Wieland gesis MSS PAV 3I/W 1,5 User manual

Wieland Electric GmbH

Brennerstraße 10-14

96052 Bamberg

Tel.: +49 (951) 9324-0

Fax: +49 (951) 9324-198

Internet: www.wieland-electric.com

Email: info@wieland-electric.com

gesis MSS PAV 3I/W 1,5 83.235.0009.5

AS-i Motor soft starter

©2010 Wieland Electric GmbH

Doc. # BA000687 - 11/2010 (Rev. B)

A) Important information – please read carefully

This instruction leaflet describes the assembly and connection of the gesis MSS

PAV 3I/W 1,5. Make sure to heed the warnings and adhere to the instructions. Für

commissioning, operation and maintenance please refer to following dokuments:

Operating manual gesis MSS PAV 3I/W 1,5 Doc.-Nr. BA000666

WARNING

•Electric installations, placing devices into operation and maintenance tasks may

only be carried out by qualified electricians with relevant training in accident

prevention and while adhering to applicable regulations.

•Protective measures and mechanisms must correspond

•to applicable regulations.

•Damaged products may neither be installed nor operated.

•The plug connectors may never be connected or removed under load.

•Before opening the device, it must be removed from the mains and the load.

B) Function description

The tree-phase electronic motor starter gesis MSS PAV 3I/W1,5 can be operated

either as direct or as reversing starter with loads up to 1.5 kW. By means of phase

angle control, gesis MSS reduces the switch-on voltage and subsequently increases

it to mains voltage. The starting current is monitored, thus it can be observed

whether the motor is running at nominal speed. In this case, relay contacts bridge

the semiconductor switches to reduce power dissipation. gesis MSS switches three-

phase motor loads and monitors the motor current. gesis MSS is an AS-i slave

which takes its supply voltage directly from the AS-i bus. The device includes an

electronic motor protection which can be parameterized via the AS-i bus. Up to

three sensors with M12 connectors can be connected.

C) Block diagram

ADDR Addressing jack X5 M12, A-coded

X1, X4 RST20i5, black X7, X8 M12, A-coded

UB Sensor Supply 20 ... 30VDC nc not connected

D) Dimensions (specifications in mm)

E) Assembly

NOTE

•The base must be even and capable of supporting the weight.

•For the mounting to the base, only the provided boreholes in the base plate of

the device may be used. Additional boreholes in other locations are not permis-

sible!

Screw the device to the supporting plate with two fastening screws M4. Use

washers.

F) Connection configuration

Three-phase connections

Input X1 (plug, black) Motor output X4 (jack, black)

NOTE

•L1 is bridged to T1 and not switched.

•Phases L2 and L3 are switched by relays/TRIACS as follows:

−clockwise sense of rotation: L2 to T2 and L3 to T3

−counterclockwise sense of rotation: L2 to T3 and L3 to T2

AS-Interface connection X5

Plug X5 Connection Meaning

1 AS-Interface +

3 AS-Interface −

Digital inputs X7, X8 (M12)

Pin Description X7/X8 Note

1 UB 24V sensor supply1

2 IN0/IN2 digital input

3 0V 0V sensor supply1

4 IN0/IN1 digital input

5 not assigned not assigned

12

3

4

5

1The supply UB for the digital inputs on X7 and X8 is

handled by the AS-Interface

NOTE

To be able to ensure compliance with protection type IP 65 all connections not

being used must be fitted with protective caps!

G) Display elements

The status LEDs inform you about the actual state of the motor starter. See also

chapter 8 („Operation“) of the operating manual.

Nr. Color Name Note I/O bit

1 red Error

2 yellow Overload

3 yellow Fault

4 yellow M rev Motor

counterclockwise

5 yellow M fwd Motor clockwise

6 yellow IN2 Input IN2

7 yellow IN1 Input IN1

8 yellow IN0 Input IN0

9 red AS-i Fault

10 green AS-i Power AS-i voltage ok.

The operating condition of the AS-Interface is indicated as follows:

LED „AS-i

power“ (green)

LED „AS-i

fault“ (red)

Meaning

no supply voltage

normal operation

no data exchange (e.g. slave address 0)

• periphery fault (e.g. AS-i supply overload on

initiator inputs)

= off; = on;• = flashing (frequency 2 Hz)

Doc. # BA000687 - 11/2010 (Rev. B)

H) Technical data

Entire device

Input voltage 400 V ±10 % AC 3-phase

Line frequency 50 Hz ±10%

Operating current per phase 4 A

Energy supply connection RST20i5 jack, 5-pole (black)

Device protection external; motor starter is to be secured on

the input side with

20 A conductor protection

Diagnostics "Status" AS-i inputs, motor status

Diagnostics "Error message" Bus error, motor failure, overload, over

current, undercurrent

Motor plug outlet

Output voltage 400 V ±10 % AC 3-phase, 50 Hz ±10%

Nominal power min./max. 0.09 / 1.5 kW

Load current min./max. 0.2 A / 4.0 A

Motor connection with 5-pin (black) RST20i5 plug

Switching component Electronic power switch

Switching frequency Max. 1,000 switches per hr.

(load-dependant)

Switching times Type 10 ms

Operating mode DB (EN 60149-1-1 und 1-3), S3 max.

runtime 10 minutes

Utilisation category AC-3; squirrel cage motors: Starting,

switching off during operation

Overload protection Current monitoring

Isolation Safe separation of load circuit to the AS-i

circuit

Protection criteria Overload function (configuration via

parameter download)

Activation characteristics Class 10 approached (parameterisable)

Conductor and overload

protection

Short circuit withstand capability Not short circuit-proof

Device protection not included in the device

Conductor and short circuit protection

of supply line

20 A

Motor protection Internal

AS Interface

Field bus communication AS-i specification V3.0 profile 7.4

(IO=7; ID=4; ID1=F;ID2=0)

Field bus connection (AS-i) with circular plug-in connector M12

Electronic/control motor switch power

supply

from AS interface 60 mA

Current consumption from AS-i Max. 200 mA

Addressing Address 0 to 31 (A-Slave)

via M12-DC jack 1.3 mm

Digital inputs (via AS-i)

Number 3

Type Two- or three-wire initiators

Supply voltage AS-i 20…30 V DC

Input current Type 5 mA

Input resistance Type 5 kΩ

Power supply current per initiator Max. 40 mA ; if all three Initiators

are connected, the sum is 120 mA

Sampling time Approx. 5 ms

Connector sensors with circular plug-in connector M12

General data

Ambient temperature -20…+40 °C (above 40 °C derating)

Degree of protection IP 65

Relative humidity 10…95 %, no condensation

Operating level ≤1000 m

Chemical composition Halogen-free, LBS-free, RoHS conformed

Mounting Wall installation

Orientation optional, preferably vertical

Error confirmation/reset Automatic error reset via process image

Approval AS-i

Noise immunity meets EN 61800-3

Noise emission meets EN 61800-3 as well as limit value

class A according to EN 55011 and EN

55014

Climate class 3 K3

Type of cooling Self-cooling

I) Ordering information

Accessories

Energy bus cable (jack–plug)

(xx=cable length)

96.453.xx80.1

Motor connection cable (plug–free end)

(xx=cable length)

96.453.xx84.1

AS-i Handheld PPG 1 83.209.2204.1

AS-i programming cable 1.5 m 83.209.2205.0

Appendix: Process image (cyclical data exchange)

Process outputs Function

BIT 3 BIT 2 BIT 1 BIT 0

0 0 0 0 Motor stop

0 0 1 0 Enable clockwise (*) motor stop

0 0 1 1 Motor clockwise

0 1 0 0 Enable counterclockwise (*) Motor

stop

0 1 0 1 Motor counterclockwise

1 0 0 0 Acknowledgement (with start error

and after end „write parameter

string“)

x x x x reserved, motor stop

(*) The direction is enabled without delay (pause on reverse) and thus, a higher

switching frequency is made possible with this function.

In cyclical slave-master mode, the state of three sensor inputs and a „Ready for

operation“ message from the drive were reported according to the binary table of

the AS-i input bits:

Process inputs Function

BIT 0 X7 / „1“=24 V

BIT 1 X8 / „1“=24 V

BIT 2 X8 / „1“=24 V

BIT 3 „1“= starter ready (no starter error)

J) Status LED error diagnostics

Fault

Cause

Error Over-

load

Fault M rev M fwd

Current in right rotation > In

−Motor load too high

−Parameter: wrong motor current value

x x

Current in left rotation > In

−Motor load too high

−Parameter: wrong motor current value

x x

Overload switch-off

−Motor load too high

−Parameter: wrong motor protection

value

x flashes flashes

Motor current undercut or motor current

asymmetry switch-off

−Motor supply line interrupted

−Parameter: wrong minimum current

value

−Parameter: wrong asymmetry value

x x flashes flashes

No rotating field detected

−Wrong phase connection

−Motor not connected

x flashes flashes

Excess temperature switch-off

−Temperature inside housing too high

flashes flashes

Invalid parameter set transmitted

−Valid parameters transmitted to soft

starter

flashes flashes

Spin-up or spin-down time counterclock-

wise

flashes

Spin-up or spin-down time clockwise flashes

Flash error

−No access to flash memory

x x x flashes flashes

This manual suits for next models

1

Other Wieland Controllers manuals

Popular Controllers manuals by other brands

Curtis

Curtis 1232E manual

Hewlett Packard Enterprise

Hewlett Packard Enterprise Aruba 7240-US Product End-of-Life Disassembly Instructions

Fisher

Fisher R622 instruction manual

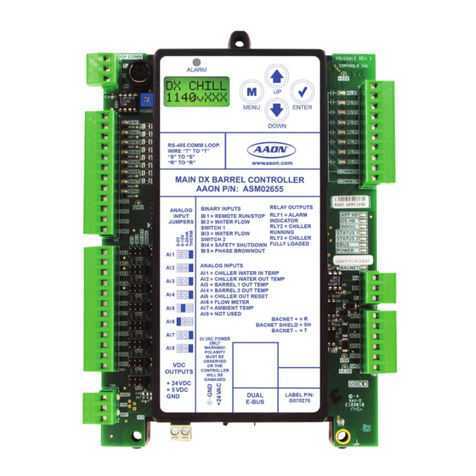

AAON

AAON ASM02655 Technical guide

Panasonic

Panasonic EYFRZ01 operating instructions

Victor

Victor EDGE ESS3 PARTS, SERVICE & REPAIR BULLETIN

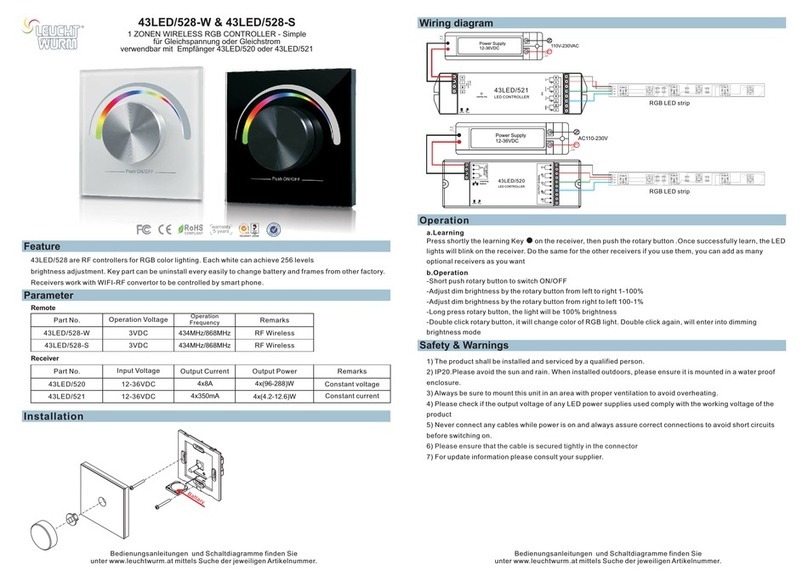

LEUCHTWURM

LEUCHTWURM 43LED/528-W manual

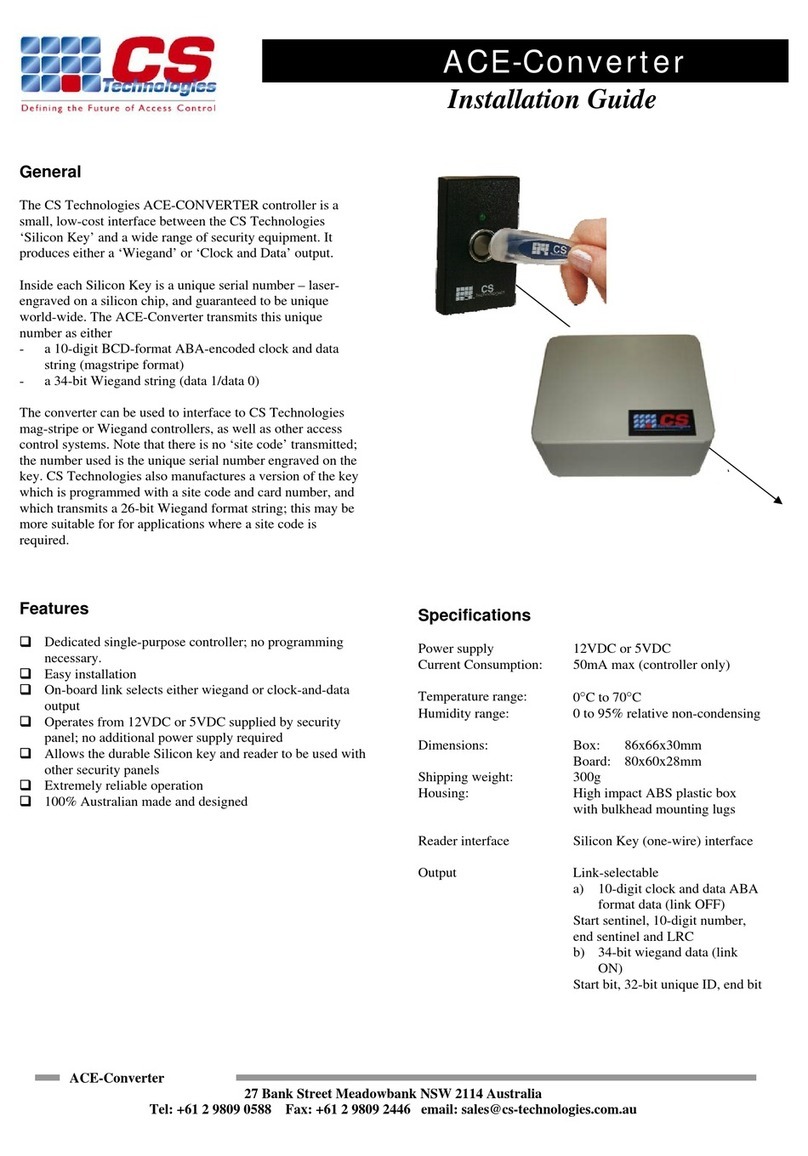

CS Technologies

CS Technologies ACE-CONVERTER installation guide

Sensibo

Sensibo Sky installation manual

Wilo

Wilo CONTROL BOX CE+ WeH Installation and operating instructions

Eaton

Eaton xComfort CSAU-01/01 Instruction leaflet

Kutzner + Weber

Kutzner + Weber H100 installation instructions