Page 2 of 70 Released 10/12/2021 Page 3 of 70Released 10/12/2021

AGATE TECHNOLOGY AT2040

AGATE TECHNOLOGY AT2040

Table of Contents

Introduction................................................................................................................................................ 4

Product Technical Support ..................................................................................................................... 4

2-Year Limited Warranty ......................................................................................................................... 4

Disclaimer ............................................................................................................................................... 4

Copyright ................................................................................................................................................ 4

Safety information ..................................................................................................................................... 5

Primary functions ...................................................................................................................................... 6

Maximum weight recommendations ....................................................................................................... 6

Specications and performance.............................................................................................................. 7

Instrumentation and control system ....................................................................................................... 8

Physical overview.................................................................................................................................... 10

AT2040 accessories................................................................................................................................. 12

Battery operation..................................................................................................................................... 13

Operation instructions ........................................................................................................................... 14

Main Menu Screen Overview................................................................................................................ 14

Navigating the AT2040 Menu................................................................................................................ 16

Using the Frequency and Amplitude Knobs ................................................................................... 16

Using the Touchscreen.................................................................................................................... 16

Using the Adjustable Displays ........................................................................................................ 16

Editing a Text Field.......................................................................................................................... 16

Using the Keyboard and Number Pad............................................................................................ 16

Using Toggle Buttons...................................................................................................................... 16

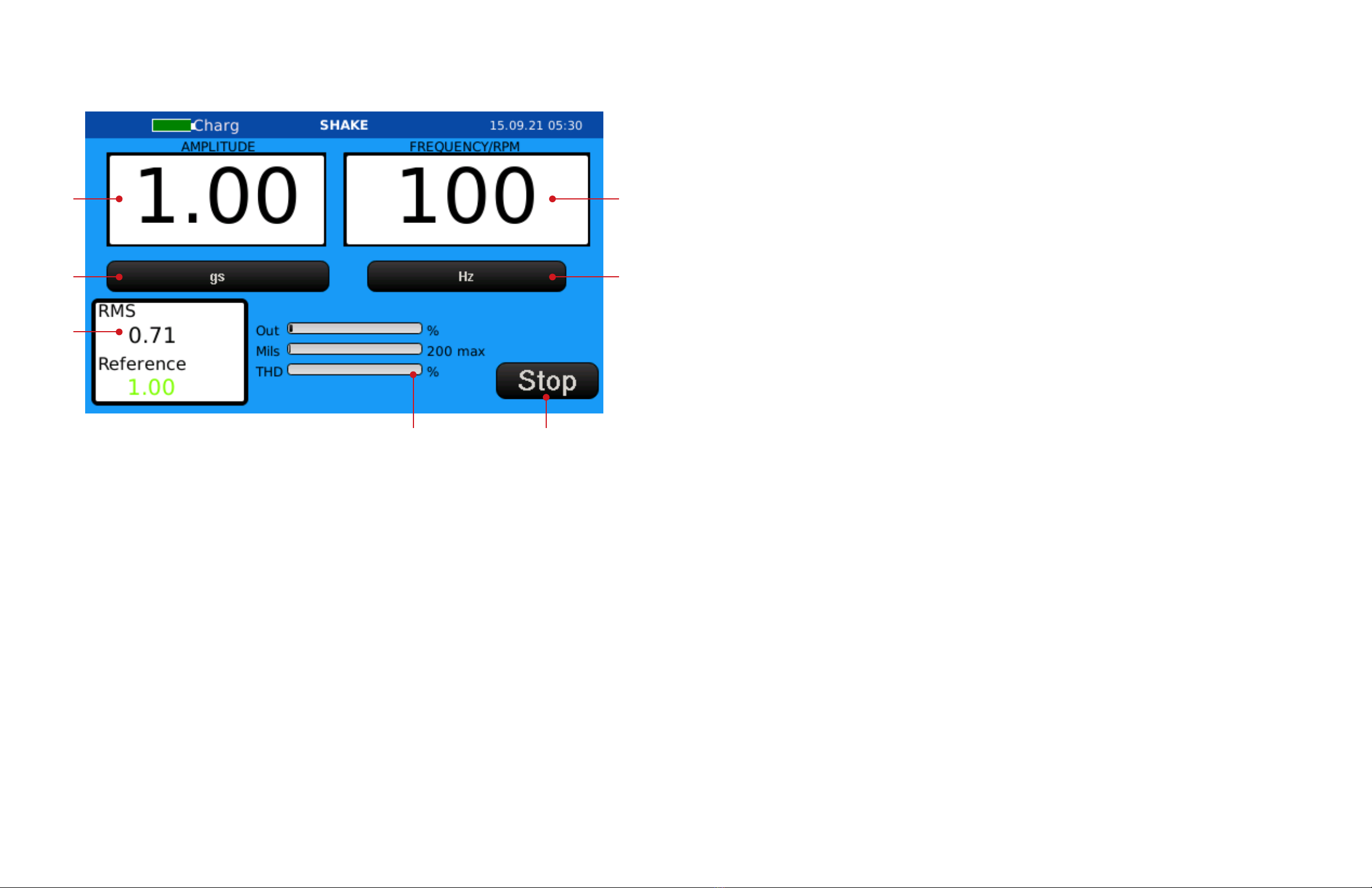

Shake Mode.......................................................................................................................................... 17

Shake Mode Screen Overview........................................................................................................ 18

Conducting a Test in Shake Mode.................................................................................................. 19

Purewave™ Overview ..................................................................................................................... 19

Test Mode ............................................................................................................................................. 20

Testing in Manual Mode ................................................................................................................. 22

Testing in Automatic Mode ............................................................................................................ 23

Calibrating IEPE Accelerometers .................................................................................................... 24

Calibrating Charge Accelerometers ................................................................................................ 25

Calibrating 4-20mA Transmitters .................................................................................................... 26

Calibrating Triaxial Sensors ............................................................................................................ 28

Calibrating Proximity Probes ......................................................................................................... 29

Setup Mode .......................................................................................................................................... 38

Deleting and Saving Previous Test Records ................................................................................... 39

Adjusting Date and Time Zone........................................................................................................ 43

Network Setup ................................................................................................................................ 44

Calibration and Company Name..................................................................................................... 45

Exporting and Importing PDF Certicate Files ............................................................................... 46

Simulation Mode................................................................................................................................... 48

Controlling the AT2040 remotely............................................................................................................ 50

Install and Setup VNC Viewer ............................................................................................................... 50

Setting up a custom sensor ................................................................................................................... 53

Designing a Custom Sensor ................................................................................................................. 53

Adding a Test Point ......................................................................................................................... 54

Deleting a Test Point ....................................................................................................................... 54

Saving a Custom Sensor ...................................................................................................................... 56

Uploading a Saved Custom Sensor...................................................................................................... 56

Deleting a Custom Sensor .................................................................................................................... 59

Customizing the PDF certicate template............................................................................................ 60

HTML Tags............................................................................................................................................ 61

HTML Tips....................................................................................................................................... 61

HTML Keywords ................................................................................................................................... 62

Product maintenance.............................................................................................................................. 68

AT2040 Recalibration............................................................................................................................ 68

Battery .................................................................................................................................................. 68

Service Notes........................................................................................................................................ 68

Operator notes......................................................................................................................................... 68

A2LA accreditation.................................................................................................................................. 69