3.

ADJUSTMENT

3-1)

Adjusting

Thread Tension

3-1)

832lFU3aZ

e

~it$~i~+~14_%h~~~11~6031d.

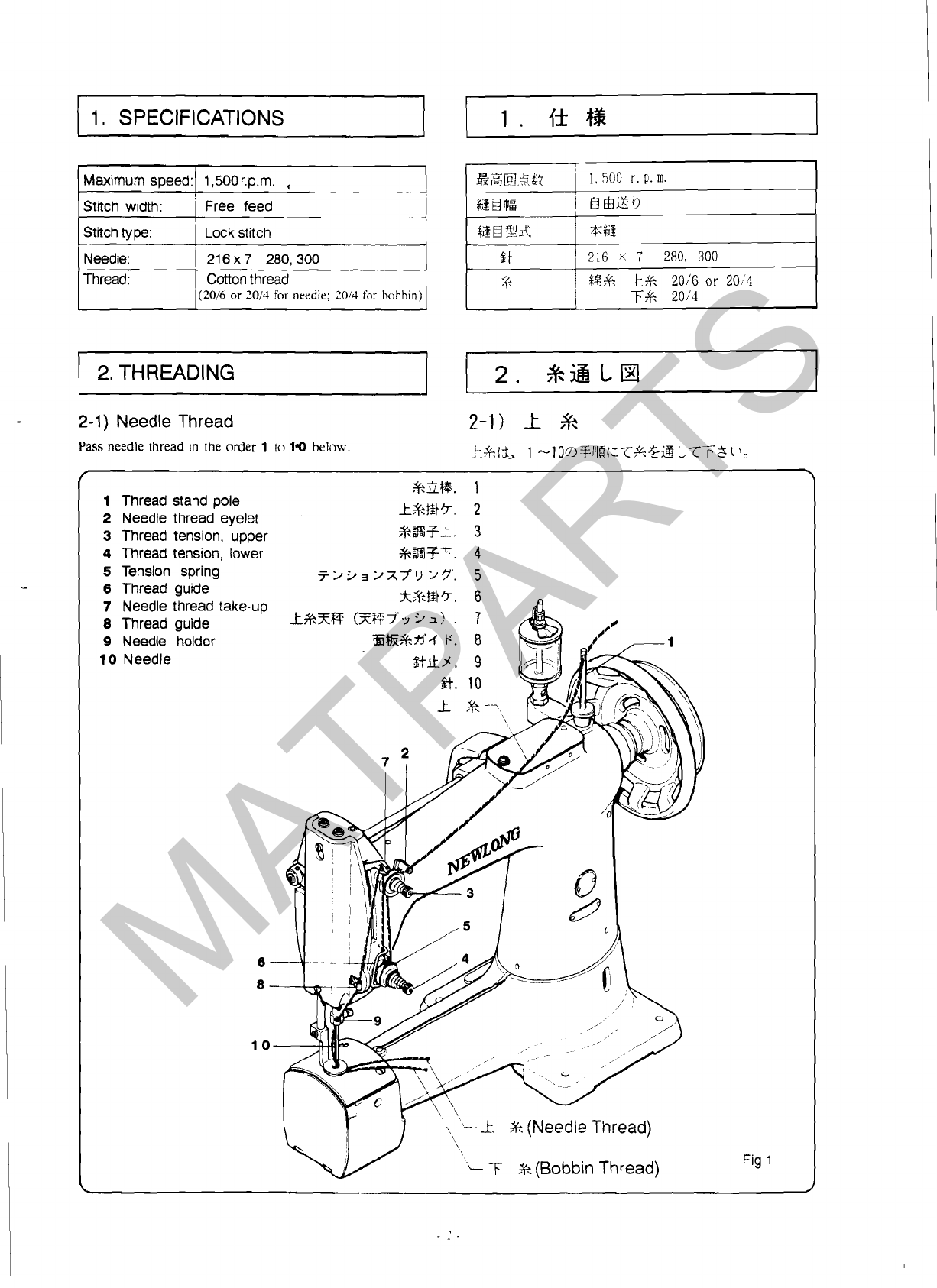

Fig 1

T%$(2)

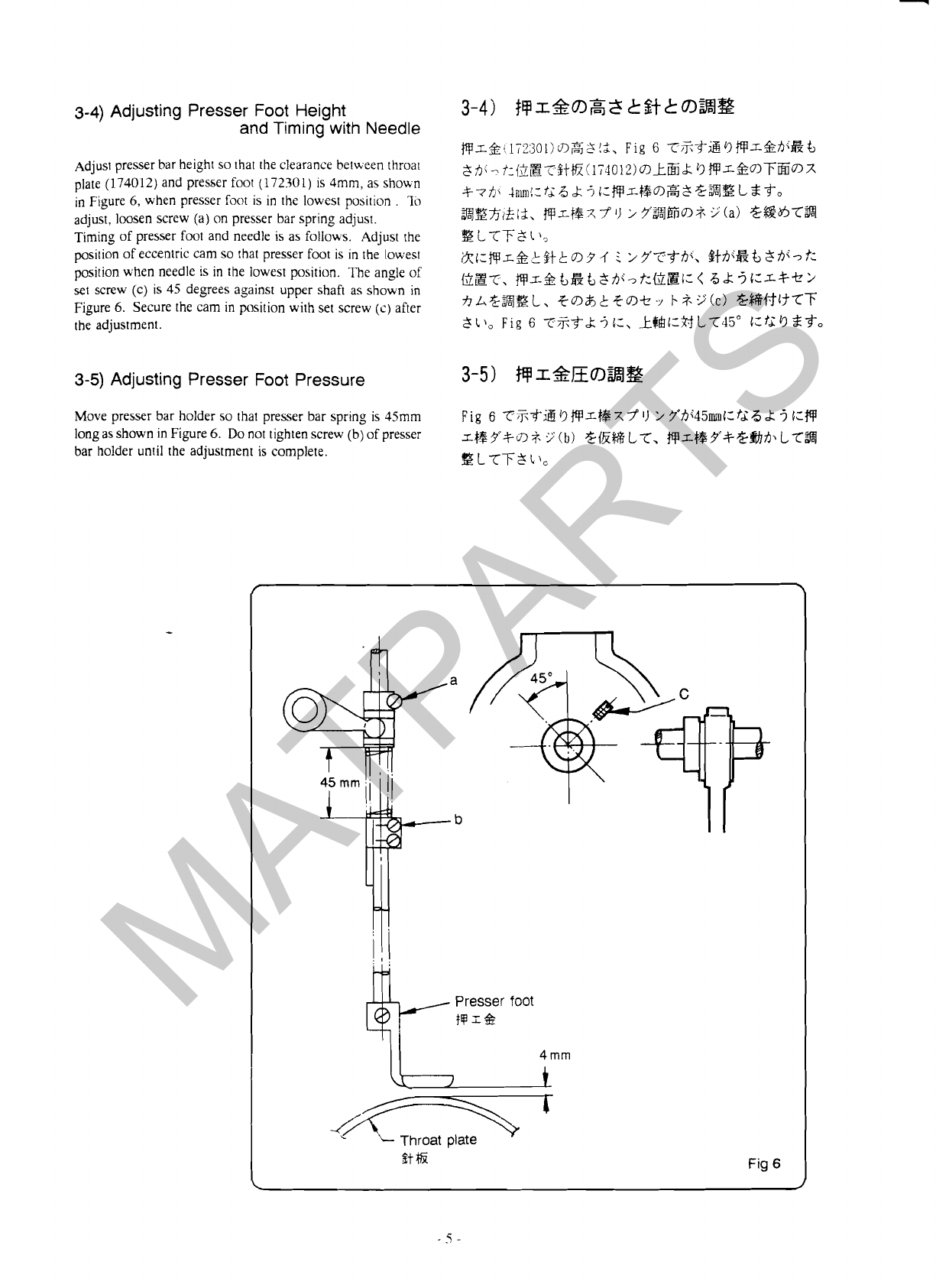

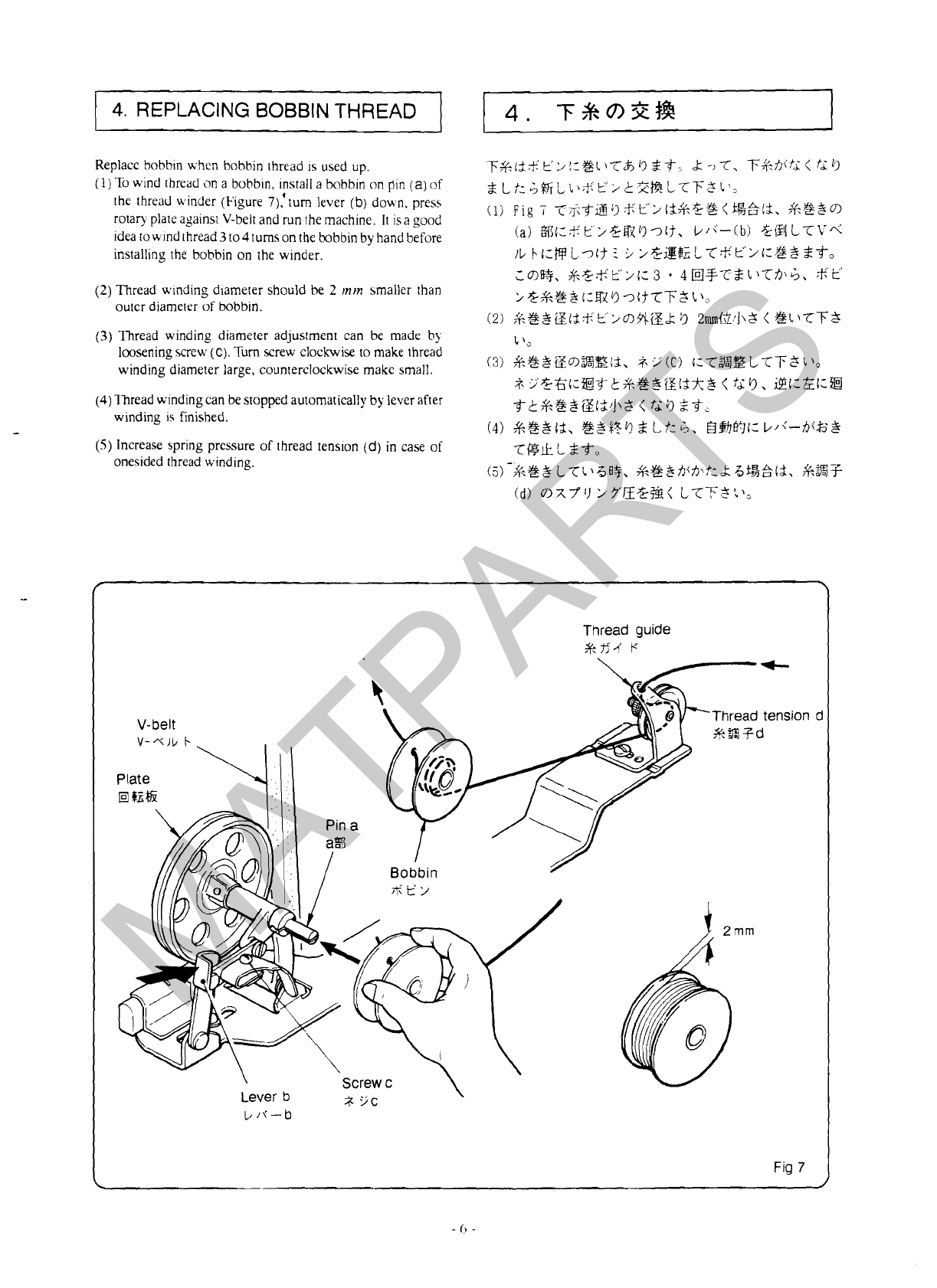

Check a sample seam to see the tightness

of

thread. For too

&flF~xy

1;

)

Y'J3555

<

L,

$i:k%h<T$$Tl\6

tight needle thread, loosen thread tension, upper

(I),

Figure

1

Tighten

it

if the needle thread is loose and raised too high. To

&gr$Eg<&

{

L?7;$

l

xll)

i

TBOE%l2kk&~~

-

-

adjust, turn thread tension nut.

t-.Y

i.fC-@L?ii~il)zE$,

3-2)

Setting

Needle

and

Adjusting Needle Bar Height

3-21

$tDRXktV3BCJ%t#~S2

(1) $+id

Fig

3?;T;$;g

4

Qtg(172132)

l~#&?+.

$thX~

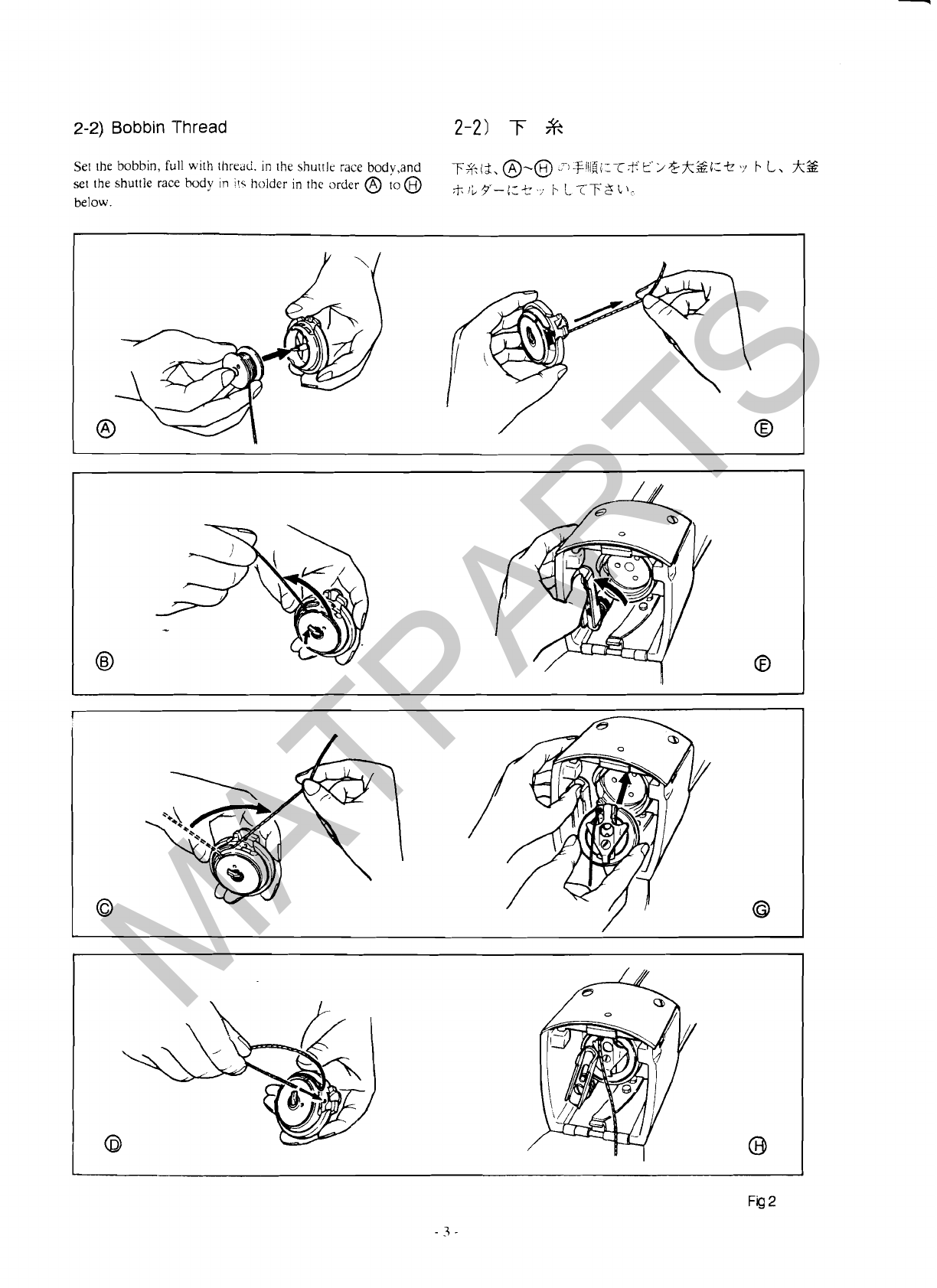

(1) Insert a new needle in needle bar (172132)asfar as

it

will

7S\L6

~~E;SA.TT'~

l)"

C

L7Stk.A

(172141)a

go (Figure

3).

Secure the needle in position with screw

(15164S28001)on needle stopper (172141).Look out tbr

the direction of needle. Theshaved part

of

the needle must

face toward the pulley of the machine.

-

(2)To adjust needle bar height, turn pulley until needle

1s

in

the lowest

position.

Thereare two mark lineson the needle

bar. Al~gnthe upper mark line with the bottom

of

needle

bar bush, upper (172151), as shown in Figure

4.

3-3)

Timing

Shuttle

Race

Body and

Needle

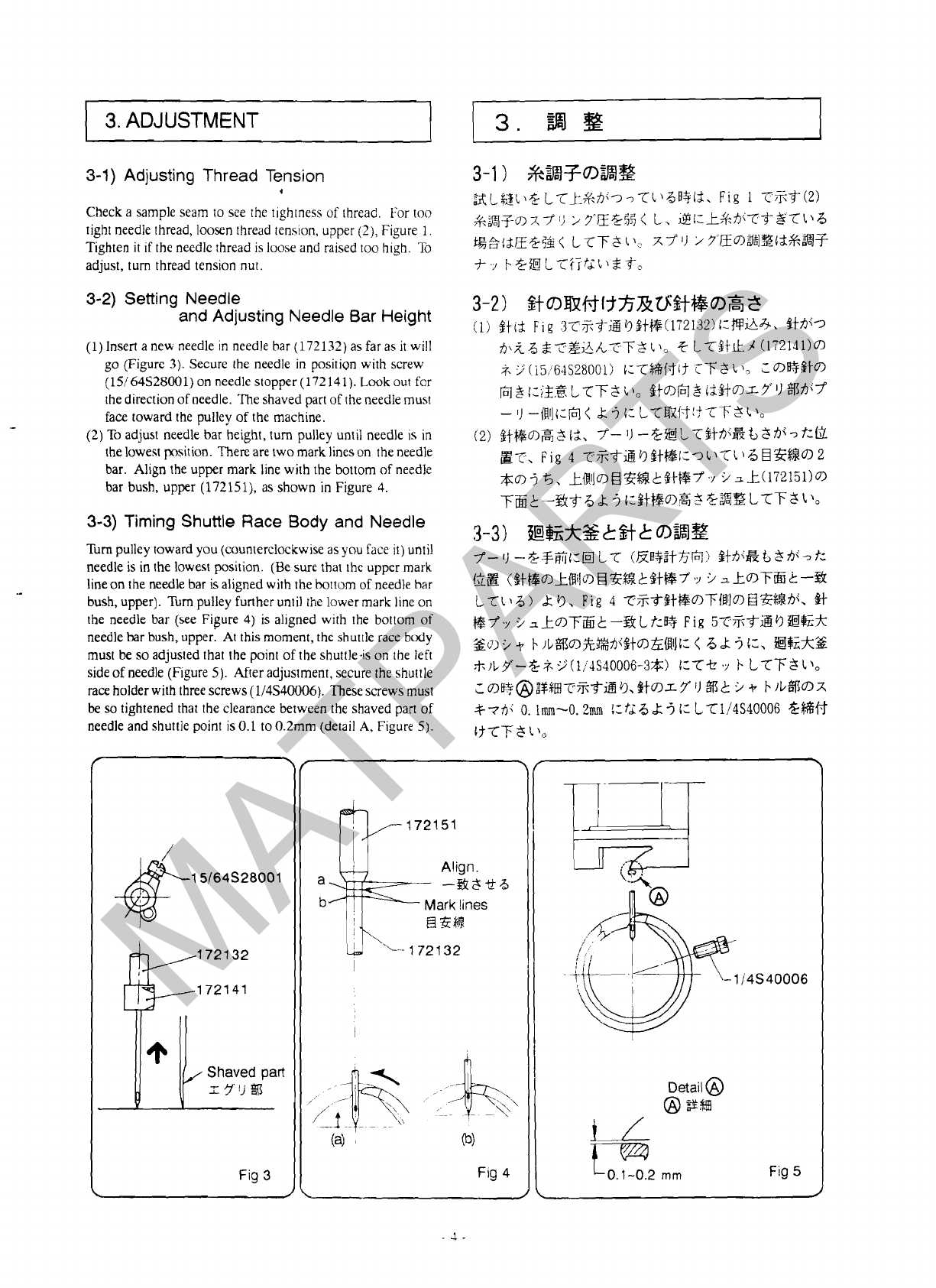

Turn pulley toward you (counterclockwise asyou face

it)

until

needle is in the lowest position.

(Be

sure that the upper mark

lineon the needle bar is aligned with the bottom of needle bar

bush, upper). Turn pulley further until the lower mark line on

the needle bar (see Figure

4)

is aligned with the bottom of

needle bar bush, upper: At this moment, the shut~lerace body

must

be

soadjusted that the point of the shuttleis

on

the left

sideof needle (Figure

5).

After adjustment, secure the shuttle

race holderwith three screws(114S40006). Thesescrews must

be

sotightened that the clearance between the shaved part of

needle and shuttle point

is

0.1 to0.2mm (detail

A,

Figure

5).

;i.

9

(i5:6+1~28001)

c:-crHc$if

rT'$

i

)7

L

o@Sta

m3i:iB3

L-crTS

L)o

$tom$

i2HDI-7'lJ

%7YY'

-

I)

-iRlli~6l<

k

3

4:

L7%!t4'!57T3

l)o

(2, $Jr~Dis,$

It,

7'-

'9

--%BL?$tA<i%t

3ni

-3

?:KL

a?.,

Fig

4

TZ$&t3$t@i:'l,l\?l~BRZ$$~2

*D5!5,

~~~~~~~%lc?$t~7~~>xk(l72151)D

TEk--%f

6

h

3

c:PtWIS3%3E

LTT:!

1~

3-3)

~&~S&$+kIn%@

7-

1)

-~+K~:IEI

LT

(EB+Zt36!)

gti~q~h

si~q-t:

G,23

($tt&OlkiFlilc?l€IZfSk$t%7'~.:,

.i

x_tOlf;%t:-%

L?l)b)

dr

13,

Fig

4

~,?;t$t@o>T;lflll~HEK:~hi,

@f

+$$Y

.i,_tDT&t:-!&LL:Q

Fig

57

iifiTiBfiC1Ek

Sol

.i

-P

+

1L%a%2%hX$ta&UltJi:

<

6

.k

3

i:,

?@%A%

;t;)LY-?&;i.

9

(li:+IS40006-3$)

t:T+

.r

i-

LTTf

1),

c

~B-+@;$~IT%-oB

5.

$tar

7

11

%f3

L

.i

+

111/%c~x

%77Y

0. lrrun-O.2mm

!:ti

b

5

C:

LT114S40006

%$%$f

if7-F$

l\o