1

1LEEB HARDNESS TEST (DEFINITION) ................................................................................................................................... 3

NOTATION OF LEEB’S HARDNESS................................................................................................................................................ 3

2SPECIFICATIONS, FEATURES AND APPLICATIONS ............................................................................................................... 3

2.1 INTRODUCTION ...................................................................................................................................................................... 3

2.2 SPECIFICATIONS...................................................................................................................................................................... 4

2.3 FEATURES ............................................................................................................................................................................. 4

2.4 APPLICATIONS........................................................................................................................................................................ 4

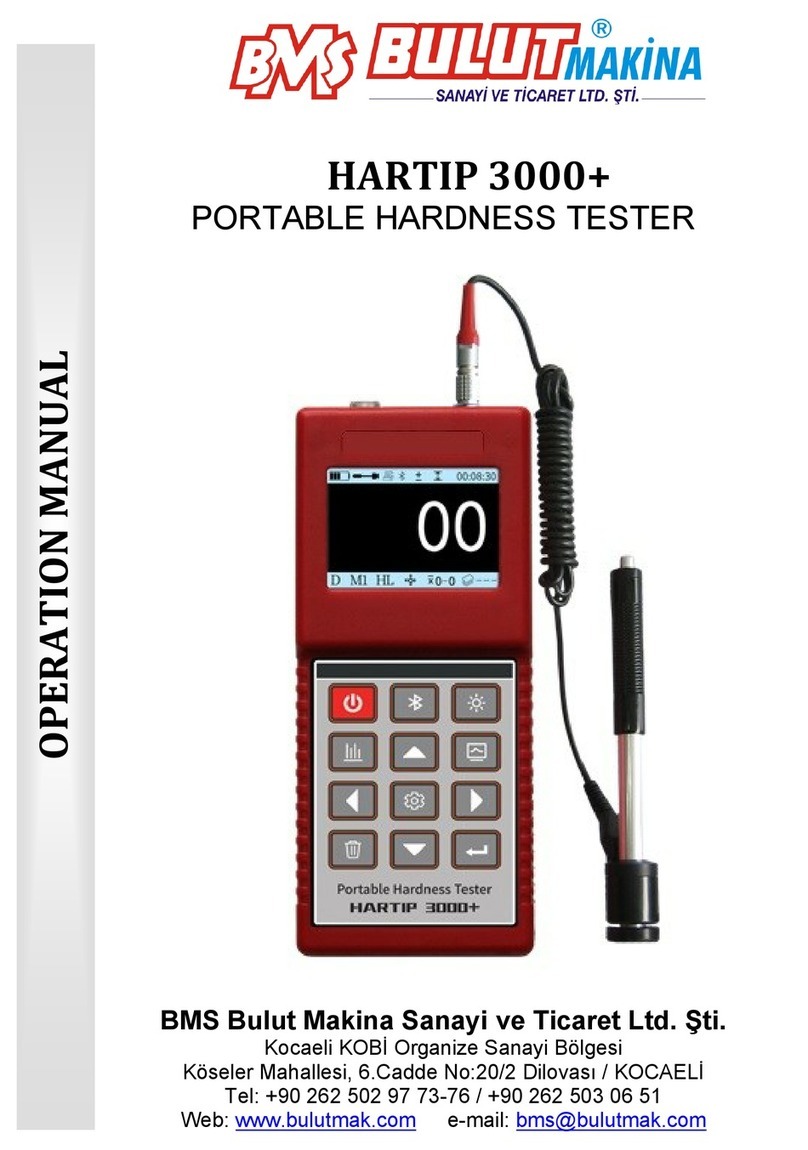

3HARDNESS TESTER PARTS NAMES...................................................................................................................................... 5

3.1 MAIN BODY .......................................................................................................................................................................... 5

3.2 TYPES OF IMPACT DEVICES ....................................................................................................................................................... 5

3.2.1 Special Features of Impact Devices ............................................................................................................................... 5

3.2.2 Internal Structure of Impact Devices ............................................................................................................................. 6

4SYMBOLS AND ILLUSTRATIONS .......................................................................................................................................... 6

4.1 MEANING OF VARIOUS SYMBOLS .............................................................................................................................................. 6

4.2 MEASUREMENT AND CONVERSION TABLE ................................................................................................................................... 6

5PREPARATION BEFORE MEASURING .................................................................................................................................. 8

5.1 REQUIREMENTS TO THE SAMPLE ................................................................................................................................................ 8

5.2 REQUIREMENTS RELATED TO SAMPLE WEIGHT .............................................................................................................................. 9

5.3 REQUIREMENT ON THE SURFACE-HARDENED LAYER OF THE SAMPLE ................................................................................................ 10

5.4 SAMPLES WITH CURVED SURFACES .......................................................................................................................................... 10

6OPERATION...................................................................................................................................................................... 11

6.1 FUNCTION OF KEY AND OPERATION DIAGRAM ............................................................................................................................ 11

6.1.1 Function of Key............................................................................................................................................................ 11

OPERATION DIAGRAM ............................................................................................................................................................. 11

6.2 SYMBOLS DESCRIPTION .......................................................................................................................................................... 13

6.3 TURN ON/OFF THE INSTRUMENT ............................................................................................................................................ 14

6.4 CUSTOMER MENU................................................................................................................................................................ 14

6.5 TAG INFORMATION ............................................................................................................................................................... 14

6.6 PROBE SIGNAL ..................................................................................................................................................................... 14

6.7 RF PORT ............................................................................................................................................................................. 15

6.8 CALENDAR .......................................................................................................................................................................... 15

6.9 BATTERY TYPE...................................................................................................................................................................... 16

6.10 VIEWING STYLE .................................................................................................................................................................... 16

6.11 SOUND............................................................................................................................................................................... 16

6.12 SCREEN LIGHT ...................................................................................................................................................................... 17

6.13 NO.OF TEST ........................................................................................................................................................................ 17

6.14 CALIBRATION MODE.............................................................................................................................................................. 17

6.14.1 Single point calibration ........................................................................................................................................... 18

6.14.2 Two point calibration.............................................................................................................................................. 18

6.15 BACKLIGHT OFF TIME............................................................................................................................................................. 18

6.16 POWER OFF TIME ................................................................................................................................................................. 19

6.17 PRINTER PORT ..................................................................................................................................................................... 19