NERI SNR-BD User manual

1

Portable Plasma / Flame CNC Cutting

Machine

USER MANUAL

SNR-BD

Neri Machine Tools Pvt Ltd.

www.nerigroup.in

www.EngineeringBooksPdf.com

2

WE THANK YOU VERY MUCH FOR YOUR INTEREST SHOWN

IN OUR PRODUCT.

Before using this machine, please read the instruction carefully.

1. Open the package, please check the center unit, make sure it is not be

broken, and make sure the packing list conform to the article.

2. Please make the voltage is(AC220V±10%, and use the isolation

transformer or other isolation voltage regulator device to make sure

the system work stably. The machine must be grounded reliably when

it is working.

3. Clean up dust on a regular basis to ensure the rail and rack clean.

4. The display screen of CNC system is easily broken, pay attention to

protect it.

5. This machine should be operated by professional, with some operation

and safety train information.

6. If there is something unclear, please contact with the local dealer or

call the manufactures.

Content

1 Machinery part--------------------------------------------------------------------3

2 CNC control system part---------------------------------------------------------8

www.EngineeringBooksPdf.com

3

Machinery Part

1 Put the crossed beam on the center unit, connect the line with the motor.

2. put the motor into the center unit.

www.EngineeringBooksPdf.com

4

3. Fix the four screws.

4. Put the security cover on the beam.

www.EngineeringBooksPdf.com

5

5. Fixed the screw of the security cover.

6.Install the anti-fire plate.

www.EngineeringBooksPdf.com

6

How to use the special crossed beam trunkings?

①Loosen the screw, remove the anti-fire plate.

②Take the security cover from the center unit.

③Loosen the screw of the trunking, take it out, put the plasma cable into the trunking, and cover

it. Then install security cover and the anti-fire plate as following picture.

www.EngineeringBooksPdf.com

7

Ports details

Parameter

Input voltage 220V

Power frequently 50HZ

Rated power 180W

Display 5.7 inch

Effective cutting range X-axis: 2000mm Y-axis: 1200mm

Speed Flame cutting: 0-1000mm/min unload>8m

Plasma cutting: 0-4000mm/min unload>8m

Cutting thickness Flame cutting: 0-150mm

Plasma cutting: 6-150mm

Transversal beam length (Y-axis) 1500mm

Longitudinal rails frame (X-axis) 2500mm

Total weight 80Kg

Gas depression Max 0.1Mpa

Oxygen depression Max 1.5Mpa

Befitting gas Ethane, propane, methane

www.EngineeringBooksPdf.com

8

CNC system part

Chapter One Summarize

1.1 System features

1) 5.7 high-definition lattice LCD, Small volume, Structure compact.

2) Processing graphics dynamic/static display.

3) High speed 16-bit and 8-bit single-chip microcomputer and hardware interpolator

control. High speed running by 0.5μequivalent 6 meters/minute.

4) Step motor high subdivision control the driver,move smoothly, low noise, the quality

improved clearly.

5) You can set begin speed and the time of rising/falling arbitrarily.

6) Supplying multiple constant loops to program simply.

7) Directly diagnose all input information of system, Convenience for you to check.

8) Multi-settings of parameter, can suit different requires.

1.2 Technology norm

1) Pulse equivalent:X-axis 0.5μ(diameter)Z-axis 1μ(or X axis 0.25μdiameter)

Z-axis 0.5μ)

2) G00 Max-speed:≥6 meter/minute(X-axis 0.25μ(diameter)Z-axis 0.5μ)

3) Number of connected shaft:2 axis

4) Input coordinate scope: +/- 9999。999mm

5) Maximum lines of user program: 540 line

6) User program space: 60K

7) Number of user program:64

8) Dimension:300*200*85

www.EngineeringBooksPdf.com

9

Chapter Two System Operation and Function

2

22

2.1 Operate panel keyboard illustration

`

【F1】-【F6】Function keys: Under different operate mode, they have different definition.

【 】,【 】Triangle sign Give up and quit:Definition of the left and right key is

same.

6

3

T

。

7

8

9

U

4

V

5

I

1

J

2

M

—

S

0

G

X

Y

F

R

H

N

L

D

-

INS

DEL

S

↓

Pgup

Pgdn

S

↑

www.EngineeringBooksPdf.com

10

【INS】:Insert key under program state. Under others, it is used for increasing LCD brightness.

【DEL】:Delete key under program state. Under others, it is used for decreasing LCD brightness.

【Pgup/ S↑】:Page-up key under program state. Under automatic and manual function, it is used

for adjust cutting-gun, when press/loosen the key, cutting-gun rising/stopping.

【Pgdn/ S↓】: Page-down key under program state. Under automatic and manual function, it is used

for adjust cutting-gun, when press/loosen the key, cutting-gun falling/stopping.

【Shift】∶Space key. It is used for distinguish between upper case and lower case under program

editing state.

【 】:Enter/Effective key

【F↑】:It is used for increase speed under automatic and manual control state, increase 1%/press once

【F↓】:It is used for decrease speed under automatic and manual control state, decrease 1%/press once

Strong current control :

Ignition automatically key under manual control state.

Strong current control :

Preheat oxygen key under manual control state

Strong current control :

Acetylene open key under manual control state

Strong current control :

Cutting oxygen key under manual control state

Strong current control :

Perforation key under manual control state

Strong current control :

Close all states under automatic and manual control state

Acetylene

opened

Ignition

Preheat

oxygen

Cutting

oxygen

Perforation

General

switches

www.EngineeringBooksPdf.com

11

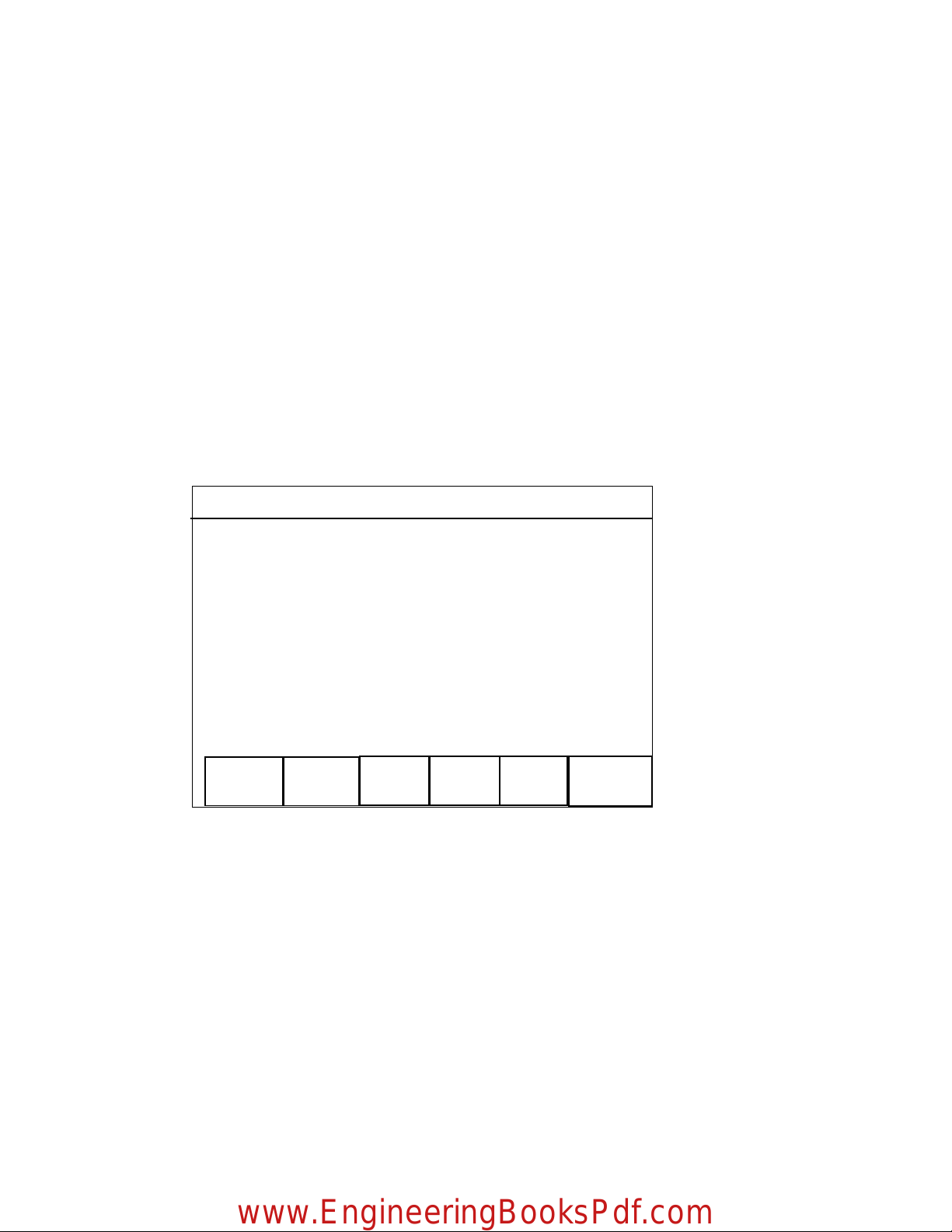

2.2 Main interface of system working

After power on,enter into main interface,please press【F1】—【F6】key and select function as

follow:

【F1】Auto:Machining program automatically.

【F2】Manual: Manual adjusting the position of lathe.

【F3】Editor:Edit/modify machining program

【F4】Parameter:Parameter setting

【F5】Diagnosis:Checking input/output information of lathe.

【F6】Return:Lathe return to origin(the position set by proximity switch)

Press【G】【G】【3】key,System will clear all contents of user program..

CNC Flame cutting Machine system

Automatic Manual Editor Parameter Diagnosis Return

www.EngineeringBooksPdf.com

12

2.3 Auto function

Under main interface ,press【F1】key, System will enter into auto function and display as follow:

*The first line display : F×〈magnification〉%=〈current speed〉,current program name and the

number of machining.

*The medium display the current coordinate of X and Y by big character.

*Under the coordinate the two lines are current continuous program, use ‘►’ indication.

*Above line of the right indicate the state is automatic machining.

*Under line of the right,indicate current system state respectively,including :Acetylene(switch),

Preheat oxygen(switch),Cutting oxygen(switch),Cutting tip(rising/falling/stopping).

*Others indication:

M—Latest instruction M.

U,V—Increment coordinate.

Speed:F* 100%=00000 Program:0001 Number:0000

Single segment Manual Free play Graphics Select segment

Return reference

point

X +0000。000

U +0000.000

V +0000.000

Preheat:0850

►G92 X100YZ0

G00 Y100

Machining

automatically

Acetylene closed

Preheat closed

Cutting closed

Cutting tip stop

www.EngineeringBooksPdf.com

13

Operate under automatic function

1.Press【F1】,System select single segment machining,Press 【F1】again, give up. Under

this state,Press【Startup】key once,System will run one instruction. Press【Quit】key,

give up this function.

2.Press【F2】,System enter into manual state, concrete function refer manual function section.

3.Press【F3】,System enter into free play state,Press【Startup】system working, display the

moving trace of cutting tip, But the operation of driver and I/O all closed to check whether

program is correct.

4. Press【F4】,System enter into graphics machining tracking state. (referring the picture below)

5.Press【F5】,System select arbitrary segment to machining,’►’ represent the first line

program that current running. Press【↑】and【↓】key ,you can select orderly the current

program. Press【Startup】,System will run from the selected program. Press【Quit】

will give up select segment machining. Attention: Under select segment machining state,

firstly, you should aim the cutting-gun to initiation position of program (easy aim). Press

【Startup】begin to select segment machining.When appear ‘Pause’ sign, you can manual

control the strong current switch to finish the prepare working, then press【Startup】,System

will begin to run from the selected segment.

6. Press【F6】,System will return automatically to reference point.

7. When lathes are not running, you can select strong current key to control Ignition, Acetylene

opened/closed,Preheat oxygen opened/closed, Cutting oxygen opened/closed and Cutting

tip rising/falling/stopping. Under normal machining state, the strong current keys are locked.

Attention: Press ignition key,if acetylene key is not open,please open acetylene valve

firstly ,then open ignition switch, after one ignition delay(refer Parameter-

--

-Control-

--

-

Ignition delay), close ignition switch. Press【K1】 key will run a preheat perforation

www.EngineeringBooksPdf.com

14

procedure.(refer M50 preheat perforation fixed cycle).Press【K2】key is general switch.

8. Press【F↑】and【F↓】,you can increase or decrease speed magnification. Note: Manual and

automatic magnification are saved respectively. The value immune to influence of power

on/off.

9.Press【Pgup/S↑】and【Pgdn/S↓】,This two keys are compound. Under edition state, they are

turn to page up and down.. Under this state they are used to control move up and down of

cutting tip. Press【Pgup/S↑】(or【Pgdn/S↓】)cutting tip moving up (or down),loose it

will stop.

Automatic graphics track

Under graphics mode, press【F】,the picture will double its size, Press【F】again,

come back. Press【↑】,【↓】,【→】,【←】key will move the display window,you can

observe every segment in detail.

10.Press【DEL】key to clear counter.

Speed: F*100%=0000 Program :0001 Number:0000

G92

×

500 Y200

X

:

0050.000 Y00200.000 M05

Preheat:

0850

www.EngineeringBooksPdf.com

15

Reference point under automatic machining

Reference point is initial point of machining program(set by G92).One program run once

(include free play), Reference point will be saved automatically(Also set by parameter).

Once reference point is set, orientation of reference point is very easy, as follows:

1)Please aim the knifepoint to special position of steel plate that waiting for cut(know

coordinate), set the current coordinate.

2)Under automatic or manual mode, if select return reference point function, system will

automatically return to reference point.

Startup under automatic machining

After all prepare work is ok, there are two means to startup the automatic machining program.

1.Press【Startup】.

2.Press outside“startup”button.(refer chapter 6.1 “outside input interface”)

Control and error compensate under automatic machining

After automatic machining beginning, only these keys are effect:

1.【Pause】: Press this , system will decrease speed till stop. Execute instruction M according to

the set of G61 to keep the current display contents. If press【Startup】, system will keep on running.

Under pause state, if find deviation of dimension, you can press【F2】key to enter into manual state

(in inch state automatically, increment is 0.01mm),Operator press direction key to adjust the

position of knifepoint, its move be considered compensation. Adjustment finished, press【Startup】

system will neglect compensation movement and keep on running according to before adjustment.

If press 【Quit】, system will return to main picture.

Error compensation under pause state is reference point’s compensation in fact.

2.【F↑】,【F↓】Moving axis adjust speed key: Increase or decrease speed magnification, change

1% once.

www.EngineeringBooksPdf.com

16

3.【Pgup/S↑】,【Pgdn/S↓】Control cutting gun rising or falling ,Press key, cutting gun rising

or falling, loose it will stop.

4.【Stop】:

::

:Outside button(refer chapter 6.1 “outside input interface”),Signal can derive

from input port. All stop when this key is effect.

Return and renew machining according to original track

During machining, because of cutting incompletely, need return and renew machining, You

can deal with as follow:

1.Press【Pause】, system will decrease speed till stop and display"pause"sign. Prompt

(Graphics mode)"F2manual F6return",Press【F2】can enter into manual compensation

function(refer below),press【F6】can enter into return and renew machining function.

If select【F6】, System will hint:

Return<-

<-<-

<-

->

->->

->forward

Indication: Press【←】, System will return along original trace. Press【→】, System will forward

along original trace base of return. During return, if reach position that want to return, You can

press【Pause】again, repeat the above-mentioned procedure, select again keep on returning or

forward.

2.You may press【Pause】again when system get to the return position,After system stop

Steady, you can press the strong current key correspondingly(like Preheat perforation, open

cutting oxygen etc.),Press【→】again, and select machining forward.

3.Above-mentioned operate can run repeatedly till get the satisfactory effect.

Break recover and power cut disposal

When system pause by man-made, it will save automatically the current working trace

(cutting tip’s position) as a break. This break will be saved forever, regardless power off. Power on

again or enter into automatic mode, if only the current program is not changed you can press【G】

key to resume break. When find the break, system will hint "pause"state, You can press the

strong current function key correspondingly (such as preheat perforation, open cutting oxygen

etc.), Press【Startup】again, system will keep on running from break’s position.

www.EngineeringBooksPdf.com

17

After machining pause, if you want to quit automatic state and enter into manual state to

move cutting tip(whatever how much),When press【G】key to begin resuming break, system will

move the cutting tip to the position of break firstly, then resume break. Of course, if you changed

the current coordinates by hand, the break will not be resumed normally.

If during machining, you encounter failure of electricity, you can enter into

automatic mode firstly after get back electric power. Press【F3】key will set the current

coordinate as break and recover like above-mentioned. Attention: This moment you must not move

the cutting tip or set the current coordinate.

Only pause operation can generate break.

2.4 Manual function

Under main picture, press【F2】enter into manual mode, display:

Display under manual function

Like automatic mode,but have any distinction:

1. Under left of the menu display the current increment value.

2. Under right hint:Press【G】, you can modify the inch increment.

3.Press【X】, you can modify the X value. Press【Y】, you can modify the Y value.

Speed: F×100%=0000 Program:0001 Number:0000

Preheat:0850

Inch increment:0001.000

Inch moving Manual Pulse

MDI

Return

parameter

Test position

X +00000.000

Y +00000.000

Manual operating

Acetylene closed

Preheat closed

Cutting closed

Cutting tip stop

M00

U 0000.000

V 0000.000

XY coordinate

G inch increment

www.EngineeringBooksPdf.com

18

Operate under manual function

1. Press【↑】and【↓】to adjust the position of X axis,Press direction- key correspondingly. The

X axis will run by speed

the maximum speed limit

the maximum speed limitthe maximum speed limit

the maximum speed limit

* Manual magnification. Press【→】and

【←】to adjust the position of Y axis. Press direction-key correspondingly, The Y axis will

run by speed

the maximum speed limit

the maximum speed limitthe maximum speed limit

the maximum speed limit

* Manual magnification.

2.Press【F1】, system will enter into inch moving state, Press the direction-key once, Motor will

move one inch increment correspondingly. Press【F1】again, return to continue state. Press

【G】key can change the inch increment.

3.Press【F2】,system will enter into manual pulse mode, display as follow:

4.Press【F4】,system will select MDI function,Under this mode,You can directly input single

segment program, such as:

G01 X100 Y200

After input one line, press【Enter】key to run at once. Press【Quit】key to cancel. MDI

MDI MDI

MDI

mode supports various G、M、S instructions. Note: The MDI instruction inputted will

be saved till modified or power off.

Speed:F×100%=0000 Program:0001 Number:0000

X axis Y axis

1.00

0.10

0.01

0.002

X +00000.000

Y +00000.000

Manual operating

Acetylene closed

Preheat closed

Cutting closed

Cutting tip stop

M05

U 0000.000

V 0000.000

XY coordinate

Enter into manual pulse mode,

Press【F1】and【F2】to select

X or Y axis.

Select valid weight:

【F3】- 1.00mm / pulse

【F4】- 0.10mm / pulse

【F5】- 0.01mm / pulse

【

】

www.EngineeringBooksPdf.com

19

5.Press【F5】,System will control cutting tip return to reference point.

6.Press【G】will change the value of inch increment, hint: input increment value, then press enter

key, this value will be saved till changed or power off.

7.Press【X】key to change value of X .hint: input coordinate of X(Y)axis, then press enter key,

the coordinate of X and Y are changed at once; Press【Y】key to change value of Y .hint: input

coordinate of Y axis, then press enter key, the coordinate of Y are changed at once

8.Press【F6】key,system enters into test-position function. Test-position is testing the precision

distance from the current position of cutting tip to the origin of machine tool. Concrete usage:

Firstly, You should aim the cutting tip to a special point(such as reference point),test the

current coordinate and modified(press“X/Y”),Press【F6】key, cutting tip begin to return to

origin of machine tool and save it as machine’s origin of parameter. Return-position is same to

test-position from shape, but their results are not same: Return-position is that send the origin

value of machine tool to current coordinates , but test-position is that send the current

coordinate to origin of machine tool.

9.Press【F↑】and【F↓】,you can adjust the manual magnification. Note: Manual and automatic

magnification are saved respectively till changed and the value immune to influence of power

off.

10.Press【Pgup/S↑】,【Pgdn/S↓】and strong-current key ,their usage is same to

auto mode.

2.5 Parameter set

Under main working picture, Press【F4】can enter into parameter set function.

Displaying:

Parameter set

Speed Adjustment Control System Save

www.EngineeringBooksPdf.com

20

Every function item save parameter as follow:

Speed---- Start speed,Adjust time,Max speed.

Adjustment---- Software limit position,Origin,reverse clearance,reference point

Control

ControlControl

Control----Machining speed limit, Ignition delay, Preheat delay, Cutting gun rising delay,

Cutting gun falling delay, Perforation cutting gun rising delay, Perforation cutting gun falling

delay.

System----Each axis’s electric gear, Driver’s subdivision.

Save----Save the changed parameters to parameter area.

2.5.1 Speed parameter

Press【F2】and select (refer picture below)

2.5.2 Adjust parameter

Press【F3】and select adjust parameters(refer picture below),Among these :

Speed parameter setting

Start speed:X 00250 Y 00250

Adjust time:X 00040 Y 00040

Max speed limit:X 05000 Y 05000

Note

:

time

’

s unit

is one percent second

Cutter Speed Adjust Control System Save

Speed

Tim

e

Start speed

Adjust time Adjust time

Max speed

Start speed

Means of each parameter refer left

picture:

Start speed and max speed ‘s unit

is mm/minute

time’s unit is one percent second

00040 express 0.4 second.

The max speed limit regulate the

max speed of by-hand and G00。

www.EngineeringBooksPdf.com

Table of contents

Popular Welding System manuals by other brands

Hypertherm

Hypertherm Powermax 30 Service manual

Lincoln Electric

Lincoln Electric RANGER 305LPG IM10043-A Operator's manual

ESAB

ESAB EAS IV instruction manual

MasterCraft

MasterCraft MIG instruction manual

Miller Electric

Miller Electric Subarc DC 650 Specification sheet

Unitor

Unitor UWI 230 TP AC/DC instruction manual

Chicago Electric

Chicago Electric 96712 Owner's manual & safety instructions

Thermal Arc

Thermal Arc 161 S operating manual

Lincoln Electric

Lincoln Electric RANGER IM10030 Operator's manual

Snap-On

Snap-On TIG 250 AC-DC Service manual

Klimawent

Klimawent SLOT 1600 user manual

Sealey

Sealey IMIG160.V2 quick start guide