New York Air Brake IP-235 User manual

....................

....................

....................

....................

Rail Vehicle Systems

IP-235

Rev. 03 (1/7/15) -en

782342assy1

Instruction Manual

Locomotive Cab Display Module (LCDM)

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

Revision: 03 1/7/15-en

This document was originally written in English.

Knorr-Bremse Group Page 2 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Contact address

New York Air Brake Ltd.

748 Starbuck Avenue

Watertown, NY 13601

USA

Phone: +1 315 786 5200

Fax: +1 315 786 5676

www.nyab.com

Knorr-Bremse Group Page 3 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

Revision History

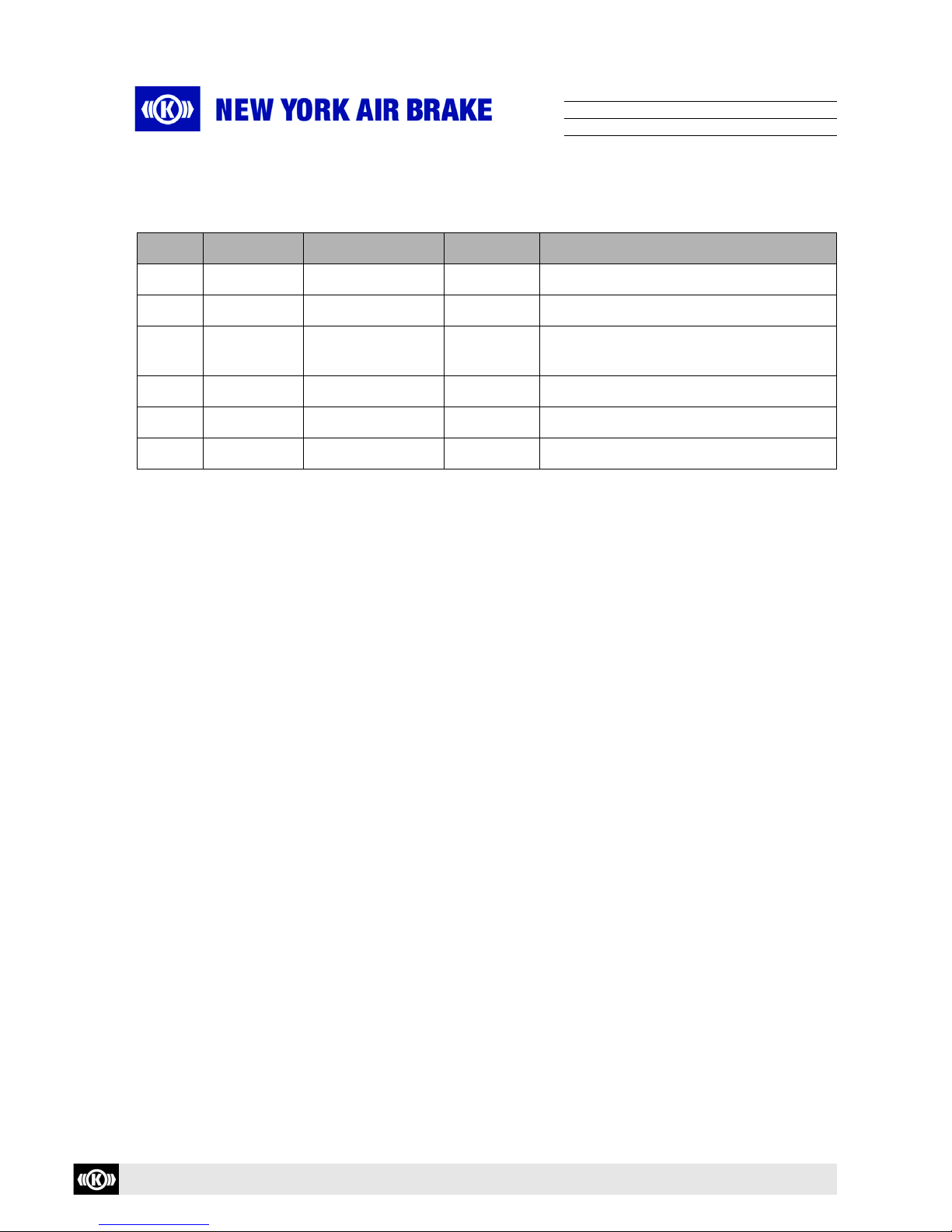

Rev. Date Name Para Description of Change

01 4/22/10 T. Lumbis ALL Original Release

02 1/21/13 J. Marra ALL Reformat and restructure

03 1/7/15 K. Deon 5.1.3 Added procedure to manually set time

and date

Knorr-Bremse Group Page 4 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

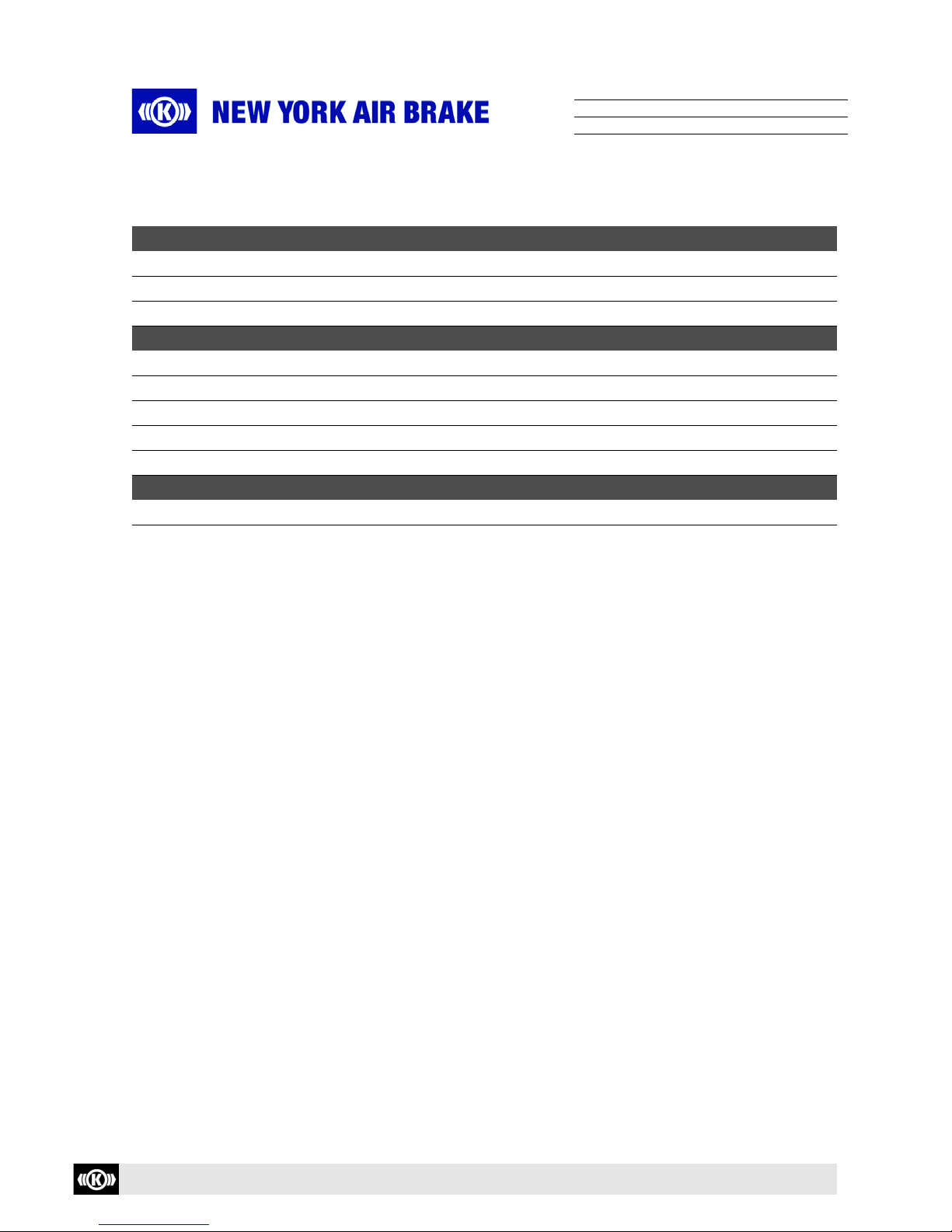

Table of contents

1 General Information 7

1.1 Introduction 7

1.2 Technical changes 7

1.3 Target Group for this Document 7

1.4 Referenced Documents 7

1.5 Danger, Warning, Caution, and Note Messages 8

2 Product Identification 9

2.1 LCDM (782340 and 782342) 9

3 Safety 12

3.1 General Safety Awareness 12

4 Product Description 14

4.1 General 14

4.2 Features 14

4.3 Electronic Components 15

4.4 Technical Data 17

5Operation 21

5.1 User Interface 21

6 Installation Requirements 26

6.1 General 26

6.2 Regulations 27

6.3 Interface 28

6.4 Commissioning and System Parameters 33

7 Maintenance 34

7.1 General 34

7.2 Line Replaceable Unit 34

7.3 Preventive Maintenance 34

7.4 Corrective Maintenance 34

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

Revision: 03 1/7/15-en

This document was originally written in English.

Knorr-Bremse Group Page 5 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

8 Diagnostics and Service Functions 36

8.1 Connections of a MF2-Compatible USB Keyboard and USB Mouse 36

8.2 Using the Ethernet Interface for the Service 36

9 Material Handling 37

9.1 Storage 37

9.2 Shipping 37

9.3 Special Handling/Hazards 37

9.4 Returned Material Authorization 38

10 Supporting Information 39

10.1 Abbreviations 39

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

Revision: 03 1/7/15-en

This document was originally written in English.

Knorr-Bremse Group Page 6 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Table of Figures

Figure 2-1 Front View of LCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2-2 Rear View of LCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2-3 Side View of LCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-4 Rear View of LCDM with Externally Mounted Audible Alarm . . . . . . . . . . . 10

Figure 2-5 Side View of LCDM with Externally Mounted Audible Alarm . . . . . . . . . . . . 11

Figure 4-1 Locomotive Cab Display Module (LCDM) . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 4-2 Temperature Ranges According to EN 50155 . . . . . . . . . . . . . . . . . . . . . . 18

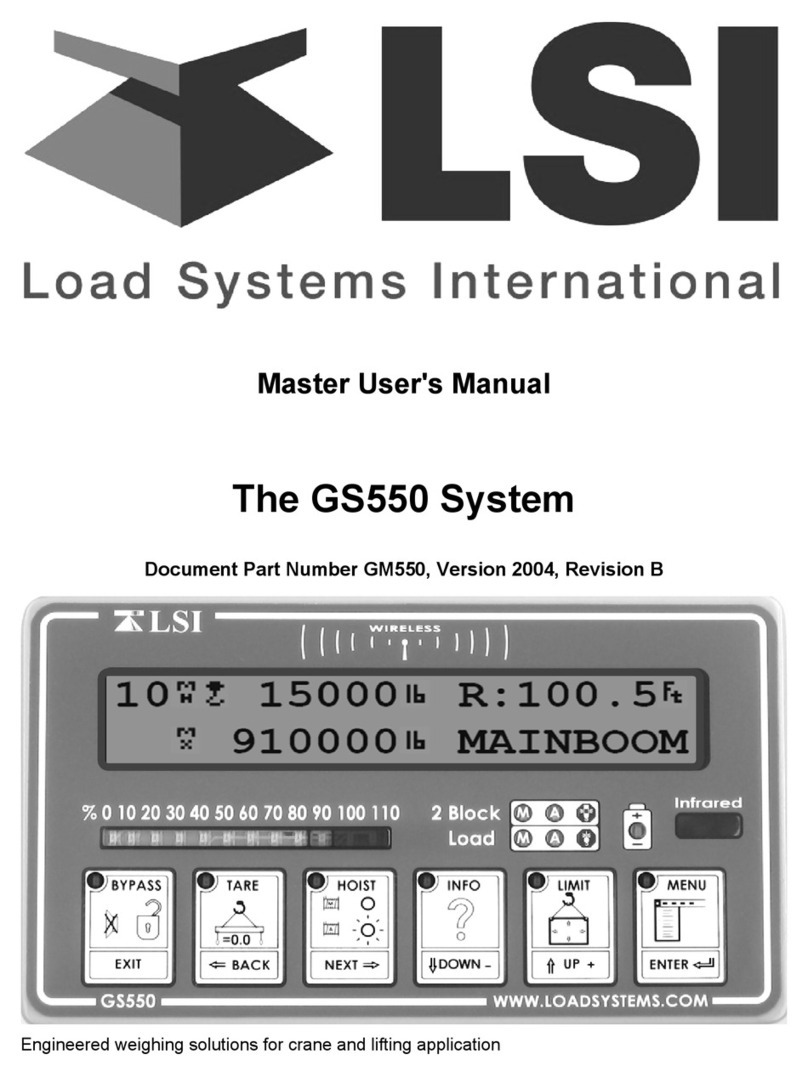

Figure 5-1 LEDs and Sensors of the LCDM (both variants) . . . . . . . . . . . . . . . . . . . . . 21

Figure 5-2 Operation of LCDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 5-3 Display Info Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 5-4 Display Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 5-5 Time and Date Adjustment Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 6-1 Connectors (rear view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 7-1 "Battery Replacement" Label on the Back of the Device (example). . . . . . 35

Table of Tables

Table 4-1 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4-2 Overview of Acoustic Signaling Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5-1 LEDs and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 5-2 Possible Keyboard Assignment (782340/782342) . . . . . . . . . . . . . . . . . . . . . . 22

Table 6-1 Plug-Pin Assignment X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 6-2 Plug-Pin Assignment X2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 6-3 Plug-Pin Assignment X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 6-4 Plug-Pin Assignment X10a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 6-5 Plug-Pin Assignment X10b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 6-6 Plug-Pin Assignment X18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 6-7 Plug-Pin Assignment X20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Knorr-Bremse Group Page 7 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

1.1 Introduction

This document contains particulars specific to LCDM models P/N 782340 (74 VDC) and P/N

782342 (110 VDC). The purpose of this manual is to assure that the product is used appro-

priately and safely.

1.2 Technical changes

NYAB reserves the right to change the equipment or this document at any time without giving

special notice.

1.3 Target group for this document

This document is intended for use by NYAB trained service technicians who

have the skill, experience, safety awareness and professional ability:

to remove and install the equipment,

to inspect, maintain and debug the equipment,

have read and understood this document from start to finish, and

are familiar with the safety codes and accident prevention regulations for these activities.

1.4 Referenced Documents

DIN EN ISO 4764 Surfaces of Components Used in Mechanical Engineering and Light Engineering

DIN 5510 Part 2 Preventative Fire Protection in Railway Vehicles

EN 50155 Railways Applications Electronic Equipment Used on Rolling Stock

IEEE RS232 Data Interface

IEEE RS422 Electrical Characteristics of Balanced Voltage Digital Interface Circuits

IEEE RS485 Electrical Characteristics of Generators and Receivers for Use in Balanced Digital

Multipoint Systems

IEEE 802.3.10 Management Information Base (MIB) Definitions for Ethernet

ISO 13406-2 Ergonomic Requirements for the Image Quality of Flat Panel Displays

1 General information

Please read this document carefully from start to finish to ensure

safety of operation. Failure to follow the safety alerts will result in

death or serious injury.

This document will be useful to other target groups as well, e.g.

project engineers. However, it does not claim to provide complete

information for such target groups.

Knorr-Bremse Group Page 8 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

1.5 Danger, Warning, Caution, and Note Messages

Warning messages are subdivided into the following hazard levels in this document:

Safety notes have a specific structure which is explained here for DANGER:

Notes do not contain any messages relevant to safety and are included only for the sake of complete-

ness.

Warning messages in other parts of this Description draw your attention to the individual risks concern-

ing your use of the product. Warning messages and notes generally precede the descriptions of the

relevant applications.

DANGER

Please read this document carefully from start to finish to ensure

safety of operation and to avoid personal injuries and damage to

equipment.

WARNING

Failure to comply with these instructions may lead to irreversible

physical injuries which may have fatal consequences.

CAUTION

Failure to comply with these instructions may lead to personal

injuries and/or to damage to the unit or the environment.

DANGER

Source of the danger

Consequences of the danger

Remedial measures

NOTE

Notes contain useful hints and additional information about the unit.

Knorr-Bremse Group Page 9 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

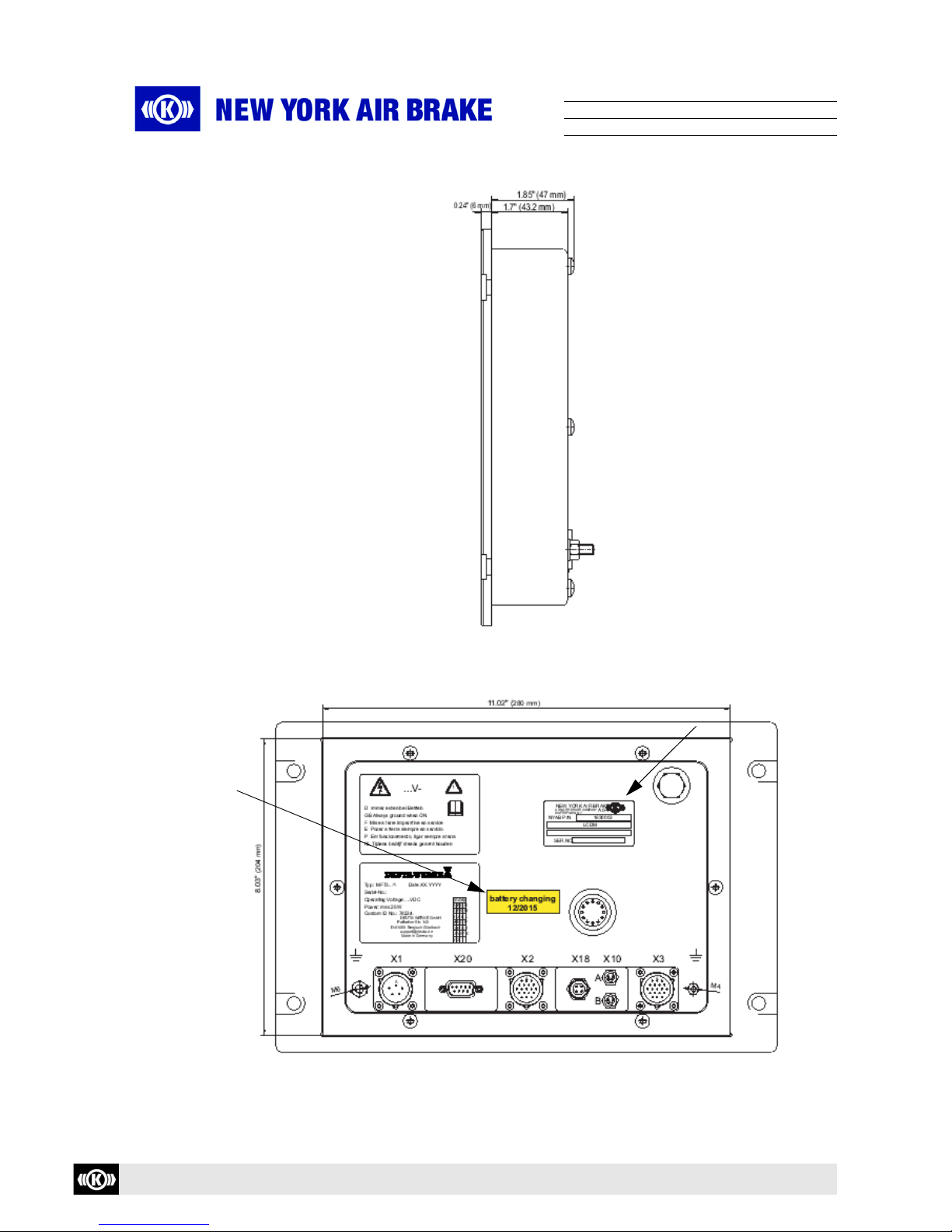

2.1 LCDM 782340 and 782342

Figure 2-1 Front View of LCDM

Figure 2-2 Rear View of LCDM (showing nameplate and labels)

2 Product Identification

Nameplate

Battery

Expiration

Decal

Knorr-Bremse Group Page 10 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

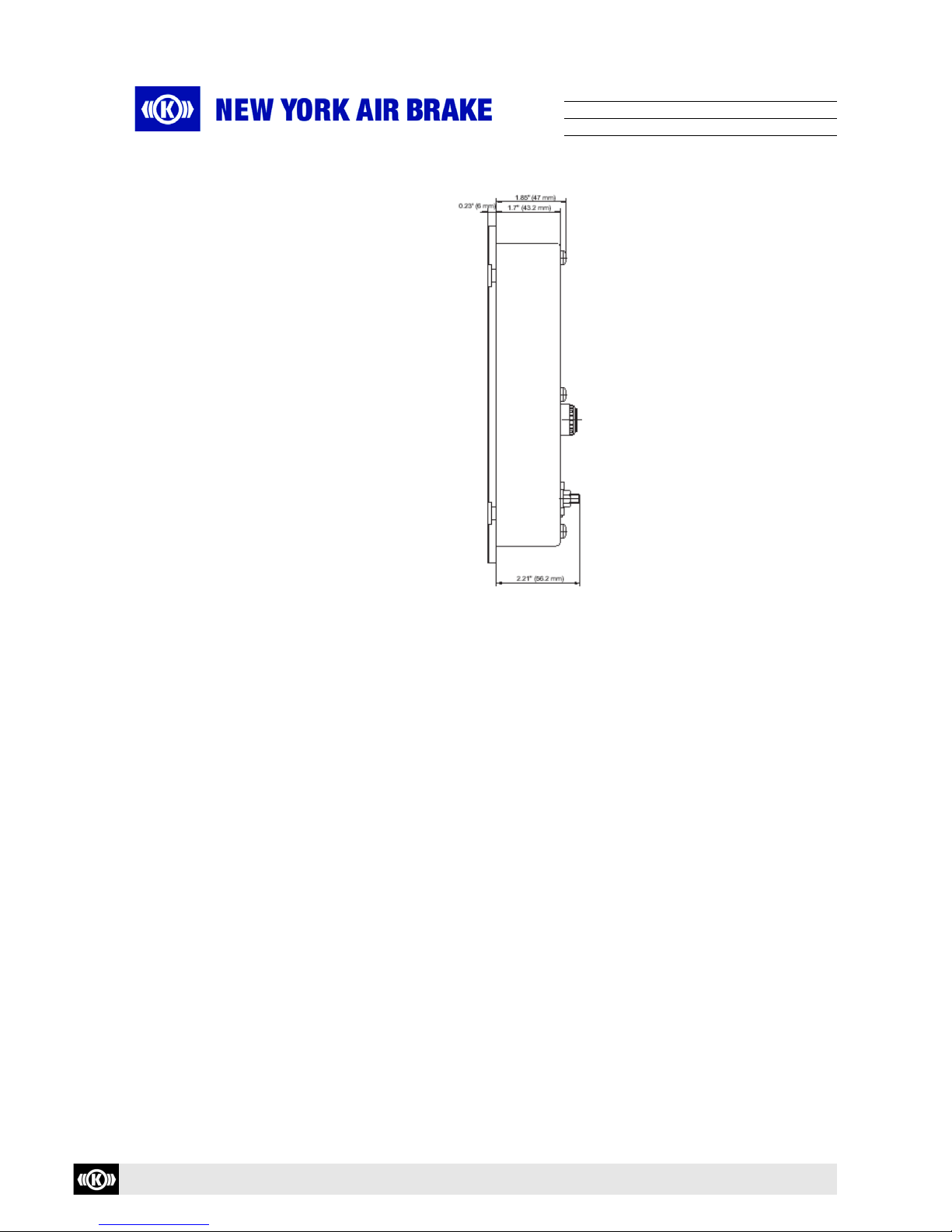

Figure 2-3 Side View of LCDM

Figure 2-4 Rear View of LCDM with Externally Mounted Audible Alarm

(showing nameplate and labels)

Nameplate

Battery

Expiration

Decal

Knorr-Bremse Group Page 11 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

Figure 2-5 Side View of LCDM with Externally Mounted Audible Alarm

Knorr-Bremse Group Page 12 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

3.1 General Safety Awareness

To prevent physical injury or death, all personnel directly or indirectly involved with the ope-

ration of the equipment described in this manual must conform to the following:

3.1.1 Observe all rules and regulations of the railroad where the equipment is being used.

Whenever there is a conflict between the instructions in this manual and the instructions of

the user railroad, the rules and regulations of the user railroad will govern.

3.1.2 When performing any operation of the equipment while it is on the vehicle (on vehicle test,

etc.) special precautions must be taken to ensure that vehicle movement will not occur which

could result in injury to personnel and/or damage to equipment. Make sure the handbrake is

applied and that the wheels are chocked to prevent vehicle from moving.

3.1.3 Shut off power and open airbrake breaker whenever continuity is to be checked or when

handling equipment connections. When shutting off power by means of knife or switch.

3.1.3.1 Attach an approved WARNING tag to the open breaker

3.1.4 Personal eye protection must be worn when doing any work to protect eyes from possible

injury.

3.1.5 Where fasteners removed from the equipment are not satisfactory for reuse, care must be

taken to select replacements that match the originals. Mismatched or incorrect fasteners can

result in equipment damage or malfunction, or possible personal injury.

3 Safety

High Voltages (AC and/or DC) are present. Always exercise extreme

care when working in close proximity to electrically energized appa-

ratus or when making current measurments. To prevent receiving

electrical shock when performing electrical tests, hands must be

clear of electrical components, contacts, and housing. There must

be no bodily contact with the work area.

Failure to comply with these instructions may lead to irreversible

physical injuries which may have fatal consequences.

Ensure that power and/or switches are turned off prior to making any

electrical connections/disconnections.

Failure to comply with these instructions may lead to irreversible

physical injuries which may have fatal consequences.

Knorr-Bremse Group Page 13 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

3.1.6 To ensure the correct functioning of each component, use only the manufacturers genuine

spare parts as replacements.

3.1.7 Appropriate tool selection is required when performing all maintenance operations to avoid

personal injury.

3.1.8 Person(s) having the appropriate job skill level, as governed by the user railroad, are required

when performing maintenance and/or operational tasks with the brake system and system

components.

3.1.9 Whenever a valve or system component is removed from a vehicle for any reason, and it is

reinstalled or replaced with a new or repaired and tested component, a stationary vehicle air

brake test and an equipment test must be performed to ensure that the component functions

properly within the system.

Knorr-Bremse Group Page 14 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

4.1 General

The Locomotive Cab Display Module (LCDM) is used in complex control and guidance

systems as a man-machine interface. It displays process data and receives inputs from the

operator.

Data entry occurs via keyboard designed with 11 function keys (softkeys).

The LCDM is based on a single-board PC ("embedded PC") with a GEODE processor.

An active matrix color display (TFT) is used for the display.

Figure 4-1 Locomotive Cab Display Module (LCDM)

4.2 Features:

• Power supply with galvanically isolated voltage converter (74 VDC or 110 VDC)

• Active Matrix color display (TFT) with background lighting, 640 x 480 pixel, 10.4"

• 4x COM interfaces (RS422 (HDLC supported)

• 1x COM interface RS232 (for service)

• 1x Ethernet interface (10/100 BaseT, with M12 connector, d-coded)

• 2x USB 1.1 interfaces (M8 connector)

• 11 illuminated function keys (softkeys)

• Operating temperature 782340 and 782342: -31° F...+158° F (-35° C...+70° C)

• No moving parts such as fan, hard disks, etc.

• Protection against formation of condensation in the device

4 Product Description

Knorr-Bremse Group Page 15 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

4.3 Electronic Components

4.3.1 Power Supply

The power unit can be adapted to the desired battery voltage with the aid of different DC/DC

converters.

Currently 74 VDC (782340) and 110 VDC (782342) applications are supported.

The device is protected against reverse polarity by the corresponding safety elements as well

as mechanically by a keyed connector.

The device does not have any externally accessible fuses. The device must be replaced if

faulty (see Section 8.4 "Corrective Maintenance" ).

The power consumption of the LCDM is typically 20 W (without heating), maximally 30 W.

4.3.2 TFT Display

The device has a 10.4" TFT display.

The display can portray 640 x 480 pixel with a color depth of 18 bit (262,144 colors) and a

viewing angle of ±60° horizontal and -55° ...+45° vertical to surface normal.

4.3.3 Background Lighting (Display)

Two CCFL tubes are used for the background lighting of the display. The brightness of the

CCFL tubes is controlled by an environment controller. The controller can switch the back-

ground lighting on and off as well as adapt the brightness automatically to the ambient

brightness and simultaneously superpose a manually set brightness value.

The keyboard is illuminated by LEDs.

4.3.4 Optical Sensor

An optical sensor in the front measures the ambient brightness and can adjust the display

background lighting as necessary.

4.3.5 Heating

For heating the device at low ambient temperatures, heaters are located directly on the main

board. When the PC-part is switched on, only one heater can be activated. The heater is

activated automatically by an environment controller.

Knorr-Bremse Group Page 16 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

4.3.6 Status LEDs

Three (3) Status LEDs, are located in the front. The LEDs can be activated from the applica-

tion via envcon daemon. The LED colors are:

Table 4-1 Status LEDs

4.3.7 Audible Alarm

*782340 with Serial Number Prefix prior to "GO" and 782342 with Serial Number Prefix prior

to "HO" have internal audible alarms.

Table 4-2 Overview of Acoustic Signaling Transmitter

4.3.8 System Clock

When powering up the operating system, the system time is synchronized with the time value

of the high-precision RTC of the mainboard.

4.3.9 Keyboard

The LCDM is delivered with 11 softkeys.

Designation Color Function

LED 1 Red Error status (optional)

Freely Available via AP1

LED 2 Yellow Operating state display:

Off – Device is off

On – Device is ready for operation

1 Hz Blinking – Device is outside of operating tem-

perature

4 Hz Blinking – Device off, watchdog limit achieved

LED 3 Blue Freely available via AP1

LCDMs w/Internal Alarm* LCDMs w/External Alarm

Location Mainboard Rear panel

Form Miniature piezoelectric buzzer Miniature piezoelectric buzzer

Volume 85 dB (at 24” (60 cm) distance, free

field)

85 dB (at 24” (60 cm) distance, free field)

Frequency 4 kHz 2.75 kHz

Knorr-Bremse Group Page 17 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

4.3.10 Ethernet

An Ethernet interface according to 10/100BaseT with M12 connector, d-coded, is implemen-

ted. Please observe Section 6.3.1, "Plug-pin Assignment" for a more detailed explanation of

these interfaces.

4.3.11 Four (4) Serial Interfaces RS422/RS485

The serial interfaces are electrically isolated RS422 and capable of sending and receiving

data via HDLC protocol. Please observe Section 6.3.1, "Plug-pin Assignment" for a more de-

tailed explanation of these interfaces.

4.3.12 Serial Interface RS232 (Maintenance)

The RS232 interface is provided for connecting a Service PC. Please observe Section 6.3.1,

"Plug-pin Assignment" for a more detailed explanation of this interface.

4.3.13 USB

There are 2 USB ports for external devices: two interfaces are available via two M8 connec-

tors which fulfill the V1.1 standard and which work with up to 12 MBit/s. For operating systems

without USB support, the Legacy Mode for USB keyboards is supported by the BIOS. Please

observe Section 6.3.1, "Plug-pin Assignment" for a more detailed explanation of this inter-

face.

4.4 Technical Data

4.4.1 Environmental

4.4.1.1 Definition of Temperatures

• Operating temperature:

Air temperature (in max. and min. limits) in the immediate environment of the device, at

which the device is permitted to be operated.

• Storage temperature:

Air temperature (in max. and min. limits) around the device at which the device is per-

mitted to be stored (equipment is isolated from power supply).

• Ambient temperature (in accordance with EN 50155)

1. Outside ambient temperature

2. Temperature inside the cabinet (Device ambient temperature)

3. Temperature of the air surrounding the printed circuit board module (temperature

inside the device).

Knorr-Bremse Group Page 18 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

Figure 4-2 Temperature Ranges According to EN 50155

(using a driver’s console as an example)

4.4.1.2 Operation temperature

782340/782342 -31° F...+158° F (-35° C...+70° C)

4.4.1.3 Storage

Temperature -31° F...+185° F (-35° C...+85° C)

4.4.1.4 Humidity

Humidity in accordance with EN 50155

4.4.1.5 Shock/vibration

Shock/vibration in accordance with EN 50155

4.4.1.6 Fire Protection

Fire Protection in accordance with DIN 5510 Part 2

4.4.2 Mechanical

4.4.2.1 Dimensions

Width 11" (280 mm), with front frame 13.6" (345 mm)

Height 8" (204 mm), with front frame 12.6" (227 mm)

Depth 1.7" (47 mm), with front frame 2" (53 mm)

4.4.2.2 Weight

Weight Approximately 7.49 lbs (3.4 kg, depending on equipment of model)

Knorr-Bremse Group Page 19 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

4.4.2.3 Protection Category

Housing IP54 (with attached wiring and unused plugs covered with a cap)

Front IP65 (when installed)

4.4.2.4 Other

Front Membrane polyester

Display Cover scratch-resistant toughened glass panel,

0.16" (4 mm) thick

The glass panel is inserted flush with the front membrane.

It is an anti-glare design with a glare value of 100.

4.4.3 Electrical

4.4.3.1 Power Supply

4.4.3.1.1 LCDM 782340

Connection reverse polarity protected

Nominal voltage 74VDC (25VDC...135VDC)

Power consumption typ. 20 W (without heating)

max. 30 W

max. starting current 25 A (30 µs.. .-50 µs)

Dielectric strength

Supply voltage primary against secondary / housing: 1,500VAC

Galvanically isolated circuits against housing: 2,000VAC (RS422),

1,000VAC (Ethernet, RS232)

Non galvanically isolated circuits against housing:

due to internal connection between secondary 0V and housing, this dielectric

strength is not given

4.4.3.1.2 LCDM 782342

Connection reverse polarity protected

Nominal voltage 110VDC (66VDC...154VDC)

Power consumption typ. 20 W (without heating)

max. 30 W

max. starting current 25 A (30 µs.. .-50 µs)

Dielectric strength

Supply voltage primary against secondary / housing: 1,500V AC

Galvanically isolated circuits against housing: 2,000V AC (RS422)

1,000V AC (Ethernet, RS232)

Non galvanically isolated circuits against housing:

due to internal connection between secondary 0V and housing, this dielectric

strength is not given.

Knorr-Bremse Group Page 20 / 40

Copyright 2015© NYAB. All rights reserved, including industrial property rights applications.

NYAB retains any power of disposal, such as copying and transferring.

Locomotive Cab Display Module (LCDM)

Maintenance Manual Doc. No. IP-235

03

4.4.3.1.3 Interfaces

Ethernet according to IEEE 802.3 10 Base T

and 100 Base Tx with M12 d-coded

4x serial interfaces according to IEEE RS422

resp. IEEE RS485, HDLC protocol

2x USB according to USB1.1, up to 12 MBit/s

1x serial interface according to IEEE RS232

4.4.3.2 TFT Display

Size 10.4" (visible diagonal measure)

Display Range 8.3" x 6.2" (211.2.mm x 158.4 mm)

Resolution 640 x 480 pixel (VGA)

Number of Colors 262,144 (18 bit)

Pixel Pitch 0.01" x 0.01" (0.33 mm x 0.33 mm)

Viewing Angle Vertical -55° to +45°

Horizontal -60° to +60°

Luminance max 550 nt (550 cd/m2)

(utilixsable 0 nt…

480nt (0 cd/m2…480cd/m2))

Contrast typical: 300:1

Response time typical: tr15 ms

tf35 ms

Design in accordance with ISO 13406-2

4.4.3.3 Audible Alarm

CCOM with Internally Mounted Audible Alarm

Signal Level approx. 85 dB at 24" (60 cm) free field distance

approx. 4 kHz continuous

LCDM with Externally Mounted Audible Alarm

Signal Level approx. 85 dB at 24" (60 cm) free field distance

approx. 2.75 kHz continuous

Table of contents

Other New York Air Brake Monitor manuals