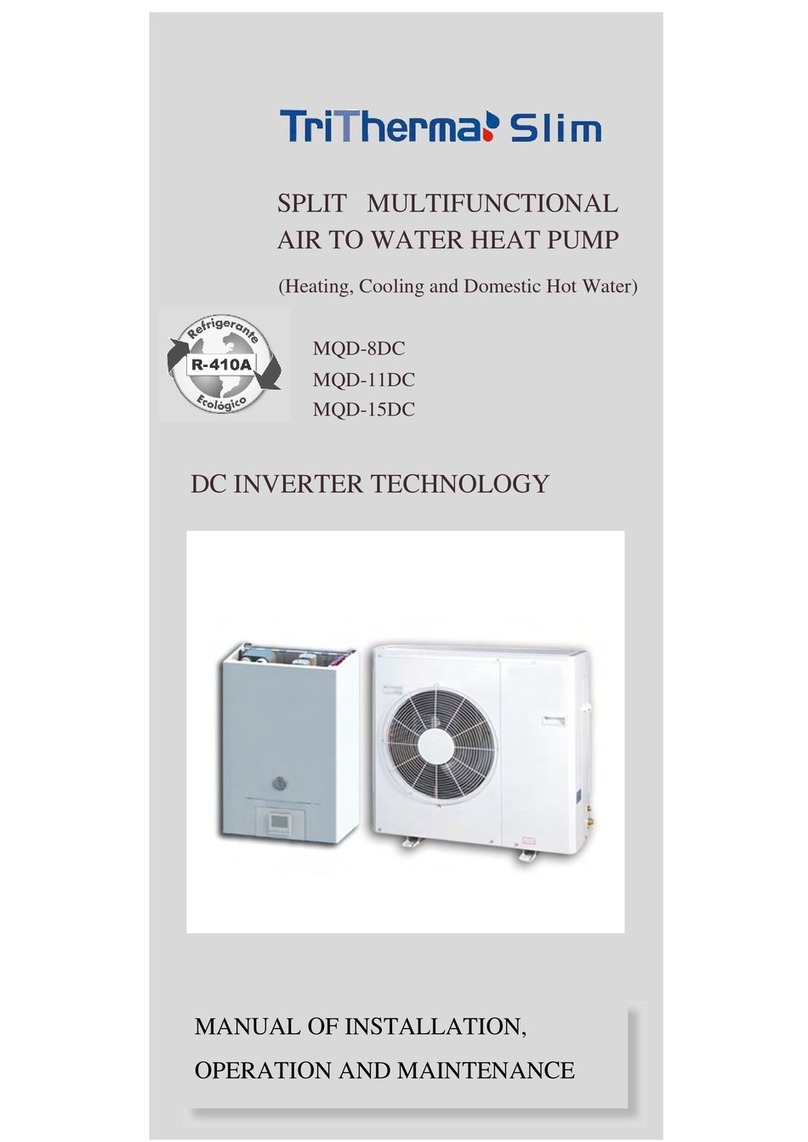

Contents

1 Introduction 4

2 Safety instructions 5

2.1 Safetywarning...................................................... 5

2.2 Safetyprecautions.................................................... 5

2.3 Legalconditions..................................................... 6

2.4 Storageandtransportconditions ........................................... 7

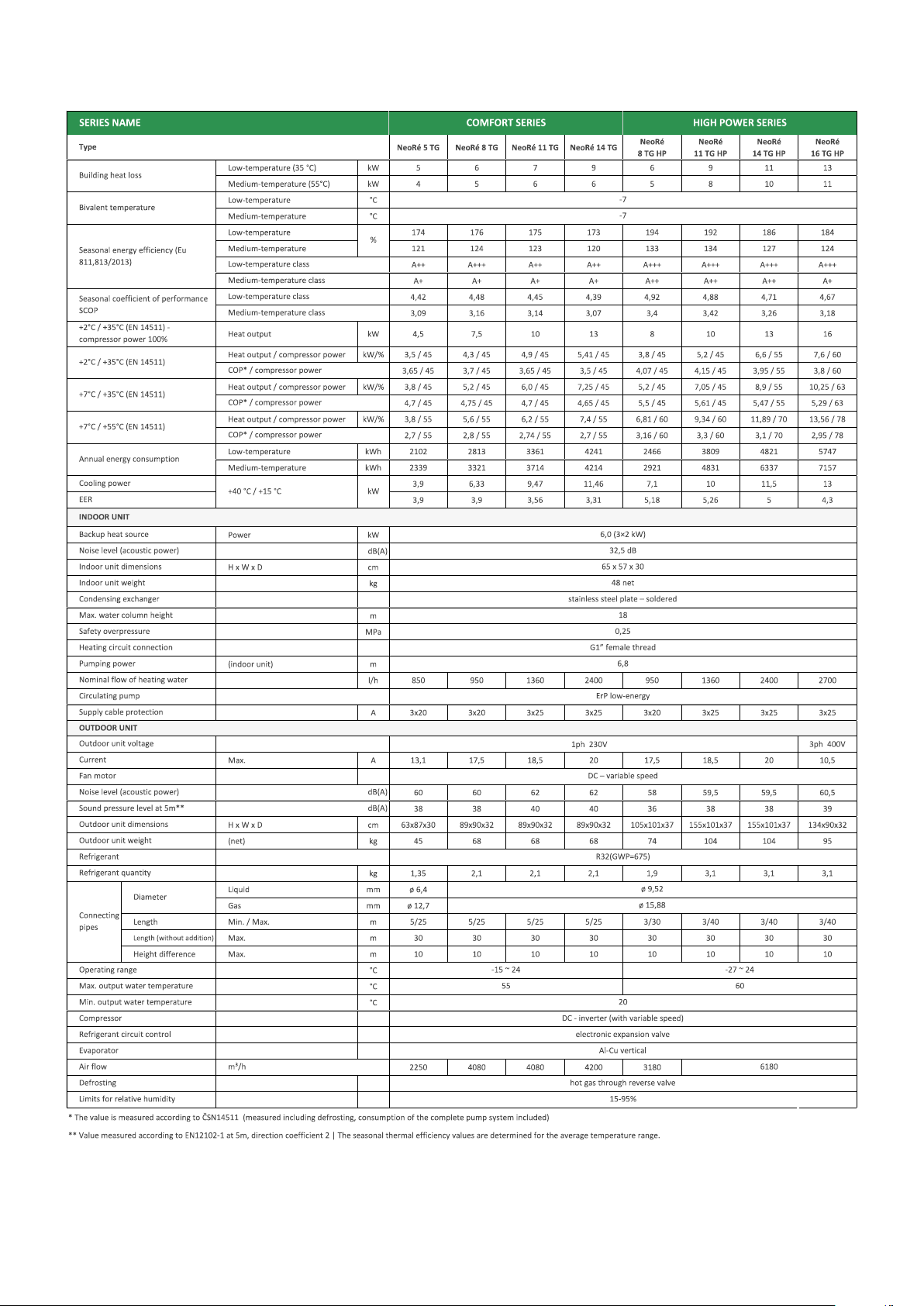

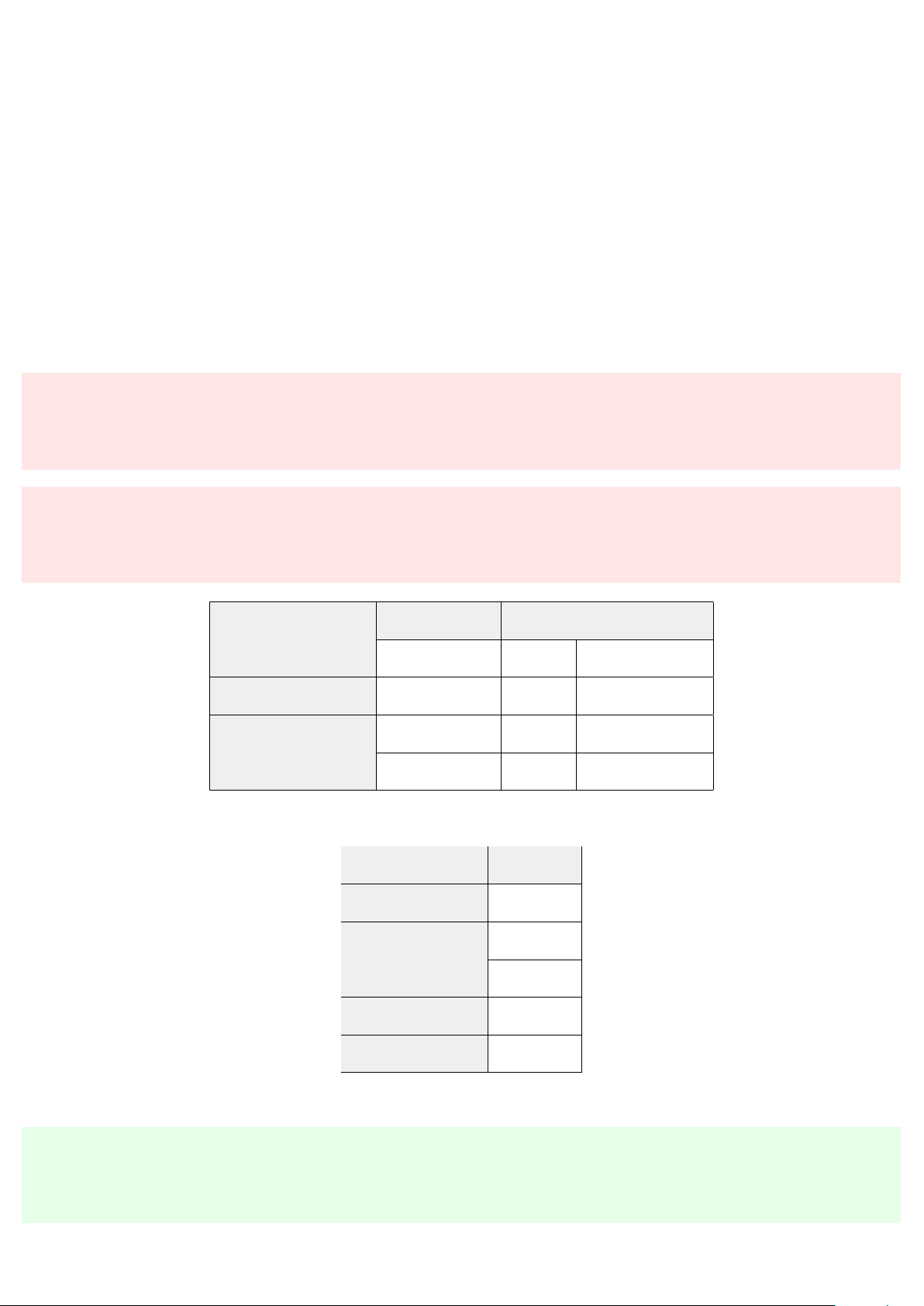

2.5 Tableoftechnicalparameters ............................................. 8

3 Installation manual 9

3.1 Workingconditions ................................................... 9

3.1.1 Workingenvironment.............................................. 9

3.1.2 Coolingcircuit.................................................. 10

3.1.3 Technical parameters of heating / cooling water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.4 Technicalparametersofwater......................................... 10

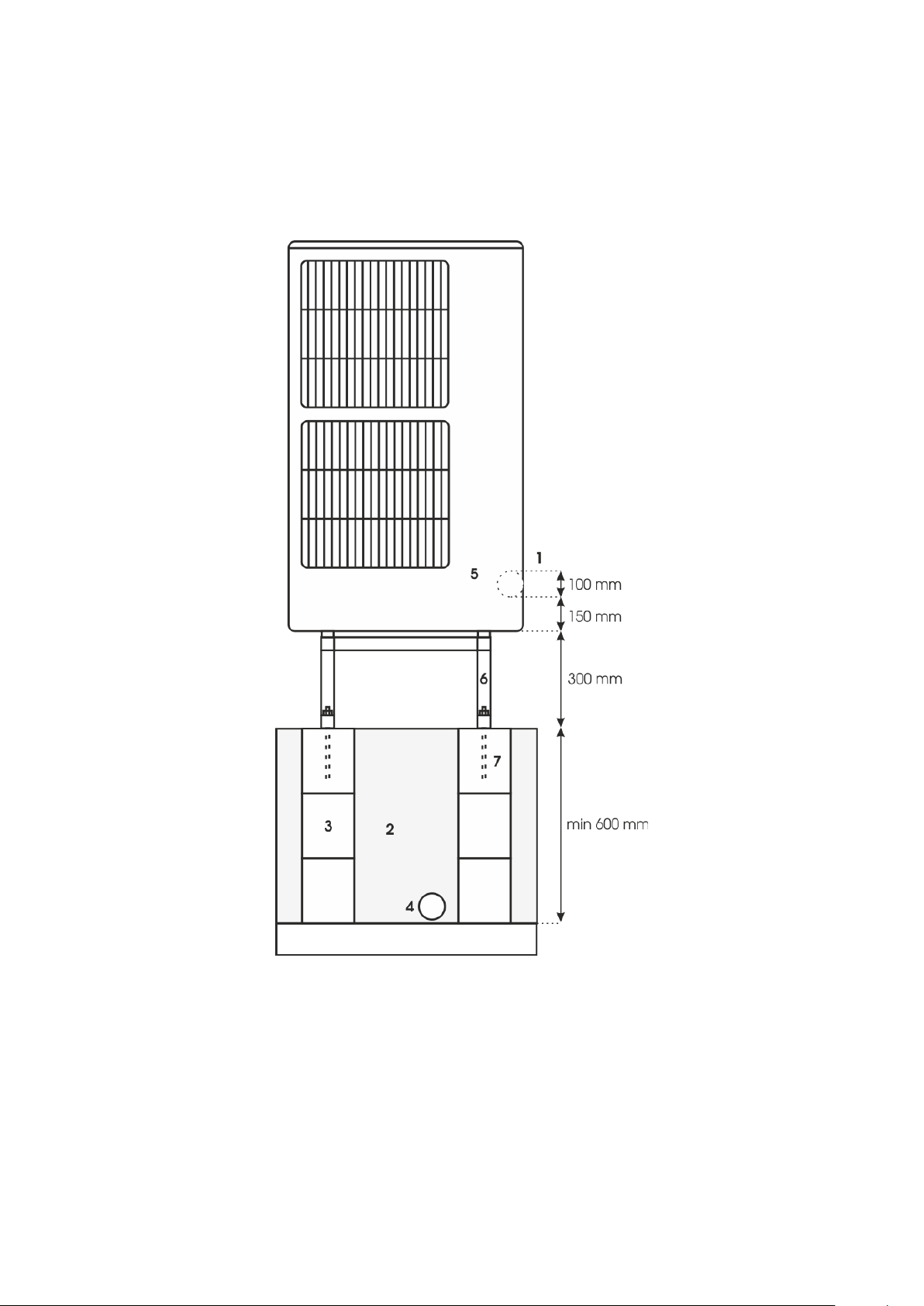

3.2 Preparation of space for the outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Fittingtheoutdoorunit ................................................. 15

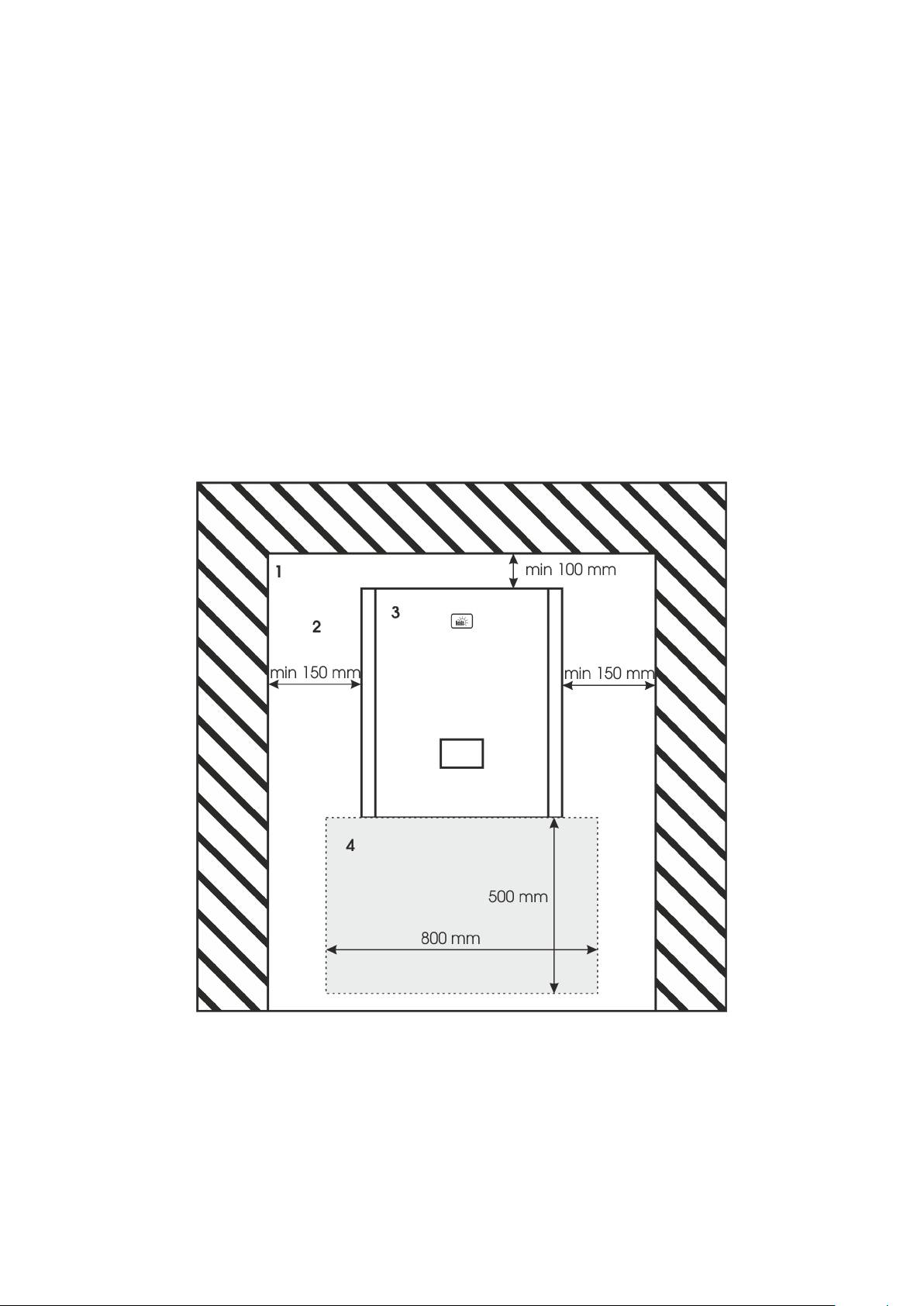

3.4 Preparation of space for the indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

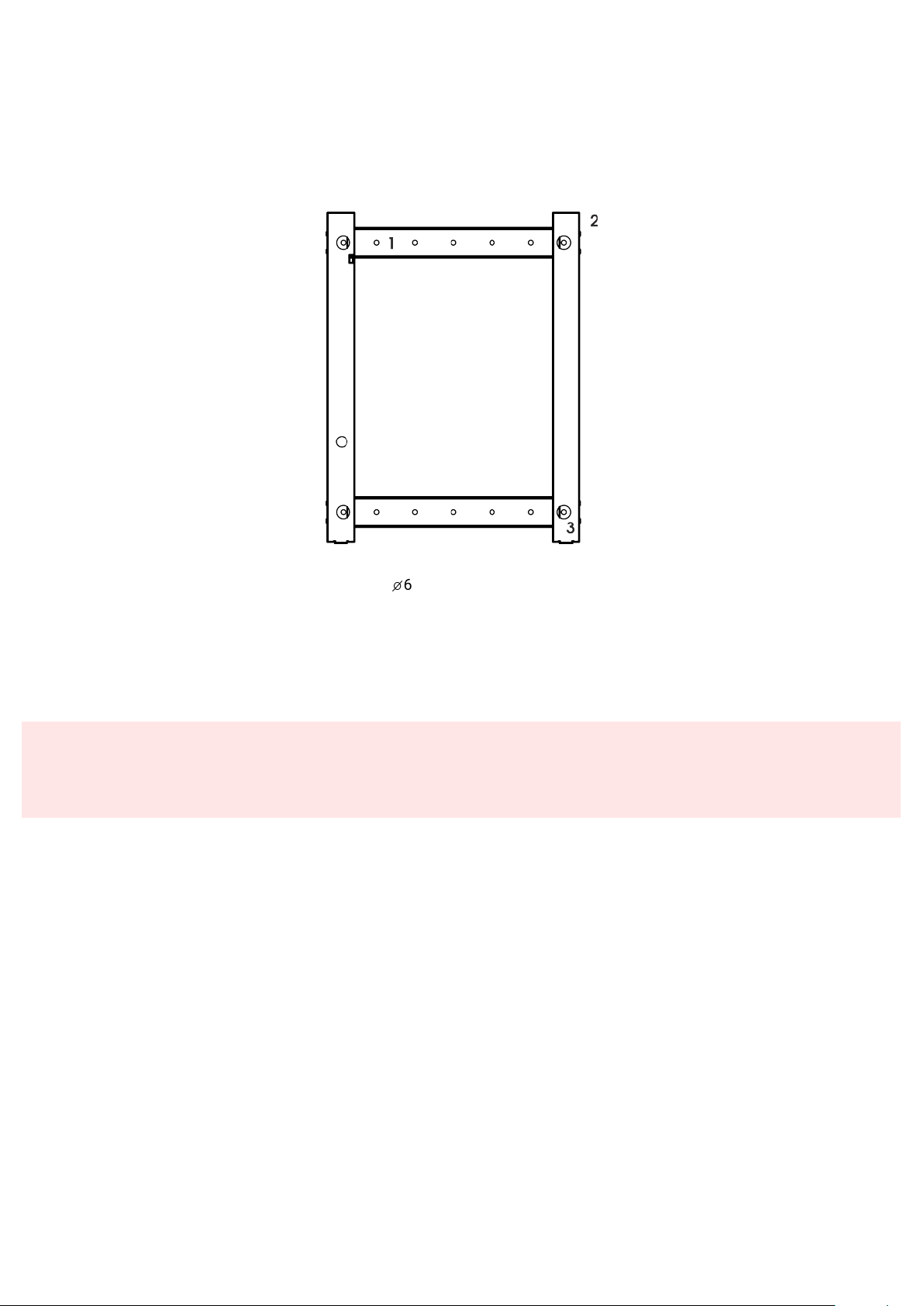

3.5 Indoorunitmounting .................................................. 16

3.6 Unitsconnection .................................................... 17

3.6.1 Refrigerantpiping ................................................ 17

3.6.2 Cableconnections ............................................... 21

3.6.3 Cableconnecting ................................................ 22

3.7 Connection of the heat pump to the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.1 Connectionmethodsfor:............................................ 29

3.8 Unauthorized connections to the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 Commissioning 31

4.1 Commissioning of the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Activation ........................................................ 31

5 Shutdown 32

5.1 Short-termshutdown .................................................. 32

5.2 Long-termshutdown .................................................. 32

6 Faults and status messages 33

6.1 Errorcodestructure................................................... 33

6.2 Overview of faults and status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 Faultsandtroubleshooting............................................... 34

6.4 Statusmessages .................................................... 36

6.5 Protectivefunctions................................................... 37

6.6 Serviceorganization................................................... 40

7 Maintenance of the device and components 41

7.1 Maintenanceoftheoutdoorunit............................................ 41

7.2 Maintenanceoftheindoorunit............................................. 41

7.3 MaintenanceoftheDHWtank ............................................. 42

7.4 Maintenanceplan .................................................... 43

8 Design documentation 44

8.1 Connection of the heat pump to the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.2 Hydrauliccircuit ..................................................... 47

8.3 Heating - range of working temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.3.1 Floordryingprogram .............................................. 50

8.4 Cooling - range of working temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.4.1 Dewpointtable ................................................. 51

8.5 Acousticparameters .................................................. 52

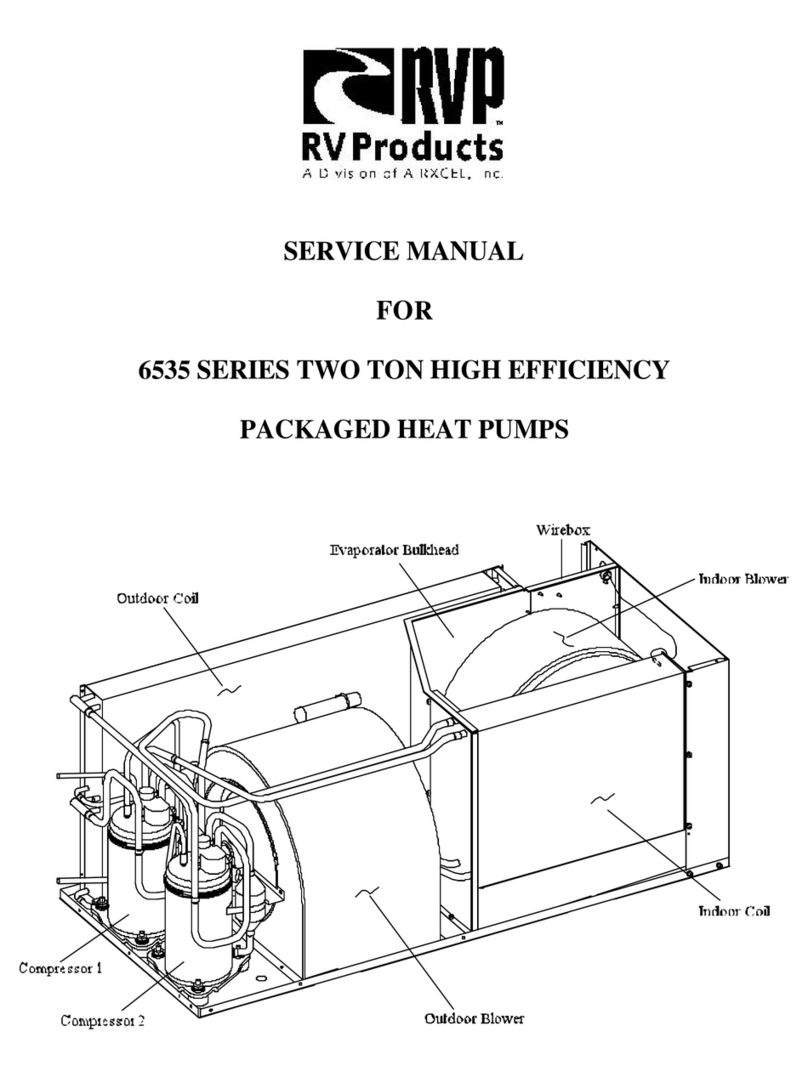

9 Technical data 53

9.1 Electrical wiring diagram of the indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2