Neolysis NEO-12 Manual

pH

ORP

13000 hr

UV

5000 hr

50

3

m

120

3

m

EN

NEO-12

NEO-24

NEO-32

NEO-12 PH

NEO-24 PH

NEO-32 PH

NEO 12 +

NEO 24 +

NEO 32 +

Model.

NEOLYSIS PRIVATE SYSTEM

PRIVATE SYSTÈME D'NEOLYSIS

SISTEMA NEOLYSIS PRIVADO

NEOLYSIS SISTEMA PRIVATO

NEOLYSIS PRIVATE SYSTEM

NEOLYSIS SISTEMA PRIVATE

INSTALLATION AND MAINTENANCE MANUAL

MANUEL D’INSTALLATION ET D’ENTRETIEN

MANUAL DE INSTALACION Y MANTENIMIENTO

MANUALE DI INSTALLAZIONE E MANUTENZIONE

EINBAU-UND BETRIEBSANLEITUNG

MANUAL DE INSTRUÇOES E MANUTENÇAO

Vers.20150129

1

ENGLISH ___________________________________________________________________

IMPORTANT: The instruction manual you are holding includes essential information on the safety measures to be implemented for

installation and start-up. Therefore, the installer as well as the user must read the instructions before beginning installation and start-up.

Keep this manual for future reference.

Disposal of waste electrical and electronic domestic systems in the European Union.

All the products marked with this symbol indicates that the product shall not be mixed or disposed with your

household waste at their end of use. It is responsibility of the user to eliminate this kind of wastes depositing them in

a recycling point adapted for the selective disposal of electrical and electronic wastes. The suitable recycling and

treatment of these wastes contributes in essential way to the preservation of the Environment and the health of the

users. For further information regarding the points of collection of this type of wastes, please contact to the dealer

where you acquired the product or to your municipal authority.

For optimum performance of the Neolysis Treatment System, we recommend you to follow the instructions given below:

1. CHECK THE CONTENTS OF THE PACK:________________________________________________________

You should find the following elements inside the box:

Power supply.

UV Reactor.

pH sensors and ORP sensors (only on NEO-XX +).

Calibration Solutions pH 7.0 (green) / pH 4.0 (red) / ORP 470 mV. (only on NEO-XX PH and NEO-XX +).

Probe holder (only NEO-XXPH and NEO-XX +).

CEE22 M connector metering pump connection.

Equipment Manual.

2. GENERAL FEATURES: _______________________________________________________________________

The germicidal effects of ultraviolet light (UV) with wavelengths around 260 nm are well known for over 100 years. Its use has been increasing in

recent years as it presents a number of advantages over chemical disinfection systems, since virtually UV light no alters the physical and chemical

composition of water, it is very effective against any type of microorganism (algae , bacteria, viruses, fungi, yeasts, etc.) further minimizing the risks

of handling and dosing of potentially hazardous chemicals. Moreover, UV treatment reduces the levels of combined chlorine in water, thereby

producing significant water savings by reducing the volume and frequency of renewal of pool water.

The NEO treatment system in addition to maintaining a certain level of chlorine in pool water, ensure the sanitary quality of pool water. The NEO

treatment system will operate when the pool recirculation (pump and filter) is operational.

The NEO treatment systems are designed and manufactured with the latest technology in UV treatment of water, thus ensuring continuous

operation and minimal maintenance.

oVersions available in Polyethylene.

oElectronic ballast with integrated control.

oVersions available with integrated pH/ORP control (NEO+ models).

oOperating hour counter.

oInput for external flow switch

oHO low-pressure lamp.

oDose : 30 mJ/cm2.

oLamp lifetime: 13.000 hours (depending on the number of ignitions).

2

2.2. SAFETY WARNINGS AND RECOMMENDATIONS: _________________________________________________

Do not use this system to a different application for which it was designed.

The equipment should be assembled and handled by truly qualified people.

Current electrical and accident prevention regulations should be followed.

Under no circumstances will the manufacturer be held responsible for the assembly, installation or start-up, nor any handling or fitting of

components unless they are carried out on its premises.

Neolysis® treatment systems operate at 230 VAC / 50-60Hz. Do not attempt to alter the system to operate at a different voltage.

Check all the electrical connectors are well tightened to avoid false contacts and their consequent overheating.

Neolysis® treatment systems have a protection degree that not allows outdoor installation. They should never be installed in places susceptible to

flooding.

Prior to the installation or replacement of any system component make sure it has been previously disconnected from the mains, and there is no

water flow through it. Use only spare parts supplied by Idegis.

Never remove the lock nut of the quartz sleeve when the water is recirculating through the UV reactor as it could be expelled and causing damage.

The UV light generated by this equipment can cause serious damage if the eyes or skin are exposed directly to the lamp. Never connect the system

when the lamp is out of reactor.

Do not handle the UV lamp until completely cold.

Always handle the UV lamp with gloves, as fat and other impurities deposited on the surface may reduce its performance and durability. In case you

have to clean the lamp surface use a soft cloth soaked with alcohol.

Keep this Operation Manual.

3

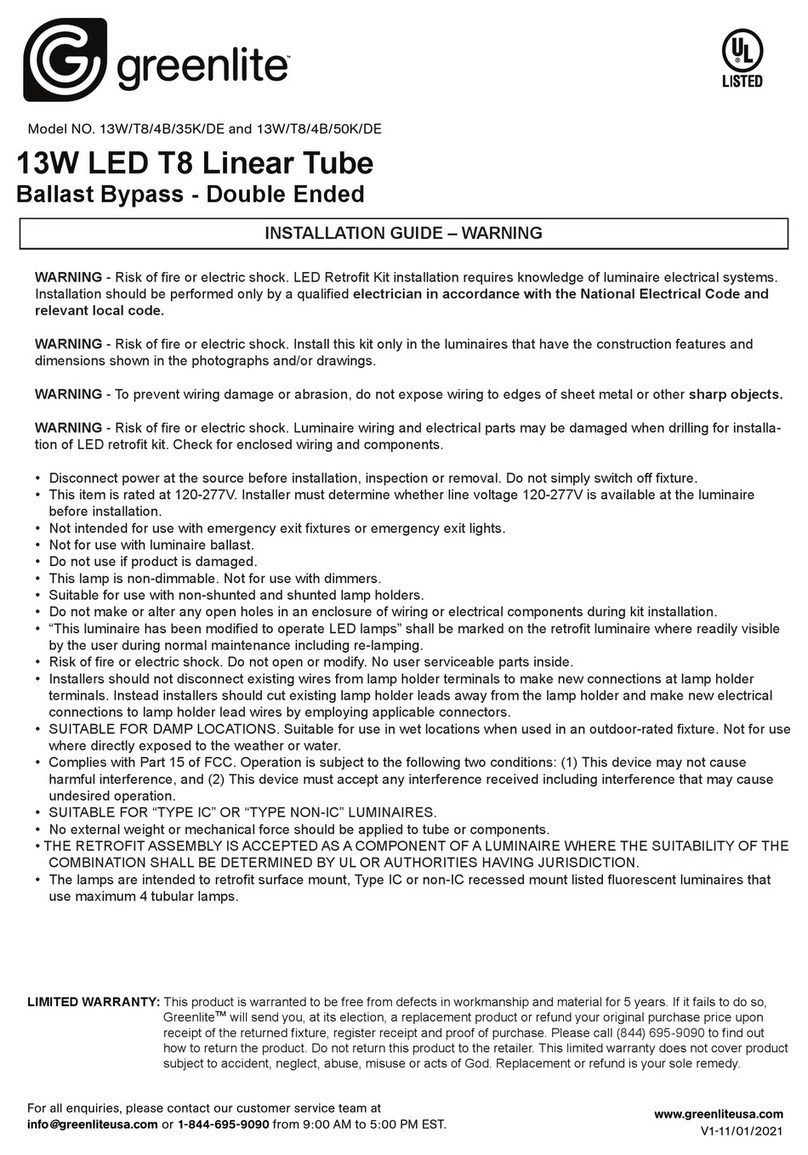

3. DATASHEET:

4

5

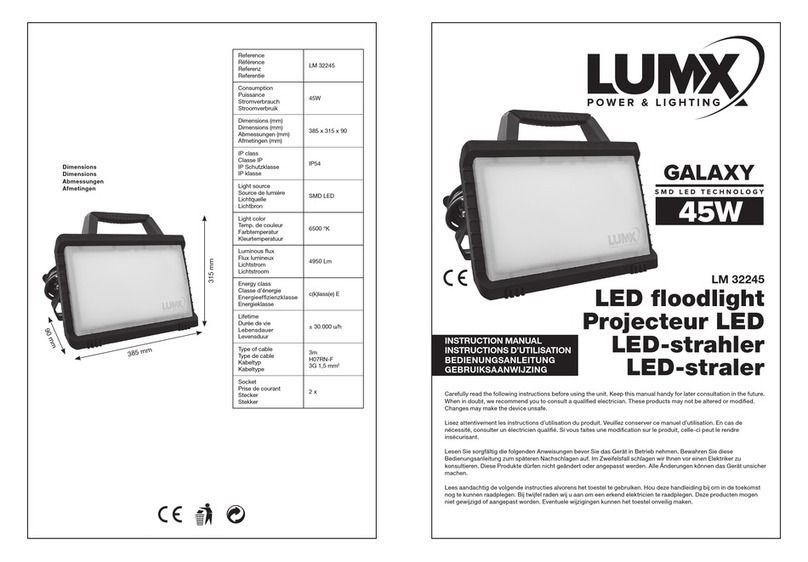

(Fig. 1)

6

4. INSTALLATION:_____________________________________________________________________________

4.1. Reactor Neolysis®

Always install the Neolysis® system VERTICALLY on a solid and rigid surface (floor) as shown in the recommended installation diagram (Fig. 1). In

order to guarantee a good state of conservation, the Neolysis® system must be installed in a dry and well ventilated place at the engine room and

never should be installed outdoors.

Beware of corrosive atmosphere formation due to pH decreasing solutions (specially, those ones based on hydrochloric acid "HCl"). Do not install

the Neolysis® system near to any stores of these chemicals. We strongly recommend the use of chemicals based on sodium bisulphate or diluted

sulphuric acid.

The reactor of the Neolysis® systems is made within which is housed the UV lamp. The Neolysis® system should always be installed behind the

filtration system, and before any other device in the installation such as heat pumps, control systems, dosage systems, salt electrolysis systems,

etc.

The installation of the UV system should allow easy access to the UV lamp by the user. The location of the Neolysis® system must have an

effective height that allows the complete removal of the UV lamp from the sleeve (about twice the total height of the unit).

It is highly recommended to install the Neolysis® system in a place of the pipe that can be easily isolated from the rest of the installation by two

valves, so that the tasks of maintenance can be carried out with no need of partial or total draining of the swimming pool. Where the system is

installed on a by-pass (recommended option), a valve to regulate the flow must be introduced.

The water inlet should be provided at the bottom of the unit thus ensuring that the reactor is always flooded, and therefore, the lamp is completely

submerged.

4.2. Electrical installation

The Neolysis® system must be connected to the electrical control box of the pool, so that the pump and the Neolysis® system are turned on (and

off) simultaneously.

Remember

The equipment should be assembled and handled by truly qualified people.

Current electrical and accident prevention regulations should be followed.

Do not alter with the power supply to operate at another voltage different than that shown on the

label on the side of the unit.

7

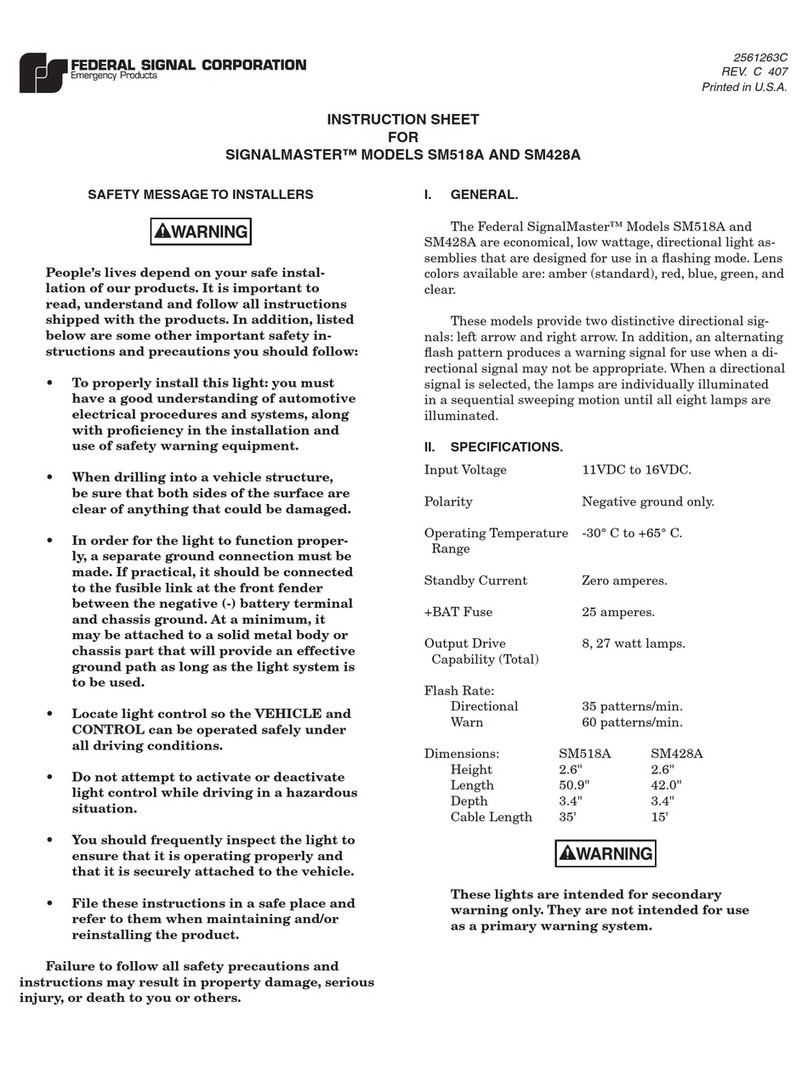

4.3. Electrical connections

9

4.4. Installation of the pH / ORP sensors (only in NEO-XX PH and NEO-XX +).

1. Insert the pH / ORP sensors into their corresponding places of the holder (Fig. 12)

2. To that purpose, loosen the connection screws and insert the sensor into the holder.

3. The sensors must be installed in the holder so that it is guaranteed that the sensors located in their ends are always submerged in the

water circulating through the pipe.

4. Always install the pH / ORP sensors vertically or with a maximum inclination of 40o(Fig. 13).

Fig. 12

Fig. 13

4.5. Control inputs of the power supply (Look on the board power supply)

Besides basic operations, the NEO Series electrolysis system has three inputs for voltage-free contacts, enabling the connection of additional

external controls. They are located on connector [CN7] of the power card (Fig. 17).

Fig. 17

The logic associated to these three inputs can be programmed during the system configuration process

[FS] OPTIONAL EXTERNAL FLOW DETECTOR CONTROL (not included with the equipment): input for potential-free contact. When the

contact connected to this input is open (external flow detector at rest), and the [FS] is configured as [FS1c], the electrolysis system switches off

due to the flow alarm. Connect the external flow detector wiring to the respective input [FS], placed in the [CN7] connector, on the unit’s power

card.

Fig. 18

10

[co] AUTOMATIC COVER CONTROL: input for potential-free contact. Depending on the status of the contact connected to it on the

automatic cover’s electric panel, this input enables you to programme a reduction of the equipment’s output current to a percentage of its

nominal value.

Fig. 19

[or] ORP / RESIDUAL CHLORINE CONTROL (unavailable in DOMOTIC-XX PLUS models): input for potential-free contact. This input can

be used to install an external controller of the electrolysis system (ORP, RESIDUAL CHLORINE, PHOTOMETER, etc.). To that purpose

connect two cables from the potential-free contact, placed in the external controller, to the corresponding input [or] placed in the system’s

control card.

Fig. 20

11

4.6. Installation of the removable control terminal (OPTIONAL)

In the Neolysis® series systems it is possible to establish a remote control of the electrolysis salt system installed in the swimming pool by means

of a control wall terminal installation. The interconnection between the power supply and the control terminal can be executed through a 6-conductor

signal cable connected to the respective connectors in power and visualization cards. The cable length will be determined by the customer’s

requirements but must be always lower than 40 meters. The terminal is 10,5 Vac auto-supplied by the communication bus, so it doesn’t need any

additional supply.

The wall terminal doesn’t require any special maintenance procedure, with the exception of these maintenance recommendations:

oUse a slightly moisten cloth to clean it.

oDon’t use aggressive cleaning products (bleach, sprays, solvents, alcohol, etc.)

The remote control is designed to be installed on a rigid wall. Its IP-65 degree allows the outdoor installation. Nevertheless, it’s recommended not to

expose the terminal to the solar rays. In order to install the remote control, follow the instructions shown below:

1. Remove the power supply cover by unscrewing the fixation screw (Fig. 11-1) and sliding upwards and outwards (Fig. 11-2). Then turn the

cover to the left (Fig. 11-3) and disconnect the communications bus (A) from power and visualization cards (Fig. 11-4).

2. Unscrewing its four fixation screws (Fig. 11-5).

3. Assemble the control terminal (Fig. 11-6).

OPTION A: installation using the original cable ref. NEO-020-XX (XX indicates the cable length in meters).

OPTION B: installation using a standard 6-conductor signal cable (each conductor must have a 0,22 mm2minimum cross section).

In both cases the maximum possible length is 40 meters. Nevertheless, using an Unshielded Twisted Pair (UTP) (Category 5e

unshielded) allows interconnection distances until 60 meters.

4. For this purpose, put the new communications cable (A) through the cable gland situated in the terminal base and connect it in either one

of the two connectors of the visualization card (CN1A, CN2A) [OPTION A], or in the connector CN-5 [OPTION B]. Combine the

visualization frontal and the terminal base using the four screws supplied.

5. Put the free end of the communications cable through the AUX 2 hole situated on the power supply base (Figs. 11-7, 11-8) and connect it

in the connector CN10A/CN11A [OPTION A] or in the connector CN-20 [OPTION B] in the power card (Fig. 11-9). Replace the cover in

the power supply (Fig. 11-7).

6. Fix the wall fixation (see section 8) in the chosen installation point and hang the control terminal on it.

12

4.7. Connection PoolStation

13

4.8. Start-up

1. Make sure the filter is clean to 100%, and that the pool and the installation does not contain copper, iron and algae.

2. The analytical condition of the water is very important to ensure that the Neolysis® system works with the highest levels of effectiveness. Before

starting the system check that the following parameters are within the recommended levels:

Iron: less than 0.3 mg./l.

Hardness: less than 120 mg./l.

Turbidity: less than 1 NTU.

Manganese: less than 0.05 mg./l.

TSS: less than 10 mg./l.

UV Transmittance: higher than 75%.

If the levels of any of these parameters exceed the recommended values is recommended to do a proper pre-treatment to correct them..

3. Balance the pool water. This allows us to obtain a more efficient treatment with a lower concentration of free chlorine in the water, and a longer

operating of the lamp in addition to a lower calcium scaling on the quartz sleeve.

a) pH must be in the range 7.2-7.6

b) Alkalinity must be in the range 60-120 ppm.

4. Check that all hydraulic connections are properly assembled and that there are no leaks in any of them.

5. Switch on the UV System (UV lamp) using the main switch on the rear side of the unit. (see 4.3):

Remember

Always connect the unit to a circuit protected by a RCD.

Never look directly at the UV lamp when it is on.

6. Let recirculate the water at least for a few minutes to evacuate air and any dirt that might be inside the UV reactor.

5. OPERATION: ______________________________________________________________________________

14

5.1. UV System

The UV system automatically powers the lamp once it is connected by the switch located on rear side of the control panel of the unit (see 4.3). After

a few seconds, once the system detects that the lamp is ignited, the led "lamp" [19] on the control panel of the unit will stay on. The main screen [18]

will show at all times the number of hours of lamp operation.

Hours of operation

By pressing "PROG" [20], the main screen [18] will show the number of "ignitions" of the lamp.

5.1.1. Alarms

Whenever the system detects a problem in the power supply circuit of the UV lamp, the alarm led [21] lights on the control panel of the unit.

LAMP

If the lamp does not start at the preset time, the main display [18] will show the message "NO RADIATION".

OPTIONAL EXTERNAL FLOW DETECTOR (FLOW SWITCH)

If during the configuration process of the system a flow detector (flow switch) is connected to the [CN6] input at the system control board

(by default, this input is provided bridged), the system automatically disconnects the lamp flashing the message "noFLO" in the system

information display [18].

The system automatically restarts once the water flow through the flow switch is restored.

Remember

Whenever the lamp is replaced you must reset the hour meter of the system. To do so, switch on the UV system with

the main switch keeping pressed the "PROG" key [20]on the control panel until you see the message "RESET" on the

main screen [18].

15

5.2. Electrolysis system

5.2. System on stand-by

The system goes into “STAND-BY” when the “”[2]key is pressed until the “0%” light blinks. When this occurs, there is no production in the

electrolysis cell (0%).

Fig. 21

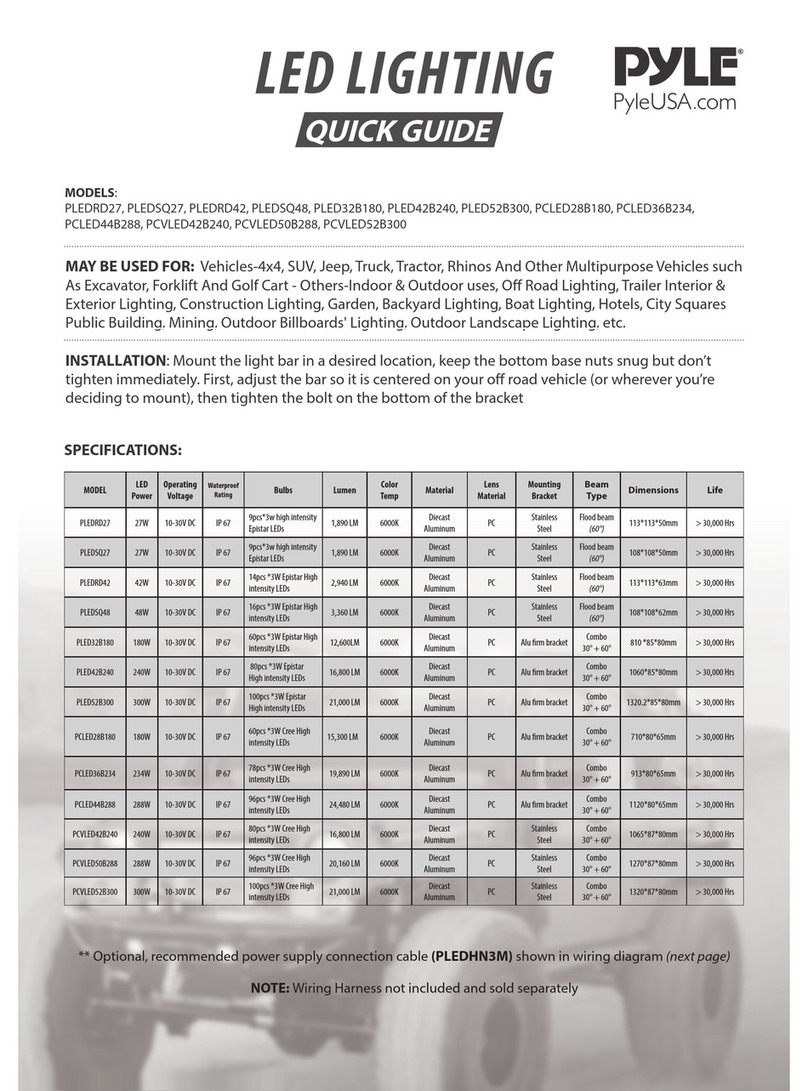

5.2.1. System configuration

The DOMOTIC Series system can be reconfigured through a menu accessed from the control panel. The system has to be set at 0% (stand-by), as

described in point 5.2, in order to access this menu. Once the system has been set at 0% (stand-by), press the “”[2] key for a few seconds until

the system information screen [17] displays “CONF”. To enable selection of each menu option, keep the “SALT TEST” [4] key pressed for

approximately 1 second. Select the desired parameter using the “”[2] / “”[2]keys and validate by pressing the “SALT TEST” [4] key for one

second again (see Fig. 23). The configuration process enables you to establish the following operative parameters:

MODEL

domotic 12

domotic 24

domotic 32

domotic 42

SOFTWARE VERSION

Shows software version (two digits)

POLARITY SWITCH

Switch every 2 hours (2)

Switch every 3 hours

Switch every 2 minutes (1)

OUTPUT LEVEL CONTROL

WHEN CLOSED COVER

(2)

System may be configured to provide an output to cell in the range 10 ... 90% of its nominal

capacity when the pool cover is closed.

COVER CONTROL INPUT ACTIVATION

Deactivated

Activated input when closed

contact (2)

Activated input when open

contact

ORP/RESIDUAL CHLORINE

CONTROL INPUT ACTIVATION

Deactivated (MANUAL) (2)

Activated electrolysis system when closed contact (AUTO) (3)

GAS DETECTOR ACTIVATION

Deactivated

Activated electrolysis system when flooded detector (2)

EXTERNAL FLOW DETECTOR

(FLOW SWITCH) ACTIVATION

Deactivated (2)

Activated electrolysis system when closed contact

(1) WARNING: only use this mode for check tasks, for short periods of time, as it could damage the electrodes. This mode is cancelled when the system is switched off.

(2) Factory defaults.

(3) Factory default value in DOM-XX PLUS systems.

Fig. 22

16

Fig. 23 System programming flow-sheet.

17

5.2.2. Production level selection

To select the desired production level, press the “”[2] / “”[2]keys until the production level light blinks. The system information screen [17] will

display the value of the production scale light [1]. The system will set its production to the desired level after a few seconds.

Fig. 24

In normal conditions, the production value [1]should be the same as the programmed value [17]. However, if the salt level in the water is outside the

permitted range (“HIGH SALT” or “LOW SALT” [9] alarms on), or there is a problem in the electrolysis cell (“ELECTRODES” [8] alarm on), the

production value [1]could be lower than the programmed and displayed value [17].

WINTER Mode:during periods of low water temperature select a production level [10] in the 50-60% range.

5.2.3. Salinity test

The DOMOTIC Series systems have an integrated system to detect the salinity level of pool water. To run the test, press the “SALT TEST” [4] key.

During the test, the production light will range from 20%-80% of the salinity scale [10], alternately displaying “SALT” and “TEST” on the system

information screen [17]. Once the test is completed, the light will blink for a few seconds on the scale [1] on the detected salinity value (see Fig. 25):

low, normal & high. The equipment will return to normal operating mode after a few seconds.

Fig. 25

The system might show lower than actual salt levels if the temperature falls beneath 20C (68 °F).

18

5.2.4 Integrated pH controller (modelos NEO-XX PH y NEO-XX +)

The integrated pH / ORP controller is supplied with a default factory calibration and programmed with the following parameters:

SETPOINT pH=”7.2” / ORP=”700 mV”

IMPORTANT: In order to have a correct regulation of the pH value, the Total Alkalinity of the pool water must be maintained in the range 60–120

ppm CaCO3. Use a pool water test kit to check the Total Alkalinity and adjust manually if necessary.

CONNECTION OF THE PH / ORP SENSORS (models NEO-XX PH and NEO-XX +)

Connect the pH / ORP sensor provided with the unit to the corresponding BNC connectors located in the unit’s base (Fig. 26).

CONNECTION OF THE DOSAGE PUMP

The DOMOTIC Series systems (NEO-XXPH and NEO-XX +) have a connector on their base for connecting a dosage pump to control the pH of the

water in the pool. The dosage pump can be connected through the CEE22 connector supplied for that purpose with the equipment (Fig. 26).

Fig. 26

5.2.5 pH Setpoint programing

Keep the “SET” [12] key pressed until the screen [16] displays the desired pH value within the 7.0 –7.8 range. Release after selection.

Fig. 27

19

5.2.6. ORP Setpoint prorgaming (only in models NEO-XX +)

Keep the “SET” [12]key pressed until the light displays the desired ORP value within the 600 –850 mV range. Release after selection.

Fig. 27b

5.2.7 Safety stop configuration of the dosage pump (PUMP-STOP FUNCTION)

The integrated pH controller has a security system (PUMP-STOP FUNCTION) acting on the dosage pump which allows to avoid the following

situations:

Damages caused by the dry operation of pump (depleted pH-minus product).

Over-dosage of pH-minus product (damaged or aged sensor).

PH regulation problems due to high alkalinity in the water (newly filled pool, high carbonate levels).

When the PUMP-STOP FUNCTION is enabled (factory default), the system stops the dosage pump after a programmed time without having

reached the pH setpoint.

Fig. 27c.

This manual suits for next models

6

Table of contents