NEW BRUNSWICK SCIENTIFIC BioFlo 415 User manual

BioFlo 415

Benchtop SIP

Fermentor

MANUAL NO: M1360-0050

Revision D

December 15, 2008

NEW BRUNSWICK SCIENTIFIC

BOX 4005 •44 TALMADGE ROAD •EDISON, NJ 08818-4005

Telephone: 1-732-287-1200 •1-800-631-5417

ii

BioFlo 415 •M1360-0050 User’s Guide

INTERNATIONAL OFFICES:

BELGIUM

New Brunswick Scientific NV-SA

Stationsstraat 180/4

3110 Rotselaar

België/Belgique

Tel: 32 (0)16 56 28 31

Fax: 32 (0)16 57 27 53

GERMANY

New Brunswick Scientific GmbH

In Der Au 14

D-72622 Nürtingen

Deutschland

Tel: 49 (0)7022 932490

Fax: 49 (0)7022 32486

CHINA

New Brunswick Scientific Co., Inc.

A903, 904 Yin Hai Building

No. 250, Cao Xi Road

Shanghai 200235, P.R. China

Tel: 86 21 6484 5955 or 5966

Fax: 86 21 6484 5933

THE NETHERLANDS

New Brunswick Scientific BV

Kerkenbos 1101, 6546 BC Nijmegen

P.O Box 6826, 6503 GH Nijmegen

Nederland

Tel: 31 (0)24 3717 600

Fax: 31 (0)24 3717 640

FRANCE

New Brunswick Scientific SARL

12-14, Rond Point des Champs Elysées

75008 Paris

France

Tel: 33 (0)1 5353 1511

Fax: 33 (0)1 5353 1557

UNITED KINGDOM

New Brunswick Scientific (UK) Ltd.

17 Alban Park

St. Albans, Herts. AL4 0JJ

United Kingdom

Tel: 44 (0)1727 853855 or 0800 581331

Fax: 44 (0)1727 835666

Web: www.nbsuk.co.uk

iii

New Brunswick Scientific User’s Guide

WARNING!

This product is not designed to contain gases within the range of their

lower explosion limit (LEL) and their upper explosion limit (UEL).

If your process requires or produces gases, be sure to verify their LEL

and UEL concentration range (available online).

CAUTION!

This equipment must be operated as described in this manual.

If operational guidelines are not followed, equipment damage and personal

injury can occur. Please read the entire User’s Guide before attempting to use

this unit.

Do not use this equipment in a hazardous atmosphere or with hazardous

materials for which the equipment was not designed.

New Brunswick Scientific (NBS) is not responsible for any damage to this

equipment that may result from the use of an accessory not manufactured by

NBS.

WARNING!

High voltage.

Always make sure this equipment is properly grounded.

iv

BioFlo 415 •M1360-0050 User’s Guide

Copyright Notice

New Brunswick Scientific

Box 4005 44 Talmadge Road

Edison, New Jersey 08818-4005

©Copyright 2008 New Brunswick Scientific

All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission from

New Brunswick Scientific is prohibited.

Disclaimer Notice

New Brunswick Scientific reserves the right to change information in this

document without notice. Updates to information in this document reflect our

commitment to continuing product development and improvement.

Manual Conventions

#NOTE:

Notes contain essential information that deserves

special attention.

CAUTION!

Caution messages appear before procedures which, if

caution is not observed, could result in damage to the

equipment.

WARNING!

Warning messages alert you to specific procedures or

practices which, if not followed correctly, could result in

serious personal injury.

Bold Text in boldface type emphasizes key words or

phrases.

This particular Warning message, whether found in the

manual or on the unit, means HOT SURFACE–and

therefore represents a potential danger to touch.

CRUSH WARNING!

Crush Warning messages alert you to specific

procedures or practices regarding heavy objects which,

if not followed correctly, could result in serious personal

injury .

v

New Brunswick Scientific User’s Guide

Every instrument manufactured by New Brunswick Scientific

is warranted to be free from defects in material and workmanship.

This apparatus with the exception of glassware, lamps and

electrodes (where supplied), is warranted for 1 year against faulty

components and assembly and our obligation under this warranty

is limited to repairing or replacing the instrument or part thereof,

which shall, within 1 year after date of shipment, prove to be

defective after our examination. This warranty does not extend

to any NBS products which have been subjected to misuse, neglect,

accident or improper installation or application; nor shall it extend

to products which have been repaired or altered outside the

NBS factory without prior authorization from

New Brunswick Scientific.

W A R R A N T Y

vi

BioFlo 415 •M1360-0050 User’s Guide

FERMENTOR/BIOREACTOR

INFORMATION SHEET

On this page, record the information for your fermentor/bioreactor and retain this for

future reference.

MODEL NUMBER: ________________________________

VOLTAGE: ________________________________

SERIAL NUMBER: ________________________________

The above information can be found on the electrical specification plate.

Purchased with the following installed options:

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

vii

New Brunswick Scientific User’s Guide

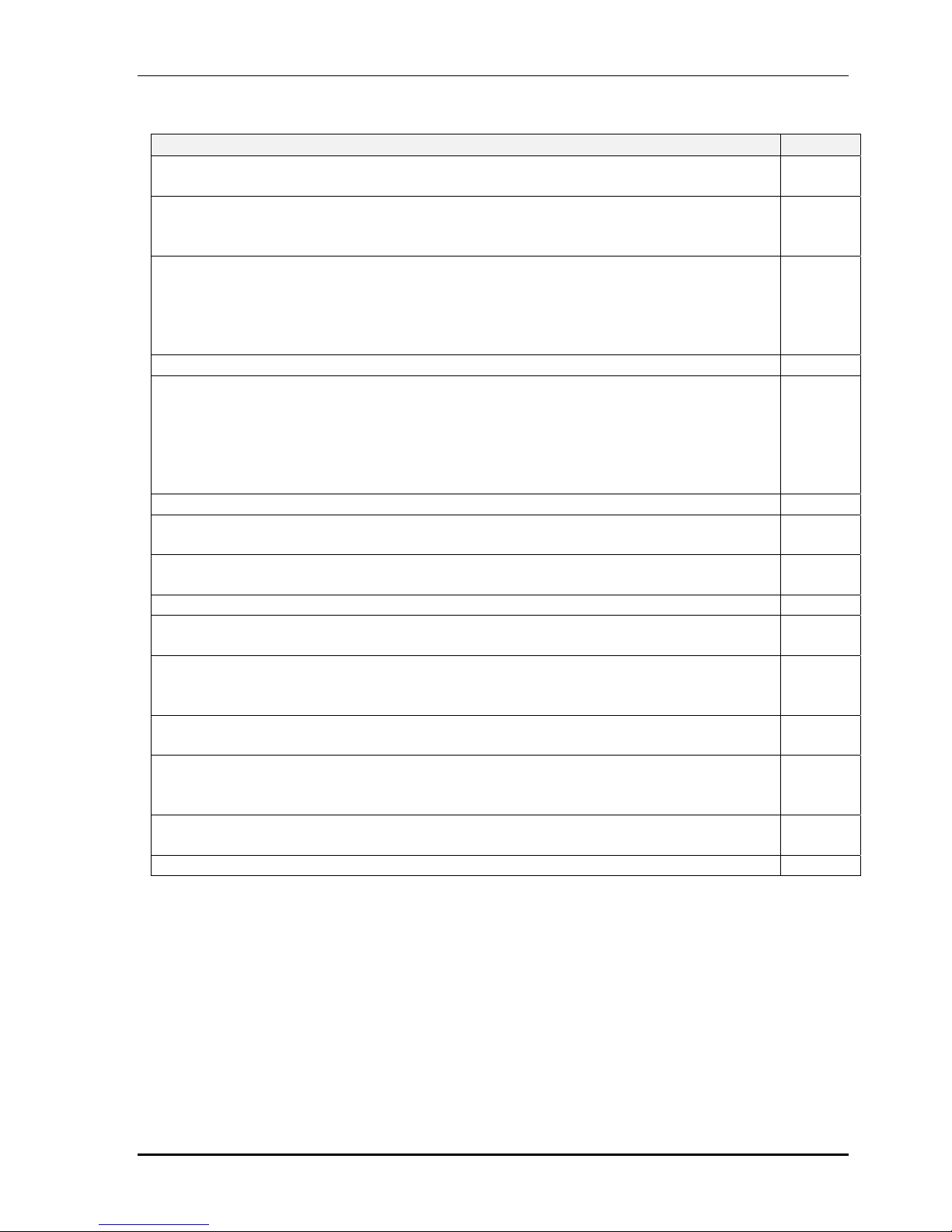

TABLE OF CONTENTS

1WARNINGS & CAUTIONS ........................................................................................................................ 1

1.1 WARNINGS .............................................................................................................. 1

1.2 CAUTIONS................................................................................................................ 1

2INSPECTION & UNPACKING OF EQUIPMENT ..................................................................................... 3

2.1 INSPECTION OF BOX(ES).............................................................................................. 3

2.2 PACKING LIST VERIFICATION...................................................................................... 3

2.3 BASIC COMPONENTS ................................................................................................... 3

3INTRODUCTION & OVERVIEW............................................................................................................... 4

3.1 SYSTEM ....................................................................................................................... 4

3.2 VESSELS ...................................................................................................................... 4

3.3 AGITATION SYSTEM .................................................................................................... 4

3.4 TEMPERATURE CONTROL ............................................................................................ 5

3.5 AERATION ................................................................................................................... 5

3.6 PHCONTROL ............................................................................................................... 5

3.7 DO CONTROL.............................................................................................................. 6

3.8 HIGH FOAM CONTROL................................................................................................. 6

3.9 EXHAUST SYSTEM ....................................................................................................... 6

3.10 SAMPLING/HARVESTING SYSTEM................................................................................ 6

3.11 RECOMMENDED ACCESSORIES &SUPPLIES................................................................. 7

3.12 SUPERVISORY SOFTWARE ........................................................................................... 7

4INSTALLATION .......................................................................................................................................... 8

4.1 PHYSICAL LOCATION .................................................................................................. 8

4.2 ENVIRONMENT ............................................................................................................ 8

4.3 INSTALLING THE CONTROL CABINET........................................................................... 8

4.4 INSTALLING THE TOUCHSCREEN.................................................................................. 8

4.5 UTILITIES .................................................................................................................. 10

4.5.1 Electrical Requirements...................................................................................11

4.5.2 Water and Drain Connections..........................................................................12

4.5.3 Gas Connections ..............................................................................................12

4.5.4 Exhaust Connection..........................................................................................12

4.6 VESSEL ASSEMBLY ................................................................................................... 13

4.6.1 Sparge & Exhaust Assemblies..........................................................................15

4.6.2 Other Ports & Plugs.........................................................................................17

4.6.3 Insert Probes .................................................................................................... 17

4.6.4 Install Motor Assembly.....................................................................................18

4.6.5 Connecting Vessel to Cabinet ..........................................................................18

4.7 ELECTRICAL CONNECTIONS ...................................................................................... 21

4.8 MAIN POWER SWITCH ............................................................................................... 21

4.9 OPTIONAL BIOCOMMAND PLUS ................................................................................ 22

4.10 INPUTS/OUTPUTS FOR ANCILLARY DEVICES ............................................................. 22

5SPECIFICATIONS ..................................................................................................................................... 24

viii

BioFlo 415 •M1360-0050 User’s Guide

5.1 CERTIFICATIONS........................................................................................................ 25

6OPERATING CONTROLS......................................................................................................................... 27

6.1 TOUCHSCREEN .......................................................................................................... 27

6.2 DISPLAY SCREENS..................................................................................................... 27

6.2.1 Touchscreen Calibration..................................................................................27

6.2.2 Start-Up Screen................................................................................................28

6.2.3 Summary Screen...............................................................................................28

6.2.4 Synoptic Screen ................................................................................................30

6.2.5 Gauge Screens..................................................................................................31

6.2.6 Adding Loops....................................................................................................32

6.2.7 Deleting Loops .................................................................................................33

6.2.8 Selecting Loop Control Modes.........................................................................34

6.2.9 Calibration Screen ...........................................................................................34

6.2.10 Cascade Screen ................................................................................................35

6.2.11 Trend Screen ....................................................................................................35

6.2.12 Pump Screen.....................................................................................................36

6.2.13 Alarm Summary Screen....................................................................................36

6.2.14 Sterilization Screen ..........................................................................................37

6.2.15 Setup Screen.....................................................................................................38

6.3 RS232/422 COMPUTER INTERFACE........................................................................... 39

7PROBE PREPARATION & CALIBRATION............................................................................................ 42

7.1 PHPROBE INSPECTION .............................................................................................. 42

7.2 PHPROBE CALIBRATION ........................................................................................... 42

7.2.1 pH Probe Installation.......................................................................................44

7.2.2 pH Probe Maintenance & Storage...................................................................45

7.3 DISSOLVED OXYGEN (DO) PROBE PREPARATION ..................................................... 45

7.3.1 Inspecting the DO Probe..................................................................................45

7.3.2 DO Probe Preparation.....................................................................................46

7.3.3 DO Probe Installation......................................................................................46

7.3.4 DO Probe Polarization ....................................................................................47

7.3.5 DO Probe Calibration: Setting Zero...............................................................47

7.3.6 DO Probe Calibration: Setting Span..............................................................48

8AUTOMATIC STERILIZATION............................................................................................................... 49

8.1 ESSENTIAL: BACKFLOW PREVENTION KIT............................................................ 49

8.2 STERILIZATION .......................................................................................................... 51

8.2.1 Priming the Water Jacket.................................................................................52

8.2.2 Sterilization Safety Features ............................................................................53

8.2.3 Starting a Sterilization Sequence .....................................................................53

8.2.4 Resetting Sterilization Parameters...................................................................55

8.3 VALVE SEQUENCING ................................................................................................. 56

8.4 STERILIZATION PHASE INDICATION ........................................................................... 58

8.5 ABORTING STERILIZATION ........................................................................................ 58

9PREPARING FOR FERMENTATION ......................................................................................................59

9.1 SYSTEMS CHECK ....................................................................................................... 59

ix

New Brunswick Scientific User’s Guide

9.2 ADDING MEDIA TO THE VESSEL ................................................................................ 60

10 GETTING STARTED................................................................................................................................. 61

10.1 CONTROL MODES...................................................................................................... 61

10.2 PUMP ASSIGNMENT ................................................................................................... 61

10.3 SETTING P&IVALUES ............................................................................................. 62

10.4 LOOP SETPOINTS ....................................................................................................... 62

10.4.1 Entering Setpoints............................................................................................62

10.4.2 Modifying Setpoints..........................................................................................63

10.5 DO CASCADE SYSTEM .............................................................................................. 63

10.6 USING LEVEL PROBES TO PROGRAM FEED PUMPS .................................................... 64

10.6.1 Setting a Feed Pump to Add Liquid .................................................................64

10.6.2 Setting a Feed Pump to Harvest.......................................................................64

10.6.3 Level Control Off..............................................................................................65

10.6.4 Pump Calibration.............................................................................................65

10.6.5 Exhaust Heater.................................................................................................66

11 CASCADE CONTROL............................................................................................................................... 67

11.1 CREATING A CASCADE .............................................................................................. 67

11.2 CONTROLLING DO BY CASCADE ............................................................................... 69

12 PLOTTING TRENDS ................................................................................................................................. 72

12.1 CREATING A TREND GRAPH ...................................................................................... 72

12.1.1 Using the Export Button...................................................................................74

12.1.2 Using the Zoom Button.....................................................................................75

12.1.3 Using the Read Line.........................................................................................75

13 ABOUT PUMPS ......................................................................................................................................... 77

13.1 PUMP SETPOINT......................................................................................................... 77

13.2 PUMP CONTROL MODE.............................................................................................. 78

13.3 PUMP FLOW RATE &CALIBRATION METHODS ......................................................... 79

13.4 PUMP PERIOD ............................................................................................................ 80

13.5 INSTALLING AN EXTERNAL VARIABLE SPEED PUMP ................................................. 80

14 ABOUT ALARMS...................................................................................................................................... 82

14.1 ABS AND DEV ALARMS ........................................................................................... 82

14.2 SETTING ALARMS...................................................................................................... 82

14.3 ACKNOWLEDGING AN ALARM ................................................................................... 84

14.4 ALARMS HISTORY ..................................................................................................... 85

15 USING THE SETUP SCREEN................................................................................................................... 87

15.1 CONTROLLER SETUP ................................................................................................. 87

15.1.1 Gas Control with 1 or No TMFC.....................................................................89

15.1.2 Gas Control with 2 TMFCs..............................................................................89

15.1.3 Gas Control with 3 TMFCs..............................................................................90

15.1.4 Gas Control with 4 TMFCs..............................................................................91

15.2 RECIPE MANAGER ..................................................................................................... 92

15.3 SYSTEM SETTINGS..................................................................................................... 93

x

BioFlo 415 •M1360-0050 User’s Guide

15.3.1 Resetting Date/Time.........................................................................................94

15.3.2 Updating Software............................................................................................94

15.4 HARDWARE SETUP .................................................................................................... 94

15.5 SECURITY SETTINGS.................................................................................................. 96

16 OPERATION............................................................................................................................................... 98

16.1 LOAD PUMP TUBING ................................................................................................. 98

16.2 INSTALL LIQUID ADDITION SYSTEMS...................................................................... 100

16.2.1 Addition Tubing Size ......................................................................................101

16.3 INOCULATION.......................................................................................................... 102

16.4 LAUNCH BIOCOMMAND (IF PRESENT) ..................................................................... 102

16.5 SAMPLING PROCEDURE ........................................................................................... 102

16.6 HARVESTING ........................................................................................................... 104

16.7 FERMENTATION PHASES.......................................................................................... 104

16.7.1 Lag Phase.......................................................................................................105

16.7.2 Exponential Growth Phase.............................................................................105

16.7.3 Steady State Phase .........................................................................................105

16.7.4 Decline Phase.................................................................................................105

16.8 BATCH OPERATION ................................................................................................. 105

16.9 FED BATCH OPERATION .......................................................................................... 105

16.10 CHEMOSTAT OPERATION..................................................................................... 106

16.11 SHUTDOWN PROCEDURE ..................................................................................... 107

17 CLEANING............................................................................................................................................... 108

17.1 CLEANING THE VESSEL ........................................................................................... 108

17.1.1 List of Wetted Parts........................................................................................108

17.2 CLEANING THE CABINET ......................................................................................... 109

18 MAINTENANCE...................................................................................................................................... 110

18.1 PHPROBE MAINTENANCE AND STORAGE................................................................ 110

18.2 DO PROBE MAINTENANCE AND STORAGE .............................................................. 110

18.3 VESSEL &TUBING................................................................................................... 111

18.4 PERIODIC INSPECTION ............................................................................................. 111

18.5 FUSE REPLACEMENT ............................................................................................... 111

18.6 PORT &ADAPTER O-RINGS .................................................................................... 111

18.7 HEADPLATE O-RING REPLACEMENT ....................................................................... 111

18.8 REPLACEMENT PARTS ............................................................................................. 112

19 SERVICE .................................................................................................................................................. 113

19.1 TROUBLESHOOTING................................................................................................. 113

19.2 SERVICE PARTS ....................................................................................................... 115

20 DRAWINGS.............................................................................................................................................. 116

20.1 LIST OF DRAWINGS ................................................................................................. 119

20.2 LIST OF TABLES....................................................................................................... 121

21 APPENDIX A: SOME GENERAL CONCEPTS..................................................................................... 122

21.1 WHAT IS A CONTROLLER?....................................................................................... 122

xi

New Brunswick Scientific User’s Guide

21.2 WHAT IS A CONTROL LOOP? ................................................................................... 122

21.3 WHAT IS PROBE CALIBRATION? .............................................................................. 123

21.4 WHAT ARE P-I-D CONSTANTS?............................................................................... 123

21.5 WHAT IS P-I-D TUNING?......................................................................................... 124

21.6 WHAT DO THE CONSTANTS MEAN? ........................................................................ 125

22 APPENDIX B: OTR................................................................................................................................. 126

22.1 DETERMINING AN OXYGEN TRANSFER RATE .......................................................... 126

22.1.1 OTR Calculations...........................................................................................126

22.2 SOME FACTORS THAT AFFECT OTR AND HORSEPOWER......................................... 127

23 APPENDIX C: FERMENTATION TECHNIQUES................................................................................ 128

23.1 MEDIA FORMULATION ............................................................................................ 128

23.2 ANTIFOAM FORMULATION ...................................................................................... 129

23.3 TUBING SIZE............................................................................................................ 129

23.4 ACID &BASE .......................................................................................................... 130

23.5 GLUCOSE FEED........................................................................................................ 130

23.6 RECOMMENDED PROCESS CONTROL SETTINGS ....................................................... 131

24 APPENDIX D: CORROSION RESISTANCE TABLES......................................................................... 132

25 APPENDIX E: GENERAL CHARACTERISTICS OF EPR................................................................... 147

25.1 IDENTIFYING EPR ................................................................................................... 147

25.2 GENERAL CHARACTERISTICS .................................................................................. 147

26 INDEX....................................................................................................................................................... 148

1

New Brunswick Scientific User’s Guide

1

1

W

WA

AR

RN

NI

IN

NG

GS

S

&

&

C

CA

AU

UT

TI

IO

ON

NS

S

The following section is a recap of all WARNING and CAUTION messages contained in

this manual. This information is essential to the safe operation of your BioFlo 415. Please

take a moment to acquaint yourself with the content of each message.

Page numbers are provided so you can review each message in its entirety and acquaint

yourself with its overall context.

1.1 WARNINGS

WARNING Page

High voltage. Always make sure this equipment is properly grounded. iv, 11, 21

This product is not designed to contain gases within the range of their

LEL and their UEL… iv

Do not use this equipment in a hazardous atmosphere or with hazardous

materials for which the equipment was not designed. 10, 12

Prime the water system before the first use of the vessel and every time the

vessel has been detached then reattached.

18

To avoid possible safety hazard, the BioFlo 415 Backflow Prevention Kit

must be installed in the water inlet line before performing a sterilization cycle. 49

Be sure to wear protective gloves when you move the sparge valve from

sterilization to sparge position.

54

Never turn the heater off during a run or the exhaust filter may clog. 66

Be careful not to pinch your fingers in the pump head levers. 100

Always turn your BioFlo 415 off and disconnect the power cord before

performing maintenance. 110, 113

1.2 CAUTIONS

CAUTION Page

This equipment must be operated as described in this manual. If

operational guidelines are not followed, equipment damage and personal injury

can occur. Please read the entire User’s Guide before attempting to use this

unit. Do not use this equipment in a hazardous atmosphere or with

hazardous materials for which the equipment was not designed. NBS is

not responsible for any damage to this equipment that may result from the use

of an accessory not manufactured by NBS.

iv

Before making electrical connections, verify that the supply voltage matches

the voltage and the power requirements marked on the electrical specification

plate (located on the rear panel of the cabinet) and the control schematics

supplied with the unit.

9, 11, 21

Never use a wrench on headplate ports; only finger tighten the adapters. 14, 15

...continued...

2

BioFlo 415 yM1360-0050 User’s Guide

CAUTION Page

On initial set-up, prior to operation, check that all impellers are tightly

fastened to the drive shaft. 18

As soon as the heater is connected to the Control Cabinet, you must make sure

there is water in the vessel jacket. Do not plug the heater cable in to the

cabinet unless the vessel jacket has been primed.

21

Before turning on the main power switch, make sure that: (1) the input water

hose is connected, the drain line is connected and the water supply is turned on;

(2) the vessel is in place and the quick-connect water lines are connected to the

vessel’s heat exchanger; (3) the power cord is properly connected to the control

cabinet and plugged into a suitable power outlet.

22

Be sure to wear protective gloves when installing a glass electrode. 44

We recommend that you avoid the use of hydrochloric acid (HCl)

with the BioFlo 415 for pH control or any other purpose, because HCl corrodes

stainless steel. Over time, it will severely damage the vessel, a costly

component to replace, and other stainless steel components.

Phosphoric and sulfuric (10% maximum concentration) acids are acceptable and

are commonly used for pH control.

45

Never let a pH probe rest on its tip, and never leave a pH probe in DI water. 45, 110

There must be liquid in the vessel for sterilization. Never begin the

sterilization process if the vessel is empty.

49

If Sterilization Temperature does not reach 121.5ºC, make sure the water

supply pressure is not too high (max. 10 PSIG).

49

Proper installation of the RTD is essential to temperature control. 59

Proper pH control is critically dependent on tubing size, which should be as

small as possible. Consult Table 9 in Section 13.3 for guidance. 65, 99

When selecting an external pump to operate with your system, please

consult with your local sales representative to be sure the model you choose is

compatible with your BioFlo 415.

80

Be sure to set the dip switches correctly when using either 4-20mA or 0-5V

inputs/outputs. 81

Acknowledging alarms is NOT a replacement for correcting the condition

that triggered the alarm. Diagnose the cause of the alarm condition and rectify

the situation to ensure proper operation of your BioFlo 415.

85

Never clean the vessel or its components or the control cabinet with abrasive

chemicals or materials.

108

Never let a DO probe rest on its tip. 110

3

New Brunswick Scientific User’s Guide

2

2

I

IN

NS

SP

PE

EC

CT

TI

IO

ON

N

&

&

U

UN

NP

PA

AC

CK

KI

IN

NG

G

O

OF

F

E

EQ

QU

UI

IP

PM

ME

EN

NT

T

2.1 Inspection of Box(es)

When you have received your order from New Brunswick Scientific, carefully inspect

all parts of the shipment for damage that may have occurred during shipping. Report

any damage immediately to the carrier and to your local NBS Sales Order Department.

2.2 Packing List Verification

Verify against your NBS packing list that you have received the correct materials.

Report any missing parts to your local NBS Sales Order Department.

2.3 Basic Components

You should have at least the following components, which will be described in greater

detail later in this manual:

•Control Cabinet •Filters

•Touchscreen •Motor

•Vessel (components installed) •Hoses/Tubing

•Sampling/Harvesting Connections •Probe Kits (pH, DO, Foam, Level)

#NOTE:

The assembled Control Cabinet/Touchscreen assembly is called a Control

Station. For purposes of clarity in this manual, however, the control

cabinet (which houses the controller) and the touchscreen will be referred

to separately by their component names.

4

BioFlo 415 yM1360-0050 User’s Guide

3

3

I

IN

NT

TR

RO

OD

DU

UC

CT

TI

IO

ON

N

&

&

O

OV

VE

ER

RV

VI

IE

EW

W

3.1 System

BioFlo 415 is a versatile sterilizable-in-place (SIP) fermentor that provides a fully

equipped system in one compact package. It can be employed for batch or continuous

culture with process control of pH, dissolved oxygen (DO), agitation, temperature,

pump feed, antifoam, level and addition analog/digital inputs and outputs.

3.2 Vessels

The fermentation vessels are designed for total volumes of 7, 14 and 19.5 liters.

Each stainless steel vessel consists of a headplate, view window and magnetic drive

agitation with Rushton impellers. Ports are provided in the headplate for the following

purposes: inoculation; base and acid addition; a thermowell for a resistance

temperature detector (RTD); a foam probe; a sparger; a harvest tube; a sampling tube;

an exhaust condenser; and dissolved oxygen (DO) and pH electrodes. The drive

bearing housing is also located on the headplate (see Figures 3a, 8, 9 and 10).

3.3 Agitation System

A removable agitation motor located on top of the bearing housing on the headplate is

connected to the agitation shaft with a magnetic drive coupling.

The motor will provide a speed range from 50 to 1000 RPM. The process-control

software ensures agitation speed control from ±1 RPM to ±5 RPM throughout the

speed range.

It is possible to cascade Dissolved Oxygen (DO) to Agitation (AGIT) so the agitation

speed will vary between the user-specified minimum and maximum setpoints in order

to maintain the set percentage of DO. (See Section 11 for further information on

setting up cascades.)

Default P & I (proportional & integral) values are preset at the factory. We strongly

recommend that you maintain the factory-set parameters.

5

New Brunswick Scientific User’s Guide

3.4 Temperature Control

The culture temperature setpoint may be selected within the range from 5°C above

coolant temperature to 80°C (±0.1°C). It is controlled by the process-control

software. The media temperature is sensed by a Resistance Temperature Detector

(RTD) submerged in the thermowell.

Default P & I (proportional & integral) values are preset at the factory. We strongly

recommend that you maintain the factory-set parameters.

3.5 Aeration

Up to four gases, including air, nitrogen, carbon dioxide and oxygen, can be

introduced into the media through the ring sparger. The flow rate is controlled

automatically by one, two, three or four thermal mass flow controller(s), according to

the definition of your system. The thermal mass flow controller is regulated

automatically according to values set via the control cabinet touchscreen. If you wish

to use a rotameter, there is an option for no thermal mass flow controller.

The percentage of oxygen blended with the sparge air can be controlled manually by

the user or automatically through the controller by applying the O2enrichment

function. (For further information on cascading, see Section 11.)

3.6 pH Control

pH is controlled in the range of 2.00-12.00 (±0.01). The pH is sensed by a Gel-filled

pH probe (see Figures 32a & 32b). Control is maintained by a P & I (proportional &

integral) controller which operates two peristaltic pumps, assigned to acid and base

addition ports, or controls the use of gas(es) for this purpose. The user can also select

a deadband value to control pH within the user-assigned range: no acid or base will be

added when the pH value falls within the deadband tolerance above or below the

setpoint.

Default P & I (proportional & integral) values are preset at the factory. We strongly

recommend that you maintain the factory-set parameters.

6

BioFlo 415 yM1360-0050 User’s Guide

3.7 DO Control

DO is controlled in the range of 0-200% (±1%). It is sensed by the DO electrode and

control is maintained by the P & I controller by changing the speed of agitation, the

thermal mass flow controller-regulated flow rate (if your system is so equipped),

nutrient addition, and/or the percentage of oxygen in aeration. The DO probe is a

polarographic probe.

Default P & I (proportional & integral) values are preset at the factory. We strongly

recommend that you maintain the factory-set parameters.

3.8 High Foam Control

Foam can be controlled during batch fermentation by a level probe located in the

headplate. The controller operates the antifoam-assigned pump that adds chemical

defoamer into the vessel as needed.

3.9 Exhaust System

The exhaust gases pass into the exhaust condenser (see Figure 5) where moisture is

removed; any residual moisture is heated past the dewpoint via the heating pad,

allowing it to pass through the exhaust filter with a reduced potential for clogging.

3.10 Sampling/Harvesting System

The sampler assembly consists of the sampler tube with a sampler needle, three tri-

clamps and a sampler valve. This assembly facilitates the aseptic removal of the

sample, or harvesting the entire contents of the vessel, to an optional sample/harvest

vial or bottle.

7

New Brunswick Scientific User’s Guide

3.11 Recommended Accessories & Supplies

Before you begin to assemble your BioFlo 415, it would be prudent to verify that you

have all of the following accessories and supplies readily at hand:

•Rubber gloves •Media

•Silicone tubing •Antifoam agent

•A tie gun •pH 4 buffer

•Plastic ties •pH 7 buffer

•Plastic tubing connectors •Silicone O-ring lubricant

•Addition bottles •An inoculation syringe

•A liquid trap

A spare parts kit is available from NBS (part number M1360-9969; see Section 19.2)

with many of the commonly required items, including a selection of tubing, clamps,

filters, connectors and addition vessels. Speak to your NBS sales representative for

more information.

3.12 Supervisory Software

In addition to the built-in software that you interface with through the touchscreen,

your BioFlo 415 system can be remotely controlled from a PC via NBS BioCommand

Plus optional supervisory software (see Section 4.9).

8

BioFlo 415 yM1360-0050 User’s Guide

4

4

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N

4.1 Physical Location

The surface on which you place the BioFlo 415 fermentor should be smooth, level and

sturdy. Ensure that the surface can bear the weight of the fermentor plus vessel contents

and any applicable ancilliary equipment.

Also ensure that there is enough space around the back and the front of the BioFlo 415 for

proper operation and access. Allow at least 4 inches of clearance behind the unit for heat

dissipation. See Section 5, Specifications, for weights and dimensions.

4.2 Environment

The BioFlo 415 fermentor operates properly under the following conditions:

•Ambient temperature range 10°C to 30°C

•Relative humidity up to 80% non-condensing

4.3 Installing the Control Cabinet

Position the BioFlo 415 control cabinet on a firm, level surface in an area where

utilities are readily available.

Level the horizontal surface of the base with four leveling glides if necessary.

Connect the power cord to the rear of the control cabinet. At a later time, once the unit

is completely assembled and all connections have been made, you will plug the power

cord into a suitable electrical outlet.

4.4 Installing the Touchscreen

With reference to Figures 1a (for location) & 1b, align the monitor with the mounting

rack on the cabinet, and use the four screws provided with the monitor to securely

fasten it to the rack. The mounting rack swivels for easy access.

With reference to Figure 1b, connect the cabinet’s power cord plug, com port

connector and VGA monitor connector to the bottom of the touchscreen monitor.

Table of contents