NeoRe TG TX Series User manual

User manual

NeoRé TG TX

Heat pump air-water

NeoRé 5TG TX

NeoRé 8TG TX

NeoRé 11TG TX

NeoRé 14TG TX

NeoRé 8TG TX HP

NeoRé 11TG TX HP

NeoRé 14TG TX HP

NeoRé 16TG TX HP

All rights and changes reserved. Last update 03.07.2020 - 0.1.0

3Quick start

UThe quick start guide can only be used if the heat pump installation has been completed, properly started and tested

by the installation company.

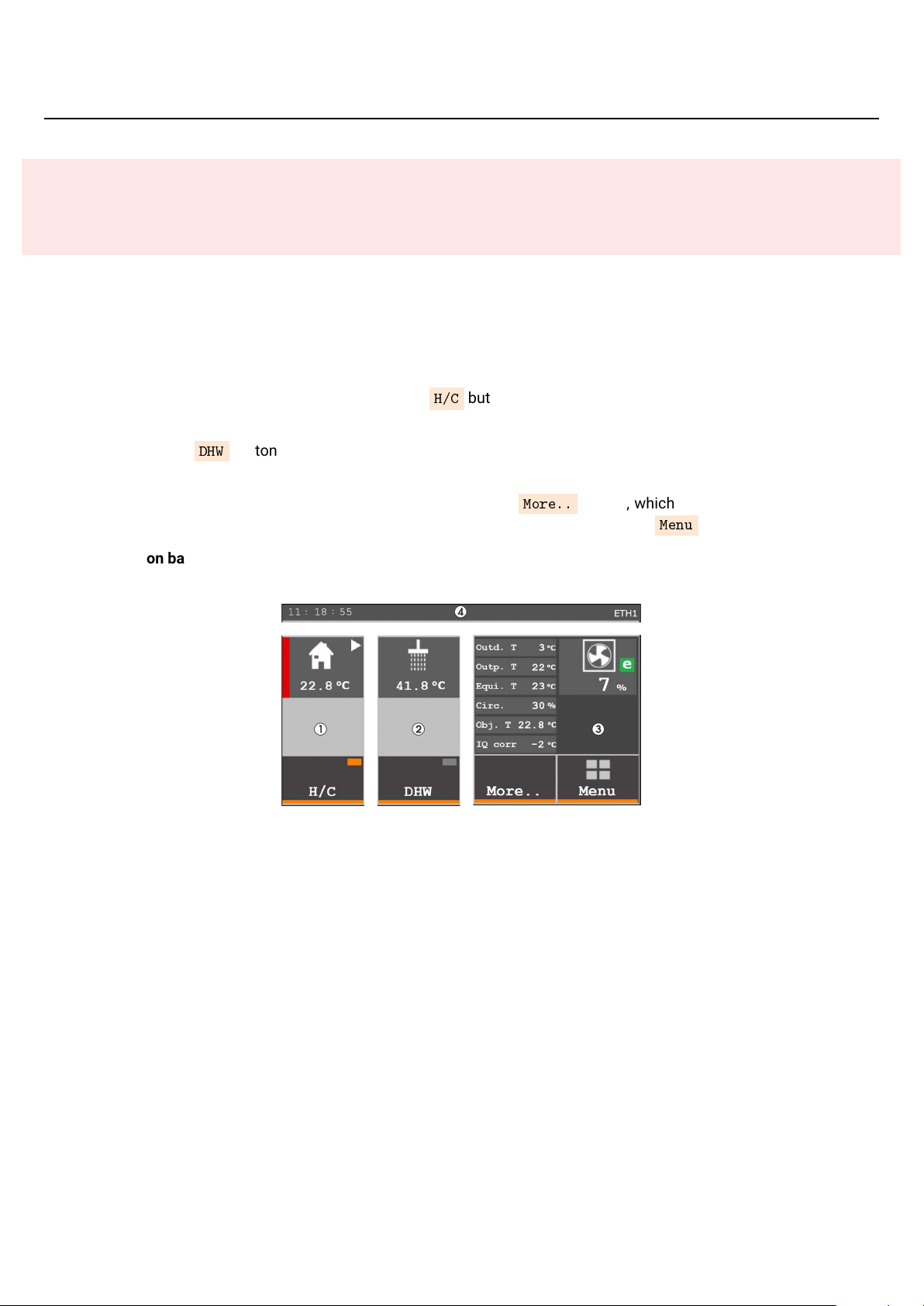

Division and description of the basic control screen

1. Object section - Displays heating / cooling mode, building temperature, circulating pump operation and building states.

To turn the heating and cooling on and off, use the

H/C

button.

2. DHW section - Displays the DHW temperature, circulating pump operation and heating states. To turn on the DHW

heating, use the

DHW

button.

3. Overview section - Displays values and parameters of selected temperatures, operating states and the outdoor unit

power. You can also switch to an extended overview using the

More..

button, which contains more values, a fault

history, measurement of supplied heat and more. To return to the main menu, press

Menu

.

4. Information bar section - This part displays the time and state of the device. On the right side, you can see if the heat

pump is connected to an Ethernet network (ETH1) and the Neota Route remote access service (CLOUD)

Figure 1: Basic division of sections (H/C on, DHW off)

Basic operation of the controller

To operate the heat pump, use the graphical user interface on the touch panel. The main menu will be displayed immedi-

ately after switching on the device or after pressing the Menu button. A complete description of the functions and operation

is given in Chapter 4 Description of the user interface (page 15).

Overview is used for basic control – activation of heating, DHW heating, overview of temperatures and energies, list of

states and errors.

Object is used for advanced setting of the requirements for building heating or cooling.

DHW is used for advanced setting of the requirements for DHW heating, its circulation and disinfection.

Graphs displays the course of important temperatures

Settings is used for general setting of the device behaviour and remote access.

More is used to set additional systems such as a secondary source or pool circuit.

2

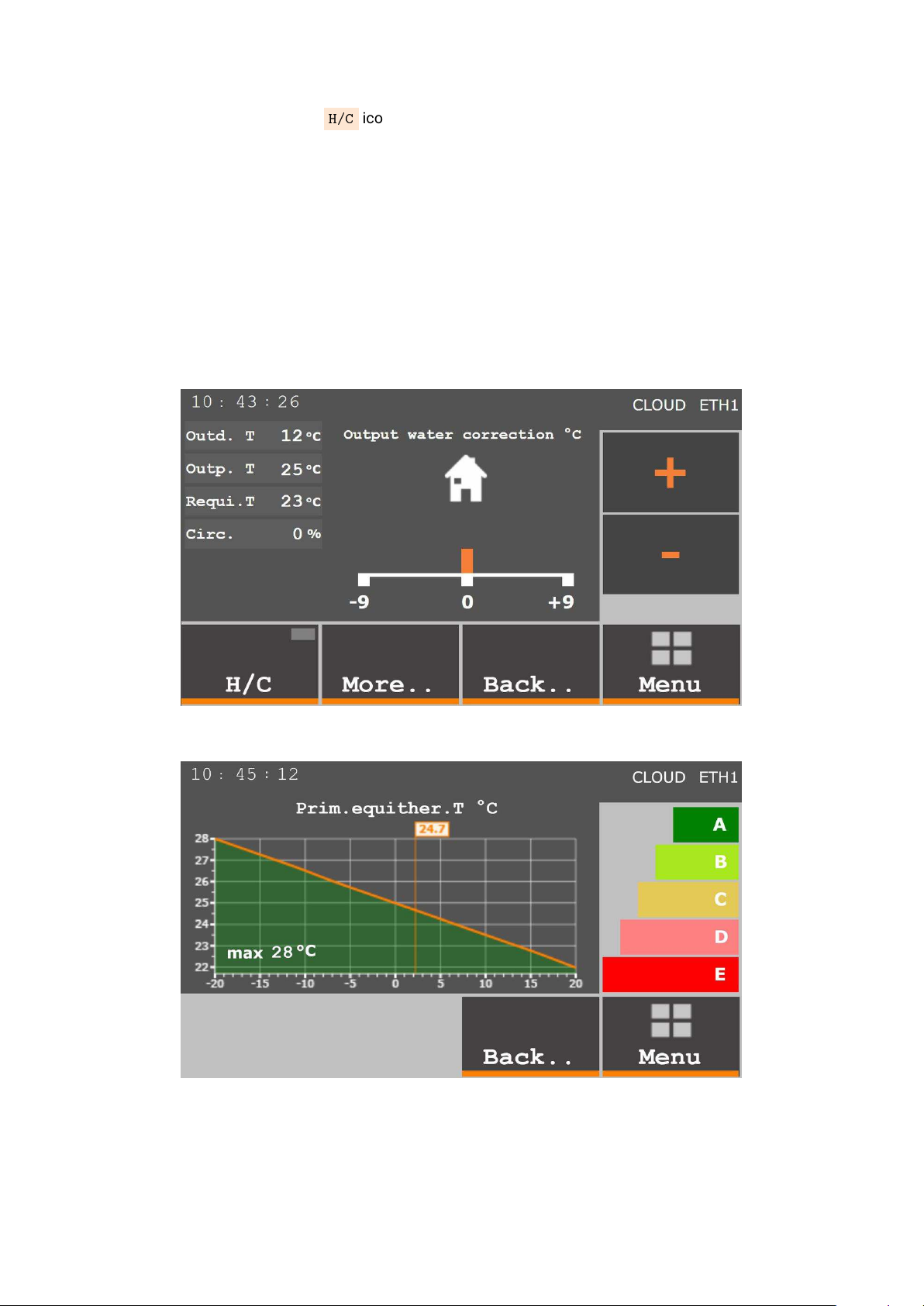

Winter operation

On the Overview screen, switch on the

H/C

icon (the rectangle on the button is orange).

You can set the equithermal curve in a simplified mode after pressing the house icon in the first column. It is the SIMPLE

NEO function.

H/C is used to switch heating/cooling on or off like on the previous screen.

More.. is used for initial selection of the equithermal curve according to the energy class of the building. Just press the

coloured label in the right column and the weather compensation curve will automatically readjust (Fig. 3)

Back.. is used to return to the Overview

Menu is used to return to the default screen

Plus Minus is used to increase/decrease the desired temperature of heating/cooling water by a maximum of 9 °C from the

default temperature

Figure 2: Basic screen SIMPLE NEO for equithermal curve correction

Figure 3: Initial selection of the equithermal curve according to the energy class of the building

3

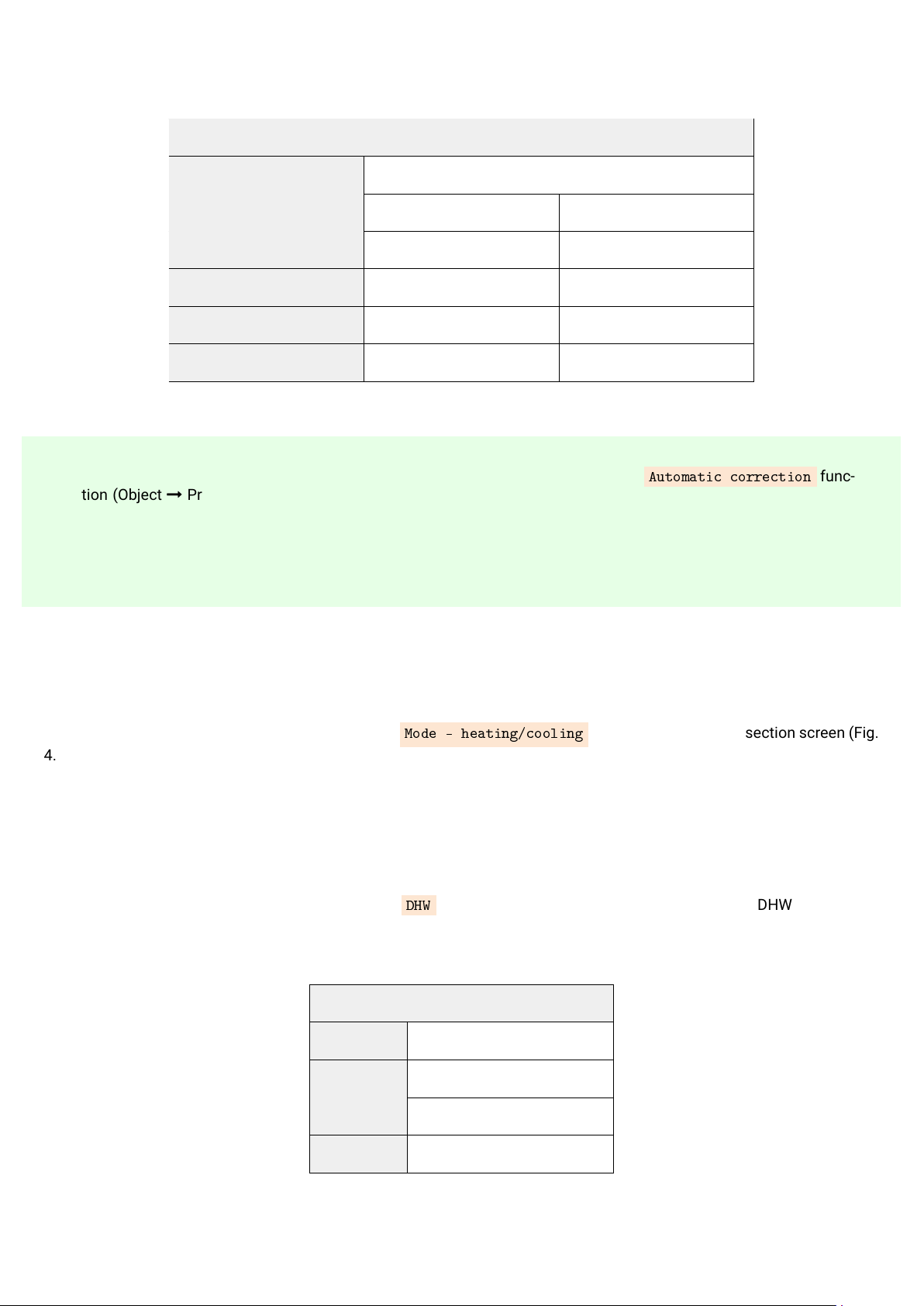

For experts: More accurate but complex setting of the equithermal curve according to Table 1 on page 4 can be made in

the Object settings. Then use automatic equithermal curve correction to adjust the heating water temperature according to

your needs.

Equithermal setting

Heating water temperature for:

Outdoor temperature

Floor or ceiling heating Radiators

19°C 22°C 25°C

6°C 28°C 40°C

−7°C 33°C 45°C

−20°C 38°C 50°C

Table 1: Equithermal curve setting

If it is too hot or too cold in the heated area, adjust the equithermal curve using the

Automatic correction

func-

tion (Object ¸Primary weather comp. curve). For example, if the room temperature is 2°C higher than desired,

enter a value of equithermal curve automatic correction of −3°C. If, on the other hand, the room temperature is

1°C lower than desired, enter a correction of 2°C. The minimum correction value is ±3°C for one entry. Remember

that the change requires some time to take effect. In the case of floor heating, this time during which the room

temperature changes is approximately 3–6 hours. In the case of radiators, this time is shorter.

Summer operation

To switch to the cooling mode in summer, use the

Mode – heating/cooling

selector on the Object section screen (Fig.

4.8 page 22). In the cooling mode, the selector is blue and, on the basic Overview screen, there is a blue stripe next to the

house icon.

DHW heating

On the overview screen (section Overview), set the

DHW

icon to ON. In the DHW settings, set the desired DHW temperature

and delay of electric heating according to Table 2 on page 4. DHW heating operates independently in both modes, heating

as well as cooling.

Setting the delay of DHW electric heating

Vessel size Delay time

200 l 40 min

300 l 60 min

400 l 90 min

Table 2: Setting the delay of DHW electric heating

4

Contents

1 Safety instructions 7

1.1 Safetywarning...................................................... 7

1.2 Safetyprecautions.................................................... 7

1.3 Legalconditions..................................................... 8

1.4 Storageandtransportconditions ........................................... 9

2 Product specification 10

2.1 Productdesignation................................................... 10

2.2 Connectiontothemains ................................................ 10

2.3 Packagecontents .................................................... 10

2.4 Indoorunitdescription ................................................. 10

2.5 Outdoorunitdescription ................................................ 11

2.6 Tableoftechnicalparameters ............................................. 12

3 Principle of operation and correct use 13

3.1 Principleofheatpumpoperation............................................ 13

3.2 Hotwaterheatingsystems............................................... 13

3.2.1 Low-temperature heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Medium-temperature heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Coolingsystem...................................................... 14

3.4 Correct principles of using a heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Description of the user interface 15

4.1 Defaultscreen ...................................................... 15

4.2 Overview ......................................................... 16

4.2.1 Meaning of graphic symbols and text abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2 Simplified setting of the weather compensation curve – SIMPLE NEO . . . . . . . . . . . . . . . . . . 21

4.3 Object........................................................... 22

4.4 DHW............................................................ 26

4.5 Graphs .......................................................... 28

4.6 Settings.......................................................... 29

4.7 More............................................................ 32

4.8 Webserveroperation .................................................. 34

4.9 NeotaRoute(cloud)................................................... 35

4.10Localnetworkconnection................................................ 35

5 Commissioning 36

5.1 Commissioning of the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2 Activation ........................................................ 36

6 Shutdown 37

6.1 Short-termshutdown .................................................. 37

6.2 Long-termshutdown .................................................. 37

7 Faults and status messages 38

7.1 Errorcodestructure................................................... 38

7.2 Overview of faults and status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 Faultsandtroubleshooting ............................................... 39

7.4 Statusmessages .................................................... 41

7.5 Protectivefunctions................................................... 42

7.6 Serviceorganization................................................... 45

8 Maintenance of the device and components 46

8.1 Maintenanceoftheoutdoorunit............................................ 46

8.2 Maintenanceoftheindoorunit............................................. 47

8.3 MaintenanceoftheDHWtank ............................................. 47

8.3.1 Tankdesludging................................................. 47

8.3.2 Heatermediumdisinfection .......................................... 47

8.3.3 Protection against galvanic and electrolytic corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5

8.3.4 Magnesiumanoderod ............................................. 48

8.3.5 Electronic anti-corrosion system – ACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.4 Maintenanceplan .................................................... 49

9 Disposal of the device 50

9.1 Disposalofthepackaging ............................................... 50

9.2 Disposaloftheindoorunit ............................................... 50

9.3 Disposaloftheoutdoorunit .............................................. 50

10 Manufacturer contact 51

10.1Documentsfordownload................................................ 51

10.2Onlinemanuals ..................................................... 51

6

1. Safety instructions

1.1 Safety warning

URead the manual carefully before installing, putting into operation or maintaining the device. Adherence to the

described procedures for the installation and operation of the device is important for long-term and trouble-free

operation. Faults and defects caused by non-compliance with the safety instructions, installation procedures and

operating rules will not be taken into account, not even damage or destruction of other related equipment. The

device may only be installed by persons with appropriate qualifications in the field of heating, cooling and electrical

engineering.

In addition, observe all applicable safety regulations related to the actual installation and operation of the NeoRé

heat pump.

The device may only be operated by a person familiar with this manual and older than 15 years. Persons with limited

physical, sensory and mental capabilities or with lack of experience and/or knowledge may operate the device only

if they are supervised or trained in the safe use of the device by the person responsible for their safety and if they

understand the dangers involved. Children must not play with the device or clean or maintain it.

UThe R32 refrigerant is a class A2L flammable gas.

To install the indoor unit, observe the minimum floor area requirement. More in Installation

Manual, Table Minimum floor area when using A2L gas in Chapter Refrigerant piping.

UThe heat pump must be installed in a room without continuous open flame operation (e.g. running gas appliance)

and ignition sources (e.g. operating electric heater).

1.2 Safety precautions

UThe heat pump is an electric device working with a voltage of 400 V! The device may only be installed and serviced

by an authorized electrician. In case of fire, do not extinguish with water or foam. Use only a powder or snow

extinguisher!

In the event of a refrigerant leak, turn off all circuit breakers located on the indoor unit and contact the service

organization indicated on the plate on the indoor unit. The R32 refrigerant is slightly flammable, non-toxic. Under

no circumstances should you try to stop the refrigerant leak yourself. It reaches very low temperatures (up to

−50°C). In the event of a leak in the interior of a building, ventilate the room. In case of inhalation of refrigerant

vapours or fire fumes, take the affected person to a ventilated place and call for medical help: phone number 112.

In case of contact with liquid refrigerant, dry the area immediately and warm it, for example with a blanket. In case

of contact with eyes, rinse immediately with plenty of lukewarm water and call for medical help: phone number

112.

7

UIn case of fire, disconnect the device from the mains and extinguish with a snow or powder fire extinguisher.

In the event of a heating water leak, turn off all circuit breakers located on the indoor unit and contact your service

organization.

When handling the refrigerant piping (cleaning, maintenance), use personal protective equipment (gloves, goggles,

protective clothing, ...).

Do not put your hands or other objects in the fan area of the outdoor unit, there is a risk of serious injury!.

Do not expose yourself to the airflow from the outdoor unit for a long time. There is a risk of severe hypothermia!

U• Perform the installation only in accordance with the installation manual, which is available at

https://www.neota.cz/en/downloads/.

• Connect the outdoor and indoor unit (refrigerant, electric) only with the material specified in the installation

manual.

• Installation work on the refrigerant and electric circuit must be performed by an appropriately authorized

person.

• Do not use flexible inlets and piping to connect the units.

• Do not operate a device that is not completely installed.

• Do not use refrigerants whose quality and purity you are not sure about. Observe the safety precautions on

the refrigerant packaging.

• Do not add refrigerant to increase performance.

• Always use a vacuum pump before filling the refrigerant.

• Pay attention to work safety and personal protective equipment during installation.

• The device must be installed by a specialist company authorized by the manufacturer. Do not attempt to

install the device yourself. You can destroy the device or cause injury.

• Do not mix two types of refrigerant. Use only the refrigerant specified on the label.

1.3 Legal conditions

Legal conditions that must be observed when handling the device.

ČSN EN 378-4+A1:2020 Art. 6.5.x

All parts of refrigeration equipment, e.g. refrigerant, oil, heat-transfer medium, filter, dehydrator, insulating material,

compressor and the entire refrigerant circuit equipment must be recovered, reused and/or properly disposed of in

connection with maintenance, repair and decommissioning. Maintenance and disposal must be performed by a

person professionally qualified for the disposal of refrigerants and oils.

ČSN EN 378-4+A1:2020 Art. 6.2.x

Used refrigerant that is not intended for reuse must be treated as waste for safe disposal. Prevent emissions to

the environment. Any handling of the refrigerant must be performed by a person professionally qualified for the

disposal of refrigerants and oils.

ČSN EN 378-4+A1:2020 Art. 6.2.x

Used oil recovered from refrigeration equipment that cannot be regenerated must be stored in a suitable separate

container and must be treated as waste for safe disposal. Oil must be drained by a qualified person.

ČSN EN 378-4+A1:2020 Art. 6.6

All activities related to recovery, reuse of refrigerant and refrigerant source must be recorded in the refrigeration

equipment’s operating log (see En 378-4 Art. 4.2). If required, it must be provided by the refrigerant supplier or

service company.

8

1.4 Storage and transport conditions

Indoor unit NeoRé IUTX16-20

Environment dust-free, non-aggressive

Temperature range -10 to 45°C

Relative humidity max 70%

Outdoor unit OU GMx or OU GPx

Environment dust-free, non-aggressive

Temperature range -10 to 45°C

Relative humidity max 90%

The outdoor unit must be stored and transported in a vertical position in the original packaging and properly se-

cured. If necessary, protect fragile parts, especially the evaporator, from damage. Overturning or leaking refrigerant

may lead to injury.

During transport, all components of the device must be secured with straps or other technical means to prevent over-

turning and injury.

If damage or refrigerant leakage occur during transport, do not attempt to stop the leak improperly. Evaporation of the

refrigerant significantly cools the affected areas and may cause injury in contact with the skin.

UThe outdoor unit must be stored and transported in a vertical position in the original packaging. If necessary, protect

fragile parts, especially the evaporator, from damage.

9

2. Product specification

2.1 Product designation

UThe NeoRé series heat pump is designed for heating family houses or smaller industrial buildings.

The product is intended for connection to a low-temperature heating system. The ideal heating system is mainly

floor, wall and ceiling heating. Connection of conventional wall-mounted radiators is possible, but it is limited by

the maximum heating water outlet temperature 55°C. (60°C for the HP version) and reduced efficiency. The heat

pump can also be used for cooling. For cooling, the outlet temperature is limited by the condensation temperature.

The heat pump is not suitable for cooling with a cooling water temperature below the condensation temperature,

e.g. fan coils. Condensation occurs on the internal equipment of the indoor unit and leads to its damage. A

suitable cooling system is cooling ceilings where condensation does not occur.

Read the manual carefully before installing, putting into operation or maintaining the device. Adherence to the

described procedures for the installation and operation of the device is important for long-term and trouble-free

operation. Faults and defects caused by non-compliance with the safety instructions, installation procedures and

operating rules will not be taken into account, not even damage or destruction of other related equipment.

2.2 Connection to the mains

UThe NeoRé series heat pump is intended for discounted tariffs of electricity distributors, either a tariff for heat

pumps or tariff for direct heating.

Before connecting the system to the mains, the relevant distribution plant must issue a permit.

2.3 Package contents

As standard, the NeoRé heat pump is supplied on a wooden pallet, to which it is attached with screws. A protective frame

provides greater safety during transport. Each indoor unit package contains the following components:

• heat pump NeoRé, indoor unit IUTX16-20, outdoor unit OI GMx or OU GPx

• user manual

• outdoor temperature sensor

• building temperature sensor (optional accessory)

2.4 Indoor unit description

The indoor unit is designed for stationary placement on a floor. Its position in the room must be chosen so that the

control and protection elements are accessible for servicing. See the figure below the text.

10

Its heart is a high-quality refrigerant / water exchanger that transfers heat to the heating system. An essential part is

the sophisticated Teco controller and its software, which not only controls the operation of the heat pump itself, but also

takes care of the thermal comfort inside your building. It provides cascade control of the heat pump together with a bivalent

source, which switches on in two stages when the heat pump’s power is insufficient. The NeoRé heat pump can also work

with other heat sources and multiple heating circuits. All this is secured by means of safety, measuring and control elements.

For comfortable and convenient operation, the NeoRé heat pump can also be connected via a web browser to a computer,

mobile phone or tablet, even remotely thanks to the Neota Route service.

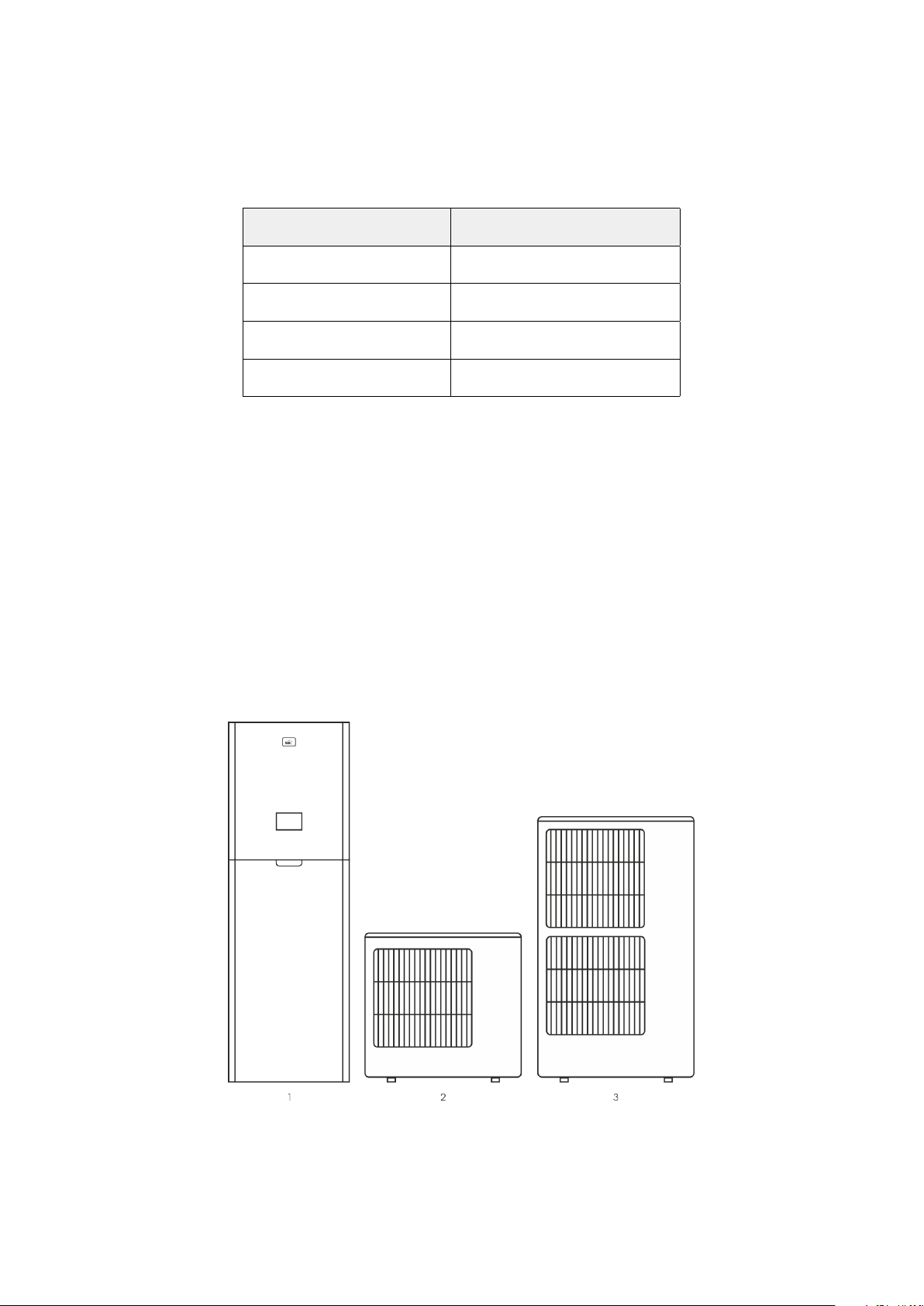

NeoRé TX COMFORT series NeoRé TX HIGH POWER series

NeoRé 5 TG TX NeoRé 8 TG TX HP

NeoRé 8 TG TX NeoRé 11 TG TX HP

NeoRé 11 TG TX NeoRé 14 TG TX HP

NeoRé 14 TG TX NeoRé 16 TG TX HP

Table 2.1: NeoRé TX COMFORT and NeoRé TX HIGH POWER series

COMFORT - outlet water temperature up to 55°C and outdoor temperature operating range −15° to 24°C

HIGH POWER (HP) - outlet water temperature up to 60°C and outdoor temperature operating range −27° to 24°C

2.5 Outdoor unit description

The outdoor unit is made of steel plates with high-quality anti-corrosion treatment by electrostatic powder coating. The

heart of the unit is a compressor unit with a DC inverter compressor, which is a progressive novelty in the area of heat pumps

and a guarantee of reliability and long life. It also contains an evaporator with anti-corrosion treatment. Variable-speed fans

control the air flow through the evaporator and ensure low noise levels. The outdoor unit also features an electronically

controlled expansion valve, control electronics and measuring elements.

Figure 2.1: 1 - Indoor unit; 2 - Single fan outdoor unit; 3 - Double fan outdoor unit

11

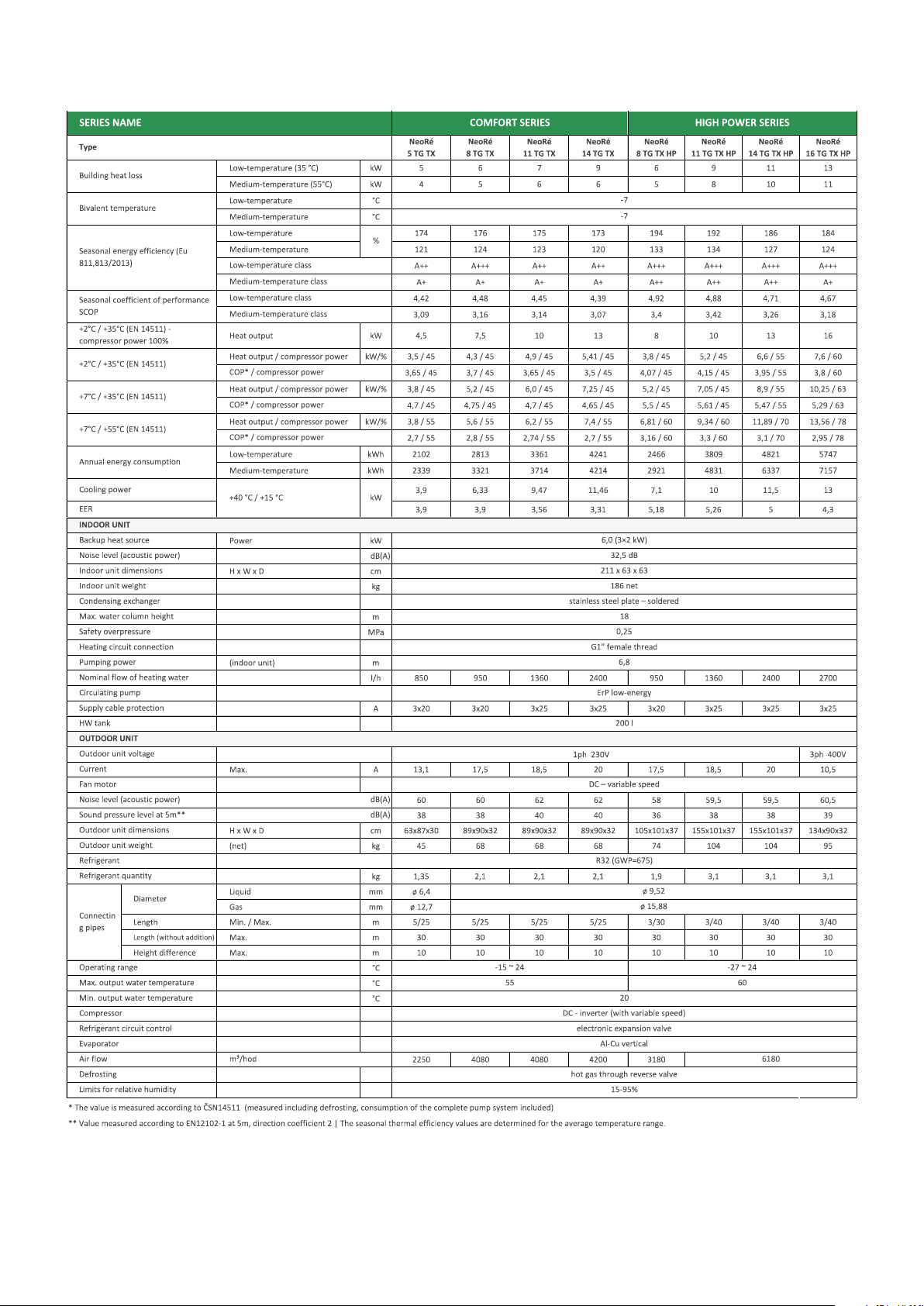

2.6 Table of technical parameters

Figure 2.2: Table of technical parameters

12

3. Principle of operation and correct use

3.1 Principle of heat pump operation

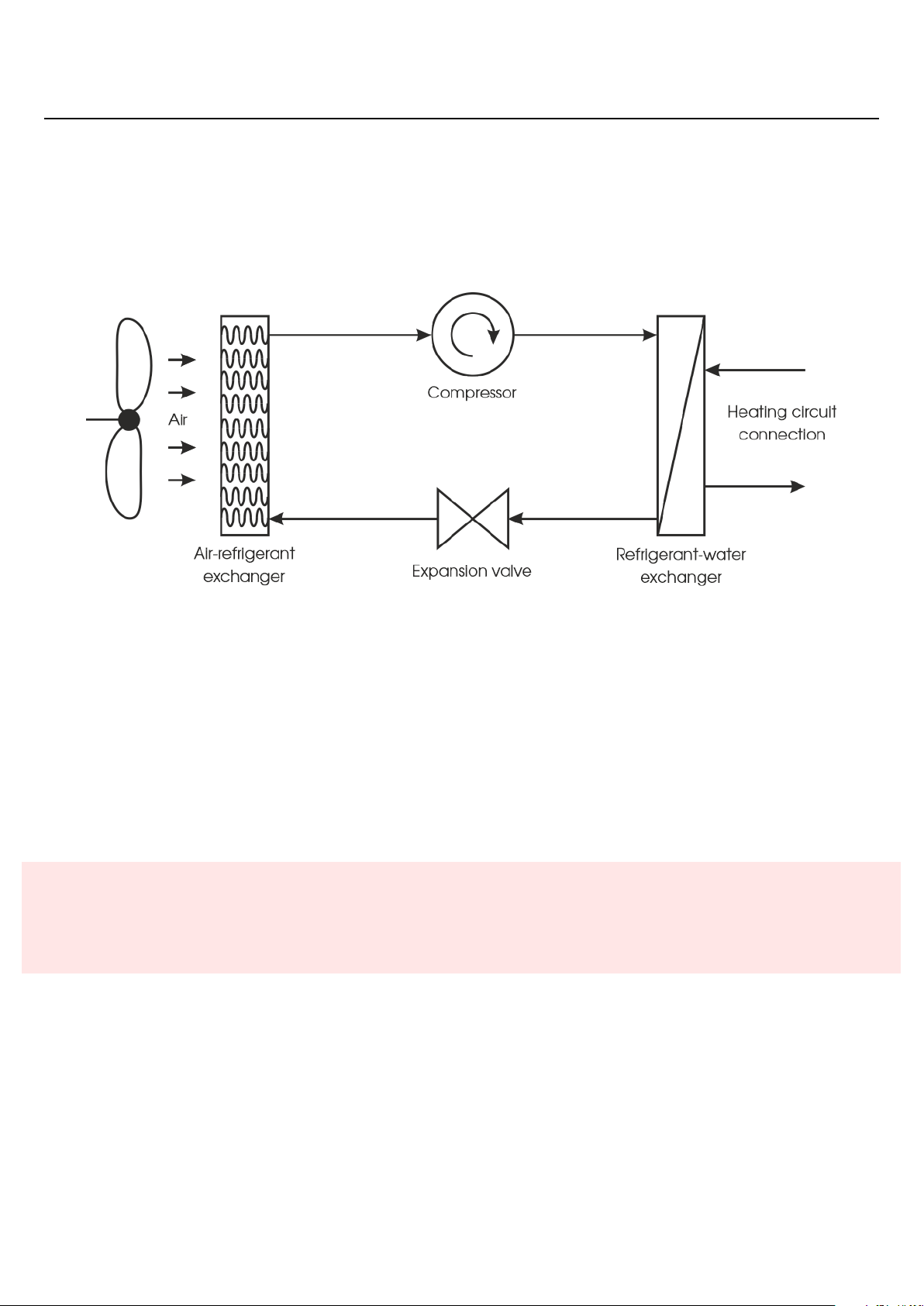

The basic prerequisite for the operation of a heat pump is a heat transfer medium with suitable properties for changing

the state at a given pressure and temperature. All these basic components are indicated in the figure below – Schematic

diagram of the heat pump operation.

Figure 3.1: Principle of heat pump operation

In the first phase The refrigerant enters the air-refrigerant heat exchanger and changes its state to gas. As a result,

the refrigerant receives energy from the air. The refrigerant continues through the piping to the compressor, where it is

compressed. This converts it to a higher temperature level. The last phase is the transfer of the obtained energy to the

heating circuit in the refrigerant-water exchanger. Here, the gaseous refrigerant condenses and transfers energy to the

heating medium. The liquid refrigerant then passes through the expansion valve again and is again evaporated in the air-

refrigerant exchanger.

3.2 Hot water heating systems

UThis section contains general facts of recommendations in the field of heating systems. It cannot be used to design

a heating system. The system must always be designed by an experienced professional. Likewise, the choice of

the heat pump power and type must be made on the basis of a calculation of building’s heat losses by an expert.

The NeoRé series heat pump is designed for hot water heating systems. For this reason, some of them are described in

the following paragraphs. The characteristics of individual heating systems differ, and therefore must be taken into account

when choosing a heat pump, whether it is a new or existing heating system. In general, however, we can say that in a heating

system we try to maximize the surface area of the heater and thus reduce the temperature of the heating water required to

transfer the required amount of energy.

13

3.2.1 Low-temperature heating system

Examples of a low-temperature heating system:

• floor heating

• ceiling heating/cooling

• wall heating

Large-area radiant systems are best suited for use with a heat pump. The heat pump is maximally efficient with these

systems and its service life is longer. They are also the most comfortable type of heating for habitable rooms.

With these systems, it is possible to induce natural thermal comfort and avoid heat build-up and large thermal differences

upwards, as is the case with traditional convective heating systems.

3.2.2 Medium-temperature heating system

Examples of a medium-temperature heating system:

• radiators

• fan coils

This heating method is less advantageous when used with a heat pump, but still usable. The small radiant surface of the

radiator plates and thus the higher temperature requirement of the heating medium reduces the efficiency of the heat pump.

The maximum heating water temperature for radiators is 55°C (60°C for HP). Using the maximum temperatures continuously

can reduce the service life of the product.

3.3 Cooling system

The heat pump can also be used for cooling. For cooling, the outlet temperature is limited by the condensation tem-

perature in the given environment. The heat pump is not suitable for cooling with a cooling water temperature below the

condensation temperature, e.g. fan coils. Condensation occurs on the internal equipment of the indoor unit and leads to its

damage. A suitable cooling system is cooling ceilings where condensation does not occur.

3.4 Correct principles of using a heat pump

A heat pump is a low-temperature heat source that pumps thermal energy between two temperature levels. Based on

physical principles, the more distant these levels are, the more energy must be put into the process. For higher efficiency of

the heat pump, these levels have to be brought as close as possible.

In practice, this means that we have to keep the heating water temperature as low as possible and the outdoor air temper-

ature as high as possible. The outdoor air temperature can only be affected by the correct placement of the outdoor unit so

that it has a sufficient air supply (pay attention to installation in enclosed yards, valleys, etc.). The heating water temperature

can be affected by a correct design and use of the heating system.

It is more advantageous to use the heat pump to heat continuously to a lower heating water temperature than

spasmodically to a higher temperature, where the heat pump is less efficient.

14

4. Description of the user interface

UBefore making changes to the device settings, carefully read what each function means and what the settings

affect. Improper adjustment can result in uncomfortable and uneconomical operation, which is associated with

unnecessarily higher equipment wear and higher operating costs.

4.1 Default screen

For the control, activation, deactivation and setting of the heat pump, use the touch screen on the front of the product

cover. The default screen (Fig. 4.1 Page 15) offers six icons, each for controlling or setting one of the heat pump functions.

Overview is used for basic control of the device, activation of heating, DHW heating, overview of temperatures and energies,

list of status and error messages.

Object is used for advanced setting of the requirements for building heating or cooling.

DHW is used for advanced setting of the requirements for DHW heating, its circulation and disinfection.

Graphs displays the course of important temperatures

Settings is used for general setting of the device behaviour and remote access.

More is used to set additional systems such as a secondary source or pool circuit.

Figure 4.1: Default screen of the touch screen

Sections

DHW

and

More..

are displayed only if the appropriate temperature sensors are connected. I.e. a DHW

temperature sensor for the

DHW

section and at least one of the storage tank or pool temperature sensors for the

More..

section.

15

Elements on the display that can be used to change values, turn functions on and off or link to another page have

an orange background. Pressing the element displays the linked page or the panel for editing the variable, which

dynamically changes according to its type.

4.2 Overview

The overview screen (Fig. 4.2 page 16) is divided into four columns.

In the first column from the left, there is a section at the top in which the heating mode is displayed (heating – red,

cooling – blue). Furthermore, it displays the current temperature of heating water, the operation of the circulating pump

using a triangular pictogram and whether the silent mode is active (speaker icon). In addition, the letter hmay appear here

if the cooling water temperature is automatically limited due to approaching the dew point.

At the bottom, there is the

H/C

control button that activates/deactivates the device. If the rectangle in the upper right is

orange, the device is operating, if the rectangle is grey, the function is switched off.

The second column shows the current temperature of domestic hot water (DHW) and, at the bottom, a button for switch-

ing DHW heating on and off. It also contains a signalling rectangle similar to the H/C button.

The third column shows a list of the most important temperatures and power of the circulating pump. Pressing the

More..

button displays the next screen containing a more detailed list of current temperatures and other device status

values.

The upper part of the fourth column shows whether heating uses the heat pump, bivalent or secondary source, percent-

age of the current heat pump power and other details about the current operating mode. The

Menu

button at the bottom

can be used to return to the default screen.

The time is displayed on the left side of the top bar. The right part may display two text abbreviations. If

CLOUD

is

displayed, the Neota Route remote management cloud service is activated. If

ETH1

is displayed, the device is connected to

an Ethernet network and can be controlled within the local network using a computer, smartphone or tablet.

Figure 4.2: Overview section

The

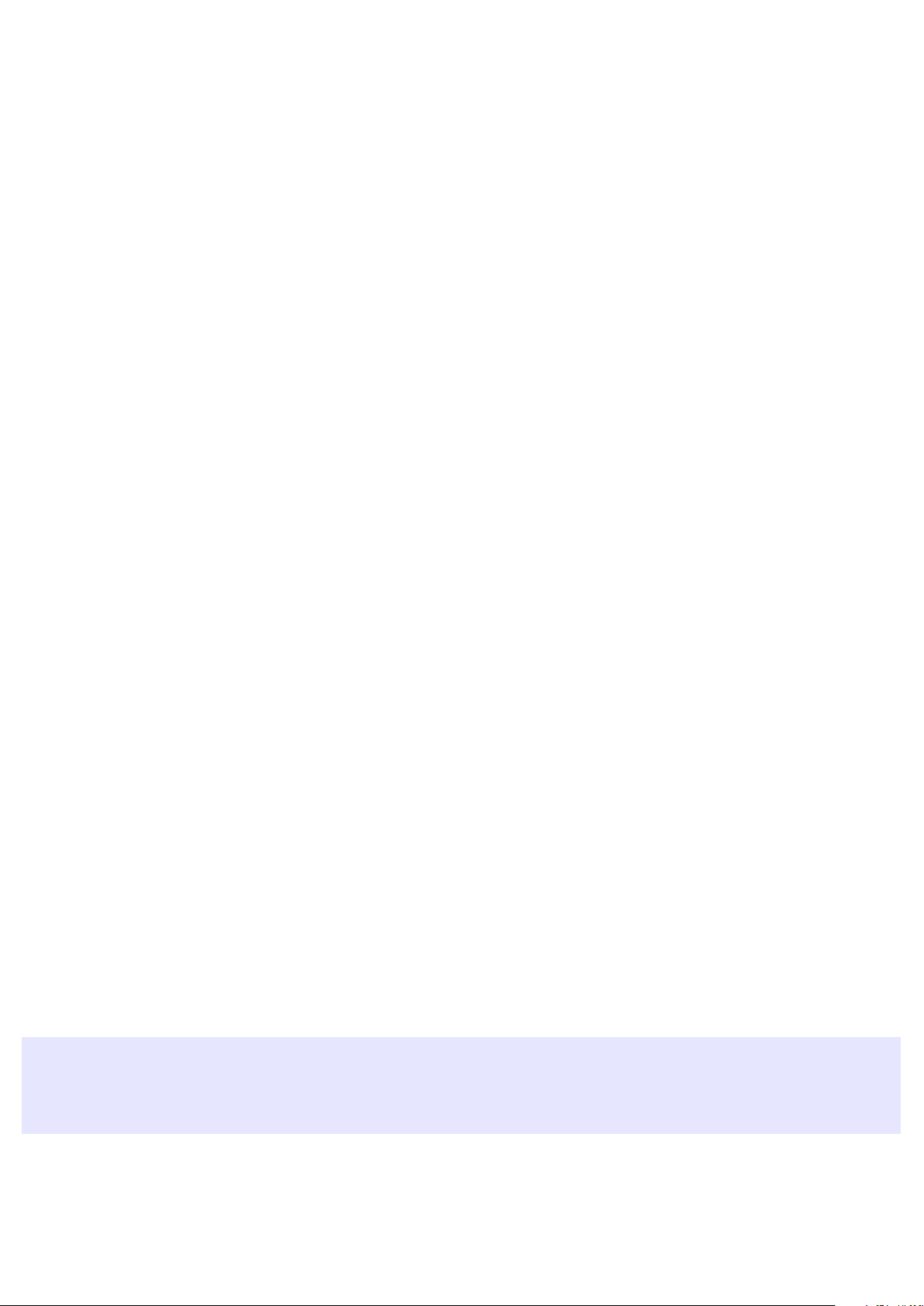

More..

menu screen (Fig. 4.3 page 17) displays a detailed list of sensed data about the device and its operation.

The upper left section displays information about the secondary circuit, the storage tank and the pool. The left centre section

displays data about the operation of the outdoor unit. Data displayed in the right section is identical to the overview screen.

The meaning of individual abbreviations is explained in Chapter 4.2.1 (page 19). Press

Energy

and

Status Error

to switch

to other screens.

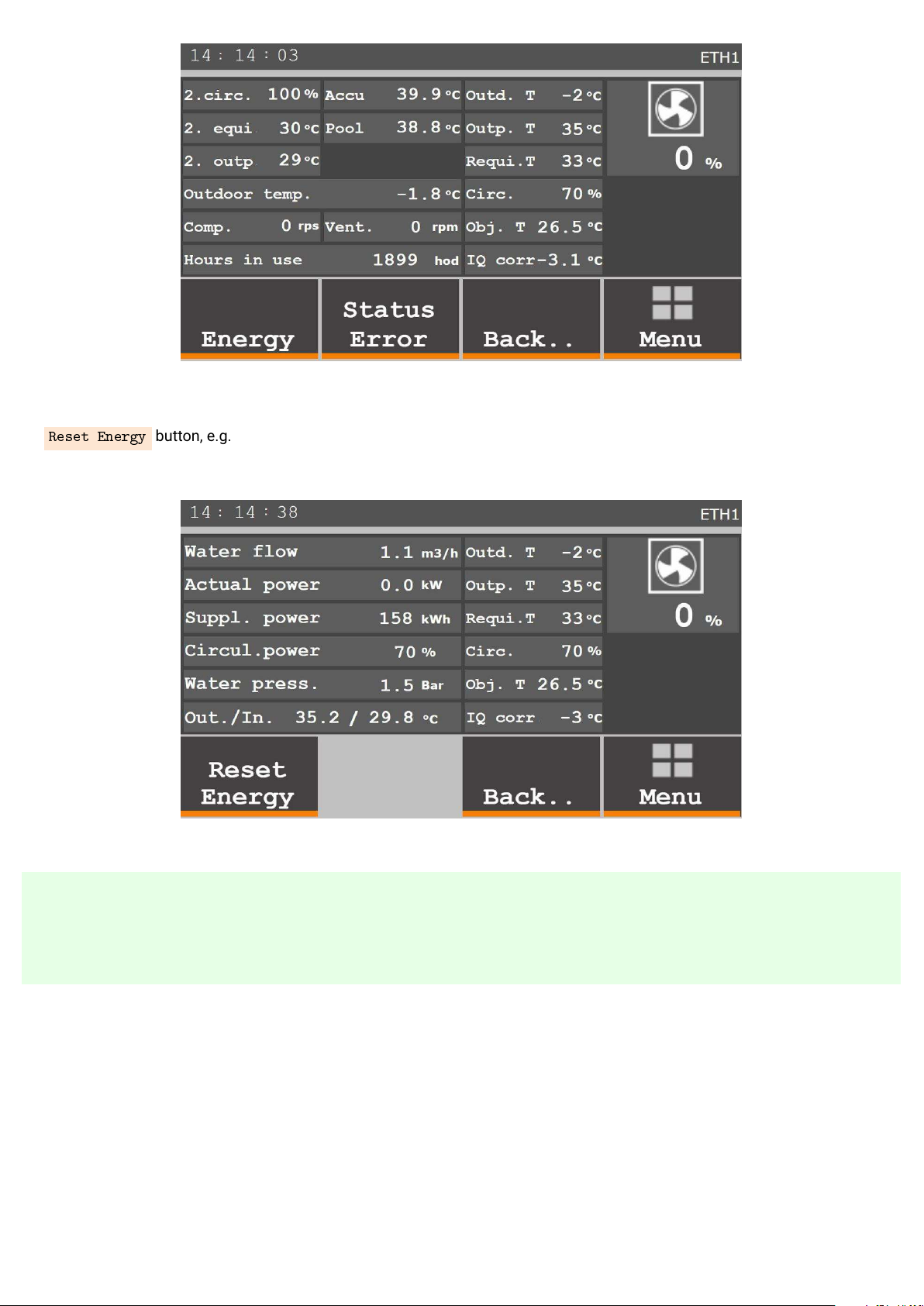

The left part of the Energy screen (Fig. 4.4 page 17) shows the quantities needed to calculate the current supplied

power, the current supplied power as well as a counter of the total supplied energy. This counter can be reset with the

16

Figure 4.3: Overview section ¸More..

Reset Energy

button, e.g. before the start of the heating season.

The right side of the screen is again identical to the previous window.

Figure 4.4: Overview section ¸More.. ¸Energy

If the current power value is negative, heat is being removed from the building. This is common, for example, when

the outdoor unit is defrosting and an ice layer forms on the evaporator, which needs to be removed to maintain

good heat transfer. This is achieved by taking part of the energy of the building and heating this evaporator.

17

The left part of the status and error screen (Fig. 4.5 page 18) shows a history of the last ten recorded problems. You can

clear the error history table using the

Reset history

button. This deletes data from the screen, but the complete record

of the operating data remains saved and is accessible from a web browser in the device settings.

The last fault that occurred is shown at the top of the right part of the screen. The white window below lists faults that

occurred and then disappeared. When a fault disappears, the device returns to normal operation thanks to the autoreset

function. However, this function resumes operation a maximum of 5 times. If a fault occurs more than 5 times, it is likely

a more serious problem that needs to be eliminated. You can use the

Autoreset

button to reactivate or deactivate this

function.

Figure 4.5: Overview section ¸More.. ¸Error status

UStored operating data must never be deleted or modified. The data record is used to analyse the operation and

faults of the device. Damage or deletion of the records may affect the validity of warranty claims.

18

4.2.1 Meaning of graphic symbols and text abbreviations

Heat pump operation – the heat pump is used for heating / cooling / DHW heating.

Secondary source operation – the secondary source is used for heating, the heat pump is used for DHW heating

Defrosting – the outdoor unit (exchanger) is defrosting, heating / cooling / DHW heating is interrupted

Outdoor air temperature too low – the outdoor temperature is lower than the permissible operating temperature,

the bivalent source (integrated electric boiler) is completely used for heating and DHW heating

Economical operation – the icon is displayed if the output water temperature is lower than 45°C and the outdoor

unit power is lower than 50%

DHW heating is blocked by the time schedule – in the DHW ¸DHW heating time schedule section, DHW heating

is not enabled for this time

Antilegionella – the DHW tank is electrically heated to eliminate Legionella (disinfection of the hot water tank

by a temperature of 60°C)

Protection of the outdoor unit exchanger from damage – in case of frost protection or low water flow through

the indoor unit, the outdoor unit is shut down for 10 minutes.

Activated limitation of the cooling water temperature when it is approaching the dew point.

Activated silent mode.

Attenuation – Attenuation is active, the parameters can be set in the

Building

¸

Attenuation time schedule

section

High tariff – device operation is blocked due to a high energy tariff

DHW heating – the DHW tank is being heated by the heat pump

DHW el. heating – the DHW tank is being heated by the electric heater

Drying – activated floor drying mode

Pool heating – the pool circuit is being heated by the heat pump

Bival 1st st. 2nd st. – the bivalent source (integrated electric boiler) is running (1st st. – first stage (2 kW); 2nd st. – second

stage (4 kW))

Outd.T – outdoor air temperature

Output – output (heating) water temperature

Weather compensation – temperature calculated by the weather compensation curve for the main circuit

Circulation – circulating pump power percentage

Building – air temperature in the reference room of the building

IQ cor. – correction value applied to the weather compensation curve

2nd circuit – opening value of the secondary circuit mixing valve

W.com. 2 – temperature calculated by the weather compensation curve for the secondary circuit

Outp. 2 – temperature of the output (heating) water for the secondary circuit

19

Outdoor temperature – outdoor air temperature

Comp. – current compressor speed

Vent. – current fan speed

Hours in use – number of operating hours of the device

Water flow – current water flow in the indoor unit

Current power – current heat output supplied by the heat pump

Suppl. power – total heat output supplied from the last energy reset

Circul. power – circulating pump power percentage

Water press. – current water pressure in the heating system

Out./In. – temperature of the output (heating) water / temperature of the return water

The meaning of error codes is described in a separate chapter 7 – Faults and status messages (page 38).

20

Other manuals for TG TX Series

1

This manual suits for next models

8

Table of contents

Other NeoRe Heat Pump manuals