Next Wave CNC SHARK User manual

Popular Inverter manuals by other brands

Phocos

Phocos Any-Grid PSW-H-5kW-230/48V Recommended Battery Settings Guide

enphase

enphase IQ8AC Installation and operation manual

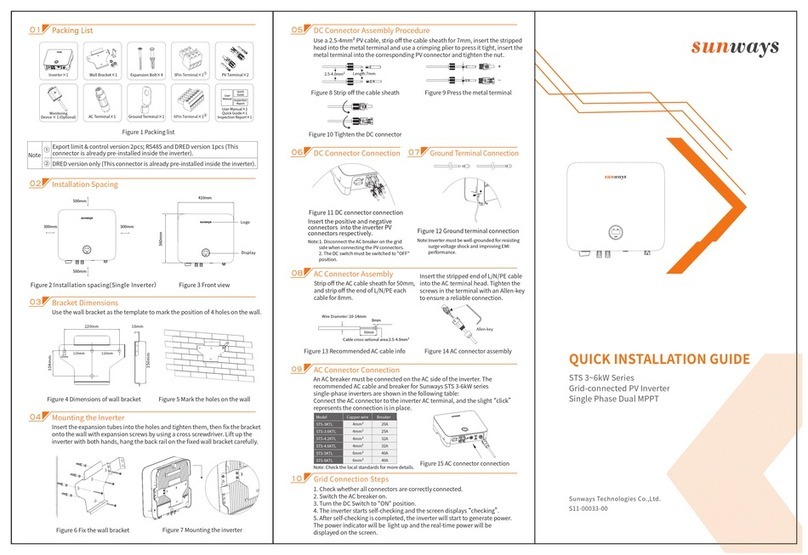

Sunways

Sunways STS-4.2KTL Quick installation guide

MOZELT

MOZELT CoolGen 4 Technical manual

Hensel

Hensel TRIA 3000 AS user manual

Telair

Telair TIG 3000D Use and maintenance manual and instructions for installation

Mitsubishi Electric

Mitsubishi Electric FR-E8TR instruction manual

Afore

Afore Residential HNS Series Installation and operation manual

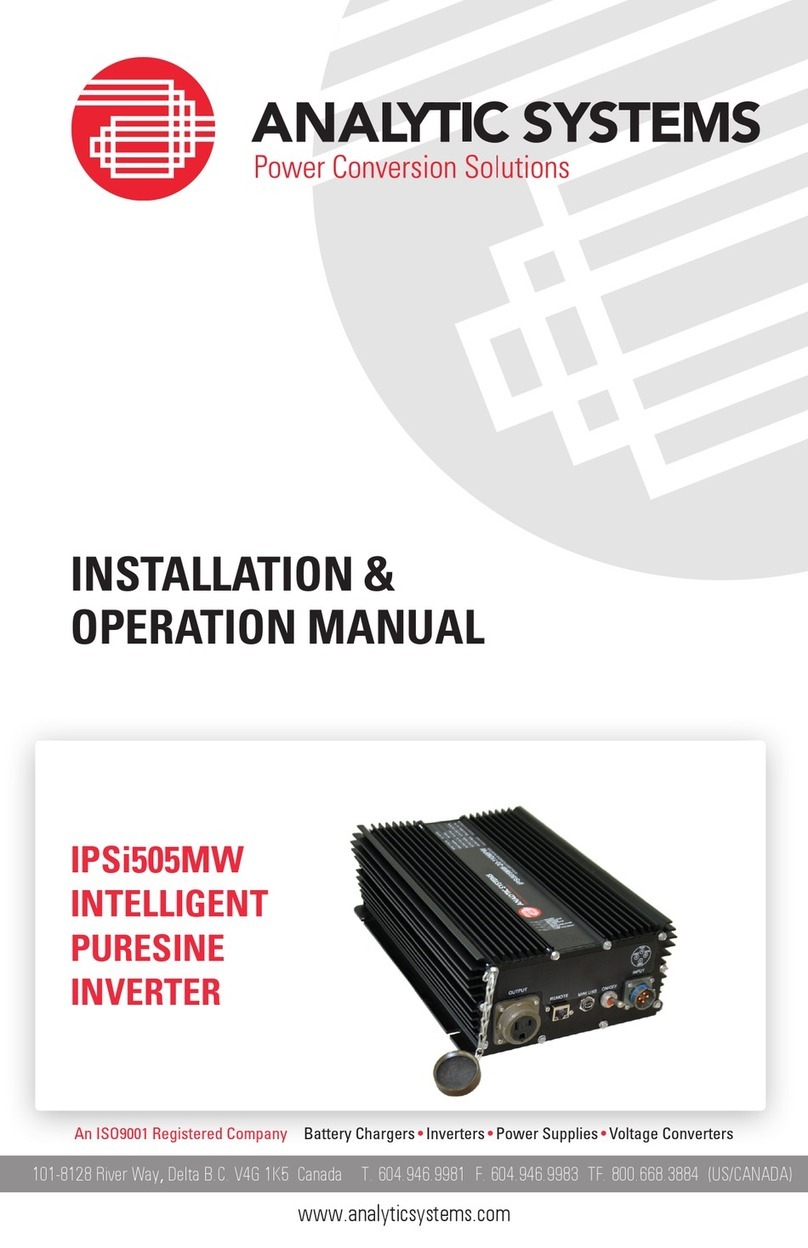

Analytic Systems

Analytic Systems IPSi505MW Installation & operation manual

GW Instek

GW Instek MFG-2000 Series quick start guide

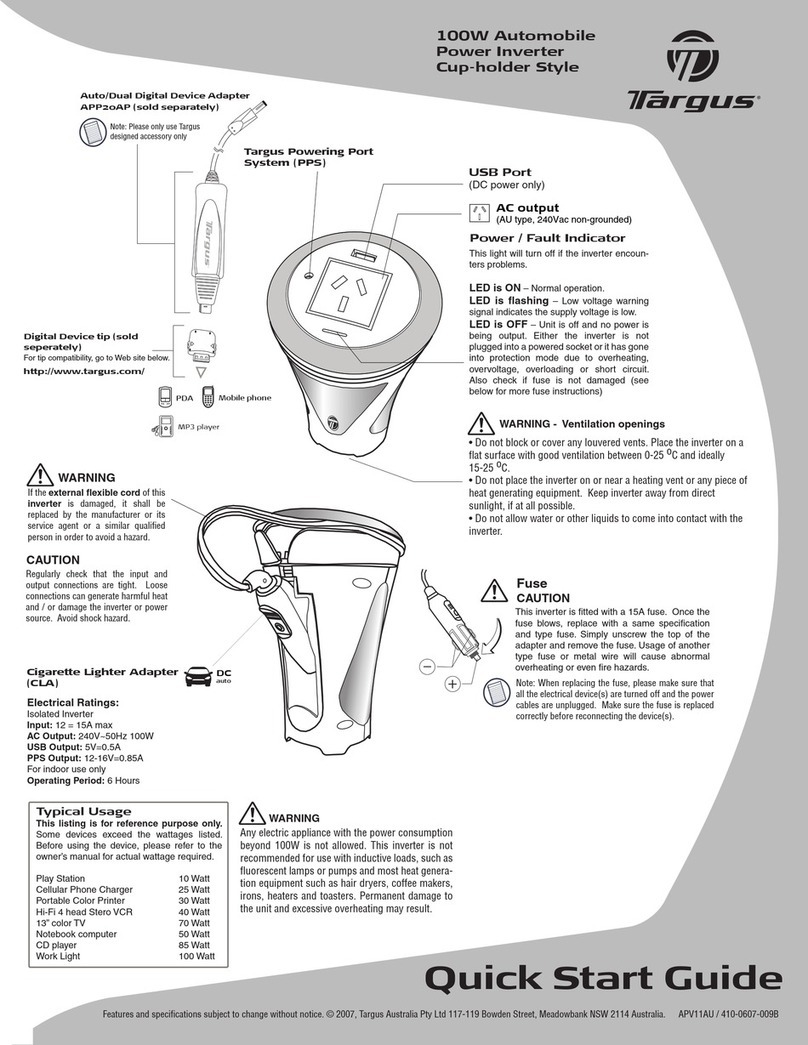

Targus

Targus 100W Automobile Power Inverter quick start guide

Renac

Renac ESC Series Quick installation guide