Neumo RIEGER N1 Operating instructions

Operating and maintenance manual

HYGIENIC-MIX PROOF VALVES N1 / NV1

Translation

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

Page 2 of 54 2021 BA-N1_NV1_EN-GB_Rev05

Gebr. Rieger GmbH + Co. KG

Kochertalstraße 32

73431 Aalen; Germany

Telephone: + 49 (0) 73 61 / 57 02-0

Telefax: + 49 (0) 73 61 / 57 02-51

http//www.rr-rieger.de

© Gebr. Rieger GmbH + Co. KG | D-73431 Aalen

All rights reserved in particular the right of duplication and distribution as well as translation No

part of the manual may be reproduced in any form or electronically stored, processed, duplicated

or distributed without the written permission of Gebr. Rieger GmbH + Co. KG.

Subject to change

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

BA-N1_NV1_EN-GB_Rev05 2021 Page 3 of 54

Table of content

1 General............................................................................................................................................ 7

1.1 Changes and reservations ....................................................................................................... 7

1.2 Warranty and liability.............................................................................................................. 7

1.3 Scope of delivery ..................................................................................................................... 8

1.4 Documentation........................................................................................................................ 8

1.5 Signs and symbols in this manual............................................................................................ 8

1.5.1 Safety signs...................................................................................................................... 8

1.5.2 Used symbols in this manual........................................................................................... 8

1.6 Name plate .............................................................................................................................. 9

1.7 Personnel qualification............................................................................................................ 9

1.7.1 Personal protective equipment..................................................................................... 10

1.8 The owner‘s duty of care....................................................................................................... 10

1.9 Used abbreviations and technical terms............................................................................... 11

2 Packaging, transport and storage.................................................................................................. 12

2.1 Packaging............................................................................................................................... 12

2.2 Transport............................................................................................................................... 12

2.3 Storage .................................................................................................................................. 12

3 Safety............................................................................................................................................. 13

3.1 Intended use.......................................................................................................................... 13

3.2 Reasonably foreseeable misuse ............................................................................................ 13

3.3 Residual hazards.................................................................................................................... 14

3.3.1 Thermal hazards............................................................................................................ 14

3.3.2 Mechanical hazards....................................................................................................... 14

3.4 Noise...................................................................................................................................... 15

4 Description .................................................................................................................................... 16

4.1 Design.................................................................................................................................... 16

4.2 Identification of the valve ..................................................................................................... 16

4.2.1 Identification by type designation................................................................................. 16

4.2.2 Identification by the article number ............................................................................. 16

4.2.3 Valve type...................................................................................................................... 17

4.2.4 Sterilise and flush .......................................................................................................... 17

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

Page 4 of 54 2021 BA-N1_NV1_EN-GB_Rev05

4.2.5 Casing ............................................................................................................................ 17

4.2.6 Nominal diameter.......................................................................................................... 18

4.2.7 Seal ................................................................................................................................ 19

4.2.8 Material of the casing.................................................................................................... 20

4.2.9 Function of the leakage space....................................................................................... 20

4.2.10 Actuator......................................................................................................................... 20

4.3 Special configurations ........................................................................................................... 22

4.3.1 Suitable for potentially explosive areas acc. to ATEX.................................................... 22

4.3.2 3-A certification............................................................................................................. 23

5 Technical data................................................................................................................................ 24

5.1 Casing configuration.............................................................................................................. 24

5.2 Dimensions and weights........................................................................................................ 24

5.3 Operating data....................................................................................................................... 25

5.3.1 Used Material................................................................................................................ 25

5.3.2 Closing pressure against the product............................................................................ 25

5.3.3 Pipe pressure................................................................................................................. 25

5.3.4 Permissible product temperatures................................................................................ 26

5.3.5 Permissible ambient temperatures............................................................................... 26

5.3.6 Surface quality............................................................................................................... 26

5.4 Technical data of the pneumatic actuator ............................................................................ 26

5.4.1 Connection .................................................................................................................... 26

6 Assembly / Installation.................................................................................................................. 27

6.1 Connection ............................................................................................................................ 27

6.2 Installation position............................................................................................................... 27

6.3 Installing the valve in a pipeline............................................................................................ 28

6.3.1 Welding instructions for the casing............................................................................... 28

6.3.2 Installing the valve parts................................................................................................ 29

6.3.3 Assembly of the sensors................................................................................................ 29

7 Commissioning .............................................................................................................................. 31

7.1 Safety during commissioning ................................................................................................ 31

7.2 Functional test without product in installed condition......................................................... 31

7.3 Commissioning ...................................................................................................................... 31

8 Operation ...................................................................................................................................... 32

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

BA-N1_NV1_EN-GB_Rev05 2021 Page 5 of 54

8.1 Safety during operation......................................................................................................... 32

8.2 During operation ................................................................................................................... 32

8.3 Shutdown of the valve........................................................................................................... 32

9 Maintenance.................................................................................................................................. 33

9.1 Safety during maintenance and repair of the valve.............................................................. 33

9.2 General.................................................................................................................................. 33

9.3 Cleaning................................................................................................................................. 34

9.3.1 Cleaning......................................................................................................................... 34

9.3.2 Cleaning and sterilisation in process............................................................................. 35

9.3.3 Table of cleaning agents................................................................................................ 37

9.4 Maintenance intervals........................................................................................................... 38

9.4.1 Values recommended for seals..................................................................................... 38

9.4.2 Pressure spring guideline values ................................................................................... 39

9.4.3 Necessary torques......................................................................................................... 39

9.4.4 Lubrication plan............................................................................................................. 40

9.5 Spare parts............................................................................................................................. 40

9.6 Parts of the valve................................................................................................................... 41

9.6.1 Explosionszeichnung...................................................................................................... 41

9.6.2 Designation of the parts................................................................................................ 42

9.7 Disassembly........................................................................................................................... 42

9.7.1 Safety during disassembly............................................................................................. 42

9.7.2 Necessary tools (not included in the scope of delivery) ............................................... 42

9.7.3 Disassembling the valve from the casing ...................................................................... 43

9.7.4 Disassembly of the remaining seals for maintenance................................................... 44

9.8 Assembly................................................................................................................................ 45

9.8.1 Safety during assembly.................................................................................................. 45

9.8.2 Necessary tools (not included in the scope of delivery) ............................................... 45

9.8.3 Assembly of the valve parts........................................................................................... 46

9.8.4 After Assembly .............................................................................................................. 48

9.9 Adjusting the stroke at the lower valve seat......................................................................... 49

10 Troubleshooting ........................................................................................................................ 50

10.1 What to do in an emergency?............................................................................................... 50

10.2 Safety during fault rectification............................................................................................. 50

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

Page 6 of 54 2021 BA-N1_NV1_EN-GB_Rev05

10.3 Faults, possible causes and their remedy.............................................................................. 50

11 Disposal ..................................................................................................................................... 52

12 Documentation of the Suppliers ............................................................................................... 53

12.1 Connection and function of the control head....................................................................... 53

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

BA-N1_NV1_EN-GB_Rev05 2021 Page 7 of 54

1General

These operating and maintenance instructions contain important information to assist you

in the safe, economic and proper use of the valve. The operating and maintenance

instructions are also directed to qualified, instructed and trained personnel who are

responsible for installing the valve to an existing system or disassembling it.

In accordance with the Machinery Directive 2006/42/EC, the valve is an incomplete

machine.

Everybody who executes works at or with the valve must have read and understood this

instruction and the safety instructions in it. Also the documents as drawings and additional

documentation must be observed. If instructions, recommendations and notices are not

followed, any possible warranty claim about the valve can be restricted or rejected.

1.1 Changes and reservations

We strive for the accuracy and timeliness of these operating and maintenance instructions.

In order to maintain our technological edge, it may be necessary to make changes to the

product and its operation without prior notice. We accept no liability for faults, failures and

resulting damages.

If applicable, also pay attention to additional information supplied.

1.2 Warranty and liability

In principle the “General sales terms and delivery conditions” of Gebr. Rieger GmbH + Co.

KG apply. These are available at least since conclusion of contract and are available on the

internet page of Gebr. Rieger GmbH + Co. KG in the currently valid version.

The Gebr. Rieger GmbH + Co. KG excludes warranties and liability claims for personal injury

and property damage, if they are caused by one or several of the following causes.

Not intended use.

Incorrect installation, commissioning.

Operation with incorrectly installed or non-functioning safety equipment.

Failure to observe the safety instructions and information in the operating and maintenance

instructions

Repairs or any tampering carried out by persons neither authorised nor trained to do this.

Unauthorised conversions or structural modifications.

Maintenance and repair work carried out incorrectly or not on schedule.

Operating supplies, accessories, spare parts and additives that are the cause of damage and for

which the manufacturer has not granted an approval. The manufacturer accepts no liability for

consequential damage.

Disasters caused by external influence or force majeure

Contamination of the product by malfunctions, e.g. of the actuator. The manufacturer of the

valve accepts no liability –the operator shall take appropriate countermeasures.

INFORMATION

If any unauthorized conversions or structural changes are made to the valve, the

declaration of conformity or the manufacturer's declaration issued will expire. Any other

certificates will also become invalid and be subject to a new evaluation process.

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

Page 8 of 54 2021 BA-N1_NV1_EN-GB_Rev05

1.3 Scope of delivery

The scope of delivery results from the order and the shipping documentation.

1.4 Documentation

The operating and maintenance instructions are an integral part of the product and thus

part of the scope of delivery. One copy of these instructions shall be made available to the

authorised personnel for the entire service life of the valve and be complete and legible. If

the product is resold, the instructions must also be passed on.

In addition to these instructions, the laws, directives, guidelines, regulations and standards

applicable in the country of use and at the place of use must be observed.

1.5 Signs and symbols in this manual

1.5.1 Safety signs

DANGER

Danger by cause!

This is a warning of hazards that could result in serious irreversible injury or even death

or damage to equipment or the environment.

WARNING

Danger by cause!

This is a warning of hazards that could result in irreversible injury and damage to

equipment or the environment.

CAUTION

Danger by cause!

This is a warning of possible hazards that could result in reversible injury and damage to

equipment or the environment:

NOTICE

Danger by cause!

This is a warning of possible hazards that could result in damage to equipment or the

environment.

1.5.2 Used symbols in this manual

Enumeration

Important points are listed here.

Important points are listed here.

Steps for action

Steps for action are described here.1.

Steps for action are described here.2.

Success monitoring

The characteristics of successful success monitoring are listed here.

!

!

!

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

BA-N1_NV1_EN-GB_Rev05 2021 Page 9 of 54

Information

INFORMATION

Helpful information for safe operation of the system is given here.

1.6 Name plate

Every valve has a type plate that enables clear identification and includes the most

important technical data.

Table 1 Name plate

In order to have the data at hand promptly if required, the data on the type plate should be

transferred to the following table:

Designation

Data

Type –Type designation

SN ––serial number –is determined when an

order is placed

month-year/######

ART –item number

Kit 5 –number of the spare parts package

5_______

Required –permitted control pressure

min. __ bar –max. __ bar

Permissible temperature

max. temp. ___ °C / ___ °F

Table 2 Type plate data

In case of any questions, the following information should be provided:

Nominal diameter

Sealing material

Casing material

Connection types (DIN 11851, DIN 11864, welding end etc.)

Accessories of the actuator (e.g. feedback signal)

1.7 Personnel qualification

All activities at the valve may only be carried out by authorised personnel

The authorised personnel must:

Gebr. Rieger GmbH + Co. KG

Kochertalstr.32, 73431 Aalen

SN: XXXXXXXXXX (Serial number)

ART: XXXXXXXXX (Item number)

Kit: 5########

Steuerdruck / Air pressure:

min. 6 bar, max 10 bar

max. temp. 130 °C / 266 °F

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

Page 10 of 54 2021 BA-N1_NV1_EN-GB_Rev05

be at least 18 years old.

be familiar with and able to apply the accident prevention regulations and safety instructions for

the system.

have been trained and instructed on the rules of conduct in the event of a malfunction.

have the physical and mental capacity to assume their responsibility and carry out the tasks and

activities at the system.

must be trained and instructed according to their responsibilities, tasks and activities at the

system

must have understood the technical documentation relating to their responsibilities, tasks and

activities on the valve and the system and be able to implement it in practice.

Notes on handling the valve safely:

Prior to starting work on the valve, make yourself familiar with the system and the field of work.

The valve may only be used for its intended purpose.

Use suitable lifting gear for transporting and mounting heavy accessory parts.

Wear personal protective equipment.

In the event of any defects of the safety equipment or other defects, notify the responsible

personnel without delay.

All identification and markings attached to the valve must be observed.

The valve may only be operated in the specified explosion protection class. This is named and

confirmed in the specified contractual documents.

1.7.1 Personal protective equipment

We recommend that personal protective clothing is worn for all work described in the

instructions. That includes e.g.

Suitable safety shoes

Suitable protective gloves

Suitable hearing protection

Suitable safety glasses

There may also be other national regulations or internal company regulations such as

wearing a protective helmet or a hair net.

1.8 The owner‘s duty of care

The operator of the system with the valve must ensure that,

the valve is only used for its intended purpose.

the valve and the system are only operated in perfect condition. Any malfunctions and defects

must be rectified as soon as they are detected.

the valve is integrated in the system according to the specifications.

the valve is only connected to pipelines, which are depressurized during connection works

tensile or compressive stress to the body must be ruled out.

if necessary, the explosion protection zone was determined in which the valve is used.

the safety instructions in these instructions are incorporated into the risk assessment for the

workplace and the conformity assessment of the system.

all local and national regulations on safety at work and environmental protection are complied

with.

the authorised personnel have been trained in handling the valve and the system.

HYGIENIC-MIX PROOF VALVES N1 / NV1

General

BA-N1_NV1_EN-GB_Rev05 2021 Page 11 of 54

the authorised personnel have understood the documentation and can implement it in practice.

only authorised personnel perform maintenance work and fault rectification

the operating instructions are always available at the valve operation point, in a legible and

complete condition.

necessary personal protective equipment is provided to the personnel.

there is a sufficient lightning is available at the workplace for the valve.

the operating instructions are always available at the valve operation point, in a legible and

complete condition.

that the limit values applicable to the valve are not exceeded.

an emergency stop button is installed on the system for any emergencies that immediately stops

the product feed.

1.9 Used abbreviations and technical terms

ANSI = American National Standards Institute: American institute for standardisation

ATEX = ATEX directives of the European Union: Directives relating to explosion protection.

AWS = American Welding Society: US-American standardisation body for welding technology

CIP = Clean In Place: the system is cleaned at the areas that come into contact with the product

without dismantling it.

DIN = German industrial standard

EHEDG = European Hygienic Engineering and Design Group: European association of companies

from the food industry, research institutes and public health institutions for the definition of

hygiene standards

EN = European standard

L = air supply

SIP = Sterilisation In Place: the system is sterilised at the areas that come into contact with the

product without dismantling it.

HYGIENIC-MIX PROOF VALVES N1 / NV1

Packaging, transport and storage

Page 12 of 54 2021 BA-N1_NV1_EN-GB_Rev05

2Packaging, transport and storage

2.1 Packaging

To ensure sufficient protection during transport the valve was packed carefully. When the

product is received, the packaging and the product should be checked for any damage. A

damaged valve must not be put into operation.

Directly after receiving the delivery: Check that the valve and the individual assemblies /

components are complete according to the shipping documents.

In the event of any transport damage: notify the forwarding company and Gebr. Rieger GmbH +

CO. KG and keep the packaging for a verification or a possible return shipment.

If parts are missing: Inform the manufacturer / supplier about the missing parts in writing.

NOTICE

Risk of damage due to improper use!

Unpack and handle the valve carefully.

2.2 Transport

The valve is normally packed and shipped in a box completely ready for installation. In

chapter 5.2 Dimensions and weights on page 22 the weights of the valve sizes are listed.

Regard the valid national and regional guidelines during transport. When necessary, use

suitable hoists for transporting the valve.

2.3 Storage

The freight packaging of the device and the spare and replacement parts are designed for a

storage period of three months following delivery. In the event of a storage period

exceeding three months: consult Gebr. Rieger GmbH + Co. KG.

If the valve is not installed and put into operation immediately after unpacking it, it must be

protected from moisture and dirt.

The following storage conditions must be complied with in order to maintain perfect quality

and functionality:

Keep the valve in its original packaging or repack it.

Relative humidity: max. 60 %.

Room temperature: + 10 °C to + 25 °C (+ 50 °F to + 77 °F)

Seals shall be stored protected against ozone and direct sunlight.

HYGIENIC-MIX PROOF VALVES N1 / NV1

Safety

BA-N1_NV1_EN-GB_Rev05 2021 Page 13 of 54

3Safety

Read the following safety instructions and information on safe operation before starting

work. Familiarise yourself with all functions. Store these instructions in a safe place and

pass them on as necessary.

In addition to the safety instructions in these instructions, the relevant statutory and

internal regulations, rules and guidelines must also be observed at the installation site.

Any failure to observe the safety instructions and regulations may result in a danger to the

life and health of persons, to the environment and to damage to equipment.

If damage or faults are detected on the valve or the system or if it can be assumed for any

other reasons that safe operation is no longer possible, the valve may no longer be

operated and the system must be shut down. Possible operational malfunctions:

Malfunctions in the control system could result in uncontrolled movements.

The valve is blocked by a part or the system.

The valve or parts of it are blocked.

Possible malfunctions, their causes and possible remedies are shown in chapter 10

Troubleshooting on page 50. They must be applied for rectifying faults.

3.1 Intended use

At the time of placing it on the market the valve corresponds to the state of the art and the

applicable safety regulations, provided it is used as intended.

RIEGER mix proof valves N1 are used for the mix-proof isolation of two lines of the system's

pipeline system. The valves are only for vertical installation.

The valve’s body and sealing materials were selected according to the flow medium and its

properties.

The properties include:

pH value

Viscosity

Chemical properties

Physical properties

Classification of the medium in an explosion protection zone according to the ATEX directive.

The valve is designed for operation with media without solid components. If the medium

contains solid components, e.g. cores, fibres or pieces of fruit, this must be taken into

account in the order and the valve must be selected accordingly. A valve selected for a

medium with defined solid components is not necessarily also suitable for a medium with

larger or different solid components.

The valve may only be operated with the flow medium for which it was selected.

3.2 Reasonably foreseeable misuse

Any unintended use and any activities not described in these instructions represent non-

permissible misuse and are outside the legal liability limits of the manufacturer.

If the valve is used incorrectly, all warranties issued by the manufacturer with the valve will

become invalid.

HYGIENIC-MIX PROOF VALVES N1 / NV1

Safety

Page 14 of 54 2021 BA-N1_NV1_EN-GB_Rev05

Misuse includes:

Use in explosive atmosphere.

Operation of the valve with other data than the agreed technical data.

Operation of the valve in a not authorized installation position.

Operation of the valve for applications for which a certificate is required, unless the valve was

ordered for this application and this is confirmed in the order; in this case the necessary

certificates are also provided.

Operation of the valve with a medium other than the agreed medium. Any change to the solid

components, e.g. size and shape, also represents misuse. To avoid damage to the valve, it is

essential to consult the manufacturer before changing the flow medium to determine whether

the valve can be used for the changed medium.

Operating the valve with products that are chemically unstable or classified as explosives.

Maintenance or repair work not carried out or carried out incorrectly.

3.3 Residual hazards

3.3.1 Thermal hazards

Danger due to hot or cold surfaces!

The surfaces of the actuators and components may be hot or very cold and cause burns.

Wear personal protective equipment.

Allow the valve to cool down or warm up.

If required due to the risk assessment for the system, the operator of the system shall attach a

safeguard against contact or thermal insulation to the system.

3.3.2 Mechanical hazards

Carelessness or negligent use of personal protective equipment may result in crushing

injuries or impact. At the valve there is a risk of unexpected malfunctions due to damage to

its components, a failure or a fault of the control system. So that dangers are recognized in

good time, the operating area must have a sufficient lightning.

Danger due to moving parts!

Reaching the valve spindle could result in serious injuries from crushing or shearing of

limbs.

Do not reach into the valve body or lock head during operation.

If required due to the risk assessment for the system, the owner of the system shall attach a

safeguard against reaching into the valve to the system

Observe the follow-up time: if the valve needs to be opened for maintenance, it must be

ensured that no components are moving any more.

Prior to all works at movable parts of the system:

1. Turn off the system.

2. Secure the system against recommissioning.

3. Wait until all parts have stopped.

Danger due to pre-tensioned compression springs

Actuators with pre-tensioned compression springs are under pressure. They may only be

disassembled by experienced and trained personnel. Send the actuator to the manufacturer

for maintenance.

HYGIENIC-MIX PROOF VALVES N1 / NV1

Safety

BA-N1_NV1_EN-GB_Rev05 2021 Page 15 of 54

Danger due to unprotected valve mechanisms

Unprotected valve mechanisms can pose shearing, crushing and pinching hazards during

installation, commissioning and setting work.

No second person is permitted in the danger zone during these activities.

Covers may only be opened or removed for the duration of maintenance and repair work.

During operation, they must be closed or mounted again correctly

Keep hands, hair, clothing and tools away from moving parts.

Do not wear open hair, wide clothes and jewels (chains, rings) during works at the valve.

Danger due to pneumatics and steam

When working on pressurised lines or components, pressurised media could be released

abruptly. That can result in uncontrolled movements of components and injuries.

Depressurise system sections or pressure lines to be opened prior to repair work.

Work on pressure pipes may only be carried out by qualified personnel.

Danger due to oil, grease and other chemical substances

Handling oil, grease and other chemical substances can result in damage to health.

Do not fail to read the safety data sheet / operating instructions before handling oil, grease and

other chemical substances. If anything is unclear concerning the application, consult the

manufacturer of the product.

Wear suitable personal protective equipment in accordance with the safety data sheet.

In the event of accidents take immediate action according to the safety data sheet.

Substances that are hazardous to the environment can pollute the soil or groundwater.

Retain, bind and correctly dispose of substances hazardous to water. The medium is possibly

also hazardous to the environment.

Leaks at valve parts where substances hazardous to water escape must be immediately repaired

and re-sealed.

Document maintenance work and system modifications at units hazardous to water in a plant

register.

3.4 Noise

No modifications to the valve are permitted that could increase noise emissions.

If required, take suitable noise reduction measures.

Wear hearing protection if required.

The valve's sound emission level is ≤70 dB(A).

HYGIENIC-MIX PROOF VALVES N1 / NV1

Description

Page 16 of 54 2021 BA-N1_NV1_EN-GB_Rev05

4Description

RIEGER mix proof valves N1 are used for the mix-proof isolation of two lines of the system's

pipeline system.

In this manual N1 is used also for NV1 valves.

They are developed, designed and built for commercial and industrial use. The leakage

drain is placed, so that this valve is suitable for vertical installation. Aggressive, neutral and

fluid media that do not impair the physical and chemical properties of the respective

housing and seal materials are suitable for use as flow media. These mix proof valves have a

pneumatic actuator with return spring. In case of loss of power or pressurised air the valve

closes.

4.1 Design

Depending on the application various casing and versions as well as versions with control

head and initiator retrieval are possible. The delivered version can be taken from the order

papers and from the name plate.

The parts of the valve are listed in 9.6 Parts of the valve on page 41.

4.2 Identification of the valve

4.2.1 Identification by type designation

The valve can be identified by its type designation. The type designation is a combination of

Type designationFigure 1

4.2.2 Identification by the article number

The valve may also be identified by the article number.

Example:

Valve type

Sterilization

N1.

0

1.

Arrangement of the outlets

-04

Nominal diameter

001

Ratio of nominal diameters

HYGIENIC-MIX PROOF VALVES N1 / NV1

Description

BA-N1_NV1_EN-GB_Rev05 2021 Page 17 of 54

Example item numberFigure 2

4.2.3 Valve type

The combination „N1“ in the type designation defines the valve as a mix proof valve N1.

In the article numbers the sequence of numbers „301“ defines the valve as a mix proof

valve N1.

4.2.4 Sterilise and flush

N1.XX.XXX-XX: In the type designation, the number can be used to indicate whether the

valve can be sterilised or not:

Number

Meaning

0

No

2

Yes

Table 3 Indication of the sterilisation in the type designation

301XX.XXXX.XX.XXXX.XX: In the article number the number combination can be used to

indicate whether the valve can be sterilised or not.

Number

Meaning

00

clocking without leakage

01

flushable without lifting

02

lower valve disc can be steam stream sterilised

03

sterilisation via flushing chamber

07

NV1, without sump

08

NV1, flushable without clocking

Table 4 Indication of the sterilisation in the item number

4.2.5 Casing

Casing configuration

301XX.XXXX.XX.XXXX.XX

Valve type

Clocking

301

10

.0

Parts of the casing

00

.01

.0404

.32

Outlets

Material of the seal

nominal diameter

Material of the casing

0

Special versions

HYGIENIC-MIX PROOF VALVES N1 / NV1

Description

Page 18 of 54 2021 BA-N1_NV1_EN-GB_Rev05

Number

Meaning

1

Casing one part = without clamp

2

Casing two parts = without clamp

3

Casing three parts = without clamp

Table 5 Definition of the casings in the item number

Arrangement of the outlets

Type designation: N1.XX.XXX-XX

Item number: 301XX.XXXX.XX.XXXX.XX

Type designation

Item number

Type designation

Item number

Type designation

Item number

Type designation

Item number

Type designation

Item number

N1.01

10

N1.02

20

N1.03

30

N1.04

40

N1.05

50

Table 6 Arrangement of the outlets

On demand there are casing configurations with other arrangements of outlets possible.

4.2.6 Nominal diameter

Ratio of nominal diameters of the outlets

N1.XX.XXX-XX

In the type designation, a three-digit number combination indicates whether the outlets

are the same size or the upper outlet is larger or smaller.

Number combination

Meaning

001

All outlets are the same size.

150

Reduced nominal width; upper side larger

200

Reduced nominal width; upper side smaller

Table 7 Ratio of nominal diameters in the type designation

A

E

A

E

A

B

C

A

B

D

D

C

A

A

B

C

A

B

D

A

C

A

HYGIENIC-MIX PROOF VALVES N1 / NV1

Description

BA-N1_NV1_EN-GB_Rev05 2021 Page 19 of 54

Nominal diameter

N1.XX.XXX-XX: In the type designations a two-digit number combination indicates, which

size the nominal diameters are. If the upper and lower nominal diameters differ, both

nominal diameters are written, separated by a slash „/“.

301XX.XXXX.XX.XXXX.XX: In the item number a four-digit number combination indicates,

which size the nominal diameters are.

Numbers

Meaning

Numbers

Meaning

Numbers

Meaning

DIN

Inch

ISO

0

1

DN 10

2

1

3/8"

4

1

DN 10 ISO

0

2

DN 15

2

2

1/2"

4

2

DN 15 ISO

0

3

DN 20

2

3

3/4"

4

3

DN 20 ISO

0

4

DN 25

2

4

1"

4

4

DN 25 ISO

0

5

DN 32

2

6

1 1/2"

4

5

DN 32 ISO

0

6

DN 40

2

7

2"

4

6

DN 40 ISO

0

7

DN 50

2

8

2 1/2"

4

7

DN 50 ISO

0

8

DN 65

2

9

3"

4

8

DN 65 ISO

0

9

DN 80

3

0

4"

4

9

DN 80 ISO

1

0

DN 100

3

2

6"

5

0

DN 100 ISO

1

1

DN 125

5

1

DN 125 ISO

1

2

DN 150

5

2

DN 150 ISO

Table 8 Nominal diameter of the pipe connections

4.2.7 Seal

The valve is sealed by O-rings.

301XX.XXXX.XX.XXXX.XX

These can be made of EPDM or FKM.

Number

combination

Meaning

01

EPDM

03

FKM

Table 9 Material of the seal - Number in the article number

HYGIENIC-MIX PROOF VALVES N1 / NV1

Description

Page 20 of 54 2021 BA-N1_NV1_EN-GB_Rev05

4.2.8 Material of the casing

Depending on the medium and the application the material of the casing is chosen. In the

article number this is defined by the last two numbers. The most used materials are:

10: 1.4301 = AISI 304, polished

11: 1.4301 = AISI 304 fine turned

20: 1.4301 = AISI 304, matt

30: 1.4404 polished

31: 1.4404 fine turned

32: 1.4404/1.4435 = 316L

33: 1.4404/1.4435 = 316L –0.6 µm and electro polished

4.2.9 Function of the leakage space

In case of a closed valve the leakage space is opened. So it is ensured, that if one of the two O-

rings is defective, the leakage is drained pressureless through the channels in the lower valve

disc. This is shown in figure 3. The liquid drops on the surface below the valve and can be

recognised during the daily inspection. In case of a leakage the valve must be maintained and

the seals with contact with the product must be changed; see 9.4 Maintenance intervals on page

37

Lower valve disc and leakage space with outletFigure 3

Before the valve opens, the lower valve plate is raised and the leakage space is closed. Then

both valve discs are lifted and the valve opens into the upper valve casing.

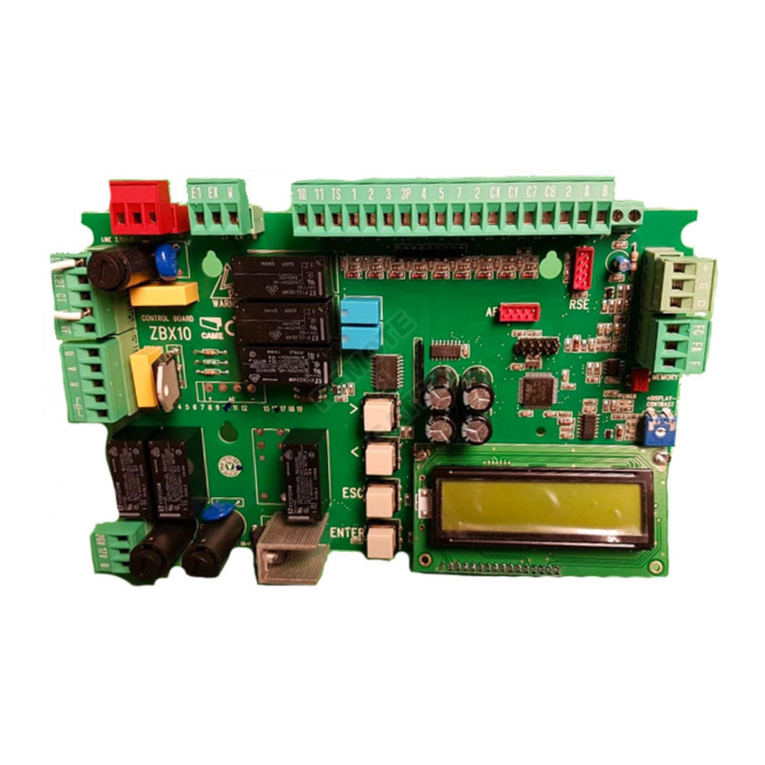

4.2.10 Actuator

The actuator is air opening / spring closing NC. There are three air connections at the

actuator. In Figure 4 they are described with L1, L2, and L3. They have different tasks.

This manual suits for next models

1

Table of contents