NeoBiotech N10 Series User manual

Operation Manual

NB-12-0006

Dry Bath Incubator

N10 Series

Foreword

Thank you for purchasing our product: Dry Bath. This manual for users

contains function and operation of the instrument. In order to use the

instrument properly, please read this manual carefully before using the

instrument.

Opening Check

Please check the instrument and Appendix with the packing list when you

first open the instrument packing case. If you find there is something wrong

with the instrument and the Appendix, do contact the vendor or the

producer.

Document NO.:AS93SM

Document Version:1st Edition, May. 2012

Safety Warnings and Guidelines

1. Important operation information of the security:

Before the users’ operation, they should have a perfect conception of

how to use the Instrument. Therefore, read this Manual carefully before

using it.

2. Security:

The operation, maintenance and repair of the instrument should comply

with the basic guidelines and the remarked warning below. If you don’t

comply with them, it will have effect on the scheduled using life of the

Instrument and the protection provided.

Operation before reading the manual is forbidden. Read the guidelines

and directions below and carry out the countermeasure according to

them.

This product is a normal and an indoor Instrument which conforms to

Standard B style- I type- GB9706.1.

Before using the device, read the manual carefully. These units are

designed for use in laboratory environments. The device must be used

by skilled personnel with the appropriate training.

The operator should not open or repair the Instrument by himself, which

will result in losing the qualification of repair guarantee or occur

accident. If there is some wrong with the Instrument, the company will

repair it.

A.C. power’s grounding should be reliable to safeguard against an

electric shock. The 3-pin plug supplied with thermo-shaker’s power cable

is a safety device that should be matched with a suitable grounded

socket.

Before power on, guarantee the voltage used should be accordant to the

voltage needed, and the rated load of electrical outlet should not lower

than the demand.

If the electric line is damaged, the user should replace it with the same

type. The user should assure there’s nothing on the electric line and the

user should not put the electric line in the ambulatory place.

Hold the jack when the user pull out the electric line, and don’t pull the

electric line.

3. The maintenance of instrument

The wells on the block should be regularly cleaned by soft clean cloth stained with

a little alcohol, to ensure the tubes fully contact with tubes, and has good thermal

conductivity without pollution.

If there are smutches on the instrument, clean them by soft cloth stained with

cleaning cream.

The Instrument should be put in the place of low temperature, little dust,

no water and no sun or strong lamp. What’s more, the place should be

good aeration, no corrosively gas or strong disturbing magnetic field, far

away from central heating, camp stove and other hot resource. Don't put

the Instrument in wet and dusty place. The vent on the Instrument is

designed for aeration. Don’t wall up or cover the vent in order to keep from

high temperature. If the user uses the more than one Instrument the same

time, the distance between them should be more than 100cm.

Power off when the user finishes the work. Pull off the connector plug

when there’s long time no use of the Instrument and cover it with a cloth or

plastic paper to prevent from dust.

Power off when cleaning the instrument.

When cleaning the well, don’t drop the cleaning liquid in the well.

Corrosive cleaning liquid is strongly prohibited.

Pull the connector plug from the jack at once in the following cases, and

contact the vendor:

There is some liquid flowing into the instrument;

Drenched or fire burned.

Abnormal operation: such as abnormal sound or smell.

Instrument dropping or outer shell damaged.

The function has obviously changed.

Contents

CHAPTER 1 INTRODUCTION--------------------------------------------------------------------------------- 1

CHAPTER 2 SPECIFICATIONS------------------------------------------------------------------------------- 2

1. THE NORMAL OPERATING CONDITION: ---------------------------------------------------------- 2

2. THE BASIC PARAMETERS AND CHARACTERISTICS----------------------------------------- 2

3. OPTIONAL BLOCK----------------------------------------------------------------------------------------- 3

CHAPTER 3 BASIC INSTRUCTIONS----------------------------------------------------------------------- 4

1. STRUCTURE OVERVIEW-------------------------------------------------------------------------------- 4

2. KEYPADS ----------------------------------------------------------------------------------------------------- 5

3. DISPLAY------------------------------------------------------------------------------------------------------- 5

CHAPTER 4 OPERATION GUIDE---------------------------------------------------------------------------- 6

1. TEMPERATURE AND TIME SETTING---------------------------------------------------------------- 6

2. RUNNING/STOP--------------------------------------------------------------------------------------------- 6

3. TEMPERATURE CALIBRATION------------------------------------------------------------------------ 7

4.TEMPERATURE CONTROL BY EXTERNAL SENSOR------------------------------------------11

5.THE EXCHANGE OF METAL BLOCK ----------------------------------------------------------------11

CHAPTER 5 FAILURE ANALYSIS AND TROUBLESHOOTING -----------------------------------13

ANNEX:WIRING DIAGRAM---------------------------------------------------------------------------------14

Dry Bath N10 Series Operation manual Chapter 1 Introduction

─1─

Chapter 1 Introduction

The dry bath is a new product controlled by the miniature computer,

which can be widely used for the preservation and reaction of the

samples, the amplification of DNA, the pre-denaturation of the

electrophoresis and blood serum coagulation.

Features of this product are as follows:

Temperature and time digital displayed in LED;

Display of setting temperature and the count down time to the constant

temperature;

Using metal blocks to avoid sample pollution;

Easy replacement, cleaning and disinfecting of metal blocks;

Built-in over-temperature protection, more reliable for using;

Calibrating temperature discrepancy;

Buzzer alarm at the end of temperature control duration.

Dry Bath N10 Series Operation manual Chapter 2 Specifications

—2 —

Chapter 2 Specifications

1. The normal operating condition:

Ambient temperature:5C 35C

Relative humidity:≤70%

Power supply:AC220V~50-60Hz

2. The basic parameters and characteristics

Basic parameters:

Type

Parameter

NB-12-0006A

NB-12-0006B

NB-12-0006C

Temperature range

RT+5C 105C

Timing time

Max. 99h59min.

Temperature control

accuracy

≤ 0.5 C

Display accuracy

0.1 C

Temperature uniformity

≤ 0.5 C

Heating time(20-105C)

≤20 min

Block

1pc

2pcs

Power

120W

240W

Fuse

250V 1.5A Ф5×20

250V 3A Ф5×20

Meas.(mm)(L×W×H)

250x190x130

365x210x150

Weight(kg)

2.5

4.5

Dry Bath N10 Series Operation manual Chapter 2 Specifications

—3 —

3. Optional block

Item No.

Capacity + Diameter

Meas.(mm)

NB-12-0006-01

96x0.2ml or 96 PCR plate

108 x 72 x 60

NB-12-0006-02

45x0.5ml Falcon

108 x 72 x 49

NB-12-0006-03

35x1.5ml Falcon

108 x 72 x 49

NB-12-0006-04

35x2.0ml Falcon

108 x 72 x 49

NB-12-0006-05

15x0.5ml + 20x1.5ml Falcon

108 x 72 x 49

NB-12-0006-06

20x1.5ml + 15x2.0ml Falcon

108 x 72 x 49

NB-12-0006-07

32x0.2ml + 22x0.5ml +

9x1.5ml Falcon

108 x 72 x 49

NB-12-0006-08

20x5ml Falcon

108 x 72 x 49

NB-12-0006-09

20x10ml Falcon

108 x 72 x 49

NB-12-0006-10

12x15ml Falcon

108 x 72 x 60

NB-12-0006-11

6x50ml Falcon

108 x 72 x 60

NB-12-0006-12

96 wells microplate

116.5 x 75 x 60

NB-12-0006-13

Plate

108 x 72 x 60

NB-12-0006-14

384 PCR plate

108 x 72 x 60

NB-12-0006-15

40x6mm tube

108 x 72 x 49

NB-12-0006-16

28x10mm tube

108 x 72 x 49

NB-12-0006-17

24x12mm tube

108 x 72 x 49

NB-12-0006-18

24x13mm tube

108 x 72 x 49

NB-12-0006-19

14x15mm tube

108 x 72 x 49

NB-12-0006-20

14x16mm tube

108 x 72 x 49

NB-12-0006-21

12x19mm tube

108 x 72 x 49

NB-12-0006-22

11x20mm tube

108 x 72 x 49

NB-12-0006-23

6x26mm tube

108 x 72 x 49

NB-12-0006-24

6x28mm tube

108 x 72 x 49

NB-12-0006-25

2x40mm tube

108 x 72 x 49

NB-12-0006-26

2x7 (Cuvette)

108 x 72 x 49

NB-12-0006-27

PT1000

NB-12-0006-28

M4

Dry Bath N10 Series Operation manual Chapter 3 Basic Instructions

—4 —

Chapter 3 Basic Instructions

This chapter focuses on the introductions of the structure, keypads and key-functions of

the instrument, as well as preparatory work before starting. Please read this chapter

before starting when uses this instrument for the first time.

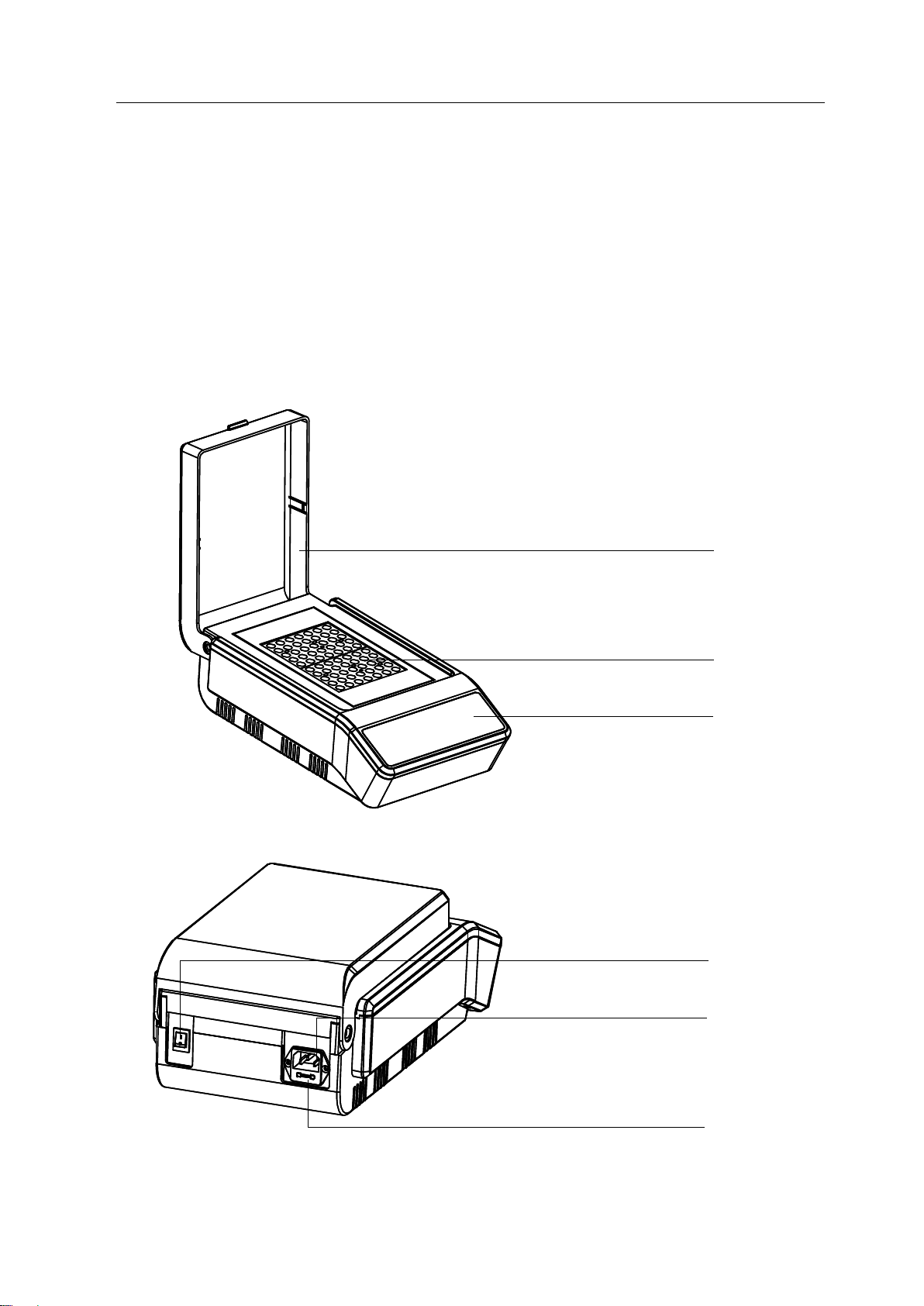

1. Structure overview

Block

Keypad

Power supply

plug

Fuse

On/Off button

Transparent cover

Dry Bath N10 Series Operation manual Chapter 3 Basic Instructions

—5 —

2. Keypads

3. Display

Start

Stop

For running, timing begins.

Drop key: For number decreasing.

For stopping, timing ends.

Up key: For number increasing.

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—6 —

Chapter 4 Operation Guide

1. Temperature and time setting

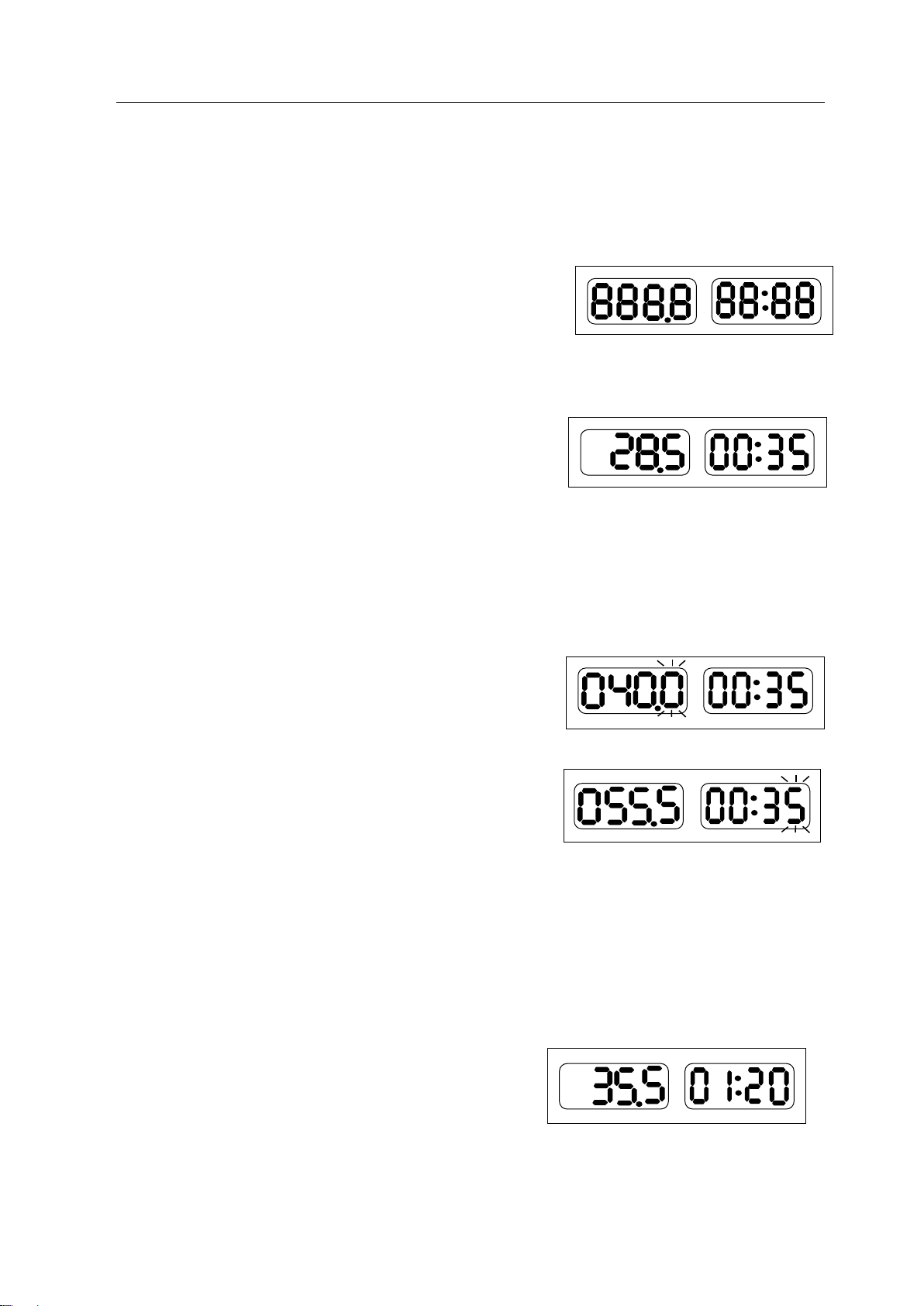

a) Press the On/Off button; the display flashes 3

times, the instrument goes into the initial

state with the sound of “beep”.

b) After about 3 seconds, the temperature

automatically goes up to the setting

temperature, the 28.5 in display is the

real-time temperature of the block (It

indicates the temperature now is 28.5°C). The

00:35 in display is the running time set

previously.(It indicates the running time is 35

min).

c) Press or in Temp to modify the

temperature.

d) Then press or at Time to modify the

time.

Wait 6 seconds to confirm the input temperature and time, and they flash

simultaneously and disappear, then the temperature automatically goes up to the

setting temperature.

2. Running/Stop

a) After the temperature and time setting

completed, the instrument automatically goes

up to the setting temperature, press “Start”

key and immediately release, then the

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—7 —

thermostat countdown begins with the sound of "beep".

Tips:Decimal point regularly flashing, which

indicatest the instrument still in the status

of temperature control, timing has not yet

begin.

Decimal point kept stationary, which

Indicates that the instrument has had constant

temperature already, the timing begins.

When timing ends, running stopped and the

buzzer alarms. Now the temperature remains

setting temperature, and displays “”.

It indicates that running is over.

b) After running ends, press any key return.

c) When running, press ”Stop”key to stop.

3. Temperature Calibration

The temperature of the instrument has been calibrated before it is sent out. But if there

is deviation between the actual temperature and the displayed temperature due to

some reasons, you can do as follows to correct the error.

Caution: the instrument uses double temperatures adjustment to ensure its veracity.

This means that it is linearly adjusted on 40℃and 100℃two points. The

temperature veracity will be within ±0.5℃after the double temperatures

adjustment.

Both the circumstance temperature and the block temperature should be lower than

35℃.

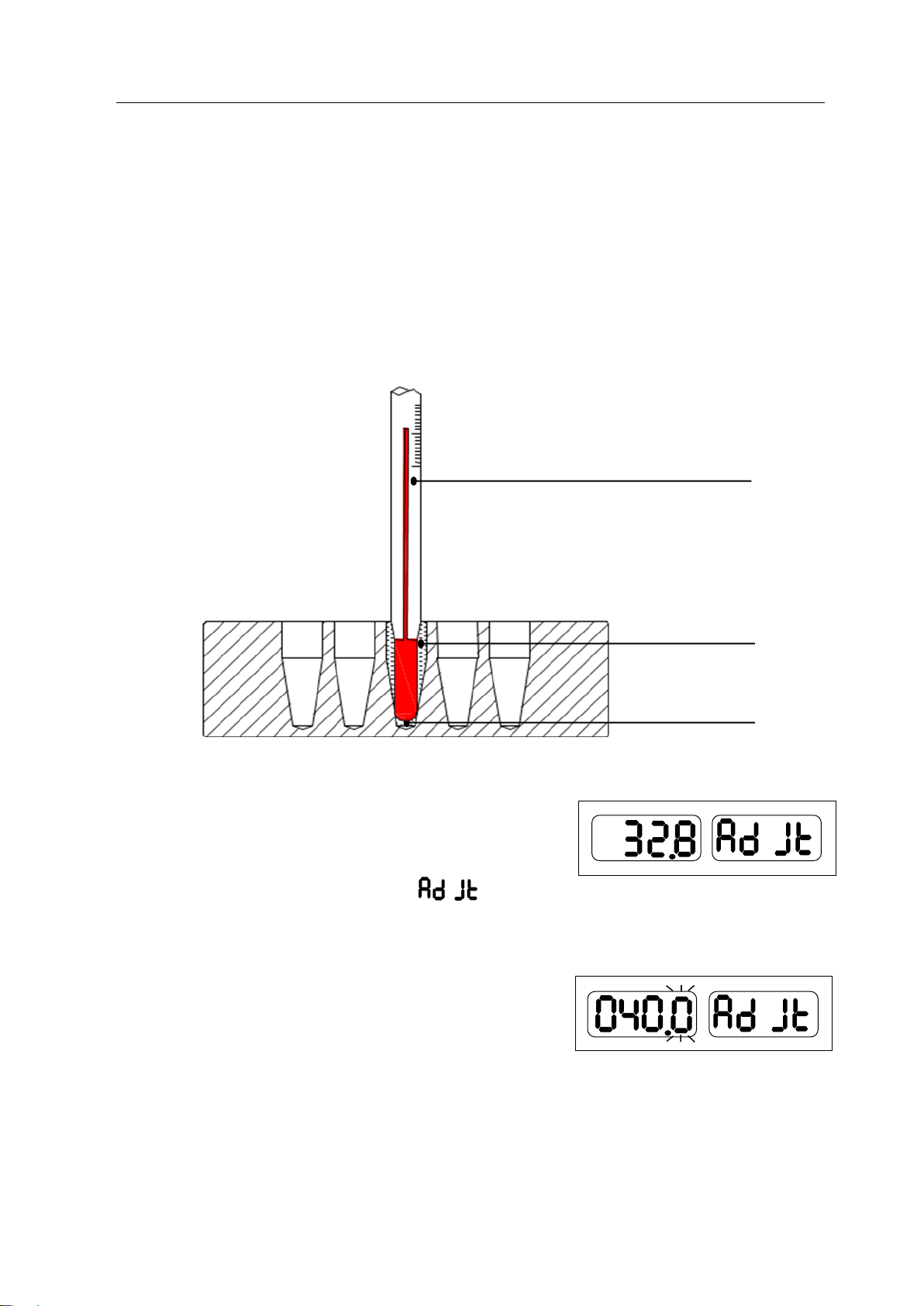

3.1. Calibrated with a thermometer, specific methods are as follows:

a) After the startup of the instrument, it enters into waiting interface. Make sure that the

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—8 —

temperature in display is below 35℃. If the temperature is higher than 35℃, you

should wait until the temperature is below 35℃.

b) Inject olefin oil into one of the cone-shaped wells, and then put a thermometer into

this well (make sure that the precision of the thermometer should be within 0.1℃

and the temperature ball should be absolutely immerged into the cone-shaped well).

See Fig a.

c) Press “Stop” key without releasing, then press

key of temperature at the same time for 3 seconds,

it will enter into temperature calibration interface,

see the right. At this point, “”displayed, which indicates entering into

temperature calibration program. The temperature displayed is current

temperature and begins to rise to 40.0℃automatically.

When the temperature reaches to 40℃constant

temperature, the decimal digit begins to flicker,

waiting for the calibrated value of 40℃. Read out the

actual value from the thermometer after 20 minutes.

Notes: Please read the actual value after 20 minutes’ constant temperature to ensure

the calibration accuracy.

Fig a

Thermometer

Olefin oil

Cone-shaped well

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—9 —

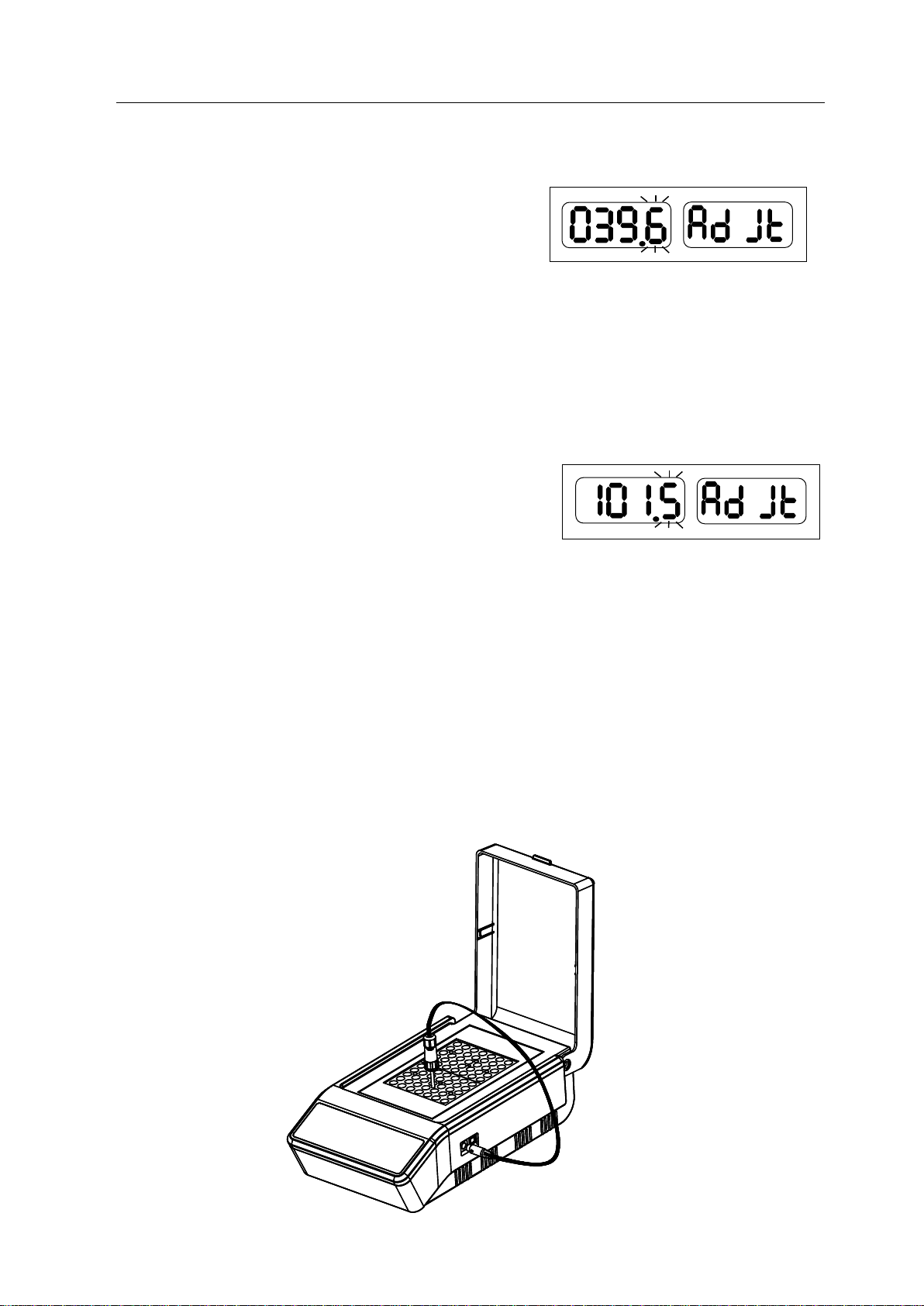

If the actual read out of thermometer is 39.6℃,

Modify the temperature to 39.6 by pressing or

. Then press “Start”to confirm the input value.

d) Then the instrument will heat to 100℃automatically, waiting till the instrument is in

100℃thermostat, input temperature calibration value. After 20 minutes’ constant

temperature, the user can read the actual value from thermometer.

Notes: Please read the actual value after 20 minutes’ constant temperature to

ensure the calibration accuracy.

If the actual readout is 101.5 ℃, modify the

temperature in display to 101.5 by pressing or .

Then press “Start” to confirm the input.

Notes: Pressing “Stop”and “”simultaneously during the temperature calibration

indicates exiting the temperature calibration program. The changed value will

be of no effect.

3.2. Calibrated with an external sensor, specific methods are as follows:

Tips

:

External sensors are optional parts, it needs to be ordered separately.

a) After the startup of the instrument, it enters into waiting interface. Make sure that the

temperature in display is below 35℃. If the temperature is higher than 35℃, the user

should wait until the temperature is below 35℃.

b) Put one end of the external sensors into a block well, and insert the other end to the

interface. See Fig b.

Fig b

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—10 —

c) Press “Stop” key without release, then press

key at the same time for 3 seconds, it will enter into

temperature calibration interface, see the right.

At this point, “ ” displayed, which indicates entering into external

temperature calibration program, the temperature displayed is external sensor’s

current temperature and begins to rise to 40.0℃automatically.

It will automatically display “

”six seconds

later, the upper displayed 32.0 is the current

temperature of the external sensor.

When the temperature reaches to 40℃constant

temperature, the decimal digit begins to flicker,

waiting for the calibrated value of 40℃. Read out

the actual value from the thermometer after 20

minutes.

Notes: Please read the actual value after 20 minutes’ constant temperature to ensure

the calibration accuracy.

Press “Stop” key to view the temperature value of

external sensor, if displayed 39.6 °C.

Press “Stop”again, or wait for 6 seconds, then

displayed “

”, modify the displayed

temperature to 39.6 by pressing or . Then press

to confirm the input value.

d) Then the instruments will heating to 100℃automatically,waiting till the instrument

is in 100℃thermostat, input temperature calibration value. After 20 minutes’

constant temperature, the user can read the actual value from thermometer.

Notes: Please read the actual value after 20 minutes’ constant temperature to ensure

the calibration accuracy.

If the actual readout of sensor is 101.5℃, modify

the temperature in display to 101.5 by pressing

or . Then press “” to confirm the input value.

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—11 —

Notes: Pressing “Stop” and “”simultaneously during the temperature calibration

indicates exiting the temperature calibration Program. The changed value will

be of no effect.

4.Temperature control by external sensor

a) Insert the external sensor into a fixed well.

b) Press “Stop” without release, then simultaneously press “”at Time for 3 seconds,

the external indicator light goes on to indicate that it has entered into the

temperature control mode of external sensor.

c) Press “Run” for program running.

Tips: After entering into the external temperature control mode, the user can

simultaneously press “Stop”and "" on Time to exit, while the external indicator

light goes off.

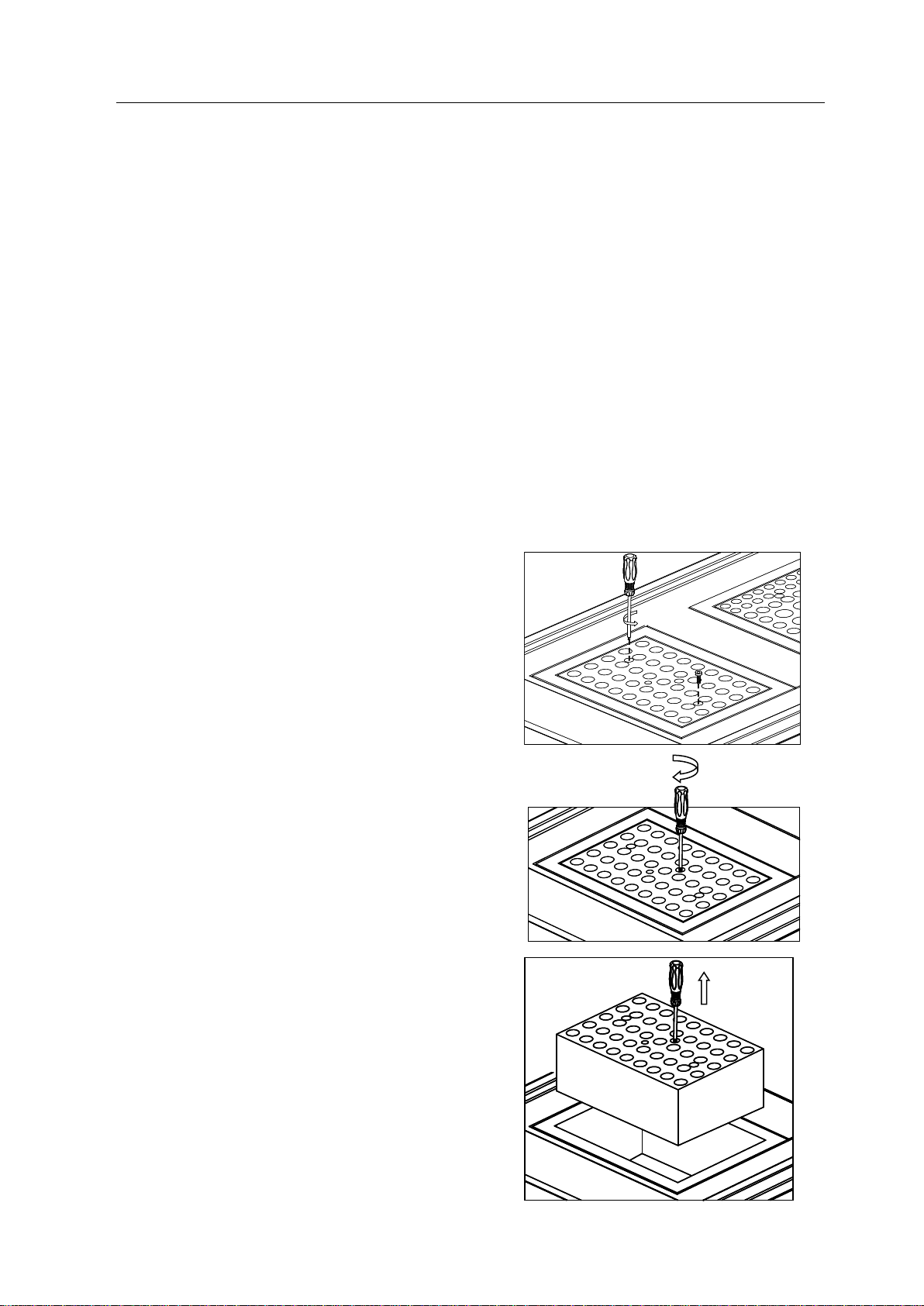

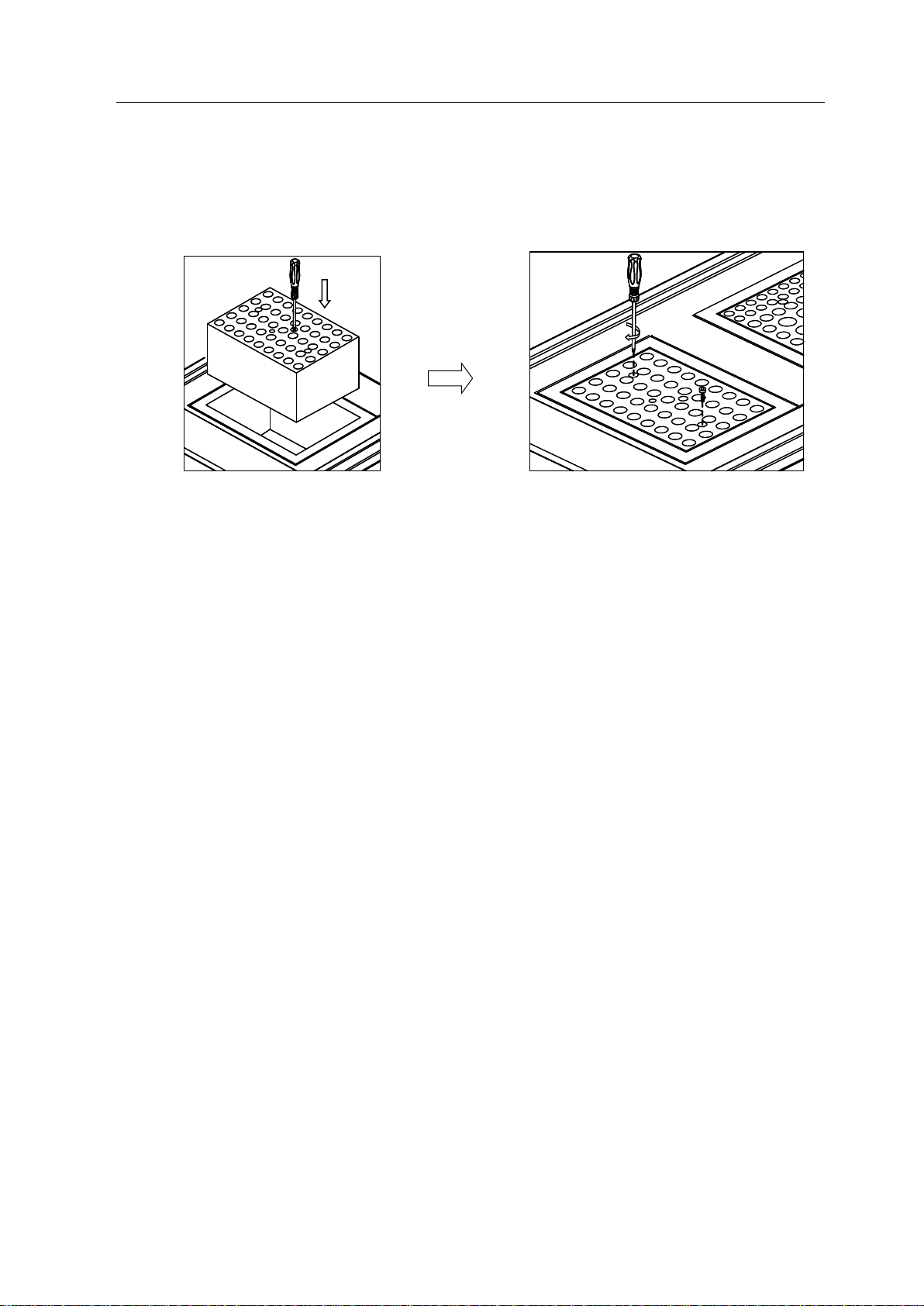

5.The exchange of metal block

a) Completely screw out the 2 screws which

were used for fixing metal blocks by

combination wrench in an anticlockwise

direction.

b) Fix the wrench in the center well of the block.

c) Pull out the wrench with the block.

Dry Bath N10 Series Operation manual Chapter 4 Operation Guide

—12 —

d) Screw the wrench out of the block, and fix it to another replaced block. Then put

it onto the instrument and fix it well by the wrench.

Dry Bath N10 Series Operation manual Chapter 5 Failure Analysis and Troubleshooting

—13 —

Chapter 5 Failure Analysis and Troubleshooting

Problems and actions

No.

Common problem

Possible cause

Action(s)

1

No display on the

screen

No power on the main

power plug

Check power supply and

plugged properly

Faulty fuse

Change fuse

On/Off button broken

Change button

Others

Contact us

2

The actual and

displayed temperatures

are quite different

Broken sensor or

loose contact of the

block

Contact us

3

“OPEn” displayed,

alarming “beep”

Sensor disconnect

Contact us

“SHOr” displayed,

alarming “beep”

Sensor short-circuit

“HHHH” displayed,

alarming “beep”

Sensor broken, or

block temperature is

too high

4

No heating

Sensor broken

Contact us

Heating tube broken

5

Keys don’t work

Faulty key

Contact us

Dry Bath N10 Series Operation manual Annex

—14 —

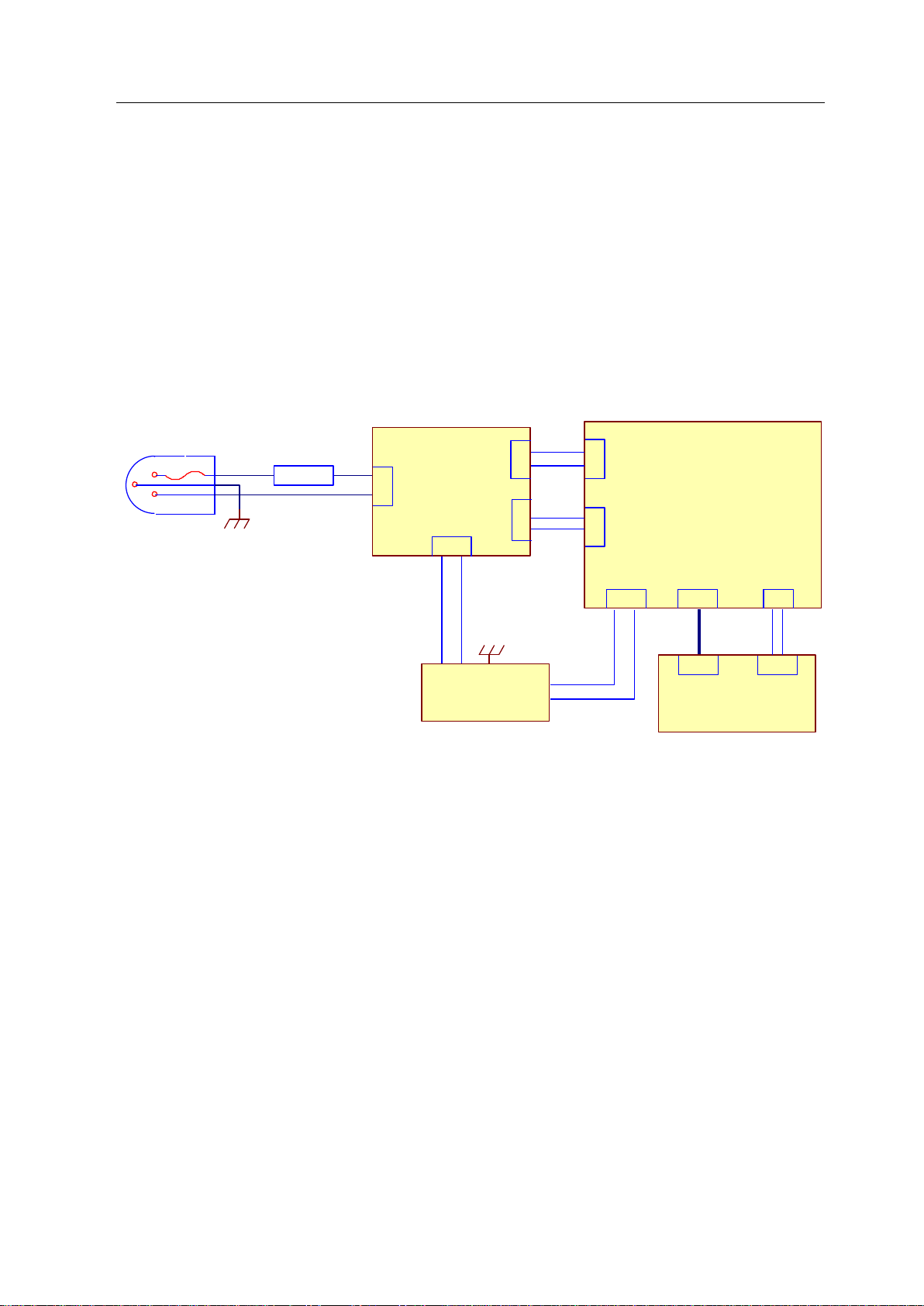

Annex:Wiring Diagram

(

for reference only

)

L

PE

NSwitch

USB PT1000

CONN BOARD

J3 J2

J1 AC220V

J4 Heat

POWER

BOARD

J3 HeatCtl

J2 AC9V

J2PT100 J4PT1000USB1 USB

J1 AC9V

X1 HeatCtl

MAIN

BOARD

HEAT

PT100

Block

Memo

This manual suits for next models

3

Table of contents