Metal Fab PIC User manual

INSTALLATION AND

MAINTENANCE

INSTRUCTIONS

PIC

IPIC

MODEL PIC/IPIC

CHIMNEY AND VENTS This symbol on the nameplate

means this product is listed by

Underwriters Laboratories Inc.

and by Underwriters

Laboratories of Canada

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS

FAILURE TO MAINTAIN REQUIRED CLEARANCES

(air spaces) TO COMBUSTIBLE MATERIALS. IT IS OF

UTMOST IMPORTANCE THAT CHIMNEY BE INSTALLED

ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

IMPORTANT: DO NOT INSTALL CHIMNEY WITHOUT

FIRST READING THESE INSTRUCTIONS

VERY CAREFULLY.

Metal-Fab’s Model PIC/IPIC Chimney has been fully tested and listed by Underwriters Laboratories, Inc.

and Underwriters Laboratories of Canada.

Chimneys installed in accordance with these installation instructions will comply with national safety

standards and building codes.

This booklet contains complete information on details concerning dimensions, installation, clearances to

combustibles, and use of non-combustible enclosures. For any additional construction information, refer

to Model PIC/IPIC Design Manual - L1690.

• BREECHING APPLICATIONS

• BOILER EXHAUST APPLICATIONS

• ENGINE/TURBINE EXHAUST APPLICATIONS

METAL-FAB, INC. • P.O. BOX 1138, WICHITA, KANSAS 67201 • (316)943-2351

GENERAL INFORMATION

LISTINGS

Metal-Fab Model PIC/IPIC Chimney is “listed” by Underwriters Laboratories, Inc (UL File No. MH8251) as “Building Heating Appliance

Chimney” for continuous operation at 1000ºF and intermittent operation (less than one hour) at 1400ºF. For higher temperature

applications, it is also “listed” as “1400ºF Factory Built Chimney” for continuous operation at 1400ºF and intermittent operation at

1800ºF. PIC/IPIC Chimney is “listed” by Underwriters Laboratories of Canada (ULC File No. CMH1272) as a continuous operation

“760ºC Factory-Built Chimney.” PIC/IPIC Chimney is “listed” for use at maximum 60-inch water column (2.19 psig) positive internal

pressure when installed in accordance with the section “PIPE AND FITTING ASSEMBLY” for 60 in.wc. in these instructions. See

TABLE 1 for clearances. For sizes 6” to 14” diameter: IPIC-2, IPIC-3 and IPIC-4 chimney is “Listed” to UL103-HT for use as a

Residential Chimney and is permitted to be installed within fully enclosed combustible construction at 2” min. clearance.

APPLICATIONS

Model PIC/IPIC building heating appliance chimneys are suitable for use with building heating appliances and other low heat

appliances as described in the Chimney Selection Chart of the National Fire Protection Association Standard No. 211, which produce

exhaust ue gas at a temperature not exceeding 1000ºF continuous. PIC/IPIC Chimneys are also suitable for use as complete

exhaust systems for diesel engines and gas turbines. The Model PIC/IPIC product line is listed for higher heat applications where

continuous temperatures are not in excess of 1400ºF and where the intermittent maximum temperatures are less than 1800ºF.

These chimneys are to be installed as required by NFPA for Factory Built Chimneys and Chimney Units. They are not to be enclosed

within combustible construction. An interior exhaust system is to be enclosed in a re resistive shaft of appropriate size and rating

where the exhaust system extends through any story of a building above that in which the connected appliance is located. An

unenclosed chimney may be placed adjacent to walls of combustible construction at the clearances specied herein. Consult local

authorities having jurisdiction.

Model PIC/IPIC chimneys are intended for use as complete systems connecting the appliance, engine or duct to the outdoors, or

as appliance connector, ue gas collector and breeching conveying ue gas to a stack built in conformance with NFPA 211, while

operating under positive forced draft, negative draft or neutral gravity ow internal pressure conditions.

The Model PIC/IPIC pipe is ideally suited to this application because it is a circular cross section (low friction loss), double-wall

insulated, high-strength to weight ratio design using high quality stainless steels.

Complete system size and capacity information can be obtained from the ASHRAE Handbook, Equipment Volume or by contacting

Metal-Fab, Inc., PO Box 1138, Wichita, KS 67201.

Refer to Metal-Fab Model PIC/IPIC Design Maual - L1690 for description of all necessary components.

MULTI-ENGINE EXHAUSTS NOT RECOMMENDED

Where multiple engines are being considered, it is recommended that they not be connected into one common exhaust system.

Exhaust gases tend to ow to cooler, non-operating engines, thereby causing formation of condensation. Consult with your engine

manufacturer before the installation of multiple engines vented into a common exhaust.

When designing engine exhaust systems:

• Provide correct pipe diameter and keep runs short with the minimum number of turns possible.

• Ensure that exhaust system is properly supported and is isolated from vibration.

• Pay particular attention to thermal expansion and placement of bellows joints.

• Provide proper condensation traps and drains.

EXPLOSION PROTECTION

The use of PIC/IPIC ttings such as lateral tees, wyes and elbows should be kept to a minimum to reduce back pressure and

accumulation of unburned fuels. When a change of direction is required in and engine exhaust system, ttings used for direction

change must be reinforced by means of plate support or wall support assemblies to prevent damage if an explosion caused by ignition

of unburned fuel should occur. Additionally, the exhaust system should be equipped with a relief valve if possible. For methods of

reinforcement and placement of relief valve, see section titled “ENGINE EXHAUST SYSTEM PRECAUTIONS.”

GREASE DUCT APPLICATIONS

Metal-Fab Model PIC/IPIC chimney is listed as grease duct for continuous temperature of 500ºF and intermittent temperatures of

2000ºF. Refer to the “Grease Duct Installation Manual L2502” for specic application information.

OPERATING PRECAUTIONS

CREOSOTE AND SOOT – Formation and Need for Removal

When wood is burned slowly, it produces tar and organic vapors which combines with expelled moisture to form creosote. The

creosote vapors condense in the relatively cool chimney ue of a slow burning re. As a result, creosote residue accumulates on the

ue lining. If ignited, this creosote makes an extremely hot re. For this reason, the chimney should be inspected at least once every

two months during the heating season to determine if a creosote or soot buildup has occurred. If creosote or soot has accumulated,

it should be removed to reduce risk of chimney re.

A licensed or qualied chimney sweep should be contacted to clean the chimney. Contact local building or re ofcials about

restrictions and installation inspection in your area. Adequate clearance is required around cleanouts to assure accessibility for

removal of caps and products accumulated within the chimney.

NOTE: Dimensions in these instructions are in American standard (feet and inches), with Metric (mm) in parenthesis except

stated otherwise.

2

CHIMNEY ENVIRONMENT

It is suggested that a chimney being installed in a corrosive

atmosphere be constructed of Type 316 stainless steel.

Type 316 stainless is resistant to corrosion and will add to

the life expectancy of the installation. Chemicals containing

halogen compounds should not be allowed to contaminate the

combustion air supplied to the heating equipment. Storage or

use of chemicals containing chlorine or chlorides in the vicinity

of equipment, or the presence of these compounds in the fuel,

or combustion air supply may lead to early deterioration of the

chimney.

Chemicals which may cause attack on chimney materials include

(but are not limited to):

•chlorinated or halogenated dry cleaning solutions,

• uorocarbon refrigerants,

•hydrochloric (muriatic), sulfuric or other acids,

• uorocarbon aerosol propellants,

•vinyl plastics (when burned),

•chlorine bleach and cleaning solutions,

•titanium tetrachloride, or

•plating or etching baths or solutions.

Any of these chemicals passing through the combustion process

produce acids which can corrode the heating equipment and the

chimney.

If corrosion is found, an immediate investigation should be

undertaken of the entire area. Any corrosive materials should

be removed to avoid future contamination. A contaminate-free

atmosphere for combustion and ventilation air must be obtained.

It may be necessary to pressurize the equipment room with its

own air supply. Any surface discoloration should be carefully

studied as it may be caused by contaminates in the fuel, or

corrosion of mild steel components of the chimney system, the

breeching system, or the equipment being vented and may be

indicative of deterioration of other components of the heating

system.

Whenever the local atmosphere is high in pollutants, constantly

or intermittently, it is recommended that the chimney components

be of all stainless steel construction. When chimney is exposed

to the elements, it is recommended that the outer wall be

either painted with one base coat and one nish coat of a heat

resistant primer and paint, or that the outer wall be constructed

of stainless steel.

TERMINATION HEIGHT REQUIREMENTS

Model PIC/IPIC chimney is to terminate a minimum of 3’ (914)

above the highest point where it passes thru a roof of a building

and a minimum of 2’ (610) higher than any portion of a building

within a horizontal distance of 10’ (3.05m) (See FIG. 1).

CLEARANCES – BOILERS AND ENGINES

CAUTION– DO NOT ENCLOSE INA CHASE OR PASSAGEWAY

OF COMBUSTIBLE MATERIAL

For appliances operating with continuous exhaust temperatures

up to 1400º F, where the chimney is installed in an open room

or fully ventilated area on the same story as the appliance to

which it is connected, Model PIC/IPIC Chimney shall be installed

at a minimum of the clearance to combustibles as indicated in

TABLE 1.

Except for installation in one or two family dwellings, a factory-

built chimney that extends through any zone above that on which

the connected appliance is located is to be provided with an

enclosure having a re resistance rating equal to or greater than

that of the oor or roof assemblies through which it passes.

Metal-Fab Model PIC/IPIC Chimney can penetrate a combustible

roof by utilizing the Roof Support Assembly (RSA) or Ventilated

Thimble Assembly (VTA). All other parts are for attachment to

non-combustible construction (i.e., oor guides, wall guides,

plate or wall support assemblies).

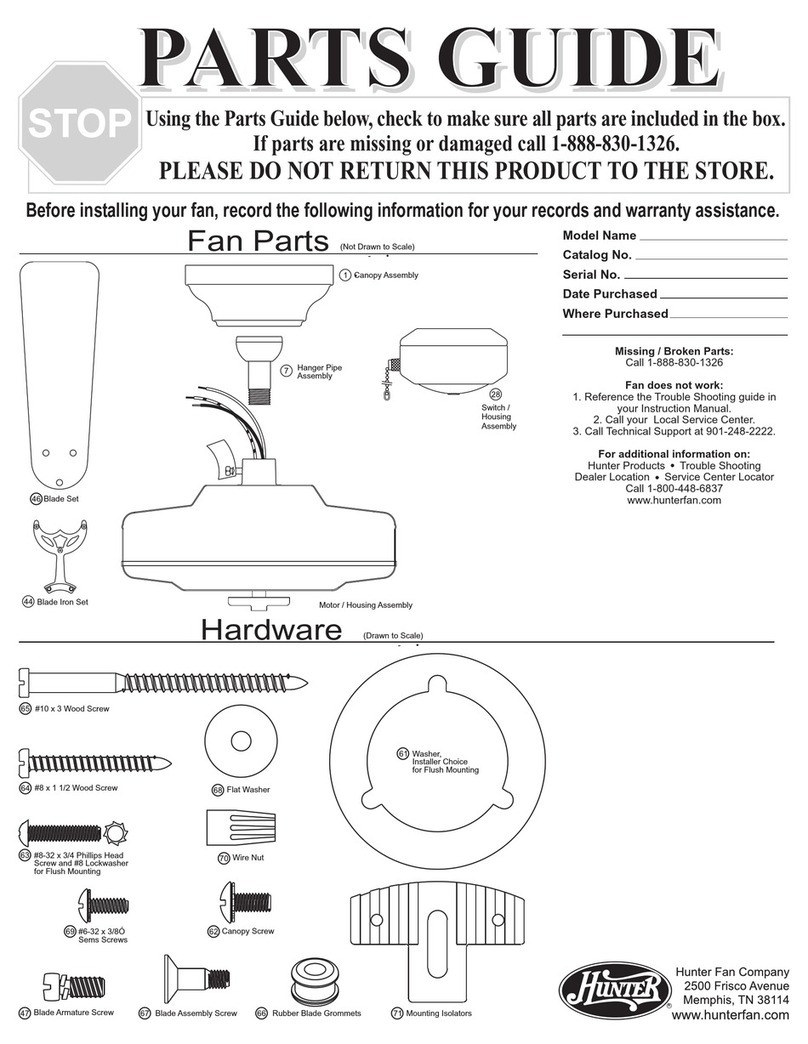

TABLE 1 - PIC/IPIC INSTALLATION CLEARANCES

Operating Temperature

1000°F Continuous

(538°C)

1400°F Intermittent

(760°C)

1400°F Continuous

(760°C)

1800°F Intermittent

(982°C)

Insulation

Thickness PIC IPIC-1 IPIC-2

IPIC-4 PIC IPIC-1 IPIC-2

IPIC-4

Exterior Wood Frame or Combustible Wall

Diameter: 6”

8 - 16”

18”

20”

22”

24 - 26”

28 - 32”

34”

36 - 40”

42 - 48”

4” (102)

4” (102)

5” (127)

6” (152)

6” (152)

6” (152)

6” (152)

6” (152)

6” (152)

6” (152)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

4” (102)

4” (102)

6” (152)

8” (204)

9” (229)

10” (254)

10” (254)

10” (254)

10” (254)

10” (254)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

Exterior Non-Combustible

Diameter: 6”

8 - 18”

20 - 42”

44 - 48”

2” (51)

2” (51)

4” (102)

4” (102)

1” (25)

2” (51)

3” (76)

4” (102)

1” (25)

1” (25)

1” (25)

1” (25)

2” (51)

2” (51)

4” (102)

4” (102)

1” (25)

2” (51)

3” (76)

4” (102)

1” (25)

1” (25)

1” (25)

1” (25)

Interior Wood or Other Combustibles

Diameter: 6”

8 - 16”

18”

20”

22”

24”

26”

28 - 32”

34”

36 - 40”

42 - 48”

4” (102)

4” (102)

5” (127)

6” (152)

7” (178)

8” (204)

9” (229)

10” (254)

10” (254)

10” (254)

10” (254)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

3” (76)

3” (76)

4” (102)

4” (102)

6” (152)

8” (204)

9” (229)

10” (254)

10” (254)

10” (254)

10” (254)

10” (254)

10” (254)

1” (25)

2” (51)

3” (76)

3” (76)

3” (76)

3” (76)

3” (76)

4” (102)

5” (127)

5” (127)

6” (152)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

1” (25)

3” (76)

3” (76)

Fully Enclosed Combustibles (UL103-HT)

Diameter: 6”-14” N/A N/A 2” (51) N/A N/A N/A

Fire Rated or

Non-Combustible

Chase

As necessary for installation and access, refer to NFPA 211.

Note: The above gures represent air space, in inches, from

outer surface to surroundings.

NOTES:

1. False ceilings are a potential hazard and require

restopping.Chimneyspassingthroughareasbetween

ceiling and roof must be installed in re-rated

enclosures in accordance with local building codes.

2. Decorative shrouds at the termination of a factory built

chimney shall not be permitted per NFPA 211.

2’ (610)

LESS THAN

10’ (3048)

MORE THAN 10’ (3048)

3’ MIN. (914)

STRUCTURE

CHIMNEY OR VENT

3

FIG. 1 - TERMINATION HEIGHT REQUIREMENTS

USE AND INSTALLATION OF INDIVIDUAL PARTS:

These instructions comprise both general and specic

requirements for all parts in the product line. Before specifying a

design or beginning an installation, these instructions should be

carefully reviewed.

PIPE WEIGHT

The average weight of the chimney, per foot of length, can be

calculated using the following formula:

PIC: 0.80 x diameter = lbs per foot

IPIC-1: 0.95 x diameter = lbs per foot

IPIC-2: 1.05 x diameter = lbs per foot

IPIC-4: 1.45 x diameter = lbs per foot

Example: 8IPIC-2: 1.05 x 8 = 8.4 lbs per foot

Chimney design should make provisions for support adequate to

ensure that chimney parts are not overloaded.

PART NUMBERS

These instructions identify Model PIC/IPIC parts by name of part

number in the text and illustrations. Actual parts also carry a ue

diameter prex and a three digit “CTO” sufx which denes the

materials of construction, such as 24IPIC30-461 for a 24-inch

diameter double wall pipe section 30 inches long with Type 304

stainless steel inner wall, Type 316 stainless steel outerwall and a

1” insulation. (See Table 2 for further explanations of CTO codes).

TABLE 2

1st DIGIT

(INNER WALL)

2nd DIGIT

(OUTER WALL)

3rd DIGIT

(INSULATION)

4 = 304 S/S

6 = 316 S/S

A = ALUMINIZED STEEL

4 = 304 S/S

6 = 316 S/S

0 = 1” AIR SPACE

1 = 1” INSULATION

2 = 2” INSULATION

4 = 4” INSULATION

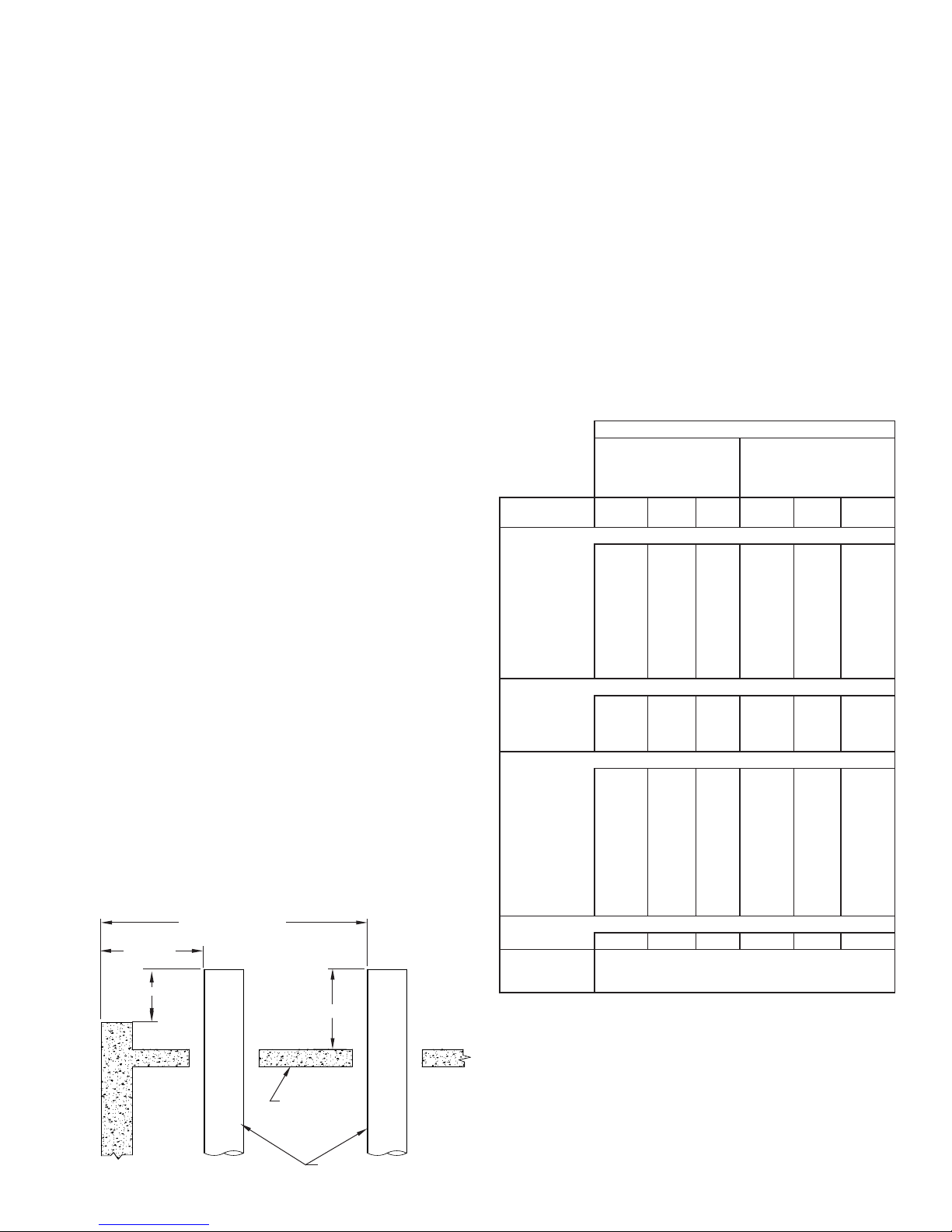

STEP 3

Join the two anged ends of

the pipe sections.

STEP 4

Install the ange band around the anges.

NOTE: Do not locate V-Clamp

hardware at the bottom side

of horizontal duct joints.

When installing ange band, tap lightly with

hammer around periphery of band while

tightening draw screws. This helps to align

anges for the best seal. Do not overtighten

draw screws.

NOTE: Allow sealant to cure 24 hours

before operating appliances.

STEP 5

(IPIC Installations Only)

Pack the void between inner and outer

walls with insulation strips.

STEP 6

Secure the outer casing with the closure

band.

When system is installed outdoors, the

upper side (upper half in the horizontal

position) of the closure band bead

should be sealed with P077 sealant to make

the casing watertight.

JOINT ASSEMBLY

The Model PIC/IPIC joint sealing system is designed for quick and

easy installation. For most applications follow Steps 1 through 6.

(For High Pressure applications, see additional steps.)

STEP 1

Fill the channel of the ange band with

the proper sealant and install below ange

of rst pipe section.

NOTE: Sealant is to be supplied

by Metal-Fab. See TABLE 3

on Page 23 for number of

tubes per joint.

CAUTION: THE USE OF ANY OTHER SEALANT ON THE

FLANGE SURFACE WILL NEGATE ALL LISTINGS OF THE

PRODUCT AND IMPAIR THE SEALING EFFECTIVENESS.

STEP 2

Apply a continuous bead of proper sealant

to one of the anges to be joined.

NOTE: For gas temperatures up to 600ºF,

use P077 sealant.

For gas temperatures over 600ºF,

use P071 sealant.

For high pressure applications,

including ALL engine or

turbine exhaust applications, use P071 sealant.

INSULATION STRIPS (PROVIDED)

4

For all ENGINE EXHAUST and other HIGH PRESSURE

applications, perform Steps 1 through 3 above, then:

4. Install the seal clip(s) on the anges 6”, 8” and 10” only.

(See TABLE 4).

Note: 6” & 8” require two seal clips located as shown.

5. Install the ange band around the anges making sure

the joint is located so the seal clip overlaps both edges

of the joint.

6. Fill the space behind the ange band on both sides of

the ange with P071 pressure sealant (See FIG. 3).

7. Pack void between inner and outer walls with insulation

strips for IPIC installations.

8. Secure the outer casing with the closure band. Apply

sealant to closure band for exterior applications only.

See JOINT ASSEMBLY and FIG. 3 for llustrations of the

joining process and nished joint.

SEAL CLIPS

SEAL CLIP BETWEEN

FLANGE AND FLANGE

BAND NOTCH

SEAL CLIP BETWEEN

FLANGE AND

FLANGE BAND BOLT

CONNECTION

Properly sealed joints are gas tight and resistant to water, oil

solvents and acids (except hydrouoric).

IMPORTANT: P071 Sealant must cure at operating

temperatures above 500°F at a minimum

3-hr curing time.

SUPPORT LIMITS - SUPPORT SPACING

TABLE 5 provides the maximum vertical distances between

supports for various support types. Using these supports, the

maximum installed chimney height is 200 feet (60.96m).

TABLE 5

Support Method Maximum Supported Height (meter)

PIC IPIC-1 IPIC-2 IPIC-4

Wall Support

Pier or Appliance Outlet

Plate Support Assembly

Roof Support Assembly

Stack Support Assembly

40’ (12.19m)

100’ (30.48m)

100’ (30.48m)

30’ (9.1m)

100’ (30.48m)

34’ (10.4m)

85’ (25.9m)

85’ (25.9m)

25’ (7.6m)

100’ (30.48m)

30’ (9.1m)

75’ (22.9m)

75’ (22.9m)

22’ (6.7m)

100’ (30.48m)

29’ (8.8m)

73’(22.3m)

73’(22.3m)

22’ (6.7m)

100’ (30.48m)

Fan Adapter Plate 6”-36” dia.

20’ (6m)

6”-28” dia.

20’ (6m)

30”-36” dia.

15’ (4.6m)

6”-26” dia.

20’ (6m)

28”-36” dia.

15’ (4.6m)

6”-18” dia.

20’ (6m)

20”-26” dia.

15’ (4.6m)

28”-36” dia.

10’ (3m)

TABLE 6

Maximum Unsupported Horizontal Spacing:

PIC

IPIC-1

IPIC-2

IPIC-4

12’-6” (3.8m)

10’ (3.1m)

9’ (2.7m)

9’ (2.7m)

Maximum Unsupported Vertical Spacing Below Roof Line:

PIC

IPIC-1

IPIC-2

IPIC-4

25’ (7.6m)

21’ (6.4m)

19’ (5.8m)

18’ (5.5m)

5

FIG. 3 – ASSEMBLED MODEL PIC JOINT

OUTER PIPE

INNER PIPE

SPACER CLIP

OUTER CLOSURE BAND

FLANGE BAND

INSULATION (IPIC ONLY)

APPLY SEALANT TO INNER

PIPE FLANGES (SEE STEP

2 JOINT ASSY.)

APPLY SEALANT TO FLANGE

BAND (SEE STEP 1 JOINT

ASSY.)

APPLY SEALANT BETWEEN

FLUE AND FLANGE BAND (SEE

STEP 6 ENGINE EXHAUST)

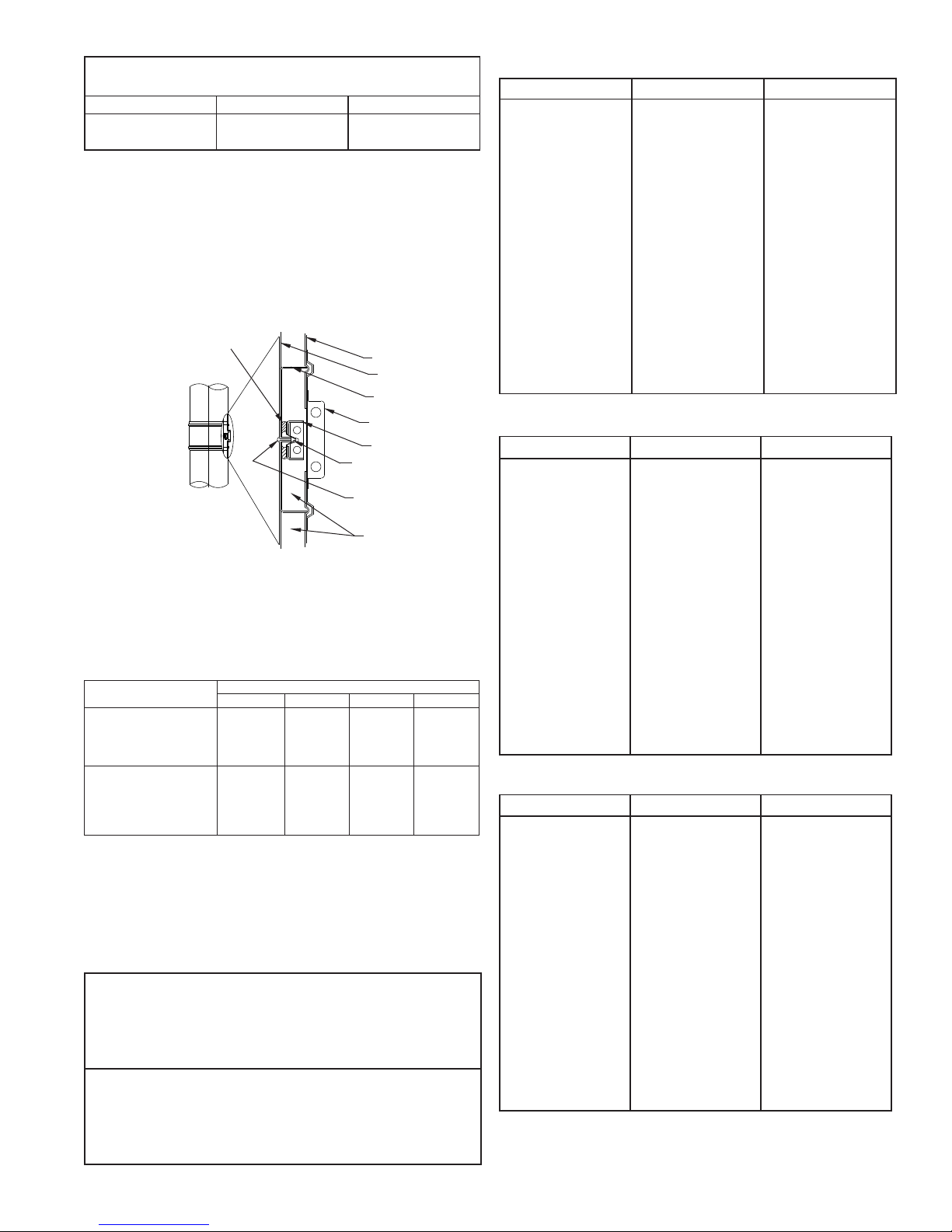

TABLE 4 - SEAL CLIPS REQUIRED PER JOINT

FOR PRESSURE SEALS

Pipe Diameter No. of Clips Part No.

6”-8” 2 SCK6-8*

10” 1 SCK10

*SCK6-8 contians 2 seal clips

TABLE 7 - PIC & IPIC-1 GUYING REQUIREMENTS

Pipe Diameter “A” “B”

6”

8”

10”

12”

14”

16”

18”

20”

22”

24”

26”

28”

30”

32”

34”

36”

38”

40”

42”

44”

46”

48”

17’ 0” (5.18m)

17’ 6” (5.33m)

18’ 6” (5.64m)

20’ 0” (6.10m)

21’ 0” (6.40m)

22’ 0” (6.71m)

23’ 0” (7.01m)

24’ 0” (7.32m)

24’ 6” (7.47m)

25’ 0” (7.62m)

26’ 0” (7.92m)

27’ 0” (8.23m)

27’ 0” (8.23m)

28’ 6” (8.69m)

29’ 0” (8.84m)

30’ 0” (9.14m)

30’ 6” (9.30m)

31’ 0” (9.45m)

32’ 0” (9.75m)

32’ 6” (9.91m)

33’ 6” (10.21m)

34’ 6” (10.52m)

8’ 6” (2.59m)

8’ 9” (2.67m)

9’ 3” (2.82m)

10’ 0” (3.05m)

10’ 6” (3.20m)

11’ 0” (3.35m)

11’ 6” (3.51m)

12’ 0” (3.66m)

12’ 3” (3.73m)

12’ 6” (3.81m)

13’ 0” (3.96m)

13’ 6” (4.11m)

13’ 6” (4.11m)

14’ 3” (4.34m)

13’ 6” (4.11m)

15’ 0” (4.57m)

15’ 3” (4.64m)

15’ 6” (4.72m)

16’ 0” (4.88m)

16’ 3” (4.95m)

16’ 9” (5.10m)

17’ 3” (5.26m)

TABLE 7 - IPIC-2 GUYING REQUIREMENTS

Pipe Diameter “A” “B”

6”

8”

10”

12”

14”

16”

18”

20”

22”

24”

26”

28”

30”

32”

34”

36”

38”

40”

42”

44”

46”

48”

10’ 6” (3.20m)

12’ 0” (3.66m)

13’ 3” (4.04m)

14’ 6” (4.42m)

15’ 11” (4.85m)

17’ 0” (5.18m)

18’ 3” (5.56m)

19’ 6” (5.94m)

20’ 2” (6.15m)

20’ 9” (6.32m)

21’ 5” (6.53m)

22’ 1” (6.73m)

22’ 8” (6.91m)

23’ 4” (7.11m)

24’ 0” (7.32m)

24’ 7” (7.49m)

24’ 7” (7.49m)

24’ 7” (7.49m)

24’ 7” (7.49m)

24’ 7” (7.49m)

24’ 7” (7.49m)

24’ 7” (7.49m)

7’ 11” (2.41m)

8’ 5” (2.57m)

8’ 11” (2.72m)

9’ 5” (2.87m)

9’ 11” (3.02m)

10’ 6” (3.20m)

11’ 0” (3.35m)

11’ 6” (3.51m)

11’ 10” (3.61m)

12’ 3” (3.73m)

12’ 6” (3.81m)

13’ 1” (3.99m)

13’ 5” (4.09m)

13’ 10” (4.22m)

14’ 3” (4.34m)

14’ 7” (4.45m)

14’ 11” (4.55m)

15’ 3” (4.64m)

15’ 9” (4.80m)

16’ 3” (4.95m)

16’ 6” (5.03m)

17’ 0” (5.18m)

GUIDE SPACING

TABLE 6 provides maximum distance between guides for

chimney installed inside building. (For exterior installations, See

TABLE 7 and FIG. 37.) These numbers represent ALL diameters

and vary depending on the amount of insulation.

TABLE 7 - IPIC-4 GUYING REQUIREMENTS

Pipe Diameter “A” “B”

6”

8”

10”

12”

14”

16”

18”

20”

22”

24”

26”

28”

30”

32”

34”

36”

38”

40”

42”

44”

46”

48”

8’ 3” (2.51m)

9’ 7” (2.92m)

10’ 9” (3.28m)

11’ 11” (3.63m)

13’ 2” (4.01m)

14’ 2” (4.32m)

15’ 4” (4.67m)

16’ 4” (4.98m)

17’ 0” (5.18m)

17’ 7” (5.36m)

18’ 2” (5.54m)

18’ 9” (5.72m)

19’ 4” (5.89m)

19’ 11” (6.07m)

20’ 6” (6.25m)

21’ 0” (6.40m)

21’ 0” (6.40m)

21’ 0” (6.40m)

21’ 0” (6.40m)

21’ 0” (6.40m)

21’ 0” (6.40m)

21’ 0” (6.40m)

6’ 8” (2.03m)

7’ 3” (2.21m)

7’ 9” (2.36m)

8’ 4” (2.54m)

8’ 11” (2.71m)

9’ 6” (2.90m)

10’ 1” (3.07m)

10’ 8” (3.25m)

11’ 0” (3.35m)

11’ 6” (3.51m)

11’ 10” (3.61m)

12’ 4” (3.76m)

12’ 8” (3.86m)

13’ 2” (4.01m)

13’ 6” (4.11m)

13’ 11” (4.24m)

14’ 3” (4.34m)

14’ 8” (4.47m)

15’ 2” (4.62m)

15’ 8” (4.78m)

16’ 0” (4.88m)

16’ 5” (5.00m)

NOTE: When chimney is installed outside building, adjacent

to wall, spacing between guides is equal to dimension “A”

in TABLE 6 (Refer to FIG. 34 on Page 15).

FIG. 7 – MAXIMUM FREE-STANDING HEIGHT ABOVE ROOF

NOTE: See TABLE 7 for “B” dimensions.

“B”

6

The guy ring consists of four (4) identical half rings with hardware

to secure them together, two (2) half closure bands and a storm

collar (FIG. 5). Select the joint where the guy ring is to be located

and assemble the inner wall joint (Steps 1 to 6 under JOINT

ASSEMBLY on Page 4). Sandwich the ange band between the

guy rings with the joints of the top and bottom rings 90º apart and

the cutouts aligned. Clamp the guy ring with the nuts and bolts

provided. Install the half closure bands above and below the guy

ring, then attach the cables or braces (See FIG. 6). Install the

storm collar above the upper half closure. The collar should be

caulked with sealant to prevent water entry.

NOTE: Cable, cable clamps and cable thimble supplied by

others.

Cable or braces (supplied by the installer) should be slightly loose

to allow for thermal expansion for single guy ring installations

(FIG. 8) or be equipped with tensioning springs on multiple

guy ring installations (FIG. 9). To reduce the effect of thermal

expansion on the guy cables or braces, a xed-point support

(plate or wall support assembly) may be installed immediately

below the rooine as shown in FIG. 8.

STORM COLLAR

GUY RING

HALF RINGS (4 PCS.)

HALF CLOSURE

BANDS (2 PCS.)

FIG. 5 - PIC/IPIC GUY RING, EXPLODED VIEW

FIG. 4 – FULL ANGLE RING FOR LATERAL SUPPORT

CLOSURE RING

STORM COLLAR

FLASHING

ROOF

PIPE DIAMETER

ANGLE RING MUST BE

USED WITH FLASHING

CHIMNEY ABOVE ROOF

When chimney is extended above rooine, special consideration

should be given to support and guying requirements. Use of a

standard or variable pitch ashing requires that the chimney be

stabilized to resist side loading. FIG. 4 and 8 depict methods

of protecting a ashing from side loads using a full angle ring

or plate support. Ventilated thimble and roof support assemblies

include lateral support rings, and additional guidance at the

rooine is not required.

GUY RING (GR)

Chimneys that extend above the roof, or are installed in severe

weather regions, may require a guy ring (GR) to enable the

chimney to resist wind loads. The guy ring is connected to

the building or other structure by means of cables or braces

TABLE 6 provides the spacing between guy rings and freestand

height for Model PIC/IPIC Chimney.

FIG. 6 – GUY RING CABLE ATTACHMENT

CASING

APPLY SEALANT BETWEEN

COLLAR & CASING

STORM COLLAR

CABLE THIMBLE

CABLE CLAMPS

GUY RINGS DRILLED FOR

3 OR MORE CABLES

NOTE: Align large holes on

Guy Ring Halves during

assembly.

FIG. 8 – GUYING FOR SINGLE SECTION

FIG. 9 – CHIMNEY GUYING REQUIREMENTS

Cables should be spaced at or near 120º intervals (3 cables)

or 90º (4 cables). Rigid bracing requires two (2) braces spaced

between 60º and 150º apart. Maximum spacing between the

xed support and the guy ring is 5 feet when rigid bracing is used

(See FIG. 10).

PIPE LENGTHS (9, 18, 30, 42)

Model PIC/IPIC pipe is available in 4 standard lengths: 9” (229),

18” (457), 30” (762) and 42” (1067). Pipe sections are joined,

using appropriate sealant, to make up desired length of run.

These sections may be modied by use of nipples or couplings

to accept auxiliary equipment such as temperature probes or

smoke monitors. Consult factory or your local representative to

obtain information regarding such modications.

DRAIN SECTION (DS)

A drain section is a special variation of an 18” (457) pipe length

with provision to drain rain or condensate from the chimney. The

pipe ue is equipped with an annular catch ring and a 1” (25)

NPT nipple extending through the casing for attachment of drain

piping. The drain piping should include a water leg of a height

at least equal to the maximum expected operating pressure at

the appliance outlet to avoid allowing ue gases to vent through

the drain. Drain section should be installed indoors to prevent

freezing (See FIG. 11).

FIG. 11 – DRAIN SECTION INSTALLATION

FIG. 10 – HEIGHT LIMITS FOR RIGID GUYING

STORM COLLAR

GUY RING

STORM COLLAR

FLASHING

ROOF

PLATE SUPPORT

SUPPORT STEEL

(BY INSTALLER)

“B”

“A”

“A”

“A”

“B”

“B”

MAXIMUM

SPACING

5 FT.

EXPANSION JOINT

OR BELLOWS JOINT

A PLATE SUPPORT OR WALL

SUPPORT ASSEMBLY MUST BE

USED AT ROOF LEVEL WHEN

RIGID GUYING IS USED

GUY RING

(ON INSIDE OF COLLAR)

USE RIGID GUYS IF

CHIMNEY IS CLOSE TO

OUTSIDE WALL

6 PIPE

DIAMETERS

OR MORE

CLOSURE RING

FLASHING AND

STORM COLLAR

FULL RING GUIDE

DRAIN SECTION

1” PIPING

TRAP HEIGHT EQUAL TO

MAX. APPLIANCE OUTLET

PRESSURE

7

NOTE: See TABLE 7 for “A” and “B” dimensions.

NOTE: See TABLE 7 for “A” and “B” dimensions.

NOTE: See TABLE 7 for “B” dimensions.

45º MANIFOLD TEE (45MT), DOUBLE LATERAL (DL)

For systems where minimizing ow resistance is desirable

or critical, a manifold tee having a 45º entrance to the trunk

is available. When used to make 90º turns, an additional 45º

elbow is required. It is particularly important to isolate the 45º

manifold tee from the effects of thermal expansion. This isolation

is typically accomplished by the use of a 2-axis support (See

FIG. 14). Otherwise, the installation details and precautions are

similar to those for the 90º manifold tee.

MULTIPLE APPLIANCE BREECHINGS (HEADERS)

When 90º or 45º manifold tees are used to manifold multiple

appliances together, it is important to make provisions for

expansion of the manifold. An expansion joint should be installed

between tees (See FIG. 15). The manifold must be supported

properly by means of plate supports or wall support assemblies

arranged to protect the tees from bending forces.

30º, 45º OR 90º FIXED ELBOWS (30L) - (45L) - (90L)

Elbows are not designed to resist bending loads and must be

protected by structural reinforcement. FIG. 16 depicts some

alternative methods for protection of elbows. Elbows may be

FIG. 14 - TWO-AXIS SUPPORT METHOD

MORE THAN 1/4” THERMAL

EXPANSION EXPECTED

BELLOWS JOINT OR

EXPANSION JOINT

PLATE SUPPORT ATTACHED

TO BUILDING STRUCTURE

DRAIN BUCKET

WALL SUPPORT

ASSEMBLY

FIG. 15 – LATERAL TEE MANIFOLD

PLATE SUPPORT ADJUSTABLE LENGTHS

OR BELLOWS JOINT

PLATE SUPPORT

90° ELBOW

OUTLET

45° MANIFOLD

TEE

45° FIXED

ELBOW

8

STANDARD 90º TEE (90MT)

The 90º Manifold Tee (90MT) may be used to connect horizontal

to vertical when a cleanout access or drain is desired. If more

than 1/4” (6) of thermal expansion is expected between the

tee and the next xed support point (the appliance outlet, for

example), the tee should be protected from bending moments

by use of an expansion joint or bellows joint. See the sections on

those ttings for additional information about compensation for

thermal expansion.

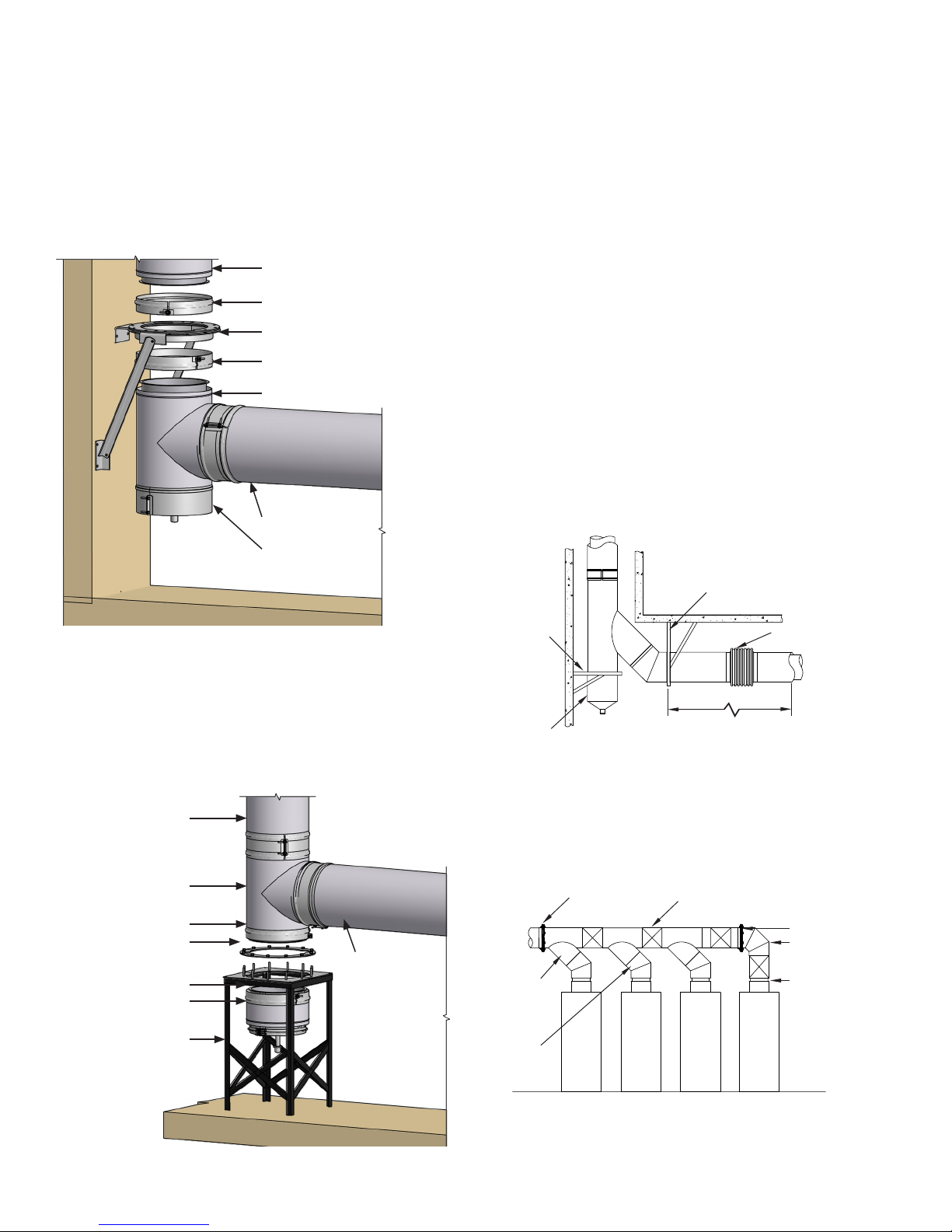

FIG. 12 – SUSPENDED TEE

PIPE RISER

HALF CLOSURE BAND

WALL SUPPORT ASSEMBLY

HALF CLOSURE BAND

TEE AT BASE OF RISER

DRAIN TEE CAP

PIPE SECTION

When a tee is used at the base of a riser, the preferred location

for support is above the tee, thus suspending the tee (FIG. 12). If

it is not possible to suspend the tee, it may be supported from the

base of the tee (FIG. 13). When this type of support is necessary,

access to the drain cap may be hindered. A drain bucket should

be used under the tee to allow access to the tee cap.

FIG. 13 – BASE SUPPORTED TEE

PIPE RISER

TEE

HALF CLOSURE BAND

CLAMP RING

(SEE NOTE BELOW)

HALF CLOSURE BAND

DRAIN BUCKET

STRUCTURAL STEEL

STAND (BY OTHERS)

PIPE SECTION

DRAIN TEE CAP (TC), CLEANOUT CAP

The unused port of a tee must be closed to prevent leakage of

ue gases. A drain tee cap is used to close the tee and drain

condensation or rainwater when the tee is installed at the base of

a rise. When the tee is to be used for cleanout or access purpose

only, a cleanout cap (TCN) is recommended. Both the drain tee

cap and the cleanout cap are equipped with closures, which

serve the dual purpose of maintaining the double wall clearance

to combustible and giving the cap a nished appearance.

The drain tee cap’s drain nipple must be connected to a suitable

disposal point. Any rain entering the chimney will wash down

and remove any combustion residue from the chimney ue. The

resulting efuent may be corrosive. The tee cap must be sealed

at the connection to the tee using the appropriate sealant for the

application. This will assure that moisture will drain through the

drain nipple, as intended.

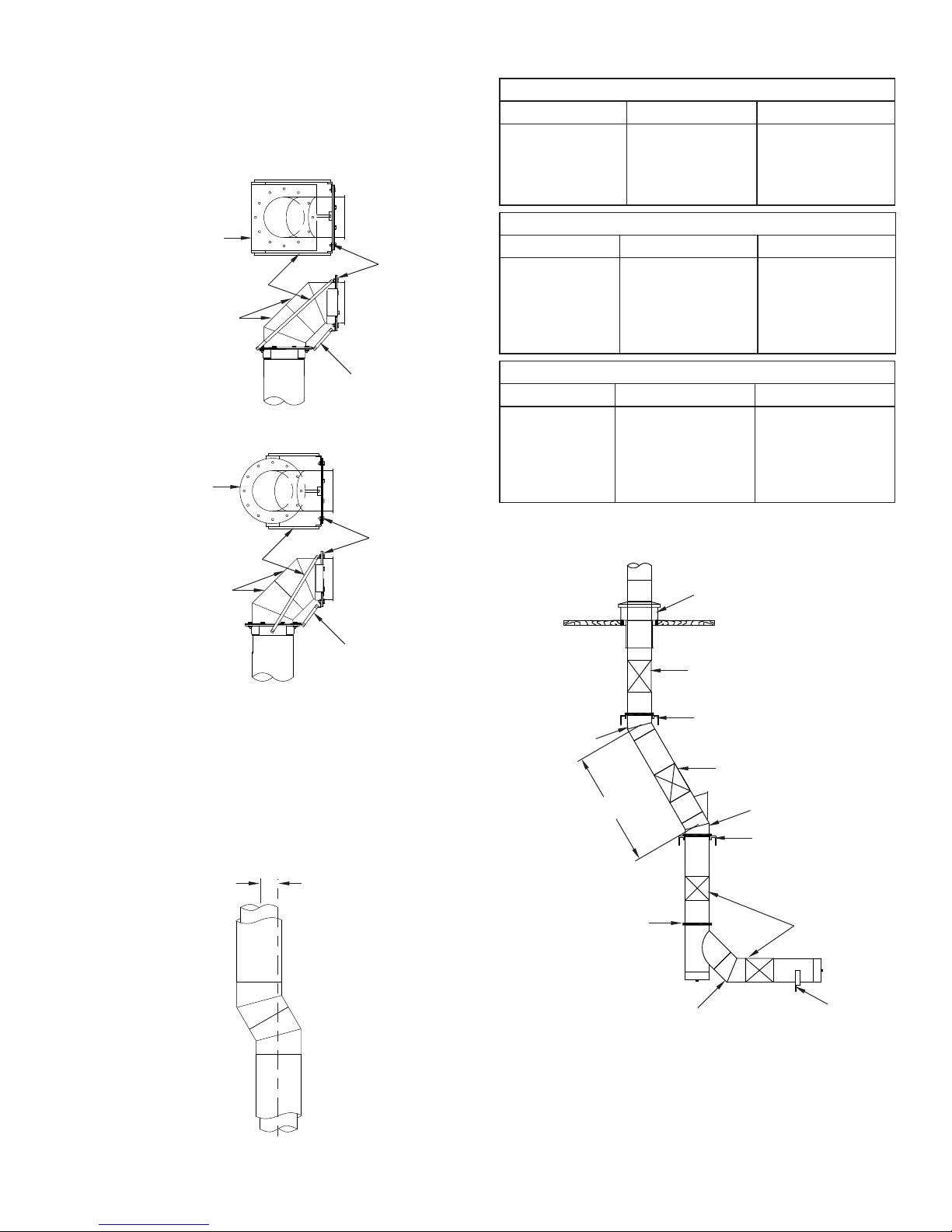

FIG. 16 – METHODS OF STRUCTURAL REINFORCEMENT

FOR ELBOWS

2-45° ELBOWS REINFORCED WITH PLATE SUPPORTS

2-45° ELBOWS REINFORCED WITH WALL SUPPORTS

CHIMNEY OFFSETS

Offsets should be avoided except when there is no other way to

route the chimney. When an offset must be used, good design

indicates that the angle used should be the minimum possible (See

FIG. 18). If the appliance currently burns solid fuel or is capable

of being converted to burn solid fuel, the offset cannot exceed 30

degrees. No more than 2 offsets (4 elbows) may be used.

TABLE 8 indicates minimum center to center offset for two

elbows connected directly to each other.

FIG. 17 — MINIMUM ELBOW OFFSETS

(REFER TO TABLE 8)

TABLE 8 - MINIMUM OFFSETS

MINIMUM ELBOW OFFSETS PIC & IPIC-1

PIPE DIA. “A” - 30° ELBOW “A” - 45° ELBOW

6” thru 12”

14”

16” thru 24”

26” thru 36”

38” thru 48”

6” (152)

7 3/4” (197)

7 3/4” (197)

8 1/2” (216)

11” (279)

9 7/8” (251)

14 1/8” (359)

14 1/2” (368)

16 5/8” (422)

19 3/4” (503)

MINIMUM ELBOW OFFSETS IPIC-2

PIPE SIZE “A” - 30° ELBOW “A” - 45° ELBOW

6” thru 10”

12”

14” thru 22”

24” thru 34”

36” thru 46”

48”

6” (152)

7 3/4” (197)

7 3/4” (197)

8 1/2” (216)

11” (279)

12 3/4” (324)

9 7/8” (251)

14 1/8” (359)

14 1/2” (368)

16 5/8” (422)

19 3/4” (503)

23 3/4” (602)

MINIMUM ELBOW OFFSETS IPIC-4

PIPE SIZE “A” - 30° ELBOW “A” - 45° ELBOW

6”

8”

10” thru 18”

20” thru 30”

32” thru 42”

44” thru 48”

6” (152)

7 3/4” (197)

7 3/4” (197)

8 1/2” (216)

11” (279)

12 3/4” (324)

9 7/8” (251)

14 1/8” (359)

14 1/2” (368)

16 5/8” (422)

19 3/4” (503)

23 3/4” (602)

Bracing, above and below the elbows, is needed to avoid

subjecting them to bending moments. In order for bracing to

be effective, it must be rigidly attached to building members or

foundation. The design of the structure used to attach supports

must include the weight of the sloped section and whatever

additional pipe is carried by the support. Additionally, an

expansion joint or bellows joint is needed between the elbows to

relieve thermal expansion stresses.

ANGLE

45° FIXED ELBOW

PLATE SUPPORT

PLATE SUPPORT

ANGLE BRACING

PLATE SUPPORT

ANGLE BRACING

45° FIXED ELBOW

ANGLE

WALL SUPPORT

“A”

FIG. 18 – SUPPORT FOR CHIMNEY OFFSETS

HALF ANGLE

RING

45° FIXED ELBOW

EXPANSION JOINT

PLATE SUPPORT

MAX. 25 FT. (7620)

(OIL OR SOLID FUEL)

WALL SUPPORT ASSY.

OR PLATE SUPPORT

WALL SUPPORT ASSY.

OR PLATE SUPPORT

30° MAX. FOR OIL OR SOLID FUEL

EXPANSION JOINT

EXPANSION JOINT

30° FIXED ELBOW OR

45° FIXED ELBOW

30° FIXED ELBOW OR

45° FIXED ELBOW

VENTILATED THIMBLE ASSEMBLY

OR ROOF SUPPORT ASSEMBLY

9

used singly or in combination to provide turns of 30, 45, 60,

75, or 90 degrees. For engine or turbine exhaust systems, it

is recommended that 90º turns be accomplished by using two

(2) 45º elbows or a combination of one 45º elbow and one 45º

manifold tee to minimize ow resistance.

90º WYE (90Y)

The 90º wye is very useful when the vertical chimney is located

between two appliances and a low-loss junction is desired. It is

ideal for engine with dual-exhaust connections. The wye tting

may be suspended by a plate support or roof support assembly.

Expansion joints or bellows joints should be used to protect the

wye from thermal expansion stresses (See FIG. 19).

EXPANSION JOINT (AL)

The expansion joint may be used to compensate for thermal

expansion and to make up odd lengths. It is essential that

sufcient installed length be allowed to compensate for abnormal,

as well as normal, operating conditions. The expansion joint

cannot be used to correct misalignment or to compensate for

lateral movement or vibration. The use of the expansion joint in

engine exhaust applications is not recommended.

An expansion joint is comprised of: (1) a collar that is 5¼” (133)

long with a ange and vee band at one end and a graphite

impregnated ring gasket at the other; (2) a 30” (762) long tube,

anged at one end, which ts into the 5¼” (133) collar; (3) an

outer jacket consisting of two half jacket assemblies; and (4)

loose insulation blanket to ll space between the tube and

casing.

Installation procedure is as follows:

1. Loosen draw screw at gasket band and slide collar toward

anged end of tube. Do not remove collar from tube.

2. Slide unanged end of tube into the upstream piece of pipe

and make up joint between pipe and collar following the

procedures outlined under heading JOINT ASSEMBLY on

Page 4.

3. Pull anged end of tube to the downstream piece of pipe and

make up joint as above (See FIG. 20).

4. For IPIC, cut insulation to desired length and wrap inner pipe

ensuring that it is covered completely before attaching half

jackets.

5. Wrap two half jackets around joint with bead at the

downstream end and punched edge overlapping plain edge

by approximate 3/4” (19). NOTE: For horizontal installations

the seams must be located at the top and bottom of the

pipe, coat unpunched edge of casing with P077 sealant to

waterproof the casing.

6. Install self-drilling screws (supplied with jacket) at punched

holed through both layers at overlap. Exercise care that half

jacket edges do not align with draw screws on ange bands

and that no screws are installed in portion of jacket which is

over casing of adjacent pieces of pipe (See FIG. 21). The

screws shipped with the expansion joint are of the correct

length to avoid penetrating the inner wall (ue) of the pipe.

Do not use any other screws to attach the casing.

FIG. 19 – 90º WYE APPLICATION, DUAL EXHAUST

ENGINE WITH

DUAL EXHAUSTS

90° WYE

TAPERED INCREASER

45° FIXED ELBOW

FLANGE ADAPTER

10

FIG. 21 - EXPANSION JOINT CASING ASSEMBLY

Note: Do not screw through casing of adjacent pipe.

FIG. 20 – EXPANSION JOINT FLUE ASSEMBLY

30” MAX. (762) OR TRIMMED AS REQ’D

8” MIN.

(203)

INSTALLED LENGTH

3-3/4”

(95)

COLLAR

PIPE

UNFLANGED END

RETAINING

SCREWS

ADJOINING PIPE

(UP SLOPE)

APPLY SEALANT

UNDER SEAM

(REF. JOINT ASSY. FOR

PROPER SEALANT)

ADJOINING PIPE

(DOWN SLOPE)

NOTES:

1. It is recommended that the pipe on both sides of the

expansion joint is supported or guided to assure that

the expansion joint will not bind during operation.

2. Installation of an expansion joint adjacent to ttings,

such as elbows, tees or wyes, is not recommended.

However, it is not always possible to avoid these

ttings.Ifanexpansionjointmustbejoinedtooneof

thesettings,theunangedendofthetubeshouldbe

awayfromthettingandttedintoapipelengthinthe

manner described in the installation procedure above.

3. Expansionjointmustbeinstalledwithaangetoange

length of not more than 22”. The minimum length for

installation must take into account the amount of

expansion that may occur during operation. Minimum

length is calculated as follows:

Expansion = Length (feet)/100 x Temperature Rise (ºF)/100

Minimum Length = Expansion + 6” (152mm)

It is recommended that the temperature used in the

above formula be at least 300ºF higher than the expected

normal operating temperature.

4. If inner tube is too long, it may be cut to length. Tube

must be a minimum of 8” (203) longer than ange-to-

angelength.Priortoinstallationofcutpipe,removeall

burrs to ensure that interference does not occur.

5. Check gasket to ensure that it ts snugly without

binding on inner pipe.

6. Outer jacket must move during expansion or

contraction. Ensure that no screws are located where

the jacket overlaps the casing of the adjacent pipe and

that it is loose enough to move as needed. Alignment

of the bead on the jacket with the bead on the adjacent

pipe will ensure that the jacket stays in the proper

location.

7. Note that the expansion joint will not support any

weight in the vertical position. It should not be used

unless both ends of run, where an expansion joint is

installed,areanchoredasxedpoints.

FIG. 22 indicates appropriate locations for expansion joints in

various orientations.

FIG. 22 – EXPANSION JOINT LOCATIONS

SEE TABLE 4 FOR

MAXIMUM DISTANCE

SEE TABLE 4 FOR

MAXIMUM DISTANCE

CHIMNEY EXPANSION UP THROUGH

ROOF. GUIDANCE IS REQUIRED

THROUGH FLASHING OR THIMBLE

EXPANSION JOINT

ABSORBS UPWARD MOVEMENT

FLASHING

EXPANSION JOINT

CAREFULLY ALIGNED

HALF OR FULL

ANGLE RING

WALL GUIDE

WALL GUIDE

WALL OR PLATE

SUPPORT

FIXED POINT

PLATE SUPPORT

90° TEE

DRAIN TEE CAP

11

VARIABLE LENGTH (VL)

The function of the variable length is to make up odd lengths of

pipe, which are not to be used for expansion compensation. The

use of the variable length in engine exhaust applications is not

recommended. The variable length is comprised of the following

components: (1) a 3¼” (83) collar with a ange at one end used

to clamp the ange at the desired length; (2) a 30” (762) long

tube anged at one end, which ts into the 3¼” (83) collar; (3)

an outer jacket consisting of two half jacket assemblies; and (4)

loose insulation blanket to ll space between the tube and casing.

A variable length can be installed at any ange to ange length

from 4”-26” (102-660). If the ue is too long to t into the adjacent

section of pipe without interfering with the ow path, it should be

trimmed to the desired ange to ange length plus 4” (102).

Installation procedure is as follows:

1. Loosen draw screw at collar and slide collar toward anged

end of tube. Do not remove collar from tube.

2. Slide unanged end of tube into the upstream piece of pipe.

Pull anged end of tube to the downstream piece of pipe

and make up joint as outlined under JOINT ASSEMBLY on

Page 4.

3. Apply a thin coat of sealant, about 1” (25) wide at the plain

end of the pipe where tube slides into mating pipe section.

Press sealant into any gap between the tube and the

mating pipe section. Apply sealant to ange of mating pipe

(See FIG. 23).

4. Slide collar into position against ange of mating pipe. Fill

ange band with sealant and install ange band.

5. Tighten bolts on clamp collar to complete installation. (For

more positive seal, apply sealant to clamp collar slot and

ared end of collar prior to tightening bolts).

6. For IPIC, cut insulation to desired length and wrap inner pipe

ensuring that it is covered completely before attaching half

jackets.

7. Wrap two half jackets around joint with bead at the

downstream end and punched edge that overlapping the

plain edge by approximately 3/4”. Note: For horizontal

installations, the seams must be located at the top and

bottom of the pipe. Coat unpunched edge of casing with

P077 sealant to waterproof the casing. Install self-drilling

screws (supplied with jacket) at punched holed through both

layers at overlap. Exercise care that half jacket edges do not

align with draw screws on ange bands, and that no screws

are installed in portion of jacket which is over casing of

adjacent pieces of pipe (See FIG. 24). The screws shipped

with the expansion joint are of the correct length to avoid

penetrating the inner wall (ue) of the pipe.

Do not use any other screws to attach the casing.

FIG. 23 VARIABLE LENGTH FLUE ASSEMBLY

TUBE

30” (762) OR TRIM TO FIT

4” MIN.

(102)

UNFLANGED END

COLLAR

ADJOINING PIPE

(DOWN STREAM)

ADJOINING PIPE

(UP STREAM)

NOTES:

1. It is recommended that the pipe adjacent to the variable

length is supported or guided to prevent sagging.

2. If a variable length must be installed adjacent to a tee,

elbow,wyeorotherttingwheretubecaninterferewith

ow,theunangedendofthetubeshouldbeawayfrom

the tting and tted into a pipe length in the manner

described in the installation procedure under FIG. 23.

3. Avariablelengthmaybeinstalledwithaangetoange

length between 4” and 26” (102 and 660) inclusive.

4. If inner tube is too long, it may be cut to length. Tube

must be a minimum of 4” (102) longer than ange to

angelength.Priortoinstallationofcutpipe,removeall

burrs to ensure that interference does not occur.

5. Note that the variable length will not support any weight

in the vertical position.

STEP INCREASER (SI) AND TAPERED INCREASER (TI)

Frequently, a diameter change is required in a chimney

installation. To accomplish such a size change, a step increaser

or tapered increaser may be used. These parts are usually used

to provide an increase of size, as the name implies. However,

they may be used to reduce the size of a run. Extreme caution

should be exercised when reducing the size of a chimney. The

resultant pressure drop may cause the chimney to mis-function

and cause spillage of ue gases into the mechanical room.

The step increaser should be used when the length of run

available for the size change is restricted. The installed length of

a step increaser is 2” (51) (See FIG. 25). The step increaser is a

non-structural part and must not be subjected to loading in either

the axial or lateral directions.

FIG. 24 – VARIABLE LENGTH CASING ASSEMBLY

Note: For IPIC, wrap increaser with insulation before

attachingoutercasing.Caremustbetakentocompletelyll

all gaps with insulation.

When sufcient length is available, use of a tapered increaser

is recommended, since it causes a considerably less pressure

drop than an equivalent step increaser. The tapered increaser

uses 5 inches of length per incremental diameter change. The

maximum length for a tapered increaser is 30” (762) or 6 pipe

sizes. A tapered increaser is considered to have the same load

strength as straight pipe (See FIG. 26).

STEPS 123456

“C” = 5”

(127)

10”

(254)

15”

(381)

20”

(508)

25”

(635)

30”

(762)

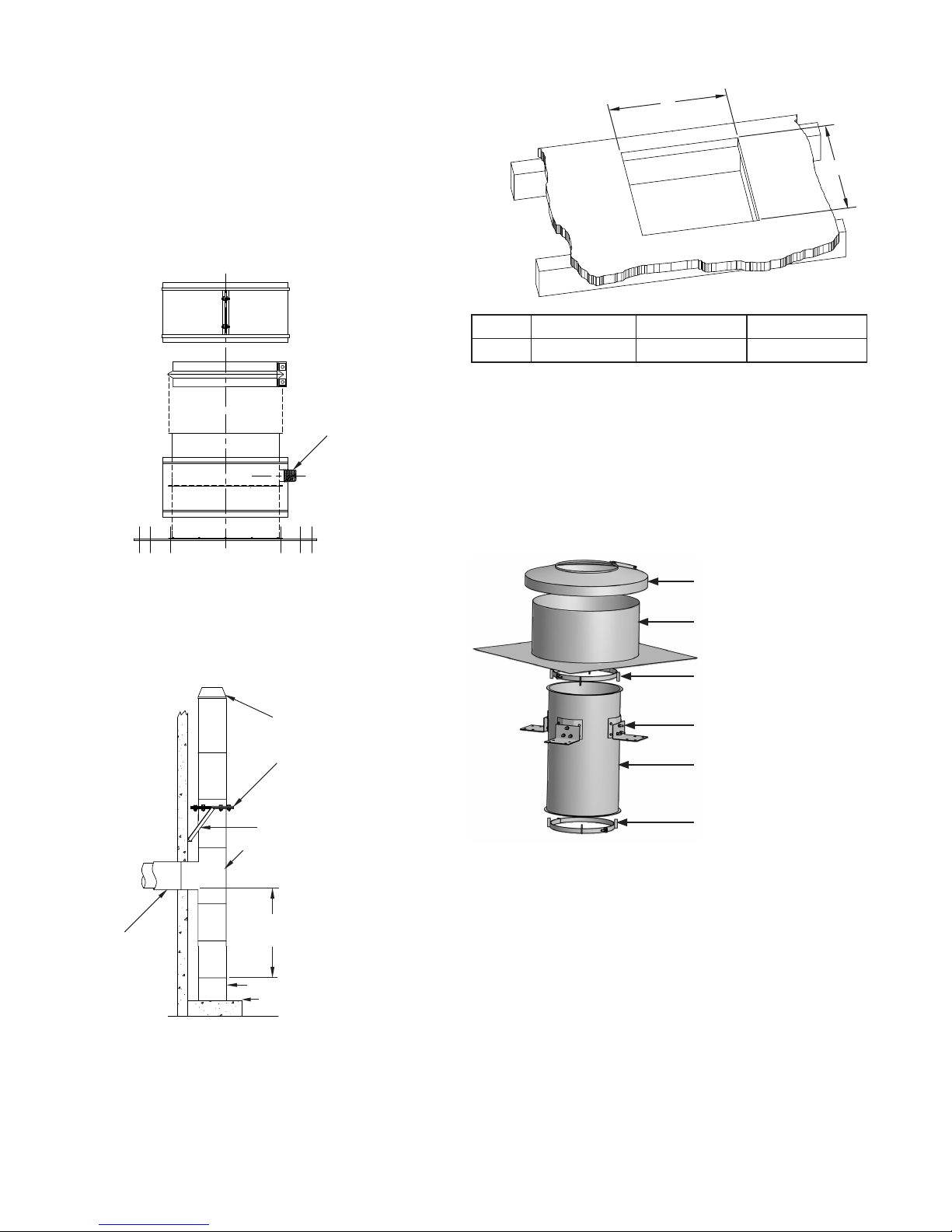

TRANSITION BAND (TB)

The transition band provides the necessary increase or decrease

in casing diameter when change in insulation thickness occurs

(FIG. 27).

FIG. 26 - TAPERED INCREASER (TI)

FIG. 27 - TRANSITION BAND (TB)

Note: Wrap pipe joint with insulation before attaching outer

casing.Caremustbe takentocompletelyllallgapswith

insulation.

HALF JACKET

SCREWS

(INCLUDED)

FIG. 25 - STEP INCREASER (SI)

INSTALLS AT 2” (51)

“A” “B”

“C”

AIR FLOW

12

FIG. 28 – PLATE SUPPORT BRACING REQUIREMENTS

“X” is a minimum of 30° when bracing is used. A welded frame

must be adequately attached to structural member for framework

rigidity if bracing isn’t used.

Pipe

Diameter

PS Plate

Thickness

Bracing for (PS) Plate Support

Height of Stack

50’ (15.24m) 100’ (30.48m)

6” - 20” 3/16” (5) 1 1/4”x1 1/4”x1/8”

(32x32x3)

2”x2”x1/4”

(51x51x6)

22” - 36” 1/4” (6) 2”x2”x1/8”

(51x51x3)

3”x3”x1/4”

(76x76x6)

38” - 48” 1/4” (6) 3” (76) channel: 3”x1 1/2”x1/4”

(76x38x6)

Pipe

Diameter

PS Plate

Thickness

Framework for (PS) Plate Support

Height of Stack

50’ (15.24m) 100’ (30.48m)

6” - 20” 3/16” (5) 1 3/4”x1 3/4”x1/8”

(44x44x3)

3”x2”x3/16”

(76x51x5)

22” - 36” 1/4” (6) 2”x2”x1/4”

(51x51x6)

4”x3”x1/4”

(102x76x6)

38” - 48” 1/4” (6) 3” channel: 3”x1 1/2”x1/4”

(76x38x6)

When the supported section is subject to thermal expansion

or is in a vertical position, so that the plate support is weight

bearing, the support structure must be braced with diagonal

members or gussets to prevent deection of the supported joint

(See FIG. 28). Plate supports are usually located adjacent

to ttings, such as tees or elbows, to protect the tting from

expansion stresses. Chimneys heights in excess of a single

plate support capability can be resupported with additional plate

support(s). An expansion joint must be used between support

points (See FIG. 29).

FIG. 29 – RESUPPORT REQUIREMENTS

A plate support assembly is to be attached only to

non-combustible construction such as block, concrete or steel

with clearance that is adequate for installation and access.

DO NOT ATTACH THE PLATE SUPPORT TO COMBUSTIBLE

CONSTRUCTION.

For maximum support, the entire perimeter of the plate support

assembly must be attached to structural framing (See FIG. 30).

Structural members are supplied by the installer.

FIG. 30 – SECTIONAL DETAIL FOR PLATE SUPPORT

PLATE SUPPORT

EXPANSION JOINT

FULL ANGLE RINGS

PLATE SUPPORT

EXPANSION JOINT

FULL ANGLE RINGS

PLATE SUPPORT

TO APPLIANCE

DRAIN

TEE CAP

90° TEE

200 FT. (60.96M)

MAXIMUM

100 FT.

(30.5M)

FLUE

CASING

FLANGE

BAND

CLAMP

RING

PLATE

13

STRUCTURAL BRACING

(BY OTHERS)

PLATE SUPPORT

CLAMP RING

BRACING

(BY OTHERS)

“X”

PIPE SECTION

PIPE SECTION

EXHAUST FLOW

PLATE SUPPORT (PS)

NOTE: See TABLE 5 for maximum supported height.

The plate support assembly is designed to provide maximal

support to vertical sections and to provide xed-point support for

horizontal sections. The plate support must be attached to the

building structure or support with rigid structural members.

NOTE: Clamp ring sections and plate sections install at

90° angles.

FULL ANGLE RING (FAR) AND HALF ANGLE

RING (HAR)

The full angle ring is used as a guide to prevent the chimney from

exing due to lateral loading. The angle ring is split for ease of

installation. It is 1/8” larger in inside diameter than the outside

diameter of the pipe to allow movement of the pipe inside the

ring (See FIG. 31).

FIG. 31 – FULL ANGLE RING & HALF ANGLE RING

HALF ANGLE RING

FULL ANGLE RING

The half angle ring is used as a saddle in horizontal or sloped

runs. It may be suspended either on rigid framework or soft

frames, such as threaded rod. The half angle ring will not replace

a plate support or other xed support in horizontal runs. It should

not be used as the sole support for the chimney.

WALL SUPPORT ASSEMBLY (WSA)

A wall support assembly consists of a full angle ring, two clamp

rings, wall brackets and struts. The clamp rings sandwich a

ange band at a pipe joint and are supported by the full angle

ring (See FIG. 32).

FIG. 32 – WALL SUPPORT ASSEMBLY ASSEMBLED VIEW

The clamp rings are installed with the splits 90º apart so that they

support each other. The notches in the clamp rings are aligned

with the draw screws of the ange band. The clamp rings and full

angle ring are then bolted together with the hardware provided to

form a rigid assembly (See FIG. 33).

FIG. 33 WALL SUPPORT ASSEMBLY EXPLODED VIEW

When attached to a non-combustible wall, with the brackets and

struts, the wall support makes up a xed-point in the chimney. An

expansion joint is required between the wall support assembly

and any adjacent xed point.

Multiple wall support assemblies may be used, in conjunction

with expansion joints or bellows joints, to support chimney

heights in excess of the allowable height for a single wall support

assembly.

DO NOT ATTACH THE WALL SUPPORT ASSEMBLY TO

COMBUSTIBLE CONSTRUCTION.

WALL GUIDE (WG)

The wall guide is designed to compliment the wall support

assembly. It is used as a lateral guide to prevent the chimney

from exing due to lateral loading.

The wall guide consists of a full angle ring with wall brackets and

struts (See FIG. 34 & 35).

BRACKETS

STRUT

SUPPORT RING

CLAMP FLANGE

HALF CLOSURE

BAND

14

Note: For IPIC, wrap pipe joint with insulation before attaching half

closure bands.

CLAMP RING

WALL BRACKET

FULL ANGLE

RING

STRUT WALL

BRACKET

STRUT

BRACE

BRACKET

HORIZONTAL

STRUT

FULL ANGLE

RING

WALL

BRACKET

VERTICAL

STRUT

FIG. 34 – WALL GUIDE ASSEMBLY EXPLODED VIEW

The proper location for a wall guide is immediately below the

outer closure band near a pipe joint. The outer band must be

able to move away from the wall guide when thermal expansion

occurs (See FIG. 36).

SPECIAL CONSIDERATIONS

When a wall support assembly is used to support a chimney on

an exterior wall, wind loading must also be considered. Below the

highest wall support assembly, the chimney must be resupported

at intervals not greater than 40’ (12.19m) (See TABLE 5). The

chimney must be equipped with wall guides between each wall

support assembly. Guide spacing is in accordance with maximum

vertical spacing in TABLE 6 on Page 5. Additionally, a wall guide

must be located between 6’ and 10’ (1.83m and 3.05m) below the

highest wall support to stabilize the freestanding portion of the

chimney above the wall support assembly (See FIG. 37).

FIG. 37 – SPECIAL CONSIDERATIONS FOR CHIMNEY ON

OUTSIDE WALL

FLOOR GUIDE (FG)

The oor guide is similar in function to a wall guide or full angle

ring, but is modied specially for use at oor penetrations. The

angle brackets and straps hold the guide centered in the oor

penetration (See FIG. 38). Maximum oor opening “X” is Duct

I.D. + 10” (254).

FIG. 38 – FLOOR GUIDE

FREE STANDING

6 TO 10 FEET

(1829 -3048)

WALL GUIDE

LOCATE EXPANSION JOINT

OR BELLOWS JOINT BELOW

WALL GUIDE

WALL SUPPORT

DO NOT INSTALL AN

EXPANSION JOINT IN

THIS AREA DUE TO

BENDING FORCES

38” THRU 48” PIC ONLY

15

STRAPS

ANGLE

BRACKET FLOOR

ANGLE

RING

“X”

“X”

DO NOT ATTACH THE FLOOR GUIDE TO

COMBUSTIBLE CONSTRUCTION.

FIG. 36 – WALL GUIDE LOCATIONS

6”-12” (152-305)

PIPE FLANGES

WALL GUIDE OR

FULL ANGLE RING

(STRUCTURE BY

OTHERS)

PIPE

DO NOT ATTACH THE WALL GUIDE TO

COMBUSTIBLE CONSTRUCTION.

FIG. 35 – WALL GUIDE ASSEMBLED VIEW

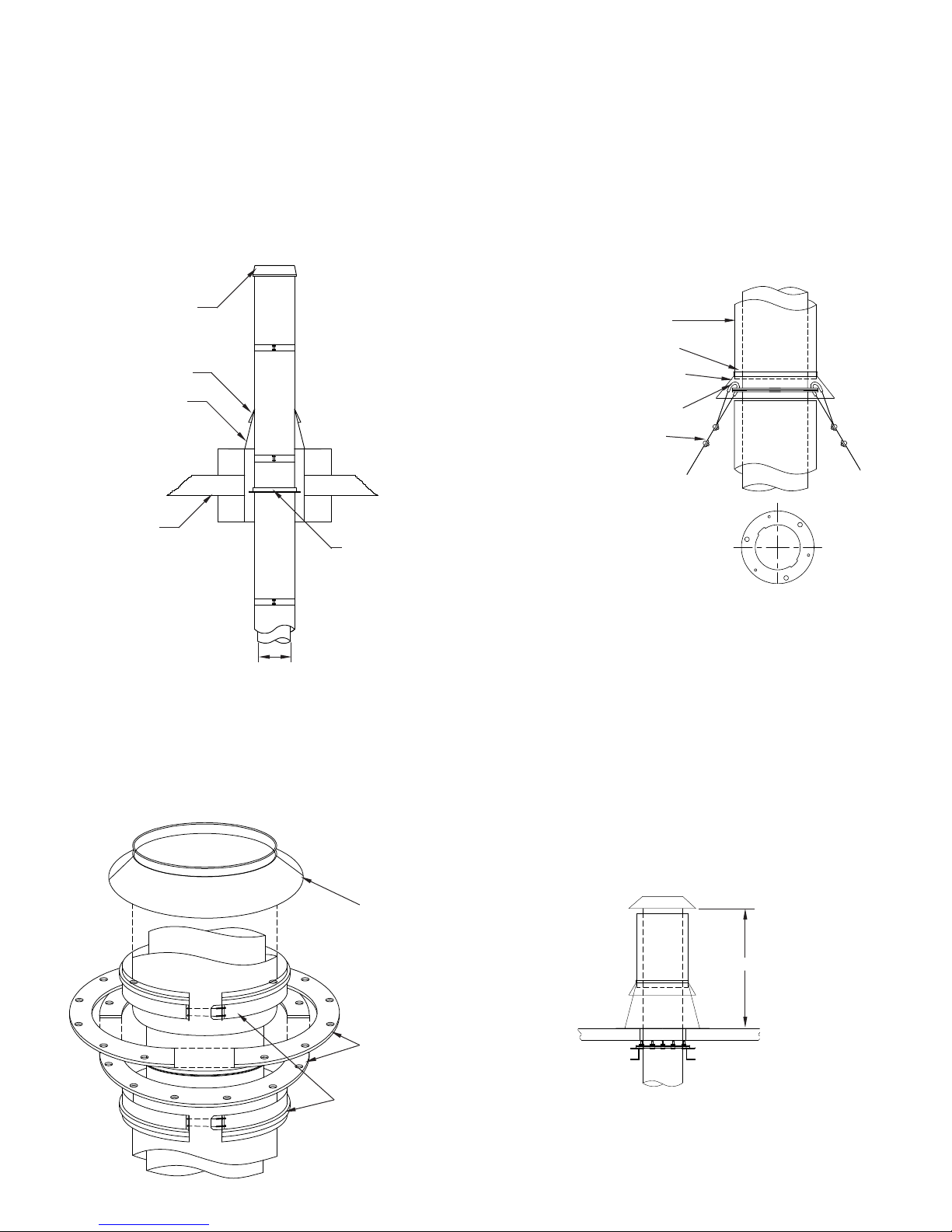

FIG. 40 – STACK SUPPORT ASSEMBLY INSTALLATION

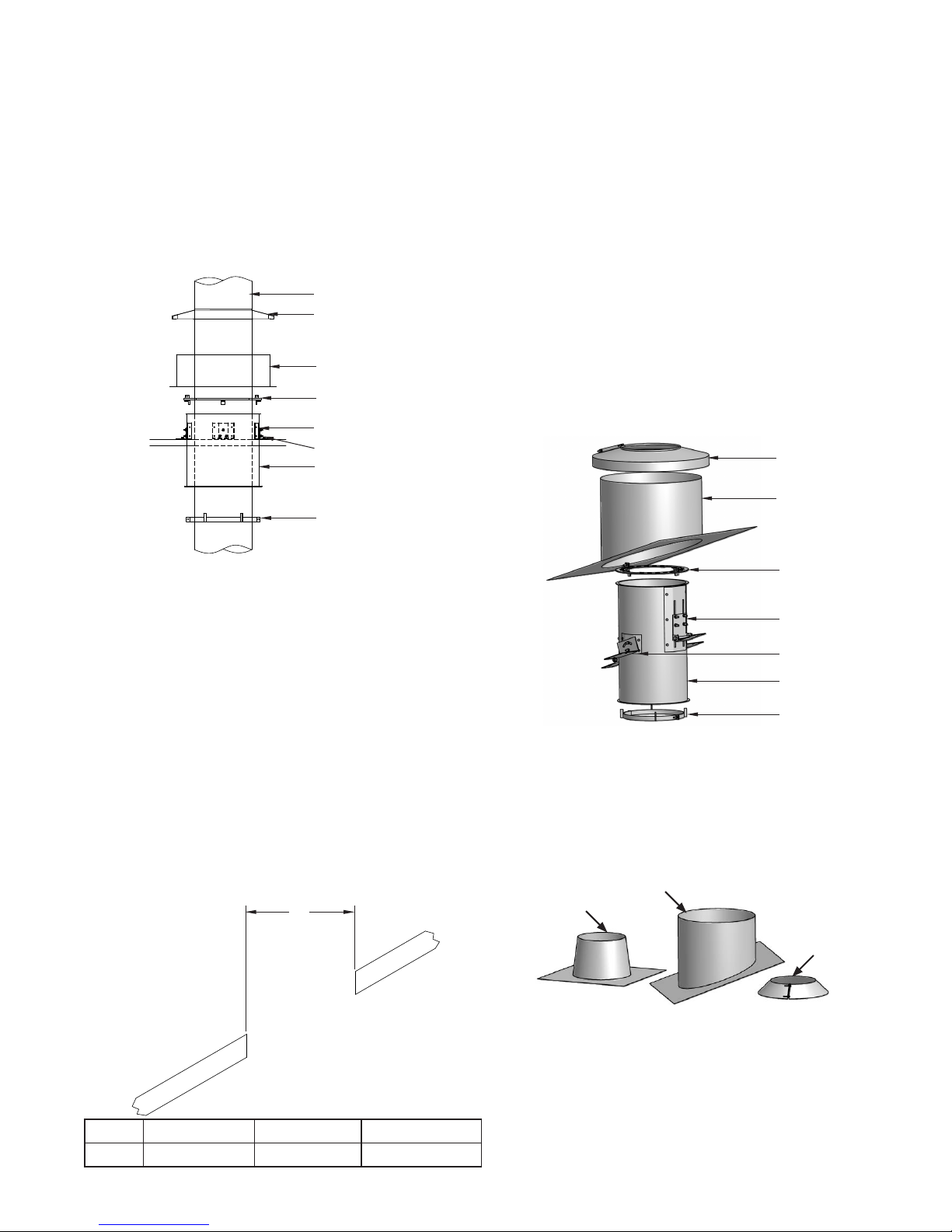

VENTILATED THIMBLE ASSEMBLY (VTA) AND ROOF

SUPPORT ASSEMBLY (RSA)

The ventilated thimble assembly is designed to allow Model

PIC/IPIC chimney to penetrate a combustible roof at a nominal

3” clearance to combustibles. FIG. 41 illustrates the required

minimum framing dimensions. The ventilated thimble is intended

for installation on a at roof. It may be used on a pitched roof if a

curb is installed at the penetration to provide a level surface for

mounting the thimble.

FIG. 41 – ROOF FRAMING FOR VENTILATED THIMBLE

ASSEMBLY OR ROOF SUPPORT ASSEMBLY

Model PIC & IPIC-1 IPIC-2 IPIC-4

“X” I.D. + 8” (203) I.D. + 10” (254) I.D. + 14” (356)

The roof support assembly is a special variation of the ventilated

thimble which also provides vertical support to the chimney. It is

especially useful when the chimney rise below the roof is long

enough to cause movement from thermal expansion to exceed

approximately 2” (51).

The ventilated thimble consists of the thimble with 4 support

brackets; 2 lateral support rings, split for ease of installation; a

ashing; a storm collar.

Installation of the ventilated thimble is as follows (See FIG. 42):

1. Cut the roof opening and reinforce the edges of the hole

as appropriate for the expected load bearing requirements.

Attach the thimble brackets to the thimble using the

hardware provided.

2. Set the thimble through the roof, making sure it is centered

in the roof penetration hole, and secure it to the roof deck

with bolts or lag screws supplied. The brackets may be

welded to a metal roof, if desired.

3. Install the chimney passing through the thimble and

extending above the roof.

4. Install the 2 split lateral support rings on the chimney casing,

one above the thimble and one below the thimble. Leave

the bolts loose enough to allow the ring to slide along the

casing. The spacer tabs are to be toward the thimble.

5. Push the lateral rings along the chimney casing until they

are completely enclosed in the thimble.

6. Install the ashing centered on the thimble. Secure it to the

roof and seal it to the roof membrane as appropriate.

FIG. 42 - VENTILATED THIMBLE ASSY. INSTALLATION

“X”

“X”

16

EXIT CONE

FULL ANGLE RING

BRACING (BY OTHERS)

NOTE: DO NOT USE VARIABLE LENGTH OR

EXPANSION JOINT BETWEEN BREECHING &

STACK SUPPORT ASSY.

STACK SUPPORT ASSEMBLY

CONCRETE PAD OR

STRUCTURAL BASE

BREECHING

90° TEE

LATERAL SUPPORT RING

FLASHING

STORM COLLAR

SUPPORT BRACKET

THIMBLE

LATERAL SUPPORT RING

STACK SUPPORT ASSEMBLY (SSA)

The stack support assembly is intended for use as a base mount

for mounting the stack on a concrete oor or a structural steel

stand. It is equipped with a predrilled steel baseplate for the

insertion of anchor bolts or studs. A 9-inch section of pipe is

attached to the baseplate and contains a false bottom 4½” (114)

above the oor. A 1” (25) NPT nipple extends through the side of

the pipe section just above the false bottom to allow drainage of

rain or condensate (See FIG. 39). It is recommended that a 90º

manifold tee with a cleanout cap be installed above the stack

support to provide access to the stack.

When using a stack support assembly as the stack base, it is

important to use exact pipe lengths to raise the stack height to

the breeching connection point (See FIG. 40). Use of variable

lengths or expansion joints in the stack under the breeching

connection defeats the purpose of the stack support assembly.

These components will not support weight.

FIG. 39 – STACK SUPPORT ASSEMBLY

1” N.P.T. NIPPLE

FIG. 43 - ROOF SUPPORT ASSY. INSTALLATION

Install lateral support ring below thimble as per step 4 above.

Then install the vertical support ring. Vertical ring consists of 2

half-clamp rings designed to lock together when assembled.

The pipe section joint will rest on top of the assembled vertical

support ring. The vertical support ring will rest on top of Thimble

Flange and carries the weight of the chimney. Because it is not

fastened to the thimble, the chimney can expand upward in the

thimble if needed.

FIXED PITCH VENTILATED THIMBLE ASSEMBLY

(FPVTA) AND FIXED PITCH ROOF SUPPORT

ASSEMBLY (FPRSA)

These components are special variations of the ventilated thimble

assembly. They provide the same clearance to combustibles and

types of support, but are designed to be installed in pitched

roofs. Installation is similar to the at roof versions except for

the following.

FIG. 44 – ROOF FRAMING FOR VENTILATED THIMBLE

ASSEMBLY OR ROOF SUPPORT ASSEMBLY

1. The roof opening is sized as a at projection (See FIG. 44)

to provide the correct clearance.

2. The thimble is centered in the roof hole with the two pivoting

brackets oriented parallel to the roof ridge and the hinged

brackets running up and down the roof. The brackets are

secured to the roof with bolts, lag screws or welding as

appropriate. Leave the bolts of the sliding mount loose until

the brackets are attached to the roof. Then tighten all bolts

and nuts.

3. Install the ashing centered on the thimble. Secure it to the

roof and seal it to the roof membrane as appropriate.

Note: The ashing pitch is xed, specify required pitch rate

with order.

FIG. 45 illustrates details of the pitched roof penetration

component installation.

FIG. 45 – FIXED PITCH ROOF PENETRATION

INSTALLATION

FLASHING (F) FIXED PITCH FLASHING (FPF) AND

STORM COLLAR (SC)

Flashings, both standard (Tall Cone) and pitched, are intended

for installation on non-combustible roofs only. The ashing is

non-ventilated and does not provide for any reduced clearance

to combustibles.

PIPE O.D.

STORM COLLAR

FLASHING

VERTICAL SUPPORT RING

BRACKET

LAG SCREW OR BOLT

THIMBLE

LATERAL SUPPORT RING

“X”

STORM COLLAR

PITCHED FLASHING

VERTICAL OR LATERAL

SUPPORT RING

HINGED BRACKET

PIVOTING BRACKET

THIMBLE

LATERAL SUPPORT RING

17

TALL CONE

FLASHING (F)

FIXED PITCH

FLASHING (FPF)

STORM

COLLAR (SC)

7. Install the storm collar around the chimney casing allowing

the ventilation spacers on the underside of the collar to rest

on the upper edge of the ashing. Tighten the draw screw

and seal between the collar and the chimney casing with

chimney sealant.

The roof support assembly consists of the same parts as the

ventilated thimble except that one of the lateral rings is replaced

with a vertical support ring. Installation is identical to the ventilated

thimble except step 4 (See FIG. 43).

Model PIC & IPIC-1 IPIC-2 IPIC-4

“X” I.D. + 8” (203) I.D. + 10” (254) I.D. + 14” (356)

To install the ashing, place it around the chimney. Secure and

seal it to the roof (FIG. 46).

CHIMNEY TERMINATIONS

STACK CLOSURE RING (CR)

The stack closure ring (FIG. 47) is the simplest method of

terminating a chimney. It provides protection of the annular

space between the inner and outer walls and leaves the top of

the chimney open to the elements. A drain section (or tee with

drain tee cap) should always be installed when a closure ring is

used as a termination. The closure ring is installed on the inner

wall and overlaps the outer wall. The joint at the inner wall should

be sealed with chimney sealant. A closure ring may be used for

either vertical or horizontal discharge.

FIG. 47 – STACK CLOSURE RING

STACK CAP (C)

The stack cap (FIG. 48) is designed to offer partial protection

from rain entering the chimney. It is equipped with an inverted

cone to divert ue gases upward to avoid contamination of the

surrounding roof area. The cap may be equipped with a birdscreen

if desired. The stack cap is intended for use as a termination only

for a vertical discharge.

A cap is attached to the top section of pipe with a ange band

and sealant. The annular opening between the inner and outer

walls of the pipe is protected with a closure ring provided with

the cap. When the chimney is terminated with a stack cap, it is

recommended that provisions be made for drainage of rain from

the base of the stack.

EXIT CONE (EC)

The exit cone (FIG. 49) is designed to produce additional gas

velocity at the chimney exit to help disperse the efuent. The

opening of the cone is based on a ratio of 0.8 times the nominal

pipe diameter. Since the exit cone is an open top termination,

provision for drainage is recommended. An exit cone may be

used for either vertical or horizontal discharge.

FIG. 49 – EXIT CONE

STACK HEAD ASSEMBLY (SHA)

The stack head assembly is designed for free, unobstructed

venting of the chimney while providing maximal protection

from rain entering the chimney. The stack head is a “low loss”

termination and is recommended by the Industrial Ventilation

Manual, 20th Edition, American Conference of Industrial

Hygienists, FIG. 8-6.

For diameters 6” – 24”, the stack head adapter section is an integral

component that attaches to the chimney ue using a ange band

and sealant. PSW sections are added to the desired height. A

closure ring is attached to the ue to protect the annular space

between the inner and outer walls from rain (See FIG. 50A). The

maximum free standing height of the stack head assembly is 60”

(1524). Heights above 60” (1524) will require guying.

FIG. 48 - STACK CAP

APPLY SEALANT

OPTIONAL BIRD SCREEN

CAP

CLOSURE RING

(INCLUDED)

FLANGE BAND

CLOSURE BAND

APPLY SEALANT 0.8 D

PIPE I.D.

18

FIG. 46 – INSTALLATION OF FLASHING AND STORM

COLLAR

With the ashing in place, the storm collar is placed around the

chimney and sealed to the casing with silicone sealer. The storm

collar should not quite rest on the ashing when the chimney is

cold (1/4” gap between the collar and the top of the ashing).

When a chimney is installed with a ashing and collar rather than

a ventilated thimble, the chimney must be stabilized by installing

either a full angle ring or a plate support just below the roof. If the

chimney height above the plate support or full angle ring exceeds

the “B” dimension in TABLE 7 on PAGE 5, it must be guyed to

avoid wind damage.

FLANGE BAND

STORM COLLAR

TALL CONE FLASHING

16 GA. PAN

PLATE

STRUCTURAL FRAME

MAINTAIN

ADEQUATE

EXPANSION

CURB

DO NOT RESTRICT

VERTICAL MOVEMENT

OF FLANGE BAND

SEALANT

MITER CUT (MC)

The miter cut is intended for use as a termination for a horizontal

discharge. It is designed to minimize the entry of rainwater

when installed in the proper orientation. Note that the miter cut

is a single wall part and requires a clearance of 18” (457) to

combustibles.

The miter cut is equiped with a birdscreen at the short side of

the miter (See FIG. 51). The miter must be installed so that the

long side of miter is on the top of the pipe to afford protection

from rain.

APPLIANCE CONNECTORS

SINGLE WALL BOILER ADAPTER (SBA)

The single wall boiler adapter is the most commonly used

appliance connector. It is designed to clamp over a shank type

ue gas outlet. A thin layer of sealant, about 1” (25) wide is spread

on the end of the appliance outlet shank. Then the single wall

boiler adapter is placed around the shank covering the sealant.

The draw screw on the split tube is tightened to hold the single

wall boiler adapter in place (See FIG. 52).

The single wall boiler adapter is 6” (152) long. A 4” (102) long

variation is available on request.

FIG. 52 – SINGLE WALL BOILER ADAPTER

FIG. 53 – FLANGE ADAPTER

FIG. 51 - MITER CUT (MC)

CLOSURE BAND

BIRD SCREEN

CLAMPING SCREW

BOILER OUTLET SHANK

CASING CLOSURE INCLUDED

FLANGE ADAPTER

FLANGE GASKET (BY OTHERS)

BOLT AND NUT (BY OTHERS)

APPLIANCE OUTLET

FIG. 50B – STACK HEAD ASSEMBLY

FLANGE ADAPTER (FA)

The ange adapter is intended for use as a connection to a Class

125 or 150 ANSI pipe ange. This type of connection requires a

ange gasket and bolt set supplied by the installer. The gasket

and bolts are typically sold by pipe, valve and ttings houses as

an “NBG” set. FIG. 53 illustrates a typical installation.

For diameters 26” thru 48” the chimney ue is terminated 9” (229)

below the required height for the installation (consult local codes).

A stack head adapter section is attached to the top section of

the chimney using a ange band and sealant. A closure ring is

attached to the ue to protect the annular space between the

inner and outer walls from rain. A plate support is located 6” (152)

below the top of the stack head adapter and PSW (Single Wall)

pipe, one size larger then the nominal chimney size, is attached

to it. The PSW pipe is equal in height to 4 times the chimney

diameter (See FIG. 50B). For guying requirements see TABLE

7 on Page 5.

Note: The structural steel supports for the stackhead are

provided by the installer. The stackhead assembly is intended

for use as a termination only for vertical discharge.

FIG. 50A – STACK HEAD ASSEMBLY

19

60” (1524) MAX FREE

STANDING HEIGHT

I.D. X 4

PSW PIPE

INTEGRAL STACK

HEAD ADAPTER

CLOSURE RING

I.D. + 2” (51)

I.D.

PLATE SUPPORT

PSW PIPE

STACK HEAD ADAPTER

CLOSURE RING

ROOF

SUPPORT STRUCTURE

TO ROOF- SUPPLIED

BY INSTALLER

6” (152)

I.D. X 4

9” (229)

I.D. + 2” (51)

ENGINE EXHAUST SYSTEM PRECAUTIONS

Engine exhaust systems require extra attention to support and

protection detail due to the possibility of delayed fuel ignition in

the exhaust system. It is important that all turns are protected

as illustrated in FIG. 14, 16 & 18 or rigidly attached to structural

framing or walls. FIG. 56 illustrates some of the special

considerations that must be considered when designing an

engine exhaust system.

IMPORTANT: When installed vertically, bellows joint must

not support weight of stack. Locate bellows joint near the

lowersideofxedsupportasshowninFIG.55.

The following components are primarily for use on engine or

turbine exhaust systems.

FIG. 55 - WALL PENETRATOR (WP)

4” MIN. (102)

COMBUSTIBLE WALLS

ATTACHED WITH 8D NAILS

OR #10 - 2” WOOD SCREWS

(4 PLACES)

WALL PENETRATOR

FIG. 56 – ENGINE EXHAUST CONSIDERATIONS

PLATE

SUPPORT

BELLOWS

JOINT

PLATE

SUPPORT

BELLOWS

JOINT

WALL

GUIDE

WALL

GUIDE

PLATE

SUPPORT

FIXED

TEE PLATE

SUPPORT

PLATE

SUPPORT

BELLOWS JOINT

HALF

ANGLE

BELLOWS JOINT

MUFFLER

ENGINE

RELIEF

VALVE

3” (76) MAX.

EXPANSION

3” (76) MAX.

EXPANSION

20

BELLOWS JOINT (BJ)

Note: Standard bellows joints require greater clearance to

combustibles that double wall components. See Table 9 for

standard single wall and optional double wall bellows joints

for clearances.

Bellows joints are recommended for vibration and expansion

movement. This type of movement is typically encountered in

diesel engine or turbine exhaust applications. FIG. 56 illustrates

typical bellows joint locations in a diesel engine exhaust system.

NOTE: Bellows Joints are required for expansion joints

in high pressure applications including engine or turbine

exhaust. Systems that use Bellows Joints are to use seal

clips (See TABLE 4 on Page 5) and additional joint sealant

per Page 23.

WALL PENETRATOR (WP)

This part is used to allow PIC/IPIC pipe to pass through non-re

rated walls at reduced clearance. It consists of a 30” (762) long

thimble with mounting brackets. The wall penetrator is mounted

as follows:

1. Cut the opening in the wall. See chart below for opening

size.

2. Position the wall penetrator tube in the opening so it is

centered. Secure it to the wall with bolts or lag screws

(supplied.)

3. Install pipe so that it passes through the center of the wall

penetrator. Install lateral braces around the pipe casing.

Leave rings loose enough to slide along pipe.

4. Push the lateral rings into the wall penetrator centering the

tabs within the ends of the tube.

Model PIC & IPIC-1 IPIC-2 IPIC-4

“X” I.D. + 8” (203) I.D. + 10” (254) I.D. + 14” (356)

BOILER FLANGE ADAPTER (BFA)

The boiler ange adapter is used to connect PIC/IPIC pipe to

anged appliance outlets other than those with ANSI pipe anges.

Typical use includes boilers, water heaters and connection to

existing fabricated pipe. The adapter is designed to sandwich

the 1/2” inner pipe ange between the appliance outlet and the

boiler ange adapter (See FIG. 54). The boiler ange adapter is

shipped with beam clips used to clamp the BFA to the appliance

ange. The connection may also be drilled and bolted or welded

if desired.

FIG. 54 - BOILER FLANGE ADAPTER INSTALLATION

CLAMP

HALF RING

BOILER OUTLET FLANGE

This manual suits for next models

1

Table of contents

Other Metal Fab Fan manuals