5. Adjusting/Elf H

The looper movernent of this rnaqh.i&e tr-as hee(r qrcge(L\

adjusted before shiprnent from the factory, but if it needs

re-adjustment when it is disassembled for repair or etc,

prcceed as foilows.

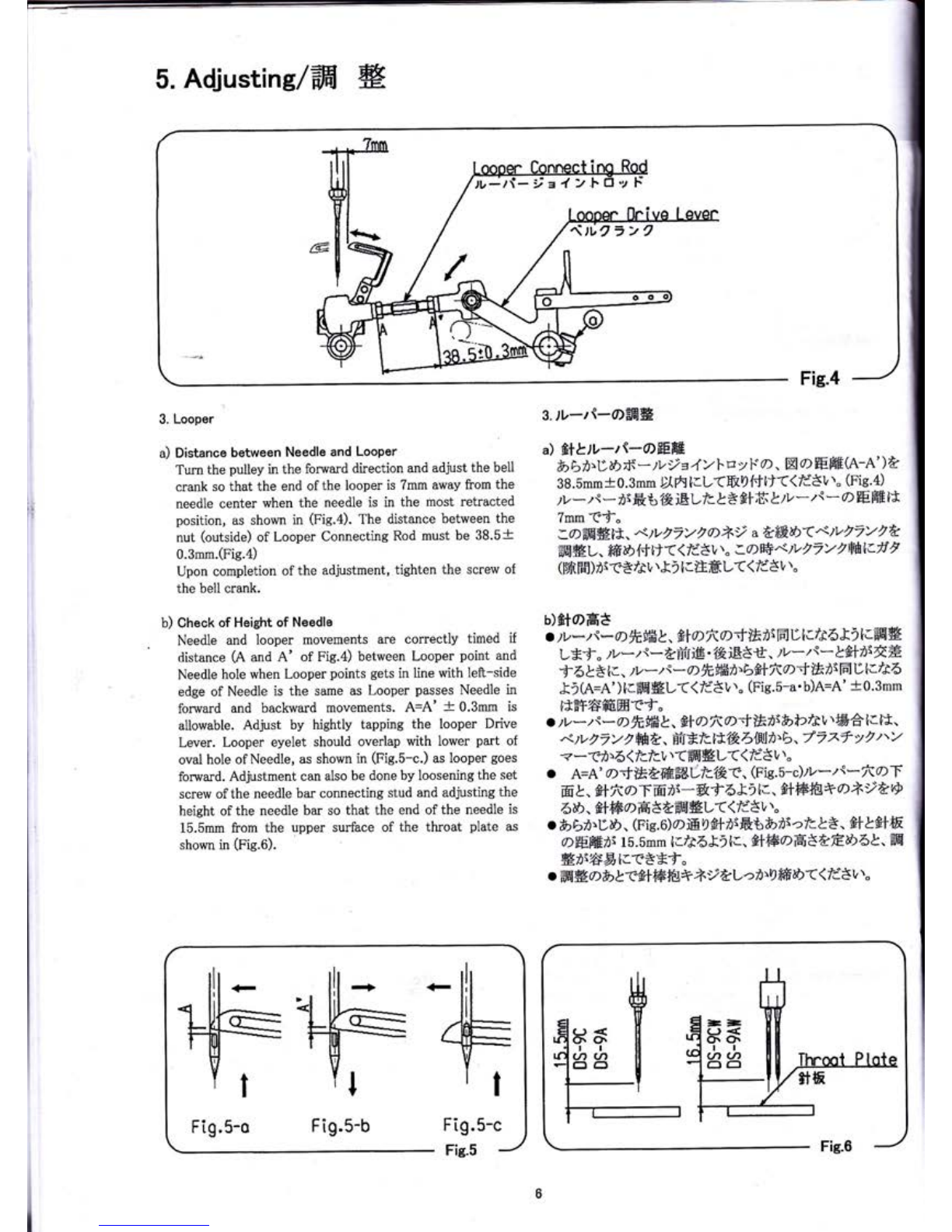

1. Thread Tension (figure 3)

Thread tension is most important for successful sewing,

Maiadjustment results in thread break, skipping stitches and

break ofbag.

Proper thread tension may slightly vary with the type of bag

and thread. The norm is given below. Thread tension

regulators are mounted so that the tension is uniform for

stitch length. To adjust the tightness of seam, adjust O,@

in Figure 3:*

1) Heavy material fiute,etc.)

Thread tension regulators O should be loosened slightly

(turn the adjust nut counterclockwise), Needle thread

controller @ after loosening set screw.

2) Lisht material

Tighten thread tension regulators O (turn the adjust nut

clockwise).

3) Needle thread

At the shipment, the needle thread controller @ for

Creped Paper Tape is adjusted a iittle downward. In case

of using sewing machine without Creped paper Tape, the

needle thread controller @ should be re-adjusted

upward.

The feed rate of thread must be adjusted according to

stitch leneth and thickness of bag. If thread tension

regulator adjustment is not sufficient for obtaining the

required thread tightness, use needle thread controller @

by moving it up or down as necessary, after loosening set

screw. Thread is tighter by moving it up (in the direction

of the arrow), and is looser by moving it down. Tighten the

set screw after adjustment.

4) Looper thread

Looper thread tension regulator @ should be adjusted in

accordance with adjustment of the needle thread tension =

regulator. Adjust it so that the looper thread will not sag.lf

looper thread tension is too much, the needle thread may

break.

2- Presser Foot Pressure

Presser foot pressure must be adjusted according to the

material of bag and thickness. Check the reverse side o{

searns. The pressure is too strong if seams show a sign of

scratches by feed dog teeth, or the actual stitch length is

shorter than the preset feed rate of feed dog teeth. In this

case, unscrew plate spring adjust screw(102171),Figure 4,

after loosening nut (5/16N24301). Be sure to tighten the nut

after the adjustment. If the pressure is too weak, seams do

not form a straight line, or the stiteh length is irregular. In

this case, increase the pressure by screwing the plate spring

adjust screw. Decrease the pressure when closing jute and

other heavy bag material, and increase it when closing pp

woven cloth and other light bag material. your machine is

adjusted for 3-ply kraft paper bags at the factory.

avtq\VvR.S$IK(\CnKKtL<.$\K\-;(\\g$'

7)r. sl3 gil tf4/r D("ffi E n\il. E i./i g ELft.b. tkq)ffi*fi

'tEt E ffit.. EEt* L(( /i3 v''"

l. #-EJA+odElB (rie.s 6ffi1)

X AH+ tt#&ffi i l^-eft684/r*[A-ef" iIHL<< fis

v \" Xffi + offi Ha HEi 6 LNrrrJtL. E ft Lrt. #o ffiWtt

&"oFtr&la9*f.

# ffi + <p'rs.3-o@> o ffi # i*# & # offi ffic & D a&v,

,s&)9E:f ,r. trErJ&L(ltCIiE4 I.EE*L(<ra'8r, \"

1) tr{rr*(ffi *A&)f€H o 3EI *

*ffi+ @ D *r) fF 3 ii./c t tu#fr\ vg 6( L ( ( ti' 3 v r"

X\ffi+ ^7 t) y I &ffi<frLT rf (D.b #ffi 7f yltE

^(E+-=#&rEf Ifi lt) g 1_a a Id8 r,.. #ffi+ ^7 y y / ti

t ylaF.luoffi t. ?(J- yT.o ElErr En €3 tu6E-e

**2L*f" EEffiL(<fdSL\.

(*Ic-t.fr EEfifi @t *i, tffiD r++T d*f )

2) ffi{a*ffiHo-dag

i6ffi +Oo X o ilfl 3 ii.f:Adfi < L(<fdtu r. 5 p67*

vl-&fi[.81L((ldsr,r"

3) r*EEffiof,aE

Tw fiffi E+ rX' v - 7 7 *7 fr t. .E' X ffi fiF @ t D LT

LJ(=aE#L(L \ Xf " 7 *7 t {F.ffiL/i r, \ H ttt,if aE€F

at'd(FffiBL(<rd3v\.

f6v'' H fiE. #otr8o)EL \-e/A aB+rdtrrE# ffffE9 rr

ffi r, \I* t*t* ffi €F@A-LT8tffiffi LEf. .E'tr ;EfiF

L kW fr fi I.-t tf 6 L fi t*ffi *0. ttDfi frit;.9173'j I

* t Jffi7t *-t'" iE rE /e {f E r +, ( 1 1 /64 s 40 0 0 9) -e t /A

ffi€FaEEL((/i8t''"

4) T*o5Eg

T *\ a #ffi+@ o ffi # lrt * a ;Affi+ tra t2it * f .

T*i\tbtlir,\t ) fc6g1_a< fdSv.," T/60lA

ifr+ Dfr 3 iraitfi L \ l, -9/6 o,/A gJtv,,t*W L tr ut

*f" iEHL<( liSt'r'

z.lH-SoffiE

#F -& o fF - '-tr,'tj.# D fi H.tE 3 o iel, \ (.=*H €F L( < ri 3

r, r" ffi cli# 0DFrftl,:.ffii,\ H AF,(<fi8L." Elr&lrI->

A. Ert\.> *, Elcffi r, r E fE- rt*, E& g 4. 3 v. LE l*#F-E

,r tfi f 3- *?-. fEu s * ffi frFR y(l 02 I 7 1) tfrX O < ffiFtrV<

T 3 r,'' " z a b t -f y I. (5/ 1 6N243 0 L) tt- -> t1,g fr#E r < rd 3

l, t" #f -E /i $$ l, r | ffi !, r E nl Effi lcffi if . E/1fi6 L \ El fiE-

66ffi r,. t:/r D *f" Bifi ,)=FlE#trE lr;6664y tffi b>< <

ld5 t, .. ffi!frfrE EMz a*tffi) t*llffi -E &86 < L(< fd

3t''" PP, n z$lt?Wryn OXb{#2}B i*ffi -E b*kd> tt

L(( ld8 t, r" TE tr)ffi D L.Z tX, 77 l. sE ofiS# tlAbrt

t=ffi#tL<L\*,f.