Net Safety SAFEGUARD CONTROLLER User manual

MAN-0115 REV 0

August 13, 2009

SAFEGUARD CONTROLLER

User Manual

(Revision 4.4 – Firmware 6.03 & later)

TABLE OF CONTENTS

TABLE OF CONTENTS .......................................................................................1

SECTION 1...........................................................................................................1

IMPORTANT SAFETY ISSUES .......................................................................................1

1.0GENERAL DESCRIPTION..................................................................................2

1.1DATA DISPLAY SCREENS...............................................................................3

1.1.1TREND SCREEN.......................................................................................................... 3

1.1.2BAR GRAPHS SCREEN............................................................................................... 3

1.1.3COMBINATION SCREEN............................................................................................. 3

1.2SPECIFICATIONS:..............................................................................................4

1.2.1DC POWER SUPPLY REQUIREMENTS ..................................................................... 4

1.2.1a150 WATT AC – 24VDC POWER SUPPLY.................................................................. 4

1.2.2RELAYS ........................................................................................................................ 4

1.2.3AMBIENT TEMPERATURE RANGE ............................................................................ 4

1.2.4HUMIDITY RANGE ....................................................................................................... 4

1.2.5ALTITUDE..................................................................................................................... 4

1.2.6HOUSINGS ................................................................................................................... 5

1.2.6aNON-INTRUSIVE MAGNETIC KEYPAD ...................................................................... 5

1.2.7APPROVALS................................................................................................................. 5

SECTION 2...........................................................................................................5

2.0BASIC OPERATION ...........................................................................................5

2.1SETUP MENU CONFIGURATION......................................................................6

2.1.1CHANGING MENU VARIABLES USING THE KEYPAD.............................................. 6

2.2CHANNEL CONFIGURATION MENUS..............................................................7

2.2.1CHANNEL SETUP ENTRY MENU ............................................................................... 8

2.2.2ALARM 1 / ALARM 2 / HORN RELAY SET-UP MENU ................................................ 8

2.2.3ALARM 3 / FAULT ALARM MENU................................................................................ 9

2.2.4DATA FROM? MENU TO SET INPUT SOURCE ......................................................... 9

2.2.4aMIN / MAX RAW COUNTS MENUS ........................................................................... 10

2.2.4bMARKER MENUS....................................................................................................... 11

2.2.4cSENSOR LIFE DETECTION (- this feature is not used at this time) .......................... 11

2.2.5LINEARIZATION MENU.............................................................................................. 12

2.2.6CONFIGURE MENU ................................................................................................... 12

2.2.6aEUNITS / MEASUREMENT NAME ASCII DATA FIELDS.......................................... 12

2.2.6bINPUT MEASUREMENT RANGE............................................................................... 13

2.2.6cDECIMAL POINT RESOLUTION................................................................................ 13

2.2.6dTURNING OFF UNUSED CHANNELS....................................................................... 13

2.2.6eCOPY DATA TO?........................................................................................................ 13

2.2.7CAL MODE.................................................................................................................. 14

2.3SYSTEM CONFIGURATION MENUS...............................................................15

2.3.1COMMON ALARM RELAYS 1 & 2.............................................................................. 16

2.3.2SG10-0195 DISCRETE RELAY “FAILSAFE” MODE.................................................. 17

2.3.3COMMON HORN RELAY & LOCAL PIEZO............................................................... 17

2.3.4COMM PORT MENUS................................................................................................ 18

2.3.5EIGHT / SIXTEEN CHANNEL MODES....................................................................... 19

2.3.6SENSOR INFORMATION (this feature is not used at this time)................................. 19

2.4AUTHORIZATION MODE .................................................................................20

2.5LCD CONTRAST ADJUSTMENT.....................................................................20

SECTION 3.........................................................................................................21

3.0MAIN I/O INTERFACE PCB.............................................................................21

Modbus Communication between SafeGuard and Digital Millennium II Series Transmitters... 22

3.1INPUT / OUTPUT OPTIONAL PCB’s ..............................................................24

3.1.1OPTIONAL ANALOG INPUT PCB # SG10-0158 ....................................................... 24

3.1.2OPTIONAL DISCRETE RELAY PCB # SG10-0195 ................................................... 25

MAN-0115 REV 0

August 13, 2009

3.1.6OPTIONAL 4-20mA ANALOG OUTPUT BOARD # SG10-0167 ................................ 27

3.1.8OPTIONAL 24VDC 150 WATT POWER SUPPLY ..................................................... 28

SECTION 4.........................................................................................................29

4.0SYSTEM DIAGNOSTICS ..................................................................................29

SECTION 5.........................................................................................................31

5.0MODBUS RS-485 PORTS ................................................................................31

5.1MODBUS SLAVE REGISTER LOCATIONS.....................................................31

SECTION 6.........................................................................................................36

6.1SAFEGUARD PM PANEL / RACK MOUNT ENCLOSURE..............................36

6.2SAFEGUARD N4 NEMA 4X WALL MOUNT FIBERGLASS ENCLOSURE ....37

6.3SAFEGUARD MAIN I/O & OPTION PCB FOOTPRINT DIMENSIONS............39

SECTION 7 – HOW TO RETURN EQUIPMENT................................................40

APPENDIX .........................................................................................................41

Appendix A: Electrostatic Sensitive Device (ESD)....................................................41

1

SafeGuard Controller User Manual

MAN-0115 Rev 0

SECTION 1

IMPORTANT SAFETY ISSUES

The following symbols are used in this manual to alert the user of important instrument

operating issues:

!

WARNINGS:

•Shock Hazard - Disconnect or turn off power before servicing this instrument.

•NEMA 4X wall mount models should be fitted with a locking mechanism after

installation to prevent access to high voltages by unauthorized personnel (see

Figure 6.2).

•Only the combustible monitor portions of this instrument have been assessed by

CSA for C22.2 No. 152 performance requirements.

•This equipment is suitable for use in Class I, Division 2, Groups A, B, C, and D or

non-hazardous locations only.

•WARNING- EXPLOSION HAZARD- SUBSTITUTION OF COMPONENTS

MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2.

•WARNING- EXPLOSION HAZARD- DO NOT REPLACE FUSE UNLESS

POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

•WARNING- EXPLOSION HAZARD- DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA

IS KNOWN TO BE NON-HAZARDOUS.

•Use a properly rated CERTIFIED AC power (mains) cable installed as per local

or national codes

•A Certified AC power (mains) disconnect or circuit breaker should be mounted

near the SafeGuard Controller and installed following applicable local and

national codes. If a switch is used instead of a circuit breaker, a properly rate

CERTIFIED fuse or current limiter is required to installed as per local or national

codes. Markings for positions of the switch or breaker should state (I) for on and

(O) for off.

•Clean only with a damp cloth without solvents.

WARNING: Read & understand contents of this manual prior to operation.

Failure to do so could result in serious injury or death.

This symbol is intended to alert the user to the presence of important

operating and maintenance (servicing) instructions.

This symbol is intended to alert the user to the presence of

dangerous voltage within the instrument enclosure that may be

sufficient magnitude to constitute a risk of electric shock.

2

SafeGuard Controller User Manual

MAN-0115 Rev 0

•Equipment not used as prescribed within this manual may impair overall safety.

1.0 GENERAL DESCRIPTION

The Net Safety Monitoring Inc. SafeGuard 16 channel Controller is designed to display

and control alarm event switching for up to sixteen detectors (Flame detectors or

transmitters with gas sensor) data points. It may also be set as an eight channel

SafeGuard Controller for applications needing fewer inputs. Alarm features such as ON

and OFF delays, Alarm Acknowledge, and a dedicated horn relay make the SafeGuard

Controller well suited for many multi-point monitoring applications. Data may be input

to the SafeGuard Controller by optional analog inputs or the standard Modbus® RTU

master RS-485 port. A Modbus RTU slave RS-485 port is also standard for sending data

to PC’s, PLC’s, DCS’s, or even other SafeGuard Controllers. Options such as analog I/O

and discrete relays for each alarm are easily added to the addressable I2C bus. Option

boards have 8 channels and therefore require 2 boards for 16 channel applications.

Note: LEL Gas sensors are connected to the SafeGuard Controller via Net Safety

Transmitters. They are NOT connected directly to the SafeGuard Controller at this

time. Perform calibrations of the transmitter/sensor head. Calibrations may

however be performed at the SafeGuard if the transmitter/sensor configuration is in

a location not easily accessible. See Cal Mode.

A 240 x 128 pixel graphic LCD readout displays monitored data as bar graphs, trends and

engineering units. System configuration is through user friendly menus and all

configuration data is retained in non-volatile memory during power interruptions. The

SafeGuard Controller’s front panel is shown below in Figure 1.0 displaying the 8 channel

bar graph screen. Additional data screens are shown in Figure 2.0.

Figure1.0

ALARM

RESET

3

SafeGuard Controller User Manual

MAN-0115 Rev 0

1.1 DATA DISPLAY SCREENS

The SafeGuard Controller offers 3 distinct graphic displays for depicting the monitored

data. These are Bar Graphs, 24 Hour Trend and Combination. Each is shown in Figure

2.0.

1.1.1 TREND SCREEN

The SafeGuard Controller’s Trend screen shown in Figure 2.0 displays a 24 hour trend of

input data for the channel selected. Horizontal tic marks are each hour and vertical tic

marks are each 10% of full scale. Dashed lines indicate alarm levels. The graphic LCD

is 240 pixels wide so each pixel represents 1/10 hour, or 6 minutes worth of data. The

trend is 100 pixels high so each represents 1% of full scale in amplitude. Since each data

point must be collected for 6 minutes before it may be displayed, it is likely input values

will fluctuate during this interval. Therefore, MAX, MIN and AVERAGE values are

stored in RAM memory for each 6 minute subinterval. To accurately portray the trend, a

vertical line is drawn between MIN & MAX values for each 6 minute subinterval. The

AVERAGE value pixel is then left blank, leaving a gap in the vertical line. This is

demonstrated in the noisy area of the 24 hour trend in Figure 2.0. If the MAX & MIN

values are within 2% of each other there is no need for the vertical line and only the

AVERAGE value pixel is darkened as in the quiet areas.

The top portion of each trend screen indicates channel #, real time reading in engrg. units,

measurement name, range, and MIN, MAX & AVERAGE values for the preceding 24

hour period. The SI field on the top right indicates number of seconds remaining in the

current 6 minute subinterval.

1.1.2 BAR GRAPHS SCREEN

The SafeGuard Controller’s Bar Graphs screen shown in Figure 2.0 allows all active

channels to be viewed simultaneously. Both engineering units values and bar graph

values are indicated in real time. Lines across the bars indicate the alarm trip points

making it easy to identify channels at or near alarm. A feature in the Systems menu tree

allows new alarms to always force the LCD to the bar graphs screen. This is useful for

applications requiring channels with alarms to be displayed.

1.1.3 COMBINATION SCREEN

The SafeGuard Controller’s Combination screen shown in Figure 2.0 offers a view of a

single channel but displays the data as a 30 minute trend, bar graph and large engineering

units. It is also useful for testing inputs for stability since MAX, MIN & AVERAGE

values refresh each time this screen is selected. For example, to test stability over a one

hour period for an input, begin timing as soon as the channel is selected. One hour later

record the MAX, MIN & AVERAGE values. The difference between MAX & MIN

indicates peak to peak excursions over the one hour period and AVERAGE is the average

for the hour. Longer or shorter tests may also be run. The numeric value shown below

the bar-graph indicates number of minutes samples have been taken. After 999 minutes

the AVERAGE buffer overflows and the error message UPDATE appears in the

AVERAGE field. Exiting this screen resets the buffer and clears the error message.

4

SafeGuard Controller User Manual

MAN-0115 Rev 0

1.2 SPECIFICATIONS:

1.2.1 DC POWER SUPPLY REQUIREMENTS

Standard SafeGuard Controller power requirements are 10-30VDC @ 3 watts applied to

terminals 9 & 11 of TB2 on the standard I/O PCB (see section 3.0). Optional features

increase power consumption as described below:

•Discrete Relay PCB option; add 2 watts per PCB (assumes all 8 relays are energized).

•Analog Input PCB option; add 1/2 watt.

•4-20mA Output PCB option; add 1 watt.

•TB2 terminals 10 & 12 of the standard I/O PCB provide a maximum of 500mA fused

output power for powering of auxiliary external devices such as relays, lamps or

transmitters. Power consumed from these terminals should be considered when

calculating system power consumption.

When wiring transmitters (detectors) to the SafeGuard Controller refer to 3.1.1

Optional Analog Input PCB # SG10-0158 and Figure 3.3.

1.2.1a 150 WATT AC – 24VDC POWER SUPPLY

*110-120 VAC @3.2A max

*220-240VAC @ 1.6A max

* A slide switch on the front of the power supply selects AC input range.

The SG10-0172 150 watt power supply (Figure 3.6) is for powering the SafeGuard

Controller and up to 16 detectors. A minimum of 5 watts per channel is available for

powering of external transmitters.

1.2.2 RELAYS

Common relays are standard and menus provide voting logic for ALARM 1,

ALARM 2, FAULT and HORN. Discrete relays are optional. Relays are Form

C dry contacts and are rated at 5 Amp for 28 VDC and 250 ~VAC RESISTIVE

loads.

IMPORTANT: Appropriate diode (DC loads) or MOV (AC loads) snubber devices

must be installed with inductive loads to prevent RFI noise spikes. Relay wiring should

be kept separate from low level signal wiring.

1.2.3 AMBIENT TEMPERATURE RANGE

-25 to +50 degrees C

1.2.4 HUMIDITY RANGE

0 to 90% R. H. Non-Condensing.

1.2.5 ALTITUDE

Recommended up to 2000 meters

!

5

SafeGuard Controller User Manual

MAN-0115 Rev 0

1.2.6 HOUSINGS

•*General purpose panel mount weighing 7 lbs and including hardware for 19” rack

mounting (Figure 6.1).

•*NEMA 4X wall mount in fiberglass enclosure weighing 17 lbs (Figure 6.2).

1.2.6a NON-INTRUSIVE MAGNETIC KEYPAD

The SafeGuard Controller’s operator interface includes five front panel touch keys. A

magnetic keypad option offers these five keys with adjacent magnetic keys. This option

is included as a standard feature. It is useful in applications where it may be inconvenient

to open the enclosure’s door to access the touch keypad.

1.2.7 APPROVALS

CSA C22.2 No 1010.1 and ISA S82.02; CSA C22.2 No 152 for combustibles; UL 1604 /

C22.2 No 213 (Div 2 Groups A,B,C,D); EN55011 & EN61000 (CE Mark). CSA File # =

219995 and may be seen at: CSA-International.org.

SECTION 2

2.0 BASIC OPERATION

The SafeGuard Controller offers 3 graphic screens for viewing monitored data and a Set-

Up menu screen for operator interface to configuration menus. They are shown below in

Figure 2.0. The Bar Graphs screen allows viewing of all active channels simultaneously.

The Trend screen displays a 24 hour trend one channel at a time. The Combination

screen displays a bar graph, large engineering units and a 30 minute trend one channel at

a time. Input channels may be displayed in sequence with the UP/DOWN keys. The

NEXT key switches between the 3 graphic data screens. When SafeGuard power is

applied, the graphic LCD returns to the screen active when power was last removed.

Setup menus are entered by pressing EDIT from any data screen, and scrolling to the

desired menu using the UP/DOWN keys. Pressing EDIT again enters the selected

menu’s tree of variables. This Setup mode may be exited manually by pressing NEXT,

or automatically when no keys are pressed for 5 minutes. Alarm relays and front panel

alarm LED indicators remain active during the Setup mode. An AUTHORIZE menu

offers a password feature to prevent tampering with the SafeGuard Controller’s

parameters.

6

SafeGuard Controller User Manual

MAN-0115 Rev 0

Figure 2.0

2.1 SETUP MENU CONFIGURATION

Variables inside system and channel menu trees allow optimum SafeGuard Controller

configuration for a wide range of demanding multi-point monitoring applications.

Access to menus is via the Setup mode by pressing EDIT and activating the Setup screen

shown in Figure 2.0. Menu trees are provided for each of the 16 channels and another for

system variables. Select the desired menu by scrolling with UP/DOWN and EDIT to

enter the menus.

2.1.1 CHANGING MENU VARIABLES USING THE KEYPAD

Upon entering a menu, a pointer controlled by the UP/DOWN keys indicates the selected

variable. Some are simple YES/NO or ON/OFF entries toggled by pressing the EDIT

key. Others, such as Measurement Name and Eunits fields may have many ASCII

character possibilities. Allowed ASCII characters are as follows:

ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxyz blank space

!"#$%&`()*+,-./0123456789:;<=>?@. EDIT places a cursor over the item and

UP/DOWN scrolls through each allowed entry. The NEXT key moves the cursor to the

next position within a field. When the field is complete, EDIT clears the cursor and

loads it into non-volatile memory where it is retained indefinitely. With no cursor

present, NEXT closes open menus in reverse order and returns the LCD to the most

recent data display.

7

SafeGuard Controller User Manual

MAN-0115 Rev 0

2.2 CHANNEL CONFIGURATION MENUS

Figure 2.1 illustrates the menu tree for configuring Channel variables. These items affect

only the specific channel selected. System specific variables are in the menu tree shown

in section 2.3.

Figure 2.1

8

SafeGuard Controller User Manual

MAN-0115 Rev 0

2.2.1 CHANNEL SETUP ENTRY MENU

The entry menu shown on the left side of Figure 2.1 allows access to all configuration

variables for the selected channel. These are Alarm 1, Alarm 2, Alarm 3, Data

From? Linearize, Configure and Calibrate.

2.2.2 ALARM 1 / ALARM 2 / HORN RELAY SET-UP MENU

Alarms 1 and 2 are identical except A1 may not be acknowledged and front panel LED

indicators are yellow while A2’s are red. Since their configuration menus are the same

only one is shown in Figure 2.2 for clarity.

Figure 2.2

The first entry determines the Setpoint value where the alarm trips. It is entered in

engineering units. For example, if a channel monitors 0-50 ppmH2S and the alarm must

trip at 10 ppm, the correct entry is 10.00.

•Latching determines either manual or automatic alarm reset operation. YES

requires a manual Alarm Reset (see Figure 1) to unlatch the alarm even though an

alarm condition no longer exists. YES also causes this alarm group’s common relay,

front panel LED, and optional discrete relay to latch. NO allows all outputs for this

alarm to automatically reset as soon as the alarm condition clears.

•TRIP ON is set to HIGH for increasing alarms or LOW for decreasing alarms to

determine if the alarm activates upon exceeding or falling below the setpoint.

•The ON DELAY / OFF DELAY entries allow ON and OFF time delays affecting

how long the setpoint must be surpassed before an alarm event transition occurs. ON

delays are limited to 10 seconds while OFF delays may be as long as 120 minutes.

Delays are useful in many applications to prevent nuisance alarms and unwanted

cycling into and out of alarm conditions.

Note: For ON DELAY the alarm is activated after the ‘set time’ is reached. For OFF

DELAY the alarm remains activated for the duration of the ‘set time’, after the alarm

condition has passed.

•The HORN ON entry allows linking this alarm to the common horn relay. NO

causes the alarm to have no effect upon the horn relay. Entering YES causes this

alarm to turn the horn relay on steady, or, to pulse it depending upon horn

configuration in the system menu (see section 2.3.3).

Discrete LED indicators on the front panel indicate the status of each alarm and relay.

Any new alarm event causes the associated LED to flash until Alarm Reset occurs

9

SafeGuard Controller User Manual

MAN-0115 Rev 0

causing an acknowledged steady on condition. Operators should recognize new alarms

by a flashing LED. Alarm Reset also acknowledges, or deactivates, the horn relay until

another new alarm occurs.

All relays are rated at 5 Amp for 28 VDC and 250 ~VAC RESISTIVE loads.

IMPORTANT: Appropriate diode (DC loads) or MOV (AC loads) snubber

devices must be installed with inductive loads to prevent RFI noise spikes. Relay

wiring should be kept separate from low level signal wiring.

2.2.3 ALARM 3 / FAULT ALARM MENU

The discrete channel alarms identified as Alarm 3/Fault may be configured either as a 3rd

level alarm, or, as a Fault alarm indicating the input is out of range in the negative

direction. When used as a level alarm, features such as on / off delays, latching, and trip

direction are also available. It is important to understand that though discrete channel

alarms (LED’s & optional discrete relays) may be set as Alarm 3 level alarms, the

common relay for this group is always a Fault alarm. The fault out of range threshold for

the channel is the most recent Fault trip point entered prior to changing the menu to

Alarm 3. The following example describes how to configure both the Fault out of range

and Alarm 3 level trip points for a channel. Example: If the common Fault relay must

trip as the input falls below negative 10% of full scale, and, the discrete alarms trip as the

input exceeds a level, then the –10% Fault setpoint must be entered first. Toggle the

TYPE menu entry to FAULT and enter –10.00% into the setpoint entry. Next, toggle the

menu back to LEVEL and enter the desired Alarm 3 level setpoint. The -10% Fault

value is retained in memory even though it no longer appears on the menu.

Figure 2.3

2.2.4 DATA FROM? MENU TO SET INPUT SOURCE

Channels may be independently configured to accept input data from the following

sources (also see Figure 2.4):

•An analog input PCB attached to the I2C bus.

•A sensor input PCB may be attached to the I2C bus. This Option Board is

however not used at this time.

•The Modbus RS-485 master port connected to modbus slave devices.

Note: Each Modbus menu selection also requests the RTU # and the Alias

register # location of the data to be retrieved from the RTU. Alias register

!

10

SafeGuard Controller User Manual

MAN-0115 Rev 0

numbers define the location of the variable representing the input value and must

be obtained from the manufacturer of the Modbus RTU device.

EDIT toggles the Data From: entry between Analog, Analog with Local Cal and Modbus

RTU (signed, unsigned & floating point).

Analog Input should be selected when the channel’s input comes from a transmitter or

monitoring device with a calibrated output such as 4-20mA. Sensor Direct is identical to

Analog Input with Local Cal and both activate the SafeGuard Controller’s Cal Mode

features. Problems may arise if calibrations are performed in two places upon the same

signal so Cal Mode menus are only visible when Sensor Direct or Analog Input with

Local Cal is selected. These applications would require the SafeGuard Controller to be

used as the calibration point; when calibration transmitter and sensor configuration at the

SafeGuard Controller, select Analog Input with Local Cal.Note that gas sensors are not

connected directly to the SafeGuard Controller at this time, hence Sensor Direct is not

used.

Figure 2.4

2.2.4a MIN / MAX RAW COUNTS MENUS

The Min Raw and Max Raw counts entries included in Input Data From: menus define

the range of input counts that provide Measurement Range read-out values described in

section 2.2.6b. This menu entry is determined by the A/D converter resolution of the

channel’s input. For example, if the input is a 10 bit Modbus® device with zero at 200

counts and 100% at 1000 counts, then this menu’s MIN should be set at 200 and MAX at

1000. If communicating with the SafeGuard Controller’s optional 12 bit Analog Input

PCB the MIN should be 800 and the MAX 4000.

If the input device’s resolution is unknown, the live counts variable on the bottom of the

screen displays actual raw A/D counts currently being read by this channel. This reading

may be used to test the input device for what A/D counts are provided for zero and 100%

if these values are unknown. Forcing the input device to read zero should provide the

A/D counts value needed to make this channel’s display also read zero. Likewise,

forcing the input device to read 100% should provide the A/D counts value needed to

make the SafeGuard channel’s display also read 100%.

* Direct Gas Sensor inputs

are not used at this time *

* The Wireless Option and features

are not used at this time *

* *

* *

11

SafeGuard Controller User Manual

MAN-0115 Rev 0

If Modbus 32 BIT is selected, a Byte Order entry appears at the bottom of the menu.

This determines WORD and BYTE alignment of data at the remote Modbus transmitter

when sending its 4 byte IEEE Floating Point values. With the pointer on this entry, the

EDIT key toggles between the 4 possible modes. Min / Max Raw values are not used in

this mode.

Note: Each Data From: item has a matching default Min/Max counts value of 20% to

100% with ± 5% over/under range applied. If the default value is incorrect for the input

device it should be edited.

2.2.4b MARKER MENUS

Some transmitters or monitoring devices providing SafeGuard Controller inputs also

indicate special modes of operation, such as Calibration, Maintenance or Fault, by

transmitting a special <4mA or negative “Marker” value. The SafeGuard Controller

offers channel Marker menus for detecting and indicating such events (see Figure 2.5).

While active, the SafeGuard Controller displays a 6-digit ASCII message to indicate the

special event and if equipped with SG10-0167 4-20mA output option, the SafeGuard

Controller also transmits the same <4mA value.

•Marker Enabled turns the marker feature ON and OFF

•The negative Marker value is entered into the Marker % field as a negative percent

of full scale. For example, -15.62% of full scale detects a marker value of 1.5mA

(1.5mA is -15.62% of full scale when 4-20mA is the range).

•It should be noted that for Net Safety Flame Detectors the current output for a

visual integrity fault is 2.0 mA this corresponds to a Marker % of -12.5%. For

Net Safety Gas Sensor Fault Condition, the current output is 2.5 mA which

would correspond to a Marker % of approximately -9.4 %.

•The Mark As menu allows user entry of the 6-digit ASCII message to be displayed

when the marker is detected.

Figure 2.5

2.2.4c SENSOR LIFE DETECTION (- this feature is not used at this time)

Sensor Life should only be activated when the Marker event is Calibration and when a

sensor life value is transmitted after each calibration. For Sensor Life to record properly

the monitor must perform as follows: After the Calibration Marker interval, 4.0mA

transmits for 10 seconds to indicate its calibration mode is complete. The monitor then

transmits between 4.0mA and 5.0mA for five seconds depending on remaining sensor life

where 4.0mA = 0% and 5.0mA = 100% remaining sensor life. The SafeGuard Controller

12

SafeGuard Controller User Manual

MAN-0115 Rev 0

reads this value and records it as the channel’s Sensor Life. Sensor Life is stored in the

SafeGuard Controller’s modbus database and displayed as a bar-graph in the Sensor Info

screen (see section 2.3.6). It is a useful tool for planning sensor replacement schedules.

2.2.5 LINEARIZATION MENU

The linearization menu allows each channel to have its own linearization curve stored in

the SafeGuard Controller’s non-volatile memory. Input versus output points must be

entered in percent of full scale values. This means if the range is 0-200 ppm H2S then

100 ppm is 50% of full scale. Zero input will provide a zero output and 100% input a

100% output. Nine intermediate points may be entered to define the curve.

EDIT

NEXT

Entry menu

Channel XX

Measurement Name

Linearization menu

Cha nne l XX

Linear izat i on

%I n p ut %Out put

10 . 0 0

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

10 . 0 0

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

Al ar m 1

Al ar m 2

Al ar m 3

Dat a Fr o m

Cal i br at e

Li near i ze

Conf igur e

Figure 2.6

2.2.6 CONFIGURE MENU

From the entry level setup menu in Figure 2.7 the CONFIGURE menu may be entered

for setting variables defining how the SafeGuard Controller presents monitored data to

the various graphic displays.

Figure 2.7

2.2.6a EUNITS / MEASUREMENT NAME ASCII DATA FIELDS

The first two items in this menu are for entering the 6 character engineering unit and 16

character Measurement Name ASCII fields. Eunits should define the units of measure for

what this channel is to display. Measurement Name should describe the source of this

data in the user’s terminology. Section 2.1.1 of this manual describes how to use the

front keypad to modify these fields.

Entry menu

Channel XX

Measur ement Name

Al ar m 1

Al ar m 2

Al ar m 3

Dat a Fr om

Cal i br at e

Li near ize

Conf i gur e

EDIT

NEXT

Input / Copy To: menu

Channel XX

CONFIGURATION

Measur ement Name

Euni t s

Zer o

Span

Decimal Points

PCTLEL

0.000

Copy No w?

10 0 . 0

Channel On? 0

YES

Copy To XX

13

SafeGuard Controller User Manual

MAN-0115 Rev 0

2.2.6b INPUT MEASUREMENT RANGE

The ZERO / SPAN entries allow configuration of the measurement range displayed by

the channel. Measurement Range works along with A/D Counts menus, described in

section 2.2.4a, to define the range of the input signal’s engineering units. For example, if

a channel’s input is 4-20mA from a transmitter monitoring 0 to 10ppm H2S, then the

Zero value should equal 0.000 and the Span value equal 10.00. The six ASCII

engineering units previously entered are automatically displayed at the top of each menu

as a reminder. Four digits must appear in this entry so trailing 0’s may appear here that

are not displayed on other data screens.

2.2.6c DECIMAL POINT RESOLUTION

Resolution of displayed channel values is configured in this menu by setting the number

digits trailing the decimal point. Values are limited to a maximum of four digits, and a

polarity sign. An auto-ranging feature displays the highest resolution allowed by this

menu’s decimal point entry. For example, if three decimal points are entered, and the

range is 0 to 100ppm, the reading will be 0.000 at 0ppm and 100.0 at 100ppm. However,

this may be undesirable due to the high resolution at zero unless the detector’s output is

extremely stable. If decimal points are limited to one, the 0ppm reading becomes 0.0 and

the 100ppm reading remains 100.0. Resolution may be limited further by setting decimal

points to 0. In the above example, this would cause 0ppm to display 0and 100ppm to

display 100.

2.2.6d TURNING OFF UNUSED CHANNELS

The Channel On? entry determines if this channel is to be utilized. Turning it off will

cause the SafeGuard Controller to never process inputs applied to this channel and no

alarms will be tripped or data displayed. Inactive channels have a line drawn through

them on the Setup screen as indicated by channels 15 & 16 in Figure 2.0. If less than 9

channels are to be activated, the SafeGuard Controller may be set for 8 channel mode,

deactivating channels 9-16. This is done in the System Setup menu described in section

2.3. The SafeGuard Controller will only allow 15 channels to be turned off. At least one

channel must remain on.

2.2.6e COPY DATA TO?

This menu simplifies the Setup procedure by allowing similar channels to be copied from

one to another. For example, if all channels are identical except for the Measurement

Name entry, channel 1 could be configured and copied to channels 2 – 16. Only

Measurement Name then must be configured on channels 2 – 16. Use EDIT to increment

channel numbers and UP/DN to point to Copy Now? Press EDIT once more to copy.

14

SafeGuard Controller User Manual

MAN-0115 Rev 0

2.2.7 CAL MODE

This SafeGuard Controller feature is only accessible when Sensor Direct or Analog

Input with Local Cal. is selected. The Analog Input with Local Cal.option may be used

if the transmitter and sensor connected to the controller are located in an area not easily

accessible. A calibration tube should be fitted to the sensor and run to an easy access

location where a gas canister is fitted and calibration performed using the calibration

menu. It should be noted that the current output from the SafeGuard Analog Output

Board will be 1.5 mA when the device is in calibration mode.

The CALIBRATION MENU allows entering the correct Cal ZERO & Cal SPAN set-

point values needed to calibrate the sensor. These are entered in the same engineering

units as input range. Set Zero &Set Span controls in this menu allow pushbutton

calibration by moving the pointer to each and pressing the EDIT key. A live reading of

the channel’s value allows calibration checks to see if an adjustment is needed.

Unintentional calibrations are reset by the Unity Gain menu item. Unity Gain resets

zero offset to 0 and span gain to 1. It is useful for returning the calibration to a known

starting place. Sensor aging may be monitored by recording zero and span readings at

Unity Gain when it is new, and again at later dates when degradation may have

occurred.

To check zero calibration, apply the ZERO calibration value to the sensor and observe

the live reading. If the zero reading differs from the zero setpoint, a calibration is needed.

To calibrate zero, move the pointer to Set Zero and press EDIT. A warning message

explains that pressing EDIT again will change the zero calibration and any other key will

exit. The procedure for span calibration is identical. For example, if an LEL combustible

sensor is to be spanned with 50% LEL span gas, the span set-point must be 50%. If 45%

LEL is to be used later, the span set-point must be changed to 45% to match the span

calibration gas. If the reading is only 40% LEL with the 50% gas applied a span

calibration is needed. Move the pointer to the Set Span entry and press EDIT twice.

Unity Gain may be used at anytime to cancel incorrect calibrations and start again. See

Figure 2.8.

Figure 2.8

15

SafeGuard Controller User Manual

MAN-0115 Rev 0

2.3 SYSTEM CONFIGURATION MENUS

Some items needing configuration are not specific to a channel but affect the entire

SafeGuard Controller system. These are located in the system entry menu shown on the

left side of Figure 2.9. System menus are accessed by pointing to the desired item and

pressing EDIT.

Figure 2.9

16

SafeGuard Controller User Manual

MAN-0115 Rev 0

2.3.1 COMMON ALARM RELAYS 1 & 2

READ THIS SECTION CAREFULLY AND TEST ALL SETTINGS BY

SIMULATING INPUT CONDITIONS THAT SHOULD ACTIVATE

THESE ALARM RELAYS!

Common Relay 1 & Common Relay 2 menus are identical and therefore discussed

only once. It is very important to fully understand these menus since they determine the

functions of each common relay.

Figure 2.10

•The Group menu entry offers additional flexibility by controlling which channels

trip this menu’s common alarm relay. The 3 choices are 1-16, 1-8 or 9-16. Some

applications have different types of detectors, or, detectors in different areas

connected to the same SafeGuard Controller. In these cases, it may be undesirable for

a detector on channel 9 to trip the same relay as a detector on channel 2. The Group

menus may restrict this. For example, channels 1-8 might be set to trip common relay

1 while channels 9-16 trip common relay 2. Another possibility is channels 1-8 be set

to trip common relay 1 while channels 9-16 trip relays on an optional discrete relay

PCB configured for Alarm 1 (see section 3.1.2).

•Failsafe controls relay activation for this common relay. Failsafe ON causes the

relay to de-energize during alarm conditions and energize when there is no alarm.

Thereby, a power failure forces the relay contact to the alarm position. Note the

common Fault relay is always failsafe and may be monitored separately to indicate

loss of power conditions in many applications.

•A1 and A2 Votes allows creation of logical AND function equations that control

common relay 1 & common relay 2. Default settings for common relay 1 are A1

Votes = 01 and A2 Votes = 00 which causes relay 1 to trip if any channel has an

A1 level alarm active. Default settings for common relay 2 are A1 Votes = 00 and

A2 Votes = 01 which causes relay 2 to trip if any channel has an A2 level alarm

active. Example: If either default setting is modified such that A1 Votes = 02 and

A2 Votes = 01, then any two channels must have an A1 level alarm active and any

one channel must have an A2 level alarm active to trip that relay. REMEMBER!

One of the A1’s and the A2 could be on the same channel. These level alarms must

come from a channel included in the Group entry described above.

!

17

SafeGuard Controller User Manual

MAN-0115 Rev 0

•Turning Acknowledge ON (not available on Alarm 1) allows the common relay to

be deactivated during alarm conditions by an Alarm Reset. This is useful if an

audible device is being driven by the relay.

All relays are rated at 5 Amp for 28 VDC and 250 ~VAC RESISTIVE loads.

IMPORTANT: Appropriate diode (DC loads) or MOV (AC loads) snubber

devices must be installed with inductive loads to prevent RFI noise spikes. Relay

wiring should be kept separate from low level signal wiring.

2.3.2 SG10-0195 DISCRETE RELAY “FAILSAFE” MODE

SG10-0195 Discrete relay options may also be configured to function in a Failsafe mode

using the System Setup menu shown in Figure 2.11. Entering YES causes these discrete

relays to have energized coils when no alarm condition exists for the associated channel

and de-energized coils when the alarm occurs. Failsafe is useful for indicating failed

relay coils and loss of power conditions. Important: SG10-0195 zoning jumpers (see

Figure 3.4) should not be used when Discrete Relays menus are set for failsafe.

Zoning jumpers cause ANY relay in the zone to energize ALL other relays in the same

zone. Zoning of failsafe relays may be accomplished with wiring at the relay contact

terminals.

Figure 2.11

2.3.3 COMMON HORN RELAY & LOCAL PIEZO

The SafeGuard Controller is equipped with a low decibel audible piezo which chirps

when keys are pressed and may be configured to audibly indicate alarm conditions. The

common horn relay is similar to the common A1 & A2 common relays.

Figure 2.12

!

Table of contents

Other Net Safety Controllers manuals

Popular Controllers manuals by other brands

Skyrc

Skyrc Leopard v2 instruction manual

Riello

Riello 20156553 manual

National Instruments

National Instruments PCI-GPIB installation guide

Johnson Controls

Johnson Controls M100G manual

Anden

Anden A77 Installation & operating instructions

Zenith

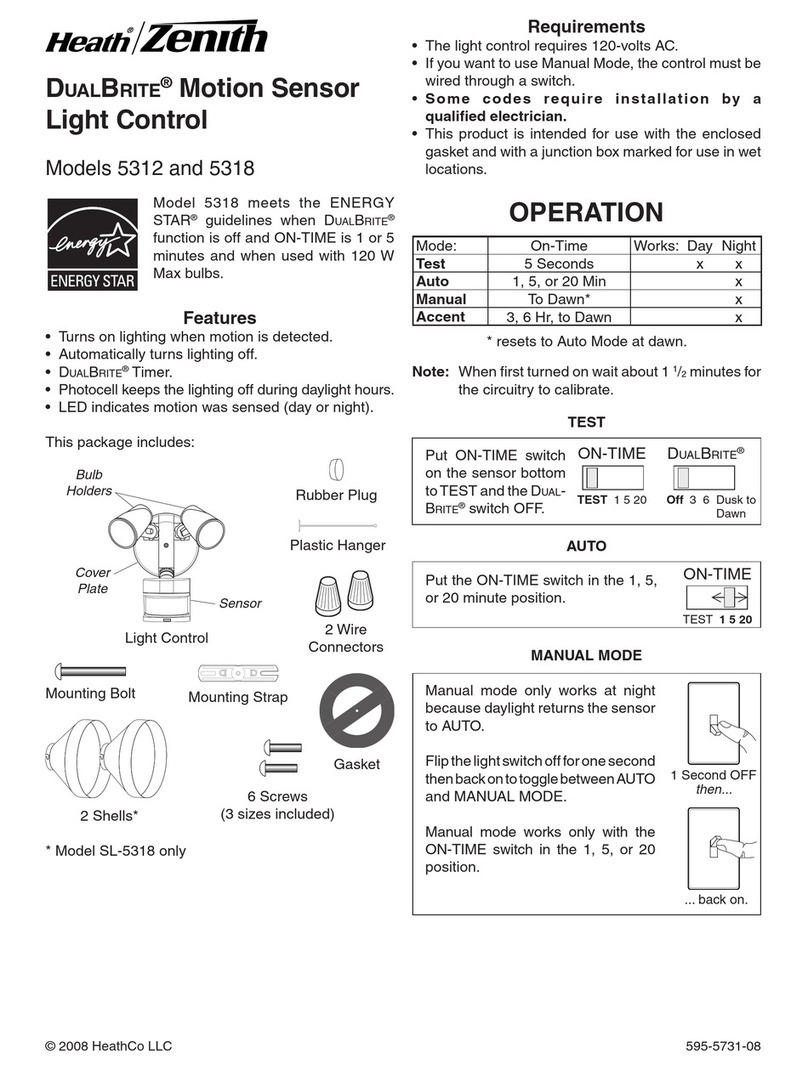

Zenith SL-5318-WH-C - Heath - Motion-Sensing Shielded Wide-Angle Twin Security... user guide