Contents

1 General information .................................................. 4

1.1 Information .......................................................... 4

1.2 Symbols used ...................................................... 4

1.3 Definition of terms .............................................. 4

1.4 Warning notes ..................................................... 4

2 Safety information .................................................... 5

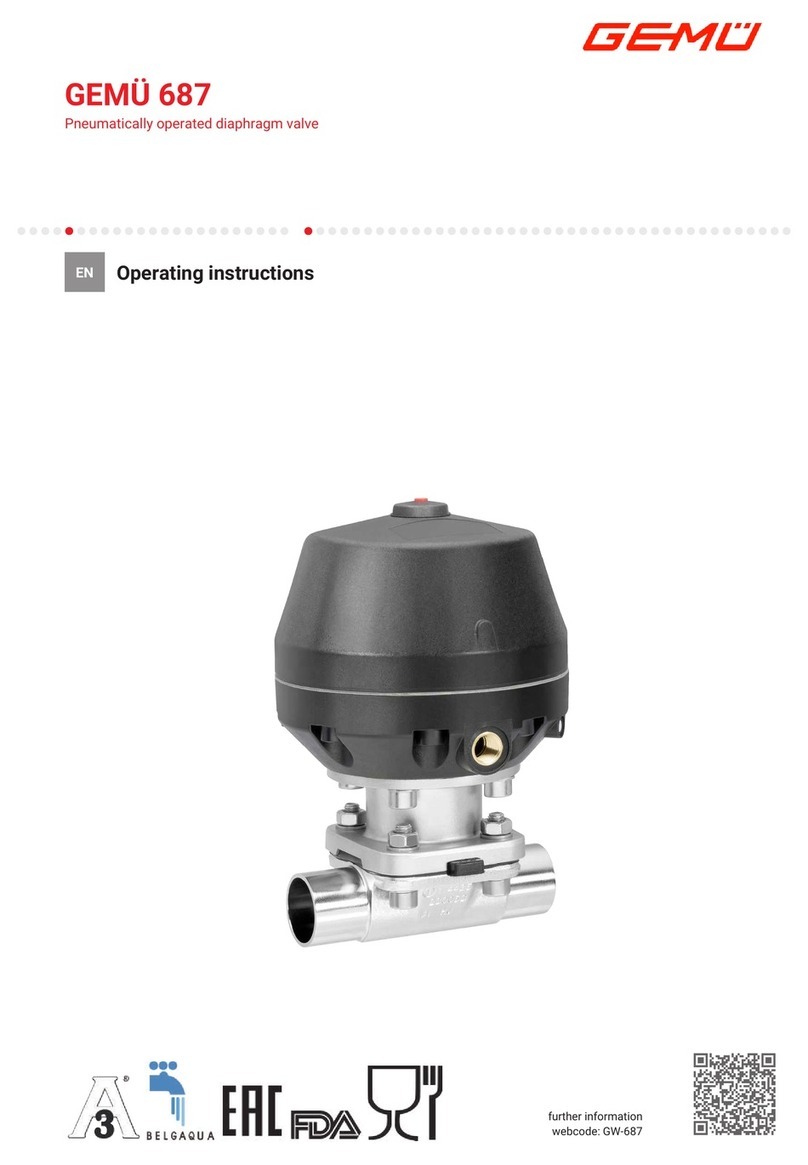

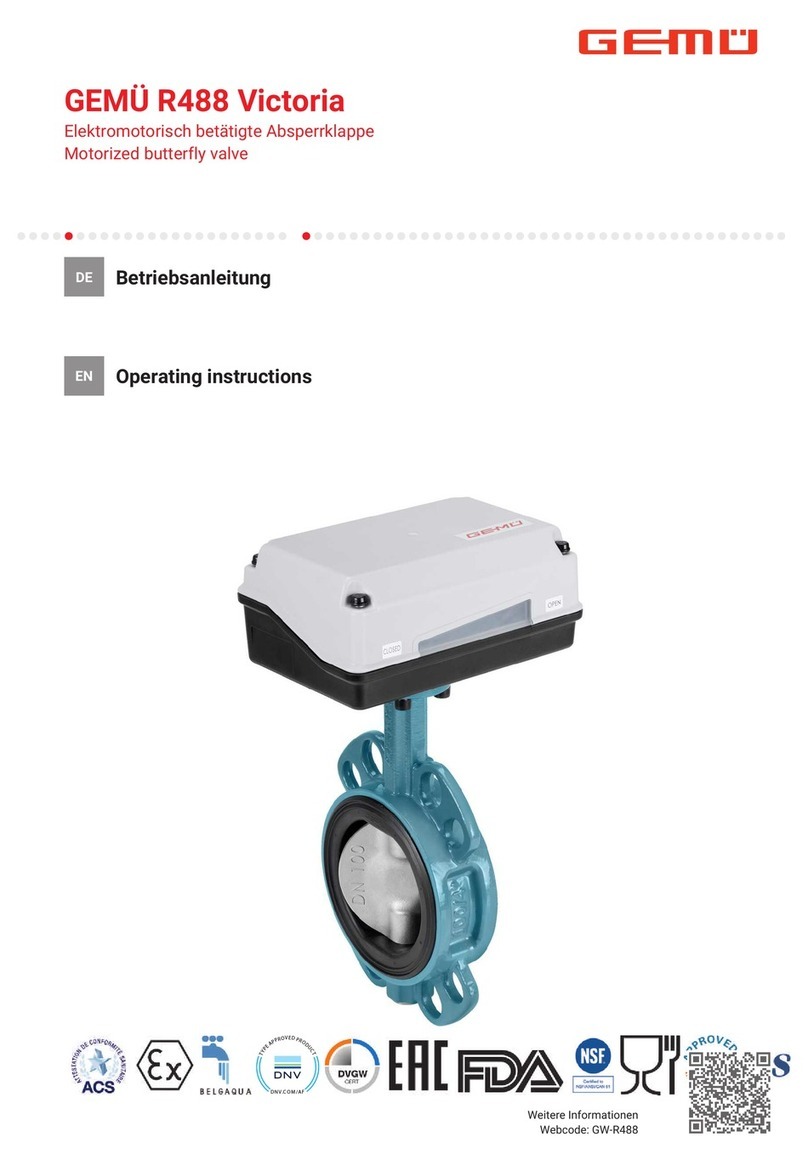

3 Product description ................................................... 5

3.1 Construction ........................................................ 5

3.2 Pressure-relief hole ............................................. 5

3.3 Control ball .......................................................... 6

3.4 Description ........................................................... 6

3.5 Function ............................................................... 6

4 GEMÜ CONEXO ......................................................... 6

5 Correct use ............................................................... 7

6 Order data ................................................................. 8

6.1 Ball valve with GEMÜ 9428, 9468 actuator ........ 8

6.2 Ball valve with J+J actuator ............................... 10

6.3 Ball valve with Bernard actuator ......................... 12

7 Ball valve technical data ............................................ 14

7.1 Medium ................................................................ 14

7.2 Temperature ........................................................ 14

7.3 Pressure ............................................................... 14

7.4 Product conformity ............................................. 16

7.5 Mechanical data .................................................. 17

8 Technical data of actuator ......................................... 18

8.1 GEMÜ 9428, 9468 actuators ............................... 18

8.2 Bernard, J+J actuators ....................................... 19

9 Dimensions ............................................................... 20

10 Manufacturer's information ....................................... 28

10.1 Delivery ................................................................ 28

10.2 Packaging ............................................................ 28

10.3 Transport ............................................................. 28

10.4 Storage ................................................................. 28

11 Installation in piping .................................................. 28

11.1 Preparing for installation .................................... 28

11.2 Installation with butt weld spigots ..................... 29

11.3 Installation with threaded connections ............. 30

11.4 Installation with flanged connections ................ 31

11.5 After the installation ............................................ 31

12 Electrical connection ................................................. 32

12.1 Connection and wiring diagram – actuator ver-

sion 1015, 2015 ................................................... 32

12.2 Connection and wiring diagram – actuator ver-

sion 2070, 4100, 4200 ......................................... 33

13 Limit switches ........................................................... 39

13.1 Setting the limit switch for 1015, 2015 and

3035 ..................................................................... 39

13.2 Setting the limit switch for 2070, 4100, 4200 .... 40

14 Commissioning ......................................................... 40

15 Operation .................................................................. 41

15.1 Normal operation ................................................ 41

15.2 Optical position indicator .................................... 41

15.3 Manual override ................................................... 41

16 Troubleshooting ........................................................ 43

17 Inspection/maintenance ............................................ 44

17.1 General information regarding actuator re-

placement ............................................................ 44

17.2 Spare parts .......................................................... 48

18 Removal from piping ................................................. 50

19 Disposal .................................................................... 50

20 Returns ..................................................................... 50

21 Declaration of Incorporation according to 2006/42/

EC (Machinery Directive) ........................................... 51

22 Declaration of conformity according to 2014/30/EU

(EMC Directive) ......................................................... 52

GEMÜ B52www.gemu-group.com 3 / 53