New York Blower AcF/PLR Series User manual

CENTRIFUGAL FANS

AcF/PLR, AF, BC, BC Pressure Blowers, EcF Plenum, RTS, HPBC

WORD ABOUT SAFETY

Beginning in June 2012, the above WARNING signage has been

placed on all nyb fans, as specified by ISO and recommended by

the European Union. Air moving equipment involves electrical

wiring, moving parts, sound, and air velocity or pressure which

can create safety hazards if the equipment is not properly

installed, operated and maintained. To minimize this danger,

follow these instructions as well as the additional instructions and

warnings on the equipment itself.

All installers, operators and maintenance personnel should study

AMCA Publication 410, "Recommended Safety Practices for Air

Moving Devices", which is included as part of every shipment.

Additional copies can be obtained by writing to New York Blower

Company, 7660 Quincy St., Willowbrook, IL 60527.

ELECTRICAL DISCONNECTS

Every motor driven fan should have an independent disconnect

switch to isolate the unit from the electrical supply. It should be

near the fan and must be capable of being locked by mainte-

nance personnel while servicing the unit, in accordance with

OSHA procedures.

MOVING PARTS

All moving parts must have guards to protect personnel. Safety

requirements vary, so the number and type of guards needed to

meet company, local and OSHA standards must be determined

and specified by the user. Never start a fan without having all

safety guards installed. Check regularly for damaged or missing

guards and do not operate any fan with guards removed. Fans

can also become dangerous because of potential “windmilling”,

even though all electrical power is disconnected. Always block

the rotating assembly before working on any moving parts.

SOUND

Some fans can generate sound that could be hazardous to

exposed personnel. It is the responsibility of the system

designer and user to determine sound levels of the system,

the degree of personnel exposure, and to comply with

applicable safety requirements to protect personnel from

excessive noise. Consult nyb for fan sound power level

ratings.

AIR PRESSURE AND SUCTION

In addition to the normal dangers of rotating machinery, fans

present another hazard from the suction created at the fan

inlet. This suction can draw materials into the fan where they

become high velocity projectiles at the outlet. It can also be

extremely dangerous to persons in close proximity to the

inlet, as the forces involved can overcome the strength of

most individuals. Inlets and outlets that are not ducted should

be screened to prevent entry and discharge of solid objects.

Danger: Do Not Enter/Confined Space

ACCESS DOORS

The above DANGER decal is placed on all nyb cleanout

doors. These doors, as well as access doors to the duct

system, should never be opened while the fan is in operation.

Serious injury could result from the effects of air pressure or

suction.

Quick-opening doors must have the door handle bolts

securely tightened to prevent accidental or unauthorized

opening. Bolted doors must be tightened for the same reason.

RECEIVING AND INSPECTION

The fan and accessories should be inspected on receipt for

any shipping damage. Turn the wheel by hand to see that it

rotates freely and does not bind. If dampers or shutters are

provided, check these accessories for free operation of all

moving parts.

F.O.B. factory shipping terms require that the receiver be

responsible for inspecting the equipment upon arrival. Note

damage or shortages on the Bill of Lading and file any claims

for damage or loss in transit. nyb will assist the customer as

much as possible; however, claims must be originated at the

point of delivery.

INSTALLATION

MAINTENANCE,

OPERATING

INSTRUCTIONS

IM-100

Page 2

HANDLING

Fans should be lifted by the base, mounting supports, or

lifting eyes/lugs only. Never lift a fan by the wheel, shaft,

motor, motor bracket, housing inlet, outlet, or any fan part

not designed for lifting. A spreader should be used to avoid

damage.

On direct drive Arrangement 7 or 8 fans, lifting holes are pro-

vided in the motor base to assist in handling the fan

assembly. These lifting holes should be used in conjunction

with the lifting eyes/lugs when lifting and positioning the fan

onto its foundation. A heavy round steel bar or appropriate

fixture can be passed through the lifting holes to simplify

attachment of the lifting device. Be sure to follow all local

safety codes when moving heavy equipment.

STORAGE

Whenever possible, fans and accessories should be stored in

a clean, dry location to prevent rust and corrosion of steel

components. If outdoor storage is necessary, protection

should be provided. Cover the inlet and outlet to prevent the

accumulation of dirt and moisture in the housing. Cover

motors with water-proof material. Remove any fan and

motor drain plugs to minimize moisture buildup. Refer to

motor manufacturer’s IM manual for further motor storage

instructions.

Any stored bearing can be damaged by condensation

caused by temperature variations. Therefore, nyb fan

bearings are filled with grease at the factory to exclude

air and moisture. Such protection is adequate for

shipment and subsequent immediate installation and

operation.

For long term or outdoor storage, mounted bearings

should be immediately regreased and wrapped with

plastic for protection. Split housed bearings may require

additional grease to completely fill the bearing housing

cavity. Rotate the fan wheel and motor shaft by hand

at least every two weeks to redistribute grease on

internal bearing parts. Each month the fan and motor

bearings should be purged with new grease to remove

condensation, since even a filled bearing can accumulate

moisture. Use caution when purging, as excessive

pressure can damage the seals. Rotate the shaft while

slowly adding grease.

For Belt-Driven units, belts should be slackened to

prevent damage to shaft, belts, and bearings.

Check shutters for free operation and lubricate moving parts

prior to storage. Inspect the stored unit periodically to ensure

the above precautionary storage measures are still in tact.

Prior to start-up, split housed bearings should have excess

grease removed such that the grease level is level with the

bottom of the shaft.

FAN INSTALLATION

nyb wheels are dynamically balanced when fabricated. Fully

assembled fans are test run at operating speeds to check

the entire assembly for conformance to nyb vibration limits.

Nevertheless, all units must be adequately supported for

smooth operation. Ductwork or stacks should be indepen-

dently supported as excess weight may distort the fan

housing and cause contact between moving parts. nyb

recommends using flexible connections at the inlet and

outlet to prevent vibration transmission from the fan to

the system and vice versa. Flexible connectors also

eliminate loading issues stemming from thermal expansion in

systems with high temperature air streams. Where vibration

isolators are used, consult the nyb certified drawing for

proper location and adjustment.

Slab-Mounted Units

A correctly designed and level concrete foundation provides

the best means of installing floor-mounted fans. The mass of

the base must maintain the fan/driver alignment, absorb

normal vibration, and resist lateral loads. The overall

dimensions of the concrete base should extend at least six

inches beyond the base of the fan. The weight of the slab

should be approximately three times the weight of the total

fan assembly weight, including the motor. The foundation

requires firmly anchored fasteners such as the anchor bolts

shown in Figure 1. Hammer-drilled expansion fasteners can

be used in less demanding applications.

Move the fan to the mounting location and lower it over the

anchor bolts, leveling and supporting the fan base with shims

at each bolt hole location. Fasten the fan securely, ensuring

that the fan base is not put into a bind when tightening

anchor bolts. This may cause distortion that can be

transferred to the bearing housings, causing excessive

vibration and premature bearing failure. You should consider

grouting in fans sized 40 and larger. When grout is used,

shim the fan at least 3/4-inch from the concrete base. Do not

rely on grout to support the fan structure. (See Figure 1.)

When isolation is used, check the nyb certified drawing for

installation instructions.

Elevated Units

When an elevated or suspended structural steel platform is

used, it must have sufficient bracing to support the unit load

and prevent side sway. A poorly designed support structure

can experience resonance triggered by the fan operating

speed. The platform should be of welded construction to

maintain permanent alignment of all members.

Figure 1

Page 3

V-BELT DRIVE

Installation

1. Remove all foreign material from the fan and motor shafts.

Coat shafts with machine oil for easier mounting. Mount

the belt guard backplate at this time if partial installation is

required prior to sheave mounting.

2. Mount sheaves on shafts after checking sheave bores and

bushings for nicks or burrs. Avoid using force. If resistance

is encountered, lightly polish the shaft with emery cloth

until the sheave slides on freely. Tighten tapered bushing

bolts sequentially so that equal torque is applied to each.

3. Adjust the motor on its base to a position closest to the fan

shaft. Install belts by working each one over the sheave

grooves until all are in position. Never pry the belts into

place. On nyb packaged fans, sufficient motor adjustment is

provided for easy installation of the proper size belts.

Warning: Do not rotate sheaves by grabbing belts by

hand.

4. Adjust sheaves and the motor shaft angle so that the

sheave faces are in the same plane. Check this by placing a

straightedge across the faces of the sheaves. Any gap

between the edge and sheave faces indicates misalign-

ment. Important: This method is only valid when the width of

the surface between the belt edge and the sheave face is

the same for both sheaves. When they are not equal, or

when using adjustable-pitch sheaves, adjust so that all

belts have approximately equal tension. Both shafts should

be at right angles to the center belt.

Belt Tensioning

1. Check belt tension with a tensioning gage and adjust using

the motor slide base. Excess tension shortens bearing life

while insufficient tension shortens belt life, this can reduce

fan performance and may cause vibration. The lowest

allowable tension is that which prevents slippage under full

load. Belts may slip during start-up, but slipping should

stop as soon as the fan reaches full speed. For more

precise tensioning methods, consult the drive

manufacturer’s literature.

2. Recheck setscrews, rotate the drive by hand and check for

rubbing, then complete the installation of the belt guard

3. Belts tend to stretch somewhat after installation. Recheck

tension after several days of operation. Check sheave

alignment as well as setscrew and/or bushing bolt tightness.

COUPLING

Coupling alignment should be checked after permanent

installation and prior to start up. Alignment is set at the factory,

but shipping, handling, and installation can cause

misalignment. Also check for proper coupling lubrication. For

details on lubrication and for alignment tolerances on the

particular coupling supplied, see the manufacturer's installation

and maintenance supplement in the shipping envelope

Installation

Most nyb fans are shipped with the coupling installed. In cases

where the drive is assembled after shipping, install the coupling

as follows:

1. It is recommended to wait until the fan is permanently

installed before beginning the coupling alignment process

in order to prevent possible misalignment during fan

installation.

2. Remove all foreign material from fan and motor shafts and

coat with machine oil for easy mounting of coupling halves.

3. Mount the coupling halves on each shaft, setting the gap

between the faces specified by the manufacturer. Avoid

using force. If mounting difficulty is encountered, lightly

polish the shaft with emery cloth until the halves slide on

freely.

Alignment

1. Align the coupling to within the manufacturer's limits for

parallel and angular misalignment (see Figure 2). A dial

indicator or laser can also be used for alignment where

greater precision is desired. Adjustments should be made

by moving the motor to change shaft angle, and by the use

of foot shims to change motor shaft height. Do not move

the fan shaft or bearing.

2. When correctly aligned, install the flexible element and

tighten all fasteners in the coupling and motor base.

Lubricate the coupling if necessary.

3. Recheck alignment and gap after a short period of opera-

tion, and recheck the tightness of all fasteners in the cou-

pling assembly.

4. .

START-UP

A start-up checklist is available on nyb’s Maintenance manuals

page under the support tools menu, Click Here. Safe operation

and maintenance includes the selection and use of appropriate

safety accessories for the specific installation. This is the

responsibility of the system designer and requires consideration

of equipment location and accessibility as well as adjacent

components. All safety accessories must be installed properly

prior to start-up.

Safe operating speed is a function of system temperature and

wheel design. Do not under any circumstances exceed the

maximum safe fan speed published in your nyb certified

drawing package, which is available from your nyb field sales

representative.

Procedure

1. If the drive components are not supplied by nyb, verify with

the manufacturer that the starting torque is adequate for

the speed and inertia of the fan.

Figure 2

Page 4

2. Inspect the installation prior to starting the fan. Check for

any loose items or debris that could be drawn into the fan

or dislodged by the fan discharge. Check the interior of the

fan as well. Turn the wheel by hand to check for binding.

3. Check drive installation and belt tension.

4. Check the tightness of all setscrews, nuts and bolts.

Ensure that anchor bolts are also properly torqued. When

furnished, tighten hub setscrews with the wheel oriented

so that the setscrew is positioned underneath the shaft.

5. Install all remaining safety devices and guards. Verify that

the supply voltage is correct and wire the motor. “Bump”

the starter to check for proper wheel rotation.

6. Check to ensure that neither the fan nor motor shaft are

rotating.

7. “Bump” the starter to check for proper wheel rotation.

8. Use extreme caution when testing the fan with ducting dis-

connected. Apply power and check for unusual sounds or

excessive vibration. If either exists, see the section on

Common Fan Problems. To avoid motor overload, do not

run the fan for more than a few seconds if ductwork is not

fully installed. Without the ductwork attached, normal oper-

ating speed may not be obtained without motor overload.

Once ductwork is attached, check for correct fan speed

and complete installation. Ductwork and guards must be

fully installed for safety.

9. All wheel, sheave, and coupling setscrews should be

rechecked after a few minutes, eight hours and two weeks

of operation (see Tables 1 & 2 for correct tightening

torques).

NOTE: Shut the fan down immediately if there is any

sudden increase in fan vibration.

Fan Shutoff for Fans with Elevated Airstream

Temperatures (Greater than 200 °F)

High temperature, rotating equipment such as fans must be

protected from “heat soaking”. Fan wheels must be rotating

whenever the airstream temperature is above 200°F. to

prevent the shaft from “sagging” causing a permanent bend in

the shaft. After the airstream temperature has fallen below

200°F, the fan can be shutdown. Start-up and shut down

procedures are required to prevent this. If a power failure

occurs, rotate the shaft manually if necessary.

If a shaft is bent due to heat soaking or binding a sudden

increase in fan vibration will occur. The shaft will need to be

removed, checked for straightness and straightened or

replaced.

FAN MAINTENANCE

nyb fans are manufactured to high standards with quality mate-

rials and components. Proper maintenance will ensure a long

and trouble-free service life. Do not attempt any maintenance

on a fan unless the electrical supply has been completely

disconnected and locked out. In many cases, a fan can

windmill despite removal of all electrical power. The rotating

assembly should be blocked securely before attempting

maintenance of any kind.

The key to good fan maintenance is regular and systematic

inspection of all fan parts. Inspection frequency is determined by

the severity of the application and local conditions. Strict

adherence to an inspection schedule is essential.

Regular fan maintenance should include the following:

1. Check the fan wheel for any wear or corrosion, as either

can cause catastrophic failures. Check also for the build-up

of material, which can cause unbalance resulting in

vibration, bearing wear and serious safety hazards. Clean

or replace the wheel as required.

2. Check the V-belt drive for proper alignment and tension

(see section on V-belt drives). If belts are worn, replace

them as a set, matched to within manufacturer’s tolerances.

Lubricate the coupling of direct-drive units and check for

alignment (see section on couplings).

3. Lubricate the bearings, but do not over lubricate (see the

bearing section for detailed specifications).

4. Ceramic-felt shaft seals require no maintenance, although

worn seals should be replaced. When lip-type shaft seals

are provided, lubricate them with "NEVER-SEEZ" or other

anti-seize compound. Schedule in accordance with the

bearing lubrication table on page 5.

WARNING: Do not remove or loosen the fan hub from the

fan wheel. Removing or loosening the fan hub from the fan

wheel will cause imbalance and void the warranty.

5. During any routine maintenance, all setscrews and bolts

should be checked for tightness. See the corresponding

table for correct torques.

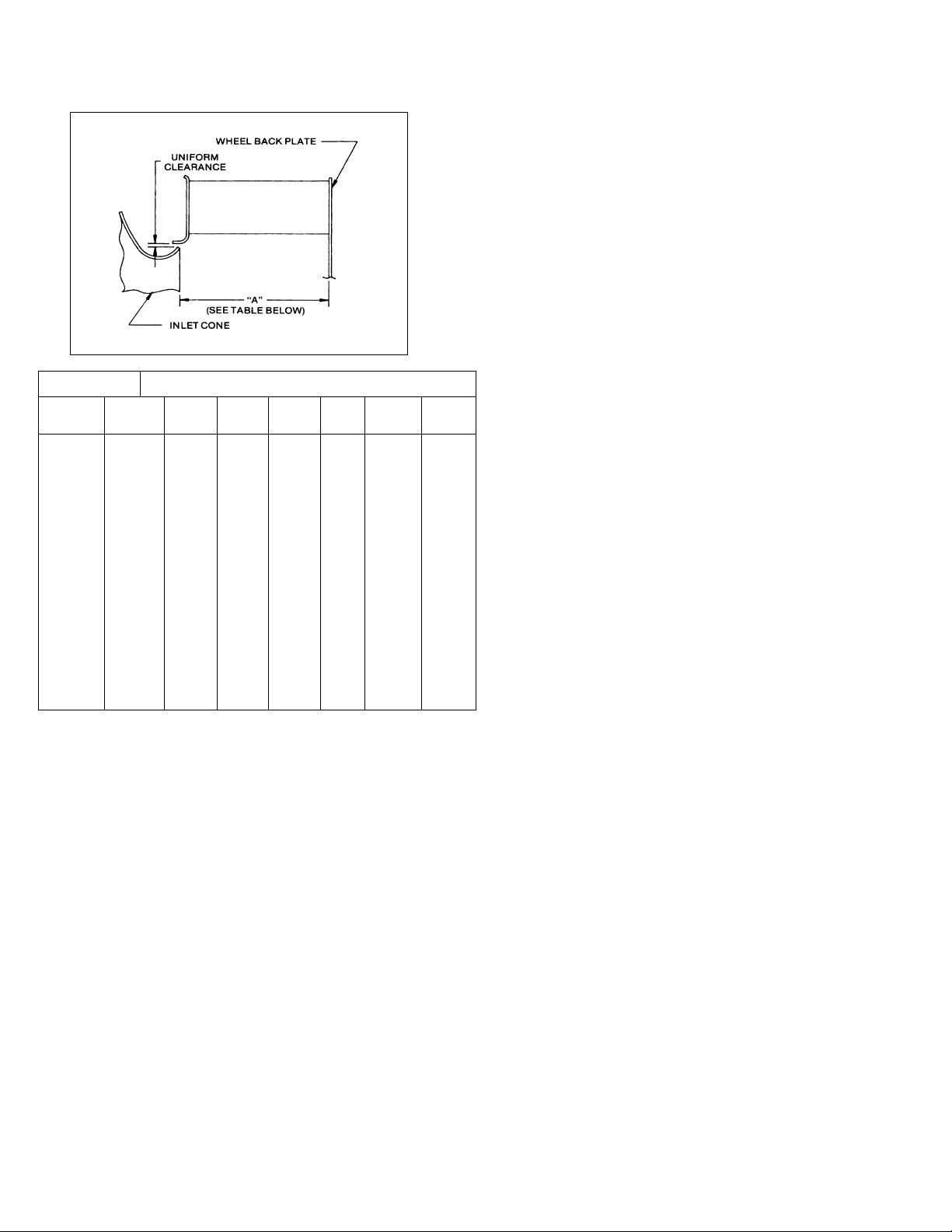

6. When installing a new wheel or cone, the proper wheel-to-

inlet cone clearance must be maintained (see Figure 3 for

correct full-width wheel dimensions) (Dims. for narrow

width wheels will vary)

Setscrew

Manufacturer

Diameter

Link-Belt

Sealmaster

SKF

McGill

Dodge

#10

40

--

35

35

--

1/4

90

65

50

85

--

5/16

185

125

165

165

160

3/8

325

230

290

290

275

7/16

460

350

350

--

--

1/2

680

500

620

--

600

5/8

1350

1100

1325

--

1200

3/4

2350

--

--

--

2000

Table 1 - WHEEL SETSCREW TORQUES

Setscrew Size

Carbon Steel Setscrew Torque*

Diameter (in.)

lb.-in.

lb.-ft.

1/4

75

6.2

5/16

144

12

3/8

252

21

7/16

396

33

1/2

600

50

5/8

1164

97

3/4

2016

168

7/8

3204

267

1

4800

400

Table 2 –BEARING SETSCREW TORQUE, lb.-in.

Note: Split pillow block bearing are fixed to the shaft

with tapered sleeves and generally do not have

setscrews.

* Stainless Steel setscrews are not hardened and should

not be tightened to more than 1/2 the values shown.

Page 5

Figure 3

WHEEL BALANCE

Airstreams containing particulate or chemicals can cause abra-

sion or corrosion of the fan parts. This wear is often uneven and

can lead to significant wheel imbalance over time. When such

wear is discovered, a decision must be made as to whether to

rebalance or replace the wheel.

The soundness of all parts should be determined if the original

thickness of components is reduced. Be sure there is no hidden

structural damage. The airstream components should also be

cleaned to remove any build-up of foreign material. Specialized

equipment can be used to rebalance a cleaned wheel that is

considered structurally sound.

Balance weights should be rigidly attached at a point that will not

interfere with the housing nor disrupt airflow. Remember that

centrifugal forces can be extremely high at the outer radius of a

fan wheel. Welding is the preferred method of balance weight

attachment. Be sure to ground the welder directly to the fan

wheel. Otherwise, the welding current could pass through the

fan bearings and damage them.

BEARINGS

Storage

Any stored bearing can be damaged by condensation

caused by temperature variations. Therefore, nyb fan

bearings are filled with grease at the factory to exclude

air and moisture. Such protection is adequate for

shipment and subsequent immediate installation and

operation.

For long term or outdoor storage, mounted bearings

should be immediately regreased and wrapped with

plastic for protection. Split housed bearings may require

additional grease to completely fill the bearing housing

cavity. Rotate the fan wheel and motor shaft by hand

at least every two weeks to redistribute grease on

internal bearing parts. Each month the fan and motor

bearings should be purged with new grease to remove

condensation, since even a filled bearing can accumulate

moisture. Use caution when purging, as excessive

pressure can damage the seals. Rotate the shaft while

slowly adding grease.

Operation

Check the setscrew torque before start-up (see

corresponding table for correct values). Since bearings are

completely filled with grease at the factory, they may run at

an elevated temperature during initial operation. Surface

temperatures may reach 180°F. and grease may bleed

from the bearing seals. This is normal and no attempt

should be made to replace lost grease. Bearing surface

temperatures will decrease when the internal grease

quantity reaches a normal operating level. Relubrication

should follow the recommended schedule.

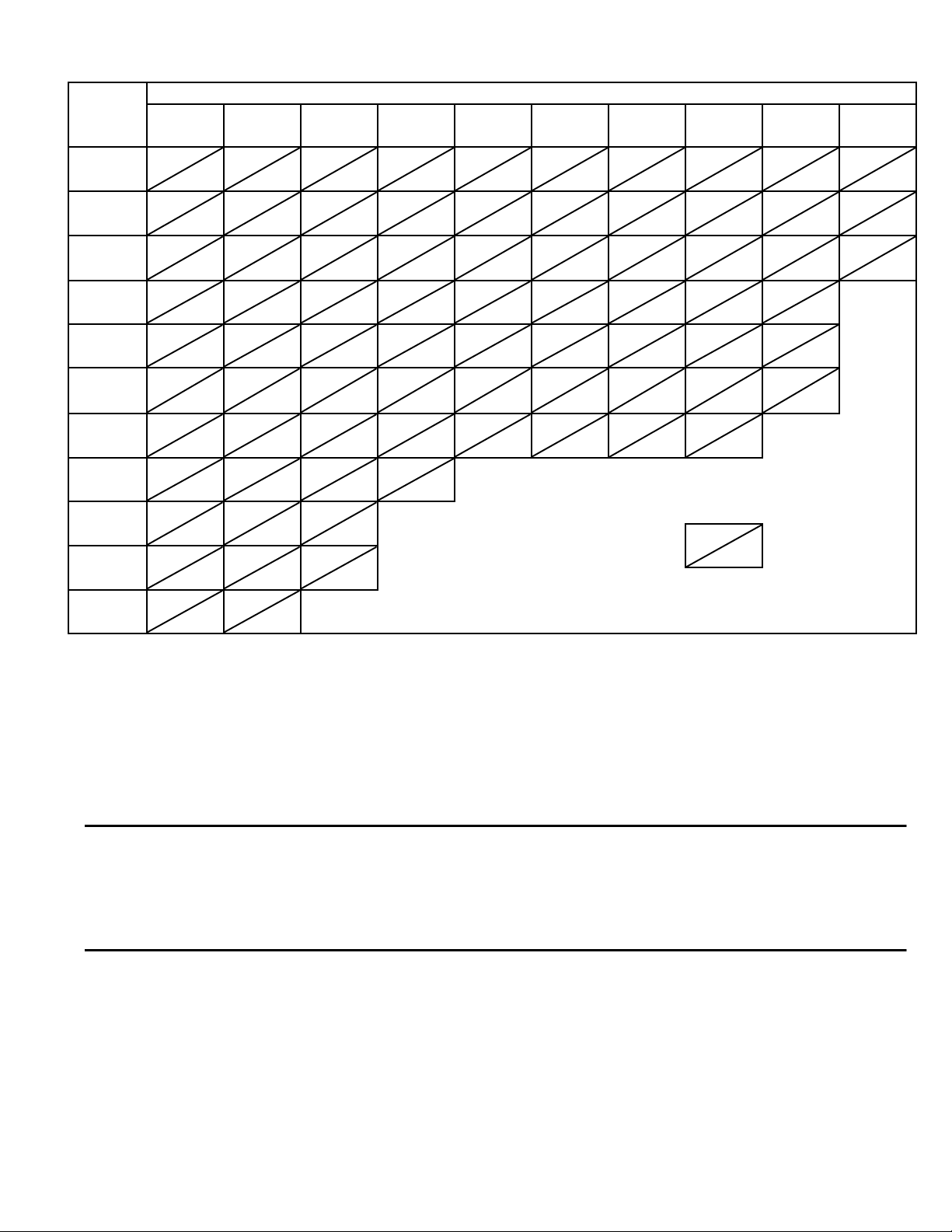

Lubrication

Use the table for relubrication scheduling according to

operating speed and shaft diameter. Fan bearings should

be lubricated with a premium quality lithium-based grease

conforming to NLGI Grade 2. Examples are:

Mobil - Mobilgrease XHP 222 Exxon - Ronex MP

Mobil - Unirex N2 Shell - Gadus S2 V220

Mobil - SHC100

These greases are for fan bearing surface temperatures of

40°F. to 180°F. For surface temperatures of 181°F. to

230°F. use Mobilith SHC220. Do not use “high

temperature” greases, as many are not formulated to be

compatible with fan bearings.

Add grease to the fan bearings while running the fan or

rotating the shaft by hand. Be sure all guards are in place

if lubrication is performed while the fan is operating. Add

just enough grease to cause a slight purging at the seals

except on split pillowblocks. Completely filled fan bearings

will run hotter until a sufficient amount of grease is purged

out of the seals.

Split pillowblock bearings (Link-Belt P-LB6800 & P-

LB6900, SKF SAF 22500, Dodge SAF-XT) should be

cleaned and repacked at approximately every eighth

lubrication interval. This requires removal of the bearing

cap. Clean out old grease and repack the bearing with

fresh grease. Pack the bearing fully and fill the housing

reservoir to the bottom of the shaft on both sides of the

bearing. Replace the bearing cap, being careful not to mix

caps, as they are not interchangeable from one bearing to

another. Do not over lubricate split pillowblock

bearings.

Refer to your motor manufacturer’s installation and

maintenance manual for motor bearing lubrication

information.

Fan Size

“A” Dimension [inches]

AcF/PLR,

BC, EcF

Plenum

AF, HPBC,

RTS

AcF/PLR

AF

BC

RTS

HPBC

EcF

Plenum

10

--

3 1/2

--

--

--

--

--

12

--

4 1/2

--

--

--

--

4 5/8

15

--

5 1/2

--

--

--

--

5 7/8

18

24

7

7 1/4

--

--

4 7/8

7 1/2

22

27

8 1/4

8

--

6 7/8

5 3/8

8 7/8

24

30

9 1/4

9

9 3/16

7 5/8

6

10 1/8

27

33

10 1/8

9 3/4

10 1/8

8 3/8

6 9/16

10 7/8

30

36

11 1/4

10 7/8

11 3/16

9 3/8

7 1/4

12

33

40

12 1/4

12

12 5/16

10 1/2

8

13 1/8

36

44

13 3/8

13 1/4

13 5/8

11 5/8

8 7/8

14 1/2

40

49

14 3/4

14 5/8

15 1/16

12 7/8

9 3/4

15 7/8

44

54

16 1/4

16 1/8

16 5/8

14 1/4

10 13/16

17 3/8

49

60

17 7/8

17 3/4

18 5/16

15 3/4

11 15/16

19 1/4

54

66

19 3/4

19 5/8

20 1/4

17 3/8

13 1/8

21 1/8

60

73

21 3/4

21 3/4

22 3/8

19 1/4

14 9/16

23 1/4

66

80

24

24

24 5/8

20 7/8

16 1/16

25 5/8

73

--

26 1/2

27 1/4

27 1/4

23 1/4

17 3/4

27 5/8

80

8

--

28 3/4

30 1/8

30 1/8

--

--

--

89

--

31 5/8

33 1/4

33 1/4

--

--

--

FULL WIDTH WHEEL CONE CLEARANCES

(contact nyb for partial width dimensions)

Page 5

BEARING LUBRICATION INTERVAL (months)

Shaft

RPM

1-500

501-1000

1001-1500

1501-2000

2001-2500

2501-3000

3001-3500

3501-4000

4001-4500

4501-5000

5/8

Thru

1

6

6

6

5 2

6 2

6 2

4 1

4 1

4 1

2 1

13/16

thru

1 7/16

6 6

6 2.5

6 1.75

4 1.25

4 1

4 1/2

2 1/2

2 1/2

2 1/2

1 1/2

1 11/16

thru

1 15/16

6 6

6 2.5

4-6 1.5

4 1.14

4 3/4

2 1/2

2 1/2

2 1/2

1 1/2

1

2 3/16

6 6

6 2.25

4-6 1.25

4 3/4

2 1/2

2 1/2

1 1/2

1 1/2

1

2 7/16

6 4

4-6 2

4-6 1

4 3/4

2 1/2

2 1/2

1 1/2

1

1

2 11/16

&

2 15/16

5 4

4 2

2-4 1

2 3/4

2 1/2

1 1/2

1

1

1

3 7/16

thru

4 3/16

4 4

4 2

2-4 1

1 1/2

2

1

1

1

4 7/16

4 4

4 1

2 1/2

1

Ball Bearings & Split Pillowblock

Spherical Roller Bearings

4 15/16

4 2

4 1

2 1/2

5 7/16

6

4

2

Non-Split Pillowblock Spherical

Roller Bearings

6

6

4

Note:

1. These are general recommendations only; specific

manufacturer’s recommendations may vary slightly.

2. Assumes clean environment, -20°F. to 120°F.

a. Consult The New York Blower Company for operation

below -20°F. ambient.

b. Ambient temperature greater than 120°F. will shorten

bearing life.

c. Under extremely dirty conditions, lubricate more

frequently.

3. Assumes horizontal mounting configuration. For vertically

mounted applications, lubricate twice as frequently.

Government Warnings

Disposal of material should be made in accordance to local government regulations.

California Prop 65 –WARNING: This product contains a chemical known to the state of California to cause cancer and/or

birth defects or other reproductive harm.

The New York Blower Company –7660 Quincy Street –Willowbrook, Illinois 60527-5530

Page 6

COMMON FAN PROBLEMS

Excessive Vibration

A common complaint regarding industrial fans is “excessive

vibration”. nyb is careful to ensure that each unit is precisely

balanced prior to shipment; however, there are many other

causes of vibration including:

1. Loose mounting bolts, setscrews, bearings or couplings.

2. Misalignment or excessive wear of couplings or

bearings.

3. Misaligned or unbalanced motor.

4. Bent shaft due to mishandling or material impact.

5. Accumulation of foreign material on the wheel.

6. Excessive wear or erosion of the wheel.

7. Excessive system pressure or restriction of airflow due

to closed dampers.

8. Inadequate structural support, mounting procedures or

materials.

9. Externally transmitted vibration.

Inadequate Performance

1. Incorrect testing procedures or calculations.

2. Fan running too slowly.

3. Fan wheel rotating in wrong direction or installed

backwards on shaft.

4. Wheel not properly centered relative to inlet cone.

5. Damaged or incorrectly installed cut off sheet or

diverter.

6. Poor system design, closed dampers, air leaks, clogged

filters, or coils.

7. Obstructions or sharp elbows near inlets.

8. Sharp deflection of airstream at fan outlet.

Excessive Noise

1. Fan operating near “stall” due to incorrect system

design or installation.

2. Vibration originating elsewhere in the system.

3. System resonance or pulsation.

4. Improper location or orientation of fan intake and

discharge.

5. Inadequate or faulty design of supporting structures.

6. Nearby sound reflecting surfaces.

7. Loose accessories or components.

8. Loose drive belts.

9. Worn bearings.

Premature Component Failure

1. Prolonged or major vibration.

2. Inadequate or improper maintenance.

3. Abrasive or corrosive elements in the airstream or sur-

rounding environment.

4. Misalignment or physical damage to rotating components

or bearings.

5. Bearing failure from incorrect or contaminated lubricant or

grounding through the bearings while arc welding.

6. Excessive fan speed.

7. Extreme ambient or airstream temperatures.

8. Improper belt tension.

9. Improper tightening of wheel setscrews.

REPLACEMENT PARTS

It is recommended that only factory-supplied replacement parts

be used. nyb fan parts are built to be fully compatible with the

original fan, using specific alloys and tolerances. These parts

carry a standard nyb warranty.

When ordering replacement parts, specify the part name, nyb

shop and sequence number, fan size, type, rotation (viewed

from drive end), arrangement and bearing size or bore. Most of

this information is on the metal nameplate attached to the fan

base.

For assistance in selecting replacement parts, contact your local

nyb representative or visit: zhttp://www.nyb.com/replacement-

parts-form/

Example 1 (Prior to 2013):

Part required: Wheel

Shop/control number: B-10106-100

Fan description: 33" PLR

Clockwise rotation

Arrangement: 1

Bearing: Link-Belt P335, 2-3/16 Bore

Example 2 (After to 2013):

Part required: Wheel

Shop number: 2013-XXXXX Wheel

Size & Type: 36 ACF

Year of Manufacture: 2013

Fan Description: ACF SW Fan Class 3 Arr-9

Suggested replacement parts include:

Wheel Component parts: Damper

Shaft Motor

Bearings Coupling

Shaft Seal Sheaves

Inlet Cone V-Belts

LIMITED PRODUCT WARRANTY

All products are warranted by nyb to be free from defects in materials

and workmanship for a period of one (1) year after shipment from its

plant, provided buyer demonstrates to satisfaction of nyb that the

product was properly installed and maintained in accordance with nyb's

instructions and recommendations and that it was used under normal

operating conditions.

This warranty is limited to the replacing and/or repairing by nyb of any

part or parts which have been returned to nyb with nyb's written

authorization and which in nyb's opinion are defective. Parts not

manufactured by nyb but installed by nyb in equipment sold to the

buyer shall carry the original manufacturer’s warranty only. All

transportation charges and any and all sales and use taxes, duties,

imports or excises for such part or parts shall be paid for by the buyer.

nyb shall have the sole right to determine whether defective parts shall

be repaired or replaced.

This warranty does not cover any customer labor charges for

replacement of parts, adjustments or repairs, or any other work unless

such charges shall be assumed or authorized in advance, in writing, by

nyb.

This warranty does not cover any product which, in the judgement of

nyb, has been subject to misuse or neglect, or which has been

repaired or altered outside nyb's plant in any way which may have

impaired its safety, operation or efficiency, or any product which has

been subject to accident.

This warranty shall be null and void if any part not manufactured or

supplied by nyb for use in any of its products shall have been

substituted and used in place of a part manufactured or supplied by

nyb for such use.

There are no warranties, other than those appearing on the

acknowledgement form INCLUDING NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, given in connection with the sale of the goods sold

hereunder. The buyer agrees that his sole and exclusive remedy, and

the limit of nyb's liability for loss from any cause whatsoever, shall be

the purchase price of the goods sold hereunder for which a claim is

made.

2

3

4

5

7

9

6

8

NON-ROTATABLE

CENTRIFUGAL FANS

ROTATABLE

CENTRIFUGAL FANS

1.INLET HANGER BRACKET

2.INLET COLLAR ASSEMBLY

3.INLET CONE WITH DIVERTER #

4.WHEEL *#

5.SHAFT *

6.HOUSING #

7.HOUSING/BEARING

PEDESTAL ASSEMBLY

8.DRIVE SIDE HANGER ASSEMBLY

9.BEARINGS *

PARTS LIST

When ordering replacement parts

supply nyb shop number from

nameplate and complete description

of parts required.

*Suggested Repair Parts

#Order for parts must

specify rotation.

WHEEL ROTATION AS VIEWED FROM DRIVE SIDE

(COUNTERCLOCKWISE)

ACF PLR AF-FORTY RTS

ARROW INDICATES CORRECT ROTATION

9

4

5

3

21

For assistance in selecting replacement parts, contact your local

nyb representative or visit: http://www.nyb.com.

Form 218 JLK

This manual suits for next models

5

Table of contents

Popular Fan manuals by other brands

Savoy House

Savoy House 54-6000-5DW-109 owner's manual

Metal Fab

Metal Fab PIC Installation and maintenance instructions

TroposAir

TroposAir Voyage 4VO40 owner's manual

Argos

Argos Challenge FS40-9HRA Assembly instructions

Soltronic

Soltronic LTG-CF5001 Installation instruction

AERMEC

AERMEC FCLI 32 installation manual