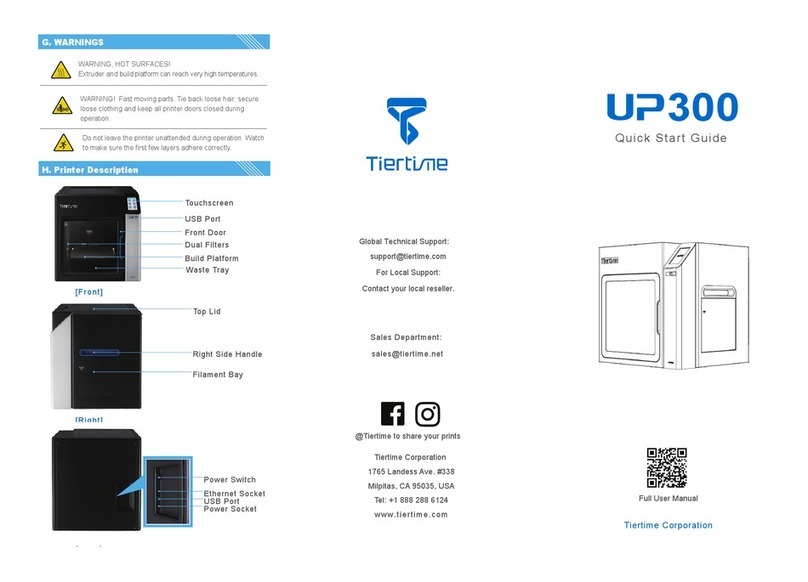

TierTime UP300 User manual

UP 300 Service Manual

1UP 300 Service Manual

2UP 300 Service Manual

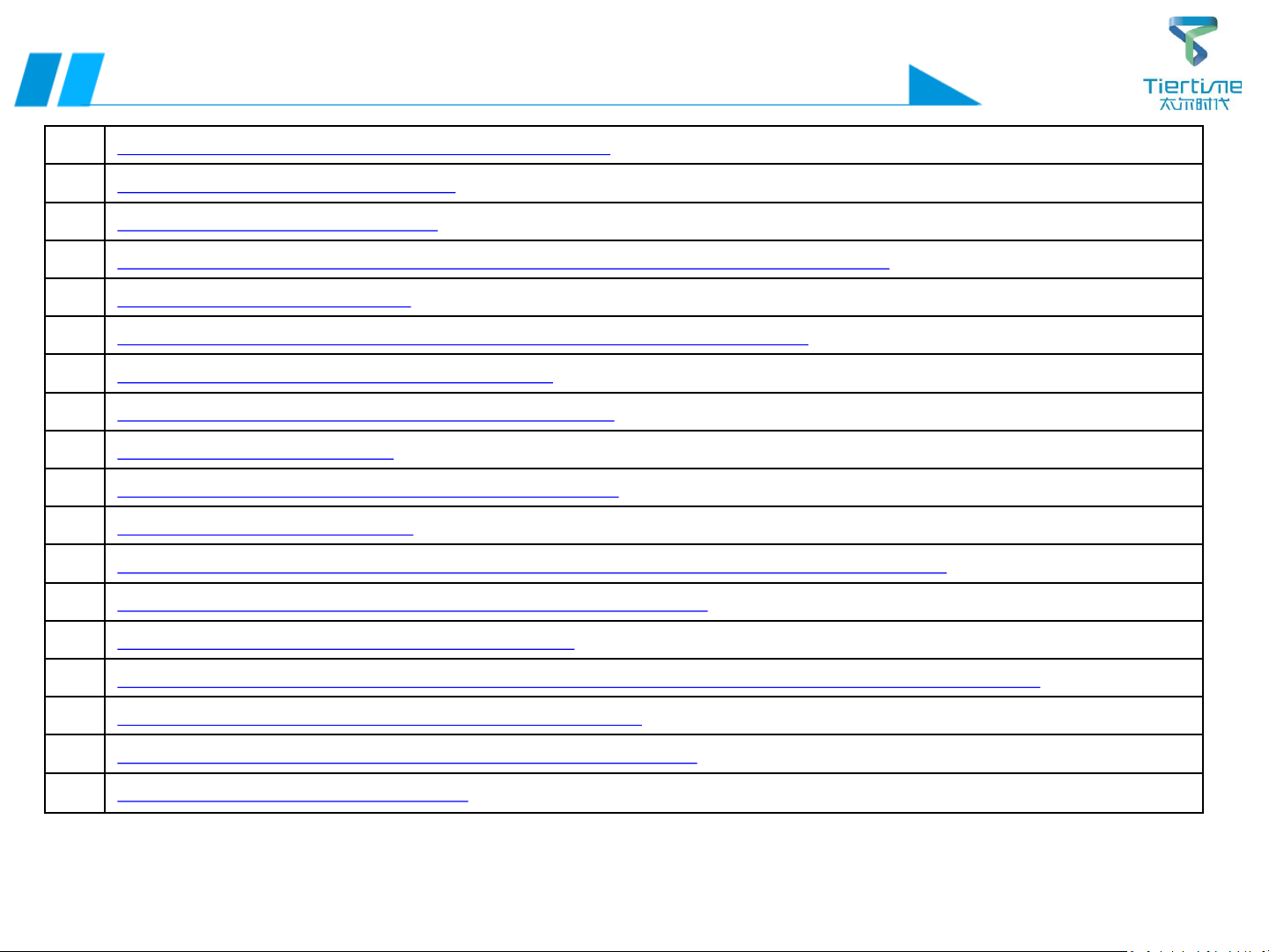

Failure Directory

01 Initialization failed: abnormal sound /can't touch the limit

02 Initialization failed: no action on an axis

03 Initialization failed: directly power off

04 A certain axis has slight abnormal sound during initialization, but initialization can be done

05 Buzzer has no sound / low volume

06 Software shows that the nozzle temperature or platform temperature is too high

07 Failed to connect UP 300 (USB), USB transfer failed

08 Failed to connect UP 300 (Wi-Fi), Wi-Fi transmission failed

09 Failed to connect UP 300 (Wi-Fi)

10 Failed to register an account (no activation email received)

11 nozzle calibration/alignment failed

12 The nozzle does not extrude filament or the filament is not smooth during extrusion and printing

13 Failed to return activation code from server when printer is activated

14 Prompt insufficient material when transferring model

15 The model displays red when clicking Print, and reports error “Model out of print range” when transmitting.

16 The device does not start printing after the print info appears

17 During printing: Z axis automatically drops / X, Y axis suddenly stops move

18

Please close the front door of the printer

3UP 300 Service Manual

Failure Directory

19 Platform temperature is too high

20 nozzle temperature is too low / no temperature rise / print model has breakpoints

21 Print model has staggered layers

22 Print model warped or deformed

23 Printing pauses automatically

24 No model or support in a certain height range, the model does not match the original image

25 The surface quality of the model is poor, the surface has abnormal texture

26 Print platform continues to heat up automatically

27 The display does not work/works abnormally (no response when tapping an icon on the touch screen)

28 Data transmission error 6/SD card error/repeated printing failure/unable to save and update high value

29 Motion system error

4UP 300 Service Manual

Operation Guide Directory

01 Method of replacing rear plate, left and right side plates (extruder parts)

02 Method of replacing mainboard adapter board

03 Method of replacing PCB-extruder adapter board

04 Method of replacing PCB-height aligning board

05 Replacing steering gear assembly

06 Method of replacing platform FFC heating wire, height aligning cable and platform adapter board

07 Method of replacing Wire-interior lights

08 Method of replacing Wire-door inspection cable

09 Replacing front door magnet

10 Method of replacing nozzle FFC

11 Method of replacing nozzle assembly

12 Method of servicing filament feeding wheel and nozzle

13 Method of replacing nozzle PCB board, heating parts, nozzle parts

14 Method of replacing Wi-Fi antenna, TF card, CPU, mainboard

15 Method of replacing FFC-Y axis cable and Y-axis limit

16 Method of replacing PCB-Y axis adapter board

17

Method of replacing HEPA filter

5UP 300 Service Manual

18 Method of replacing centrifugal fan

19 Method of replacing platform aluminum substrate

20 Method of replacing wire feeder and wire inspection limit

21 Method of replacing X-axis motor

22 Method of replacing X-axis connecting rod assembly

23 Method of replacing X-axis belt

24 Method of replacing X-axis light bar

25 Method of replacing X-axis limit

26 Method of replacing Y-axis belt

27 Method of replacing Y-axis motor

28 Method of replacing Y-axis light bar assembly

29 Method of replacing Z-axis screw motor

30 Method of replacing Z-axis limit

31 Method of replacing 26P color cable

32 Method of replacing screen power cable, signal cable, CFC-USB disk interface, SD card

33 Method of replacing display, Wi-Fi component, USB disk interface board

35

36

Operation Guide Directory

6UP 300 Service Manual

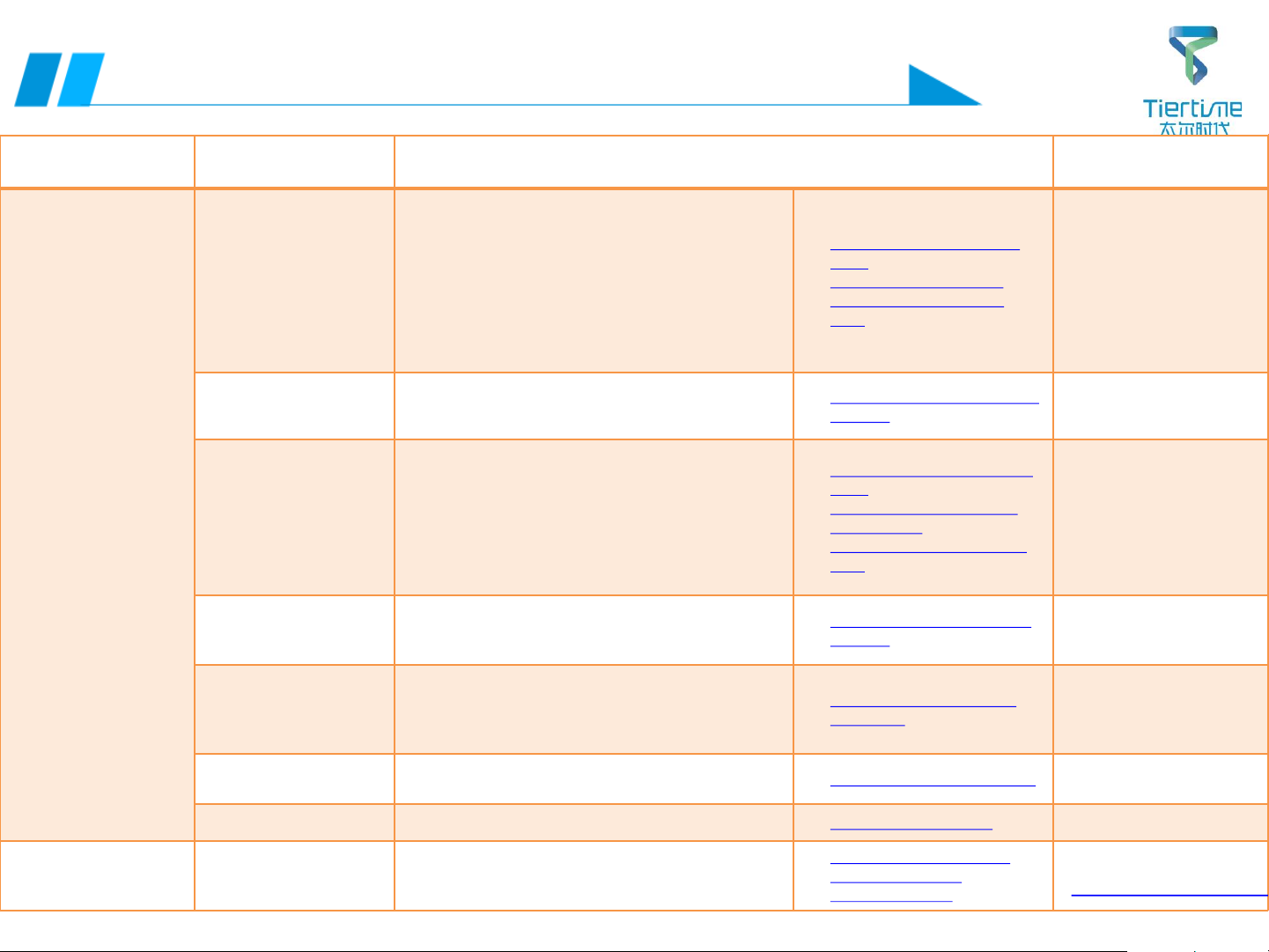

Failure Cause Solution Remark

⚫An axis has abnormal

sound during

initialization

⚫Manual three-axis

motion can’t touch the

limit switch

⚫The only method is to

turn off the power

➢Confirm the fault

axis

The axis that causes the initialization failed is the

fault axis (initialization sequence: Z-X-Y)

Normal initialization:

➢Z axis collides downwards with

limit once;

➢X axis collides backwards with

limit twice;

➢Y axis collides rightwards with

limit twice;

➢LED light is on

➢Limit switch of fault

axis is

deformed/damaged

Turn off the power, and move the XY axis manually; if

the fault axis can’t touch the limit contact or no

sound is made after touching the limit contact, the

limit is damaged and should be repaired or replaced;

if the failure still exists, process as follows;

✓Remove and

replace X limit

✓Remove and

replace Y limit

✓Remove and

replace Z limit

➢Do not break off the limit with

hands if it can’t touch

➢Limit wire, motor

wire broken, plug

loose, needle

retreated

Turn off the power, remove the rear panel and check

if the limit (on mainboard side) and motor wire of

the fault axis is broken; if not, re-plug the

limit/motor plug of the fault axis

Turn off the power and replace the motor of the fault

axis

✓Remove and

replace X motor

✓Remove and

replace Y motor

✓Remove and

replace Z motor

➢Check which axis isn’t moving

normally during initialization,

touch the limit by hand, and

check whether it can resume

normal initialization

➢Mainboard

damaged Turn off the power and replace the mainboard ✓Remove and

replace mainboard

➢Mainboard adapter

board damaged Turn off the power and replace the mainboard

✓Remove and

replace mainboard

adapter board

➢CPU damaged Turn off the power and replace the CPU ✓Remove and

replace CPU

➢Display damaged Turn off the power and replace the display ✓Remove and

replace display

Failure 01: Initialization failed: abnormal sound /can't touch the limit

Back to Directory

7UP 300 Service Manual

Failure Cause Solution Remark

⚫A certain axis has no

action during initialization

and the motor has no

motion sound

⚫Initialization is always in

the state that can’t be

finished

⚫The only method is to

turn off the power

➢Confirm the fault

axis

The axis that causes the initialization failed

is the fault axis (initialization sequence: Z-

X-Y)

Normal initialization:

➢Z axis collides downwards with

limit once;

➢X axis collides backwards with

limit twice;

➢Y axis collides rightwards with

limit twice;

➢Motor wire of fault

axis broken, needle

retreated, plug loose

➢Check if the motor of

the fault axis is

damaged

Turn off the power, check if the motor wiring of

the fault axis is damaged, and if the plug is broken;

if not, remove the mainboard and check if the

motor wire is broken or if the plug is loose

Turn off the power, open the rear panel, plug an

intact motor into the motor terminal of the

mainboard, and then initialize and test the motor

for damage. Replace the motor of the fault axis

✓Remove and

replace X limit

✓Remove and

replace Y limit

✓Remove and

replace Z limit

➢After abnormal initialization by

touching the limit with hand, push

each axis by hand to see if there is any

power failure

➢Mainboard damaged Turn off the power and replace the mainboard

✓Remove and

replace

mainboard

➢CPU damaged Turn off the power and replace the CPU ✓Remove and

replace CPU

Failure 02: Initialization failed: no action on an axis

Back to Directory

8UP 300 Service Manual

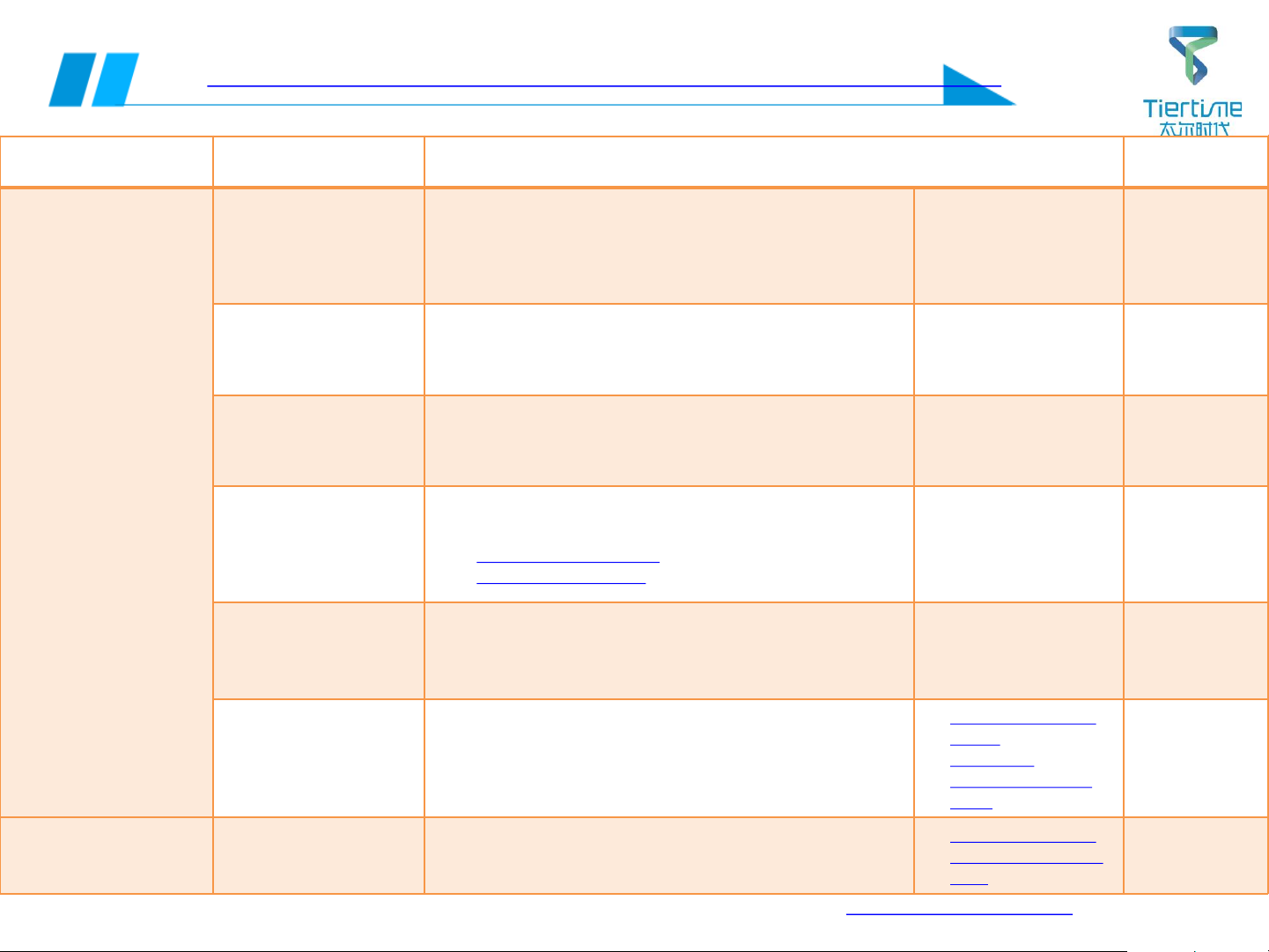

Failure Cause Solution Remark

⚫The machine

directly powers

off and restarts

when the

initialization

function is

triggered in any

method

⚫The cause of this

fault is a short

circuit

➢26P colour cable

➢Platform FFC short

circuit

➢Platform adapter

board damaged

➢LED light short

circuit

➢

Height aligning cable

short circuit

Turn off the power and replace the 26P color cable

Turn off the power, replace the platform adapter

board

Replace the LED light cable

Replace the height aligning cable

✓Replace the platform adapter

board

✓Replace the LED light cable

✓Replace the height aligning

cable

Short circuit is easy to

damage the mainboard and

platform adapter board

➢Platform adapter board is

damaged

➢Mainboard is damaged,

there is obvious burning

during initialization, and the

light appears

➢Short circuit of

aluminum substrate

Turn off the power, and replace the aluminum

substrate assembly

✓Replace the aluminum substrate

assembly

➢nozzle adapter

board short circuit

➢nozzle CFC cable

adapter board

➢nozzle FFC cable is

damaged or contact

is poor

Turn off the power and replace the nozzle adapter

board

Turn off the power and replace the mainboard

adapter board

Turn off the power and check if the FFC cable of the

nozzle has defects such as false connection,

crushing, and plug loose. If yes, replace it

✓Replace the PCB nozzle adapter

board

✓Replace the mainboard cable

adapter board

✓Replace the FFC-Y axis adapter

cable

➢Short circuit of

internal components

of the nozzle

Turn off the power and replace the nozzle assembly ✓Remove and replace the nozzle

assembly

➢Power cable or

signal cable of

screen short circuit

Turn off the power, check if the power cable and

signal cable are damaged, and if the connector is

broken or the plug is loose. If yes, replace the

power cable, signal cable / re-plug

✓Replace the power cable and

signal cable

➢Mainboard

damaged Turn off the power and replace the mainboard ✓Remove and replace mainboard

➢CPU damaged Turn off the power and replace the CPU ✓Remove and replace CPU

➢Display damaged/

power/signal cable

damaged

Turn off the power and replace the display

Check if the power/signal cable is disconnected or

broken

✓Remove and replace display

✓Remove and replace

power/signal cable

Failure 03: Initialization failed: direct power off

Back to Directory

9UP 300 Service Manual

Failure Cause Solution Remark

⚫Initialization can be

done normally, but

abnormal sound is

caused by slight friction

of the faulty axis during

initialization and

printing

➢Fault axis lacks

lubrication

If it is Y/X/Z axis, check if there is any jam or dry

noise; if yes, lubricate the fault axis bar with

industrial grade lubricating oil directly

If it is Z-axis, remove the rear panel first, and

then apply the industrial grade lubricating oil

evenly to the screw motor

✓Disassemble the rear

panel

➢Y axis abnormal

sound

Turn off the power, manually pull the Y-axis

nozzle holder, and check if the Y-axis motor

pulley is loose

Y-axis light bars not parallel, too tight

✓Remove and replace Y

motor

✓Replace Y-axis light bar

➢X axis light bar

abnormal sound

Turn off the power, manually pull the Y-

axis, and

check if the X-axis has obvious blackening or

axial scratches

✓Remove and replace X-

axis light bar

It is difficult to

replace Y-axis

linear bearing; it

is recommended

to replace the Y-

axis assembly

➢X-axis pulley

abnormal sound

Turn off the power supply and manually pull the

Y-axis to check if the X-axis motor pulley is loose

Place the belts on both sides of the pulley, and

pull the Y-axis back and forth five times to check

if the belt has obvious displacement and wear

✓Replace X-axis belt

✓Replace X motor

➢Z axis abnormal

sound

Check if the 26P color cable with black net under

the platform falls off

Failure 04: A certain shaft has slight abnormal sound during

initialization, but initialization can be done

Back to Directory

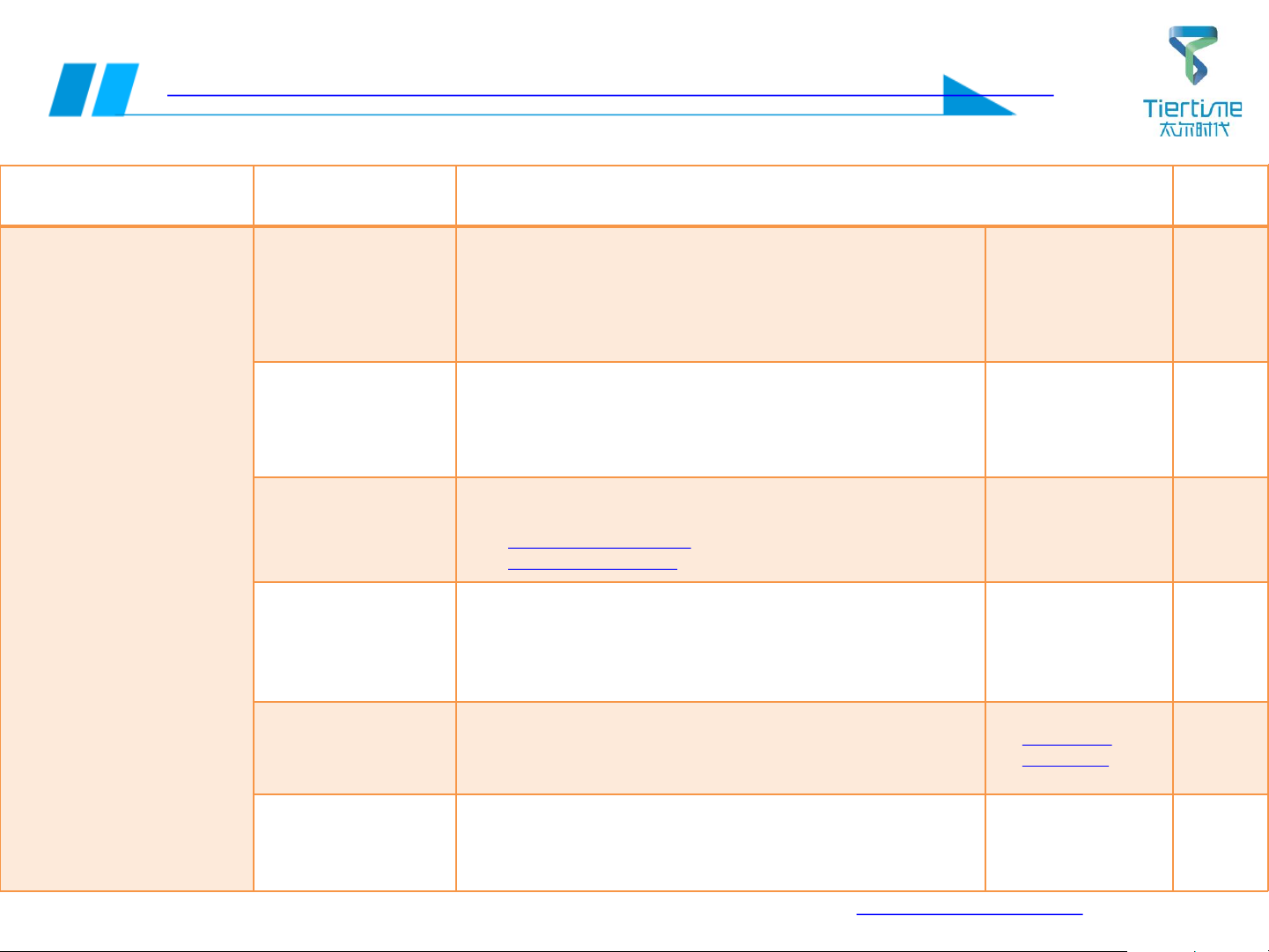

10UP 300 Service Manual

Failure Cause Solution Remark

⚫

No sound under

any operation

⚫Low volume under

any operation

➢

Buzzer / display

damaged

Turn off the power, remove the display,

and replace the buzzer components on

the display

Remove and

replace display

➢Mainboard

damaged

Turn off the power and replace the

mainboard

✓Remove and

replace

mainboard

Failure 05: Buzzer has no sound / low volume

Back to Directory

11

UP 300 Service Manual

Failure 06: Software shows that the nozzle

temperature or platform temperature is too high

Software reports nozzle high

temperature error

Software reports platform high

temperature error

Failure Cause Solution Remark

⚫

Reports nozzle

high

temperature

when the

nozzle powers

on

⚫Printing stops

and reports

nozzle high

temperature

error

⚫Platform

automatically

heats up after

initialization

⚫Software

reports

platform high

temperature

error when

loading model

➢nozzle (nozzle

plate,

temperature

control

components,

etc.)

Turn off the power, remove and replace

the nozzle PCB board

Turn off the power, remove the nozzle,

and replace the integrated liquefied gas

Turn off the power and replace the

nozzle assembly

✓Remove and replace

the nozzle assembly

✓Remove and replace

the nozzle plate

✓Remove and replace

the integrated

liquefied gas

It is

recommende

d to replace

the nozzle

assembly

➢nozzle is not

heated, fan

doesn’t run

when the

motor is

turned on

Turn off the power and replace the

nozzle PCB adapter board

Turn off the power and replace the

nozzle PCB board

Remove and replace

nozzle PCB adapter

board

➢FFC-platform

heating wire

false

connection

Re-plug or replace the FFC-platform

heating cable

✓Replace FFC-platform

heating cable

➢26P adapter

cable short

circuit

Re-plug or replace the 26P color cable ✓Replace the 26P color

cable

➢Mainboard

damaged

Turn off the power and replace the

mainboard ✓Remove and replace

mainboard

Printing stops and reports nozzle

high temperature error

Back to Directory

12UP 300 Service Manual

Failure Cause Solution Remark

⚫

When the UP 300 is

connected with a

USB cable, there is

no prompt on the

connection, and

the software

control operation

can’t be performed

⚫Unstable

connection state

causes

transmission model

data to fail/crash

after connection

➢USB cable is not

fixed/loose; USB

cable is damaged

Check if the USB cable is damaged (damaged, connector

deformed), and re-plug the USB cable on the mainboard

and PC

If the fault persists, replace the USB cable

➢USB port on PC The USB interface of the connected PC may be damaged.

Change the USB interface or check it with another PC

➢Software driver

installation failed

Connect the device to the PC with USB and update the

UP300 driver in the PC device manager (drive location:

software installation directory)

➢Software version

problem

Download the latest control software from the designated

official website

http://www.tiertime.com

https://www.up3d.com

➢PC mainboard is

underpowered

Change another PC (some MACs have experienced

insufficient power supply to the mainboard and the symbol

of “USB connection” always flashes when connecting, and

eventually the connection is abnormal)

➢Peripheral interface

board damaged /

display damaged /

external interface

board damaged

Turn off the power and replace the peripheral interface

board

Turn off the power and replace the display

Turn off the power and replace the peripheral interface

board

✓Remove and replace

display

✓Replace the

peripheral interface

board

➢Screen signal/

power cable

Turn off the power, and replace the screen signal/ power

cable

✓Remove and replace

screen power / signal

cable

Failure 07: Failed to connect UP 300 (USB), USB transfer failed

Back to Directory

13UP 300 Service Manual

Failure 08: Failed to connect UP 300 (Wi-Fi), Wi-Fi transmission failed

Failure Cause Solution Remark

⚫When UP300 is

connected wirelessly,

there is no prompt on

the connection, and the

software control

operation can’t be

performed

⚫Unstable Wi-Fi

connection state causes

transmission model data

to fail/crash after

connection

⚫Error when connecting

Wi-Fi: the printer is not

responding

➢The wireless status

of the connection

between the PC

and the UP300 is

different

Restart the UP 300 and UP Studio software, and confirm that the

display and PC are connected to the same Wi-Fi

If the workspace has multiple Wi-Fis for different purposes, its

Wi-Fi name needs to be distinguished from other Wi-Fis

➢Insufficient

wireless signal

strength / wireless

signal instable

Restart UP 300 and the software and reconnect;

Reconfigure wireless settings;

Replace a more stable and stronger wireless signal

➢Software version

problem

Download the latest control software from the designated

official website

http://www.tiertime.com

https://www.up3d.com

➢Wireless router is

not compatible

Check the router type. Currently, the UP Studio software only

supports wireless router in the 2.4GHz band. It is not compatible

with other routers and needs to be replaced with a router

supporting the 2.4GHz band

➢CPU damaged Connect Wi-Fi with the PC in the standard procedure. If it can’t be

connected normally, turn off the power and replace the CPU

✓Remove and

replace CPU

➢Wi-Fi cable

assembly or

display damaged

Turn off the power and replace the Wi-Fi cable assembly or

display

✓Remove and

replace the Wi-Fi

cable assembly or

display

Back to Directory

14UP 300 Service Manual

Failure Cause Solution Remark

⚫When UP300 is connected wirelessly, there is no

prompt on the connection, and the software

control operation can’t be performed

⚫Unstable Wi-Fi connection state causes

transmission model data to fail/crash after

connection

⚫Error when connecting Wi-Fi: the printer is not

responding

➢The wireless

status of the

connection

between the

display and the

PC is different

Restart the UP 300 and UP Studio software,

and confirm that the display and PC are

connected to the same Wi-Fi

If the workspace has multiple Wi-Fis for

different purposes, its Wi-Fi name needs to

be distinguished from other Wi-Fis

➢Insufficient

wireless signal

strength /

wireless signal

instable

Restart the router

Restart UP BOX and the software and

reconnect;

Reconfigure wireless settings;

Replace a more stable and stronger wireless

signal

➢Software version

problem

Download the latest control software from

the designated official website

http://www.tiertime.com

https://www.up3d.com

➢CPU damaged

Connect Wi-Fi with the display in the standard

procedure. If it can’t be connected normally,

turn off the power and replace the CPU

✓Remove and

replace CPU

➢Wi-Fi cable

assembly or

display damaged

Turn off the power and replace the Wi-Fi

cable assembly or display

✓Remove and

replace the

Wi-Fi cable

assembly or

display

Failure 9: Failed to connect UP 300 (Wi-Fi)

⚫Software error

Back to Directory

15UP 300 Service Manual

Failure 10: Failed to register an account (no activation email received)

Failure Cause Solution Remark

⚫

No error. When

register an account

with the UP Studio

software, the

message has been

sent to the specified

email address, but

the activation email

has not been

received

➢Intercepted as spam Check the spam and restore the email

➢Software version

problem

Download the latest control software

from the designated official website

http://www.tiertime.com

https://www.up3d.com

➢PC firewall settings Check your firewall settings

➢

Some email suffixes

have limitation

(e.g. .org)

Replace with commonly used email for

registration (QQ, NetEase, 263, etc.)

Back to Directory

16UP 300 Service Manual

Failure 11: nozzle calibration/alignment failed

Failure Cause Solution Remark

⚫Error: nozzle temperature too high

⚫Error: Calibration failed

⚫There is abnormal sound several

times when the platform rises to

the nozzle and no error reported

➢nozzle

temperature is

high during

calibration or

height aligning

after the nozzle

extruded

Wait for the nozzle temperature to drop

below 80°C

Clean residual

wire on the

nozzle before

aligning

➢Height aligning

cable damaged

Unplug the height aligning cable connecting

the height aligning assembly

✓Replace the height

aligning cable

➢Short circuit or

damage to

height aligning

PCB board

Remove the height aligning assembly and

replace the height aligning PCB board

✓Replace height

aligning PCB board

➢Steering gear is

not powered

Remove and replace the steering gear

assembly

✓Replace the steering

gear assembly

➢Mainboard

damaged

Turn off the power and replace the mainboard

✓Remove and replace

mainboard

➢nozzle adapter

cable is broken Remove and replace the nozzle adapter cable

✓Remove and replace

the nozzle adapter

cable

Back to Directory

17UP 300 Service Manual

Failure Cause Solution Remark

⚫Extrusion

failure when

the nozzle

extrudes the

wire

⚫The nozzle

suddenly

stops in

printing

process

➢Material problems (wire

used up, knotted, damp,

broken, uneven diameter)

Rearrange unrolled wires

Put in a drying oven for drying

Replace with new materials or reinstall

materials

➢nozzle plugging Clean or replace the nozzle ✓Remove and replace the

nozzle

➢nozzle height and platform

compensation value setting

is unreasonable

Reset nozzle height

Calibrate the platform manually (using

calibration sheet)

➢

nozzle CFC cable is damaged

and the contact is poor

➢nozzle FFC adapter cable

Turn off the power and check if the CFC cable of

the nozzle is damaged, and replace if yes

Check the nozzle FFC cable for damage, if

replace if yes

✓Remove and replace the

nozzle FFC cable

✓Remove and replace the

nozzle CFC cable

➢nozzle (nozzle plate, nozzle

motor, temperature control

components, etc.)

Turn off the power, remove and replace the

nozzle board

Turn off the power, remove the nozzle, and

replace the integrated liquefied gas;

Turn off the power and replace the nozzle

motor

Turn off the power and replace the nozzle

assembly

✓Remove and replace the

nozzle assembly

✓Remove and replace the

nozzle board

✓Remove and replace the

integrated liquefied gas

✓Remove and replace the

nozzle motor

It is recommended

to replace the

nozzle assembly

➢Mainboard damaged Turn off the power and replace the mainboard ✓Remove and replace

mainboard

Failure 12: The nozzle does not extrude filament or the

filament is not smooth during extrusion and printing

Back to Directory

18UP 300 Service Manual

Failure 13:Failed to receive activation code from server

when printer is activated

Failure Cause Solution Remark

⚫

Error: Failed to receive

activation code from

server

⚫

Error: “Not factory

activation status” /

“Failed to acquire

activation status”

⚫

Error: “Activation code

error” / “Activation failed,

wrong activation code”

➢The number of

prints reaches

the preset value

Download the latest control

software from the designated

official website, connect to the

network and activate CPU

http://www.tiertime.com

https://www.up3d.com

➢Error when CPU

is activated,

failed to return

activation code

from server

Query whether the CPU number

has been imported into the

database

➢Failed to get

activation status

The customer shall

return the CPU

to the factory

➢The activation

code returned by

the server does

not match the

printer’s check

code

Need to confirm with the IT

department of the factory

whether the serial number has

been uploaded to the cloud

Back to Directory

19UP 300 Service Manual

Failure Cause Solution Remark

⚫Error when transferring data model:

material not enough, continue?

➢The remaining

material in the

filament spool is

not enough to print

the model being

transferred

Remove the cover of the

wire box and check if the

remaining filament in the

box is about to run out

➢Software material

weight setting is

improper

Set the actual weight of the

material being used in the

wire box in the “Material”

interface of the UP Studio

software

Software prompt

Failure 14: material not enough when transferring model

Back to Directory

20UP 300 Service Manual

Failure 15: The model displays red when clicking Print, and reports error

“Model out of print range” when transmitting

Failure Cause Solution

Remark

The model displays red

when sending a print task

and the error “Model out of

print range” is reported

when transmitting

➢The model is not

automatically placed

after being scaled

and moved, and

some areas are

outside the molding

space

Set to automatically place and

retransfer the model in the software

➢Model size out of

molding range

In the software, if you select the

model with the left mouse button,

you can know the maximum size of

the XYZ-axis. It can’t be transferred

and printed if it exceeds the molding

space of UP 300

The forming space of UP 300 model

is X*Y*Z=205mm*255mm*225mm

➢nozzle height value

not reasonable

Restart the machine and re-run the

height aligning

Software error

Model shows red

(not primary color)

Back to Directory

Other manuals for UP300

1

Other TierTime 3D Printer manuals

TierTime

TierTime UP mini 3 User manual

TierTime

TierTime UP300D User manual

TierTime

TierTime UP300D User manual

TierTime

TierTime UP Plus 2 User manual

TierTime

TierTime UP BOX Installation and operation manual

TierTime

TierTime UP mini User manual

TierTime

TierTime UP BOX User manual

TierTime

TierTime UP mini 2 Configuration guide

TierTime

TierTime UP BOX+ User manual

TierTime

TierTime UP300 User manual