New York Air Brake IP-225-C User manual

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

748 Starbuck Avenue, Watertown, NY 13601

Phone +1 315 786-5200 Engineering Fax: +1 315 786-5673

LIQUID CRYSTAL DISPLAY MONITOR

(LCDM)

OPERATOR MANUAL

IP-225-C

July 2011

IP-225-C 2 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

THIS PAGE INCLUDED FOR DOUBLE SIDED COPYING

IP-225-C 3 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

Revision

Level Section Change Date

01 ALL Original Release July/11

IP-225-C 4 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

THIS PAGE INCLUDED FOR DOUBLE SIDED COPYING

IP-225-C 5 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

TABLE OF CONTENTS

Table of Tables .............................................................................................................................................7

1.0 INTRODUCTION..............................................................................................................................8

2.0 general.............................................................................................................................................8

2.1 Definition of Temperatures ..........................................................................................................8

2.2 Abbreviations...............................................................................................................................8

2.3 Standards list with status of issues..............................................................................................8

3.0 PRODUCT DESCRIPTION..............................................................................................................9

3.1 Introduction..................................................................................................................................9

3.2 Features.......................................................................................................................................9

3.3 Electronic Components .............................................................................................................10

4.0 Mechanical drawings......................................................................................................................13

4.1 Version 782340/782343 with keyboard.....................................................................................13

4.2 Version Tbd with Touch Panel...................................................................................................14

5.0 Technical Data...............................................................................................................................16

5.1 Climate and environmental conditions.......................................................................................16

5.2 Mechanical Data........................................................................................................................16

5.3 Electrical data............................................................................................................................17

6.0 Further utiliZation notes .................................................................................................................19

6.1 Important Notice ........................................................................................................................19

6.2 Transportation............................................................................................................................19

6.3 Storage......................................................................................................................................19

6.4 Handling front membranes........................................................................................................19

6.5 Environmental details on materials............................................................................................19

7.0 Installation requirements................................................................................................................20

7.1 Installation conditions ................................................................................................................20

8.0 Installation......................................................................................................................................21

8.1 Installation Regulations/Notes...................................................................................................21

8.2 Plug-pin assignments ................................................................................................................22

9.0 Commissioning and system parameters........................................................................................29

9.1 Important Notice ........................................................................................................................29

10.0 Operation .......................................................................................................................................30

10.1 Operating instructions................................................................................................................30

10.2 Operation and display................................................................................................................30

11.0 Diagnostics and service functions..................................................................................................34

11.1 Connection of a MF2-compatible USB keyboard and USB mouse...........................................34

11.2 Using the Ethernet interface for the service..............................................................................34

12.0 Maintenance...................................................................................................................................35

12.1 Important Notice ........................................................................................................................35

12.2 Smallest exchangeable unit.......................................................................................................35

12.3 Preventive maintenance............................................................................................................35

12.4 Corrective maintenance.............................................................................................................36

13.0 Decommissioning...........................................................................................................................37

13.1 Important Notice ........................................................................................................................37

13.2 Disassembly ..............................................................................................................................37

13.3 Abbreviations.............................................................................................................................38

IP-225-C 6 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

TABLE OF FIGURES

Figure 2-1 Temperature Ranges According to EN 50155 ...........................................................................8

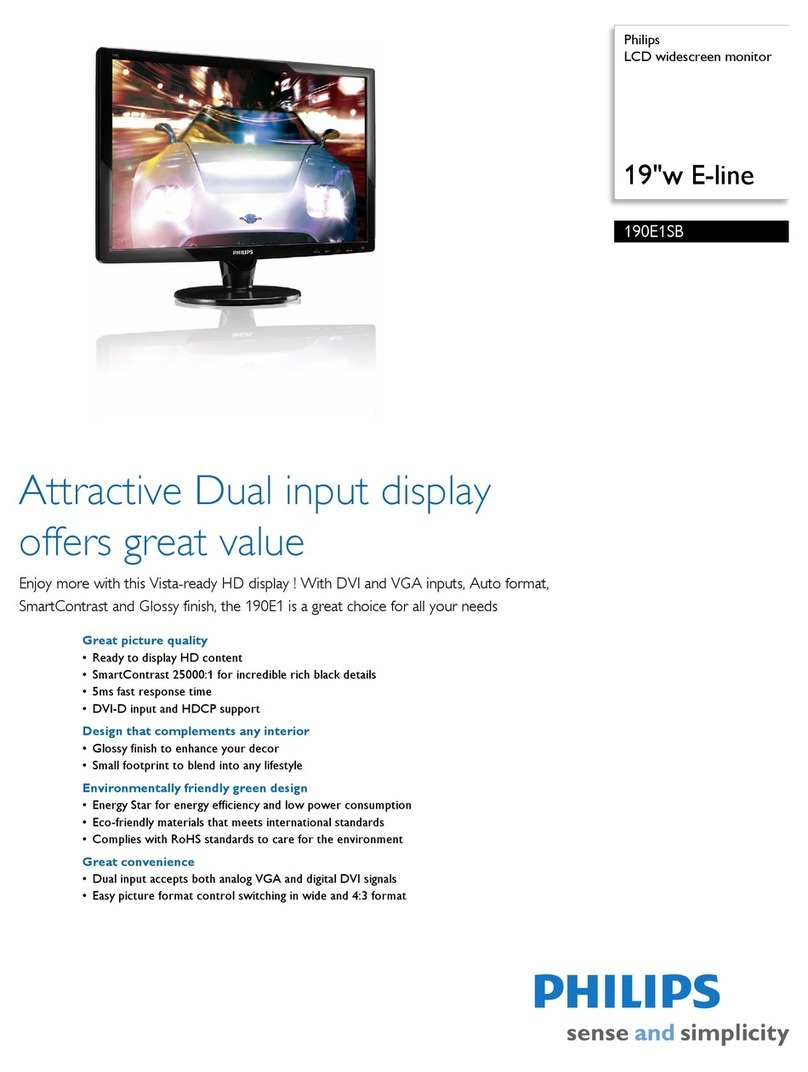

Figure 3-1 LCDM Multi-Functional Terminal................................................................................................9

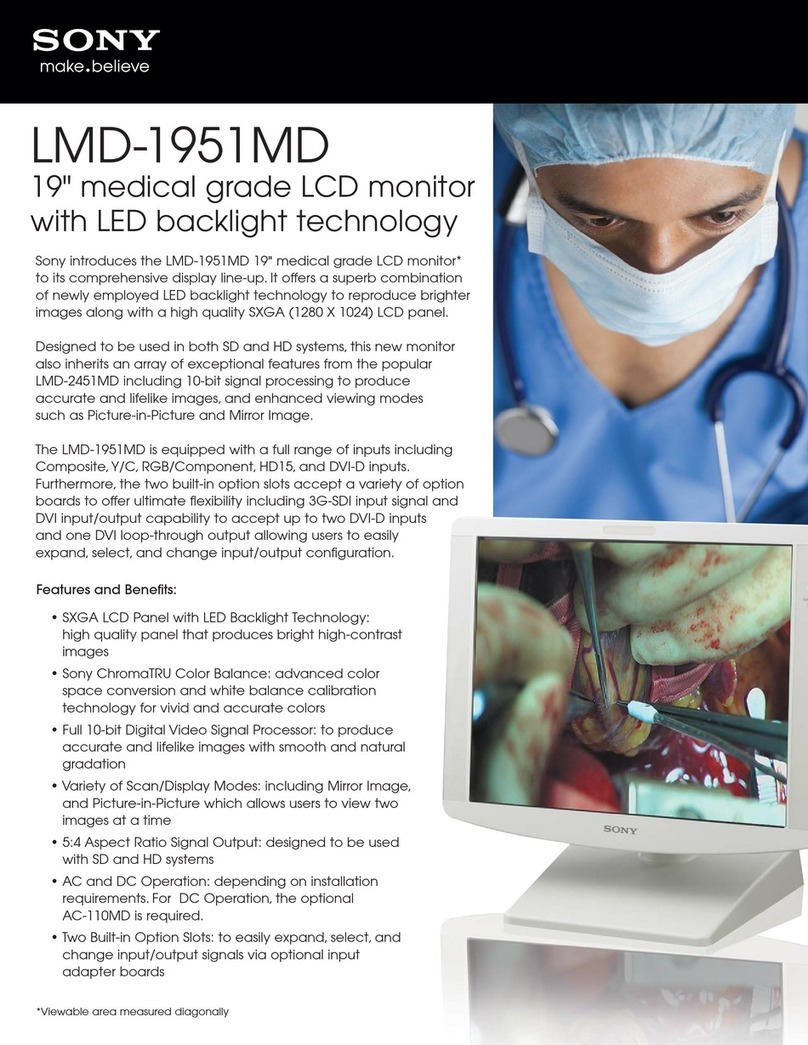

Figure 4-1 Front View with Dimensional Drawing (782340/782343) .........................................................13

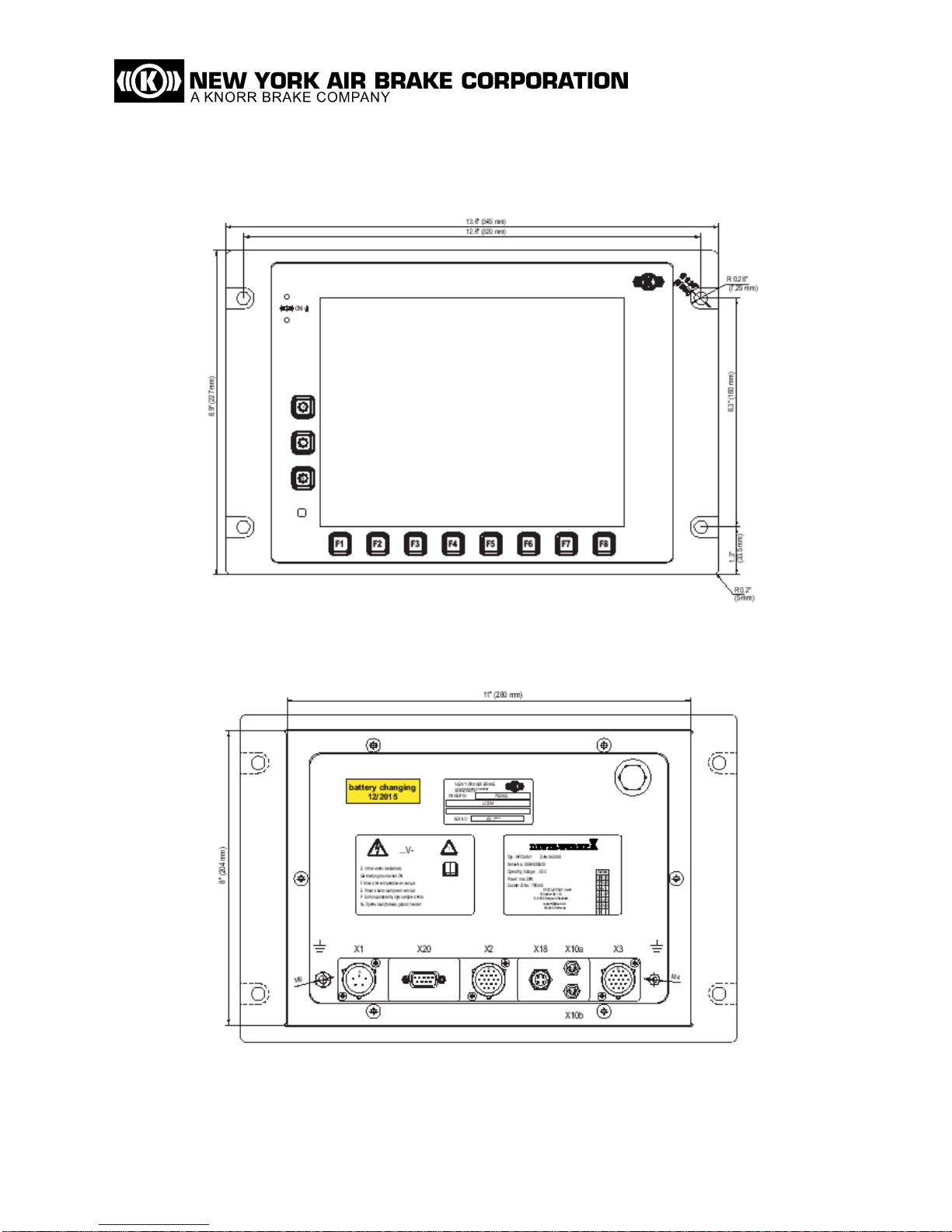

Figure 4-2 Rear View with Dimensional Drawing 782340/782343 ............................................................13

Figure 4-3 Side View 782340/782343 (upright).........................................................................................14

Figure 4-4 Front View with Dimensional Drawing (Tbd)............................................................................14

Figure 4-5 Rear View with Dimensional Drawing Tbd (example illustration of labels) ..............................15

Figure 4-6 Side View Tbd (upright)............................................................................................................15

Figure 8-1 Connectors (rear view).............................................................................................................22

Figure 10-1 LEDs and Sensors of the LCDM ............................................................................................30

Figure 10-2 Operation of LCDM with Keyboard (782340/782343)............................................................32

Figure 12-1 “Battery Replacement” Sticker on the Back of the Device (example)....................................36

IP-225-C 7 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

TABLE OF TABLES

Table 3-1 – Status LEDs.............................................................................................................................11

Table 3-2 Overview of Acoustic Signaling Transmitter............................................................................11

Table 8-1 Plug-Pin Assignment X1............................................................................................................23

Table 8-2 Plug-Pin Assignment X2............................................................................................................24

Table 8-3 Plug-Pin Assignment X3............................................................................................................25

Table 8-4 Plug-Pin Assignment X10a........................................................................................................26

Table 8-5 Plug-Pin Assignment X10b........................................................................................................26

Table 8-6 Plug-Pin Assignment X18..........................................................................................................27

Table 8-7 Plug-Pin Assignment X20..........................................................................................................28

Table 10-1 LEDs and Sensors...................................................................................................................31

Table 10-2 Possible Keyboard Assignment (782340/782343) ..................................................................33

IP-225-C 8 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

1.0 INTRODUCTION

The purpose of this operator’s manual is to assure that the product is used appropriately and

safely.

2.0 GENERAL

2.1 Definition of Temperatures

Operating temperature:

Air temperature (in max. and min. limits) in the immediate environment of the device,

at which the device is permitted to be operated.

Storage temperature:

Air temperature (in max. and min. limits) around the device at which the device is

permitted to be stored (equipment is isolated from power supply).

Ambient temperature (in accordance with EN 50155)

1. Outside ambient temperature

2. Temperature inside the cabinet (Device ambient temperature)

3. Temperature of the air surrounding the printed circuit board module (temperature

inside the device).

Figure 2-1 Temperature Ranges According to EN 50155

(using a driver’s console as an example)

2.2 Abbreviations

Refer to Appendix A for a complete list of abbreviations used in this document.

2.3 Standards list with status of issues

In this document the standards will only be designated by their standards number.

Appendix B contains the standards with their complete designations and respective

status of issue. More standards can be listed in this table than are necessary for the

product.

IP-225-C 9 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

3.0 PRODUCT DESCRIPTION

3.1 Introduction

The LCDM multi-functional terminal is used in complex control and guidance systems

as a man-machine interface. It displays process data and receives inputs from the

operator.

Data entry occurs via keyboard (version 782340 or 782343) or via a touch panel

(version Tbd).

Operation of keyboard version is designed with 11 function keys (softkeys).

The LCDM is based on a single-board PC (“embedded PC”) with a GEODE processor.

An active matrix color display (TFT) is used for the display.

Figure 3-1 LCDM Multi-Functional Terminal

3.2 Features

Power supply with galvanically isolated voltage converter (74 VDC or 110 VDC)

Active Matrix color display (TFT) with background lighting, 640 x 480 pixel, 10.4"

Resistive touch panel (Tbd only)

4x COM interfaces (RS422 (HDLC supported)

IP-225-C 10 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

1x COM interface RS232 (for service)

1x Ethernet interface (10/100 BaseT, with M12 connector, d-coded)

2x USB 1.1 interfaces (M8 connector)

11 illuminated function keys (softkeys)

Operating temperature 782340/782343: -31 F...+158 F (-35 C...+70 C)

Operating temperature Tbd: -13 F...+158 F (-25 C...+70 C)

No moving parts such as fan, hard disks, etc.

Protection against formation of condensation in the device

3.3 Electronic Components

3.3.1 Power Supply

The power unit can be adapted to the desired battery voltage with the aid of

different DC/DC converters.

The 782340 and Tbd are equipped with a DC/DC converter for 74V battery

voltage, and the 782342 has a DC/DC converter for 110V.

The device is protected against reverse polarity electrically by the

corresponding safety elements as well as mechanically by a plug notch.

The device does not have any externally accessible fuses. The device must be

replaced if faulty (see Chapter 13.4 "Corrective maintenance" on page 58).

The power consumption of the LCDM is typically 20 W (without heating),

maximally 30 W.

3.3.2 TFT display

The device has a 10.4" TFT display.

The display can portray 640 x 480 pixel with a color depth of 18 bit (262,144

colors) and a read angle of ±60° horizontal and -55° ...+45°vertical to surface

normal.

3.3.3 Background lighting (display)

Two CCFL tubes are used for the background lighting of the display. The

brightness of the CCFL tubes is controlled by an environment controller. The

controller can switch the background lighting on and off as well as adapt the

brightness automatically to the ambient brightness and simultaneously

superpose a manually set brightness value. The tubes can be easily replaced.

The keyboard is illuminated by LEDs.

IP-225-C 11 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

3.3.4 Optical sensor

An optical sensor in the front measures the ambient brightness and can adjust

the display background lighting as necessary.

3.3.5 Heating

For heating the device at low ambient temperatures, heaters are located

directly on the main board. When the PC-part is switched on, only one heater

can be activated. The heater is activated automatically by an environment

controller.

3.3.6 Status LEDs

Three (3) Status LEDs, whose functions are partially pre-installed, are located

in the front. The LEDs can be activated from the application via envcon

daemon. The LED colors are:

Designation Color Function

LED 1 Red Error status (optional)

Freely Available via AP1

LED 2 Yellow Operating state display:

Off – Device is off

On – Device is ready for operation

1 Hz Blinking – Device is outside of

operating temperature

4 Hz Blinking – Device off, watchdog

limit achieved

LED 3 Blue Freely available via AP1

Table 3-1 – Status LEDs

3.3.7 Acoustic Signaling Transmitter

782340/782342 tbd

Location Main board Rear panel

Form Miniature piezoelectric buzzer Miniature piezoelectric buzzer

Volume 85 dB (at 24” (60 cm) distance,

free field) 85 dB (at 24” (60 cm) distance, free

field)

Frequency 4 kHz 2.75 kHz

Table 3-2 Overview of Acoustic Signaling Transmitter

Activation can occur through the application via envcon daernon.

IP-225-C 12 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

3.3.8 System clock

When powering up the operating system, the system time is synchronized with

the time value of the high-precision RTC of the main board.

3.3.9 Keyboard

The LCDM is delivered with 11 soft-keys. The keys are illuminated.

3.3.10 Ethernet

An Ethernet interface according to 10/100BaseT with M12 connector, d-coded,

is implemented.

3.3.11 Four (4) serial interfaces RS422/RS485

The serial interfaces are electrically isolated RS422 and capable of sending

and receiving data via HDLC protocol. Please observe Chapter 8.2 "Plug-pin

assignment" as of Page 22 for a more detailed explanation of these interfaces.

3.3.12 Serial interface RS232 (Maintenance)

The RS232 interface is provided for connecting a Service PC. Please observe

Chapter 8.2 "Plug-pin assignment" as of Page 22 for a more detailed explanation

of this interface.

3.3.13 USB

There are 2 USB ports for external devices: two interfaces are available via two

M8 connectors which fulfill the V1.1 standard and which work with up to 12

MBit/s. For operating systems without USB support, the Legacy Mode for USB

keyboards is supported by the BIOS.

IP-225-C 13 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

4.0 MECHANICAL DRAWINGS

4.1 Version 782340/782343 with keyboard

Figure 4-1 Front View with Dimensional Drawing (782340/782343)

Figure 4-2 Rear View with Dimensional Drawing 782340/782343

(example illustration of labels)

IP-225-C 14 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

Figure 4-3 Side View 782340/782343 (upright)

4.2 Version Tbd with Touch Panel

Figure 4-4 Front View with Dimensional Drawing (Tbd)

IP-225-C 15 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

Figure 4-5 Rear View with Dimensional Drawing Tbd (example illustration of labels)

Figure 4-6 Side View Tbd (upright)

IP-225-C 16 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

5.0 TECHNICAL DATA

5.1 Climate and environmental conditions

5.1.1 Operation temperature

782340/782343 -31

F...+158 F (-35 °C...+70 °C)

Tbd -13

F...+158 F (-25 ~C...+70 C)

5.1.2 Storage

Temperature -31 F...+185 F (-35 °C...+85 °C)

5.1.3 Humidity

Humidity in accordance with EN 50155

5.1.4 Shock/vibration

Shock/vibration in accordance with EN 50155

5.1.5 Fire protection

Fire protection in accordance with DIN 5510 Part 2

5.2 Mechanical Data

5.2.1 Dimensions

Width 11” (280 mm), with front frame 13.6” (345 mm)

Height 8” (204 mm), with front frame 12.6” (227 mm)

Depth 1.7” (47 mm), with front frame 2” (53 mm)

5.2.2 Weight

Weight Approximately 7.49 lbs (3.4 kg, depending on

equipment of model)

5.2.3 Protection Category

Housing IP54 (with attached wiring and unused plugs covered with a cap)

Front IP65 (when installed)

5.2.4 Other

Front Membrane polyester

IP-225-C 17 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

Display Cover scratch-resistant toughened glass panel,

0.16" (4 mm) thick

The glass panel is inserted flush with the front membrane.

It is an anti-glare design with a glare value of 100.

Touch Panel (Tbd only) polyester, antireflection

Chemical compatibility in accordance with DIN 42115.

5.3 Electrical data

5.3.1 Power supply

5.3.1.1 782340/782342

Connection reverse polarity protected

Nominal voltage 74VDC (25VDC...135VDC)

Power consumption typ. 20 W (without heating)

max. 30 W

max. starting current 25 A (30 µs.. .-50 µs)

Dielectric strength

Supply voltage primary against secondary / housing:

1,500VAC

Galvanically isolated circuits against housing:

2,000VAC (RS422),

1,000VAC (Ethernet, RS232)

Non galvanically isolated circuits against housing:

due to internal connection between secondary 0V and housing, this

dielectric strength is not given

5.3.1.2 tbd

Connection reverse polarity protected

Nominal voltage 110VDC (66VDC...154VDC)

Power consumption typ. 20 W (without heating)

max. 30 W

max. starting current 25 A (30 µs.. .-50 µs)

Dielectric strength

Supply voltage primary against secondary / housing:

1,500V AC

Galvanically isolated circuits against housing:

2,000V AC (RS422),

1,000V AC (Ethernet, RS232)

Non galvanically isolated circuits against housing:

due to internal connection between secondary 0V and housing, this

dielectric strength is not given.

IP-225-C 18 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

5.3.1.3 Interfaces

Ethernet according to IEEE 802.3 10 Base T

and 100 Base Tx with M12 d-coded

4x serial interfaces according to IEEE RS422

resp. IEEE RS485, HDLC protocol

2x USB according to USB1.1, up to 12 MBit/s

according to IEEE RS232

5.3.2 TFT Display

Size 10.4” (visible diagonal measure)

Display Range 8.3” x 6.2” (211.2.mm x 158.4 mm)

Resolution 640 x 480 pixel (VGA)

Number of Colors 262,144 (18 bit)

Pixel Pitch 0.01” x 0.01” (0.33 mm x 0.33 mm)

Viewing Angle Vertical -55° to +45°

Horizontal -60° to +60°

Luminance max 550 nt (550 cd/m2)

(utilixsable 0 nt…

480nt (0 cd/m2…480cd/m2))

Contrast typical: 300:1

Response time typical: tr15 ms

tf35 ms

Design in accordance with ISO 13406-2

5.3.3 Acoustic Signaling Transmitter

782340/782343

Signal Level approx. 85 dB at 24” (60 cm) free field distance

approx. 4 kHz continuous

Tbd

Signal Level approx. 85 dB at 24” (60 cm) free field distance

approx. 2.75 kHz continuous

IP-225-C 19 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

6.0 FURTHER UTILIZATION NOTES

6.1 Important Notice

Check for complete delivery

Carefully unpack the LCDM. Check for completeness, correct type, and correct

connections as well as for possible signs of transport damage. Dispose of the

packaging only after completing these steps.

6.2 Transportation

Transportation of the LCDM should only occur in the originally supplied or similar

packaging.

When returning the LCDM, sufficient protective measures must be made to avoid

damaging the device.

6.3 Storage

Storage temperature -31 °F...+185 °F (-35 °C...+85 °C)

Storing the LCDM should only occur in the originally supplied or similar packaging.

6.4 Handling front membranes

For devices with a front membrane, the following points must be observed in particular:

It may not be operated or actuated with pointed or sharp-edged objects.

It may not be operated or actuated permanently, such as can happen if the device is

stored face downwards or if keys are wedged.

It may not be cleaned with strong detergents or brought into contact with solvent or

caustic chemicals. A list of compatible chemicals can be obtained from NYAB.

6.5 Environmental details on materials

All materials are halogen-free, asbestos-free and are rustproof. Environmentally

hazardous or harmful materials as well as PCB-bearing capacitors and materials are

not used.

IP-225-C 20 of 38 Rev. 01

© Copyright New York Air Brake. All rights reserved. CONFIDENTIAL

7.0 INSTALLATION REQUIREMENTS

7.1 Installation conditions

This section is aimed solely at trained electricians. Basic knowledge of installation,

EMC measures and safe behavior is required.

NOTE

In order to avoid malfunctions or damage, all the instructions

in this section must be complied with.

Designated operational location

The equipment is intended for use on rail vehicles. It is installed in the driver’s cab.

Installation conditions

A permanently secured connection to the vehicle earth (operating earth) must be

established at the prescribed connection (earthing bolts). This requires a maximum 3 ft

(1 m) long metal braid with a minimum diameter of 0.015 sq in (4 mm

2

). The service

and maintenance personnel must be electro-statically discharged to protect the

operating resource.

Wiring and signal requirements

The supply voltage (battery voltage) and all related signals may not be connected to

the operating earth; otherwise the potential isolation in the device will be cancelled and

safe operation cannot be guaranteed.

Signal reference to the vehicle battery is only permitted for the supply voltage. Lines

with battery-related signals may not be fed to the unit in combination with the signaling

lines.

Shielded cabling throughout is specified for the lines of the RS-422 serial interfaces.

The shield must be applied to the side of the LCDM device by a conductive plug

housing. Preferably, the shield should be applied on both sides.

The service interfaces Ethernet, RS-232 and the USB interfaces are only for testing

and diagnosis purposes and may not be connected when the vehicle is in operation.

The braided screens of all screened cables must have an optical range of at least 85%.

The connections to the line screens shall be made appropriately in relation to EMC. All

shielding and earth connections must be connected via a broad contact surface.

Unused plugs must be covered with a cap.

Evaluation and peripheral device requirements

All connected devices must comply with the technical specifications given in the

operating instructions to ensure correct function.

Table of contents

Other New York Air Brake Monitor manuals