MOZELT CoolGen 4 User manual

Technical Manual

CoolGen 4

Please observe the following safety

information and recommendations

before start-up !

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 2

English

2. Usage to the Intended Purpose

Synchronous generators with integrated electronics are

components for installaon in machines which are used

in industrial plants.

Start-up of the power generators is not allowed before

it has been veried that the machine in which the

generators are installed conforms to the Machinery

Direcve.

The generators conform to the protecon goals of the

low-voltage direcve.

Operaon is only allowed when the EMC Direcve is

adhered to.

The technical data and informaon about connecon

condions are given in the nameplate and documentaon

and shall be adhered to by all means.

3. Transport, Storage

The instrucons for transport, storage and proper

handling are to be observed.

Defects detected aer delivery shall be reported

immediately to the carrier. Before start-up, the supplier is

to be noed, if necessary.

4. Installation

The installaon and cooling of the devices must be

carried out according to the provisions of the respecve

documentaon.

The generators are to be protected against inadmissible

loads. They are only to be touched in such a way that no

components are bent and/or insulaon clearances are

changed. Avoid touching the electronic elements and

contacts.

1. General

During use the generator may have live, bare, if

applicable, also hot surfaces. In the case of inadmissible

removal of the required cover, inappropriate use, wrong

installaon or operaon, there is the risk of death or

severe injury or material damage.

All work concerning the transport, installaon and start-

up as well as maintenance are to be carried out by

qualied technical personnel (IEC 364 and/or CENELEC

HD 384 or DIN VDE 0100 and IEC Report 664 or DIN VDE

0110 and naonal regulaon for accident prevenon or

VGB 4 are to be observed).

Qualied technical personnel according to these basic

safety references are persons who are familiar with the

installaon, assembly, start-up and operaon of the

product and possess corresponding qualicaons for

their acvity (dened in IEC 364 or DIN

VDE 0105).

For reasons of safety and the preservaon of

documented system data and funcons, repairs to the

generator or its components may only be undertaken by

the manufacturer.

Technical data, as well as data concerning connecon

condions, are to be taken from the rang plate and the

documentaon and are to be strictly observed.

Safety information / General information

All passages provided with the „warning“ sign in the manual contain informaon

important for avoiding danger!

WARNING

All passages provided with the „cauon“ sign in the manual contain informaon

necessary for avoiding damage to the power supply or accessories!

CAUTION

It is absolutely necessary to observe the

following warnings.

If these warnings are not observed,

serious personal injuries with fatal result,

severe injuries to health or considerable

damage to property cannot be ruled out!

WARNING

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 3

English

5. Electrical Connection

When working on energized power generators, the

applicable naonal accident prevenon regulaons shall

be observed.

The electrical installaon is to be carried out in

accordance with the relevant regulaons (e.g. line cross

secons, provision of safety arrangements). Further

instrucons are given in the documentaon.

The manufacturer of the system is responsible for

adherence to the EMC legislature. Instrucons for

installaon in accordance with the EMC Direcve are

given in the documentaon of the power generators.

6. Operation

Installaons into which the generators are built must be

equipped, if necessary, with addional monitoring and

protecon devices.

The manufacturer’s documentaon is to be observed.

Aer separang the generators from the drive unit, live

components and line connecons must not be touched

when the generator spindle is running, due to the

voltage.

All covers are to be kept closed during operaon.

In the electronics, there are intermediate

circuit capacitors.

Their discharge may take longer than 10

minutes!

Before start of work, verify isolaon from

power supply!

If this is not observed, serious personal

injuries with fatal result, severe injuries

to health or considerable damage to

property cannot be ruled out!

WARNING

7. Applicable Documents

A prerequisite for the use of a power

generator is that these operang

instrucons have been read and

understood. In parcular, the safety

notes contained there are to be

observed.

If these notes are not observed,

serious personal injuries with fatal

result, severe injuries to health or

considerable damage to property

cannot be ruled out!

WARNING

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 4

English

Table of contents

1. Technical descripon 5

1.1 General informaon 5

1.2 Range of Applicaon 5

1.3 Descripon 5

1.4 Funcon mode 5

1.5 Protecon Concept, Behaviour in the Case of Faults 6

1.6 Safety regulaons magnet operaon 6

2. Technical Data 7

2.1 Performance Data 7

2.2 Accessories 7

2.2.1 MFD display 7

2.3 Generator Drives 8

2.3.1 Belt Drives 8

2.3.2 Hydraulic Drives 8

3. Assembling 9

3.1 Assembling instrucons 9

3.2 Installaon of „BELL CLUTCH“ Coupling 9

3.3 EMC Notes Electromagnec Compability 10

3.3.1 Interference Immunity 10

3.3.2 Interference Radiaon 10

3.4 Magnet Connecon 10

3.5 LED Funcons 10

3.6 Control cable 11

3.7 Terminal Box 11

3.8 Terminal Block 12

3.8.1 Start command via switch line on the MFD display 12

3.8.2 Start Command via Terminal Block 12

3.9 USB Connecon 12

3.10 Cable Allocaon 230 Volt 13

3.11 Dimensional Drawings Power Generator 14

4. Commissioning 15

4.1 Safety Notes 15

4.2 Operang instrucons 16

4.3 Operaonal indicators MFD 17

4.4 Fault indicators MFD 19

4.5 Assembly Plan Power Generator 22

4.6 Mechanical Speed Measurement 23

5. Shutdown 23

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 5

English

English

1.2 Range of Applicaon

The MOZELT power supply system with synchronous

generator is designed to supply and acvate load liing

magnets on mobile excavators.

At present it is available with the output sizes 13, 20 and

30 kW.

Due to the duty rang of 100% (ED), the generators are

the opmal soluon for loading and handling in the

industrial scrap metal industry.

The maintenance-free and compactly designed generator

system is powered by the diesel engine of the excavator

or the hydraulic system.

1.3 Descripon

* rpm = revoluons per minute

1. Technical descripon

1.1 General informaon

MOZELT does not take any liability for the consequences

resulng from inappropriate, negligent or incorrect

installaon or operaon of the synchronous generator

with integrated electronics.

The condions of guarantee of MOZELT in the valid

version at the me of purchase shall apply for the

equipment.

The content of the present manual is considered correct

at the me of prinng for the indicated generator

version. MOZELT reserves the right to make changes

which represent a technical advantage.

Any change to the generators which is not performed by

us, including the installaon of addional devices, can

lead to a change of the technical specicaon and the

content of the documentaon and manual and therefore

leads to an exclusion of our liability, also from the

guarantee.

CAUTION

CAUTION

CAUTION

CAUTION

The rated speed of a generator of the

CG 4-series is around 3000 rpm*.

In this connecon, the range from

2700 rpm to 3400 rpm is to be

regarded as the tolerance range.

It is parcularly important that the

rotaonal speed remains constant

and no uctuaons occur!

The most important operang and switching states

are indicated in a mul-funcon display (MFD) in the

operator‘s cab.

1.4 Funcon mode

The transformaon of brushless three-phase voltage into

DC voltage in the generator and its contactless delivery

aer acvang the generator provides the operator with

comfort and the highest safety.

The generator CG 4 is praccally maintenance-free. The

abolion of contactors or relay circuits in the external

electrical plant area, as well as the absence of adjustment

buons or potenometers, protects this installaon

system against faulty operaon.

Important!

The electronic modules are equipped

with electrostacally sensive CMOS

and MOS components.

It is absolutely necessary to observe the following

instrucons since otherwise these switching circuits

can be destroyed.

• For servicing work, rst equipotenal bonding (stac

charging) is to be ensured between electronic modules,

tools, measuring devices and personnel.

• Grasp electronic modules by the edges only, do not

touch components and their connecons.

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 6

English

The generator CG 4 is independent of the on-board

electrical system, and produces its own supply voltage for

internal control and monitoring. The machine is overload

and short-circuit proof.

The correct supply voltage is regulated automacally for

the magnet aached to the generator and the necessary

release me is opmized and implemented for every

kind of material to be loaded.

The operator can read o important operang condions

from the funcon display (MFD) in the operator‘s cab.

The display of the relave duty rang in % (ED) is to be

observed for the range 50% to 100% of the aached

load liing magnet. If this exceeds the value 80% ED, the

danger of the magnet overheang is signalized by a red

LED.

It is then recommended to change the work mode or to

take a break to allow the magnet to cool down.

The localizaon of work related errors in the 230 V cable

system is directly possible. Cable damage and

shortcircuits in the 230 V cable system lead to immediate

disconnecon of the supply voltage (passive protecon

for individuals).

1.5 Protecon Concept, Behaviour in the Case of

Faults

The intrinsic safety of the power generator is enhanced

by an extension of the monitoring funcons, Installed

monitors ensure a high operaonal reliability of the

system.

In case of fault, the electronics is immediately blocked. At

the same me, a fault is indicated and the LED „Ready for

operaon“ exnguishes.

The following monitoring funcons are integrated:

• Overload protecon

• Insulaon monitoring

• Overtemperature protecon

• Overspeed protecon

• Open magnec circuit

• Short circuit

1.6 Safety regulaons magnet operaon

The operaon of a load liing magnet on a mobile

excavator represents a special mode of operaon and

an increased safety risk. In contrast to working with

a hydraulic grabber, the magnet picks up all available

ferromagnec material immediately aer it is switched

on.

This may even be more than the load-carrying capacity of

the mobile excavator allows.

Similarly, the magnet suddenly releases the lied

material aer it is switched o, if there is cable damage

or a short-circuit in the magnet feed cable. This can

lead to dangerous situaons in the working vicinity, for

example, if falling material causes other objects to be

hurled up by lever force. Furthermore, it is not excluded

that pieces of scrap iron may separate from the magnet

during a swiveling procedure, if these are located at the

lower end of the lied material cluster.

For these reasons, it is parcularly important to observe

the following principle:

WARNING

WARNING

The magnet can oscillate strongly aer load release!

For this reason, the mechanically safe aachment of

the magnet in the form of a special magnet suspension

at the end of the arm on the mobile excavator is highly

recommended!

Do not swivel the working equipment

or change the locaon of the

excavator with the magnets

switched on without a

payload - unintenonally

lied materials can lead to

human injury by lever force!

While working with the load

liing magnet it is forbidden to

stand within the extended reach of

the excavator

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 7

English

English

2. Technical Data

2.1 Performance Data

Model CoolGen 4 13 kW 20 kW 30 kW

Rated voltage 230 V 230 V 230 V

Max. output current 57 A DC 87 A DC 130 A DC

Operang speed range * 2700....3400 U/min **

Venlaon Internal venlator

Weight 58 kg 87 kg 135 kg

Protecon class IP 55

Permied ambient

temperature

-25° C…..+50° C non-condensing

Installaon height < 1000 m NN, above 1000 m output reducon of 1% per 100 m

2.2 Accessories

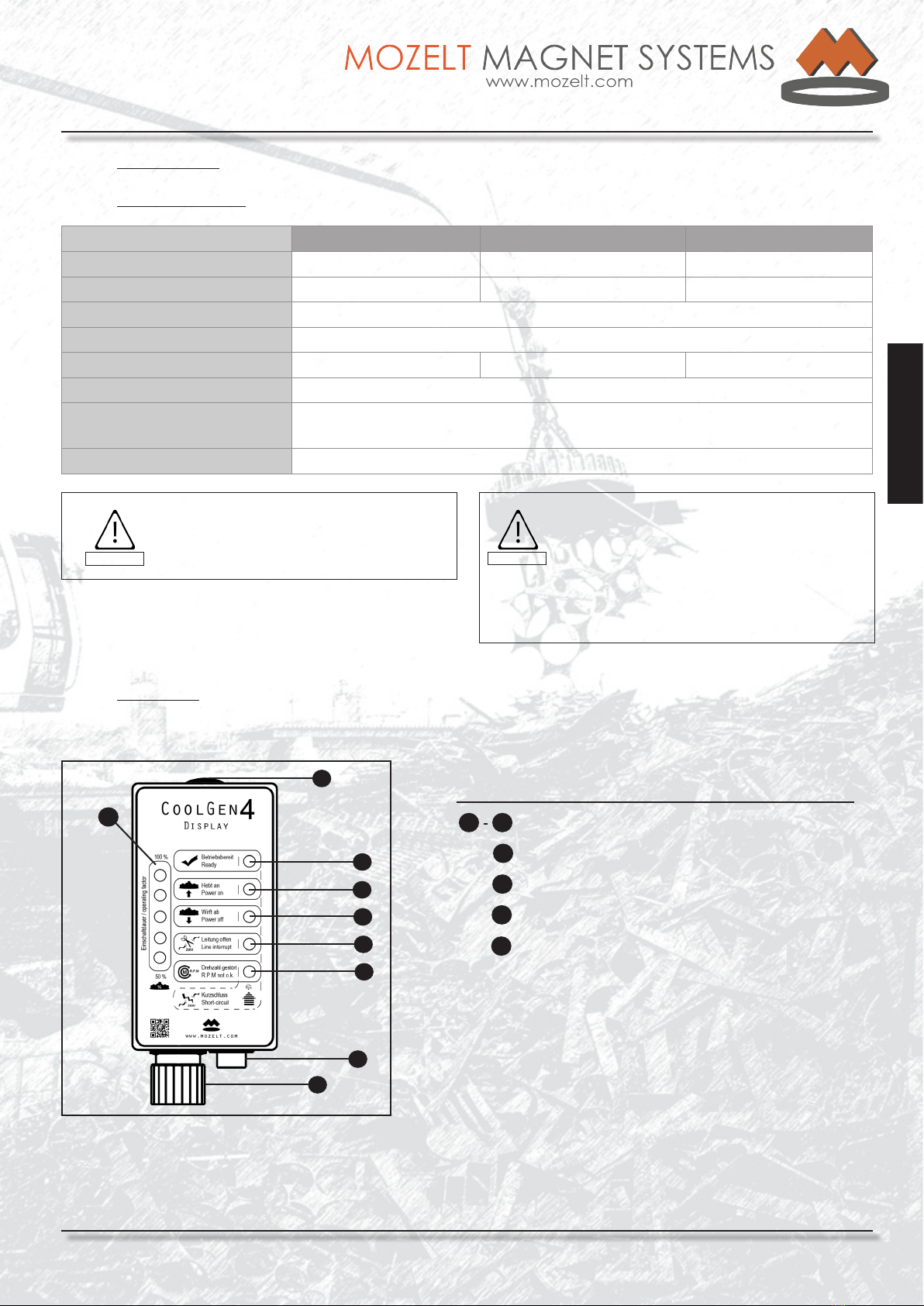

2.2.1 MFD display

The data indicated on the nameplate

are of signicance!

CAUTION

When the power generator is installed

in a casing or under a cover the

temperature of the air used for cooling

should not be more than 50 °C max.

(maximum internal temperature of the

casing / cover!)

CAUTION

1

2

3

4

5

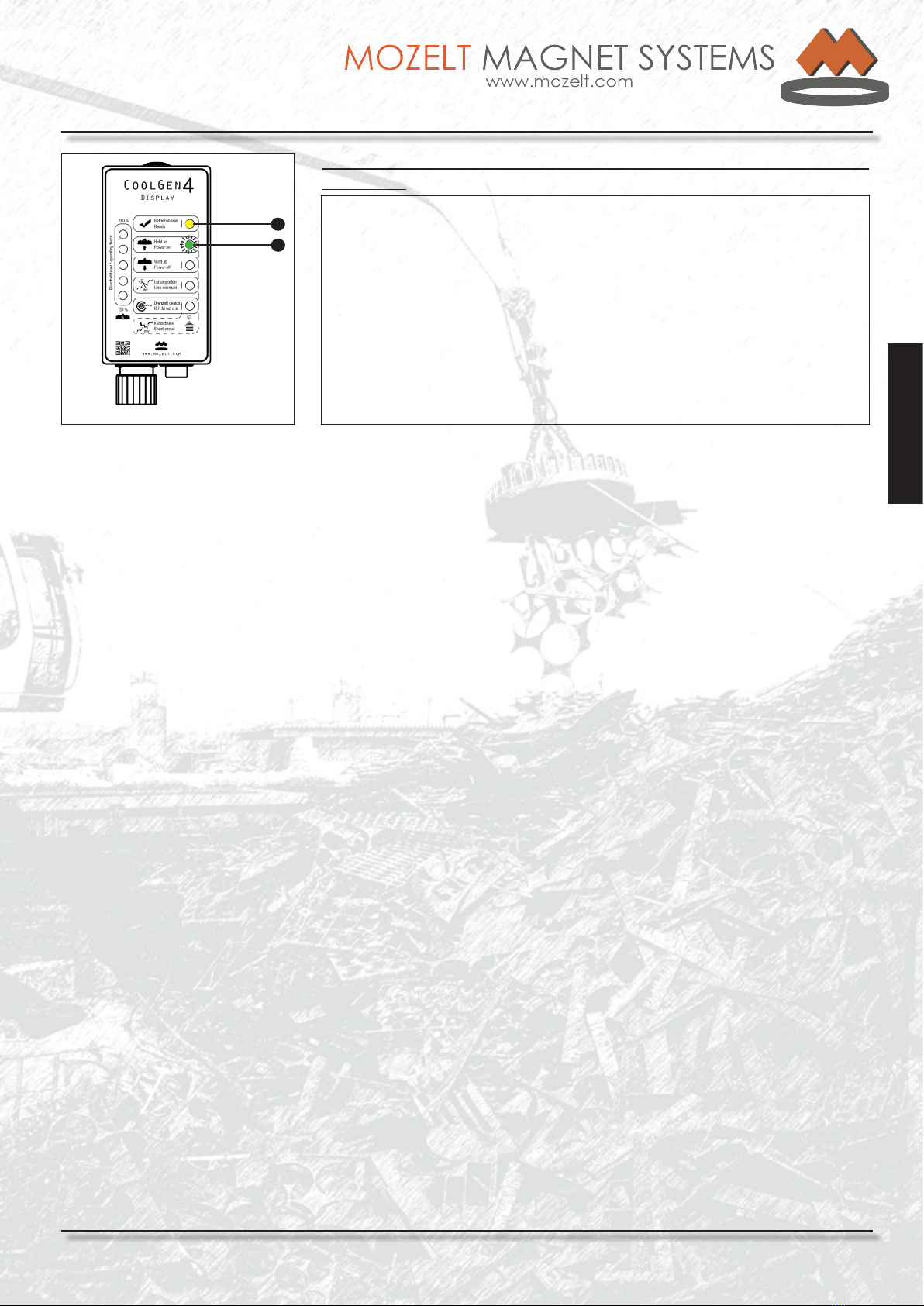

Fig.: 1 | General view CG4 Display

The dierent operang condions of the generator are

indicated in the funcon display (MFD) via LEDs.

An addional 6 LEDs indicate the working loading

ulizaon of the magnet (On/O rao) within the range

50…100%.

The release switch to turn the magnet on/o is also

aached to this display unit.

6

7

9

8

The most important operang states can be immediately

read o:

15Funcon and fault indicaon

6Relave duty factor of the magnec disks in %

Cover USB connecon (servicing purposes)7

Screw terminal for switch line / pushbuon

8

Connecon for control line

9

* guaranteed performance data at 100 % duty factor

** in the range of 2350 rpm to 2700 rpm, limited operaon at

reduced output voltage is possible.

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 8

English

2.3 Generator Drives

Depending on the type of mobile excavator, the power generator is mechanically or hydraulically driven.

Both variants are designed so that the necessary operang speed of the power generator is ensured as soon as the

diesel engine has reached its full speed.

2.3.1 Belt Drives

To ensure that the belt runs straight both axes must be ush with each other. The sha axes shall be parallel with the

axis of the generator.

It is recommended to use a Laser alignment device for aligning the belt pulleys.

For adjustment of the pretension, we recommend the use of belt measuring devices. During and aer installaon, the

belt is to be revolved several mes. This causes uniform seling of the pulley.

The rst check of the run-in belt pulley is carried out aer 0.5 to 4 hours.

The belt tension should be checked every 6 to 12 months and, if necessary, corrected.

2.3.2 Hydraulic Drives

Hydraulic generator drives are always to be supplied with a priority ow of hydraulic oil.

This means the supply ow should not be adversely aected by motor uctuaons, liing, travelling or other

movements. Depending on the manufacturer of the construcon machine, this is implemented in various technical

designs. Please ask the respecve manufacturer for informaon on this maer or contact us for the alternave

soluon of the „HydraBrain“ system.

With some hydraulic drives, opmum operaon is also possible at low speed of the diesel engine. For this, please

check the manual of the mobile excavator manufacturer.

Never reach into the running belt

drive!

WARNING

Never operate the power generator

without belt guard!

WARNING

Fig.: 2 | Belt drive

Fig.: 3 | Hydraulic drive with „BELL CLUTCH“ coupling

For hydraulic motor drives, speed peaks up to 4000 rpm are allowed at the moment of shutdown

of the magnet, if they do not last longer than 0.5 seconds. At speeds above 3400 rpm and below

2700 rpm, magnet operaon is not, or only to a limited extent, possible.

CAUTION

CAUTION

It is parcularly important that the speed

remains constant and does not show any

uctuaons!

CAUTION

Speeds above 3400 rpm can destroy the

power generator!

CAUTION

The speed should be measured not only

during no-load operaon, but also during

the starng and shutdown phase!

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 9

English

English

3. Assembling

3.1 Assembling instrucons

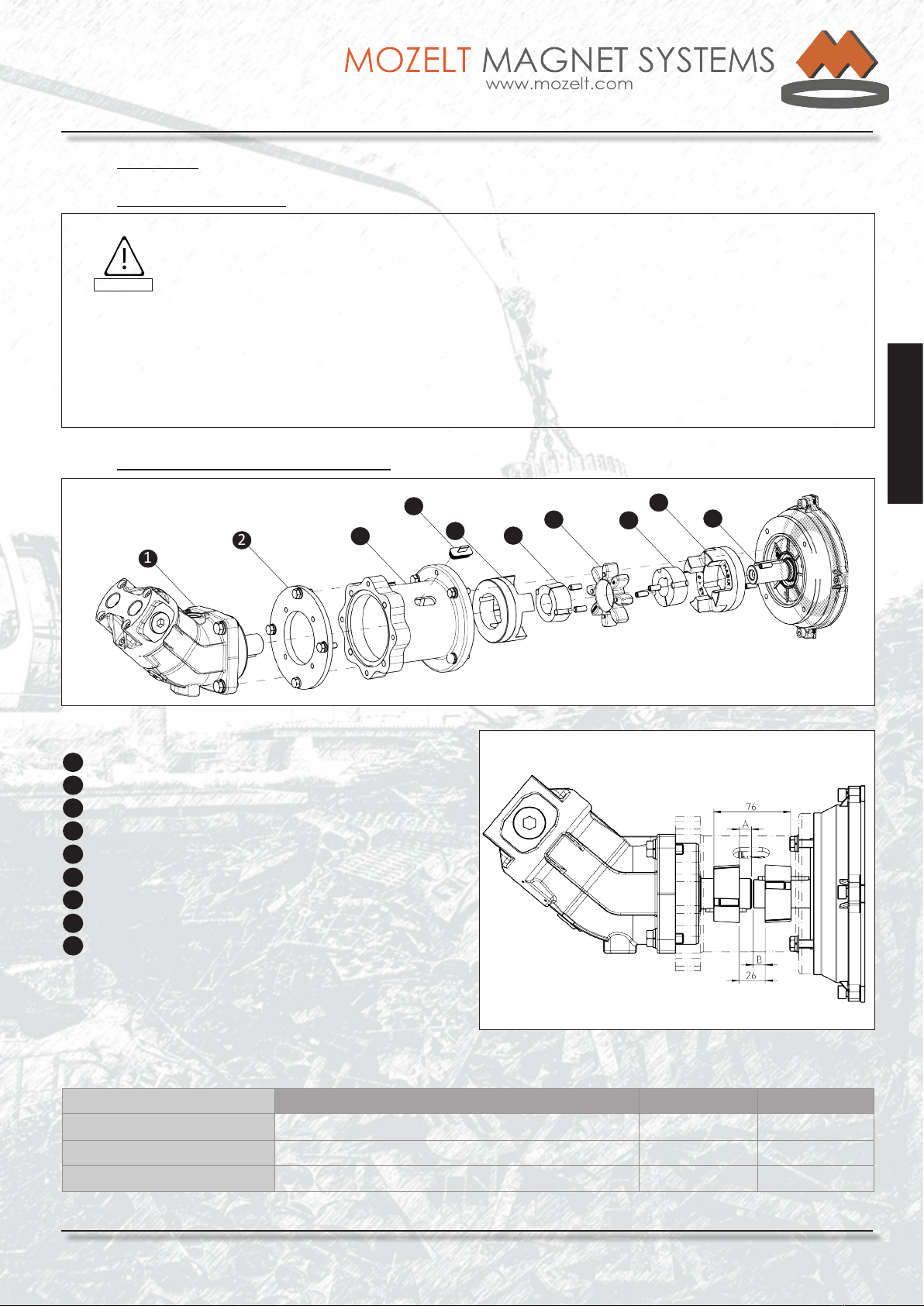

3.2 Installaon of „BELL CLUTCH“ Coupling

Table of distances coupling halves

1

2356

78

5

8

4

Generator type Hydraulic motor Distance A Distance B

T4002 / CG4 13 kW Bosch-Rexroth 16 ccm / Sunfab 17 ccm 0 mm 0 mm

T4002 / CG4 13 kW Bosch-Rexroth 23 ccm / Sunfab 25 ccm 12 mm 12 mm

T4002 / CG4 20 kW Bosch-Rexroth 23 ccm / Sunfab 25 ccm 11 mm 0 mm

1

2

3

4

Hydraulic motor

Adaptor ring for 16/17 ccm hydraulic motors

Clutch bell

Cover for speed measurement

6

7

8

9

Clamping bushing on the hydraulic motor

Coupling spider

Clamping bushing on the power generator

Sha / end shield on the power generator

5Coupling half

Fig.: 4 | Explosion drawing „BELL CLUTCH“ coupling

Fig.: 5 | Distance drawing coupling halves

1

CAUTION

The environmental atmosphere must be free of aggressive dust, corrosive vapours, gases and

liquids. The generator is to be protected against moisture according to IP 55.

Synchronous generators with integrated electronics may not be operated in areas classied as

dangerous, unless they are installed and cered in an approved housing.

The generators are designed for foot assembly

Make sure that the heat produced by the generator can be dissipated. The venlator screen must always be kept

free, in order to ensure an adequate supply of fresh air. All heat sources must be considered when determining

the ambient temperature, so that the temperature does not rise above the permissible maximum value for the

generator.

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 10

English

3.3 EMC Notes Electromagnec Compability

As all electrical equipment, synchronous generators with integral electronics can emit electromagnec energy and

be inuenced by it.

Electromagnec compability requires on the one hand that equipment is insuscepble to interference as regards

electromagnec radiaon, i.e. that they cannot be inuenced, and on the other hand does not exceed a certain

level of interference radiaon, and as a consequence does not interfere with other equipment.

These levels depend on the environment in which the equipment is operated. Here a disncon is made between

industrial and residenal environments including business and commercial as well as light-industrial environments.

This chapter is to serve as a guideline for installaon of the drives to avoid EMC problems and realize an EMC-

compliant wiring in accordance with the EMC Direcve.

3.3.1 Interference Immunity

CG4 ... are extremely suscepble to interference as regards electromagnec radiaon.

Interference immunity is achieved for the equipment without addional aids. In addion, all inducon components,

such as relay and contactor coils, electromagnec brakes, etc. are to be interference-suppressed using suitable

components (e.g. RC elements).

3.3.2 Interference Radiation

To avoid unallowable interference radiaon it is absolutely necessary to observe the given wiring instrucons.

Non-line-related interference radiaon is directly emied by the integrated electronics and wiring within a

frequency range of 30 MHz to 1 GHz. It is mainly generated by the fast logic circuits and has very low energy.

Problems with other electronic equipment due to this are not be expected.

Line-related interference radiaon in the frequency range of 150 kHz to 30 MHz is mainly caused by switching of

the power semiconductors. Because of the independent network, no problems with other equipment will occur.

3.4 Magnet Connecon

The electrical line connecons and plug-in connecon (plug / coupling) are matched to the corresponding output of

the power generators. In the process, the highest requirements are made on funconality and safety.

Please only use original MOZELT spare parts as required.

3.5 LED Funcons

Fig.: 6 | LED funcons on the control card

Various operang states are in addion indicated on the control card

of the power generator via LED. The following operang states can be

read o via the LED:

1Ext. pushbuon input LED Status external pushbuon input via terminal block

2

3

4

5

Signal output LED Selecon signal output

Status LED Status „On“

Supply voltage LED Internal electronics supply voltage available

Fault LED LED signals a fault

6Stand-by LED Stand-by LED

2 4 6

35

1

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 11

English

English

3.6 Control cable

Cable for control signals must be shielded. The cable shield must be connected to the connector shell.

The signal ground must not be grounded.

If necessary, please use only original spare parts.

3.7 Terminal Box

Before isolaon of power generator and electronics, the following warning should be observed:

The discharge me begins aer nal shutdown of the power generator!

Fig.: 8 | Connecon control line on the power generator

5

1Magnet connecon 230 V DC

2

3

4

5

Protecve earth conductor connecon

Terminal block

USB connecon

Screw terminal control line

Fig.: 7 | Terminal box

Steuerelektronik

1

4

2

3

5

6

6Control card

WARNING

In the electronics, there are intermediate circuit capacitors.

Their discharge may take longer than 10 minutes!

Before start of work, verify isolaon from power supply!

If this is not observed, serious personal injuries with fatal result, severe

injuries to health or considerable damage to property cannot be ruled out!

Fig.: 9 | Terminal block

3

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 12

English

3.8 Terminal Block

Wiring of the hydraulic and temperature sensor terminals is always arranged in the same way. Due to the various

switch wirings there are the following possibilies:

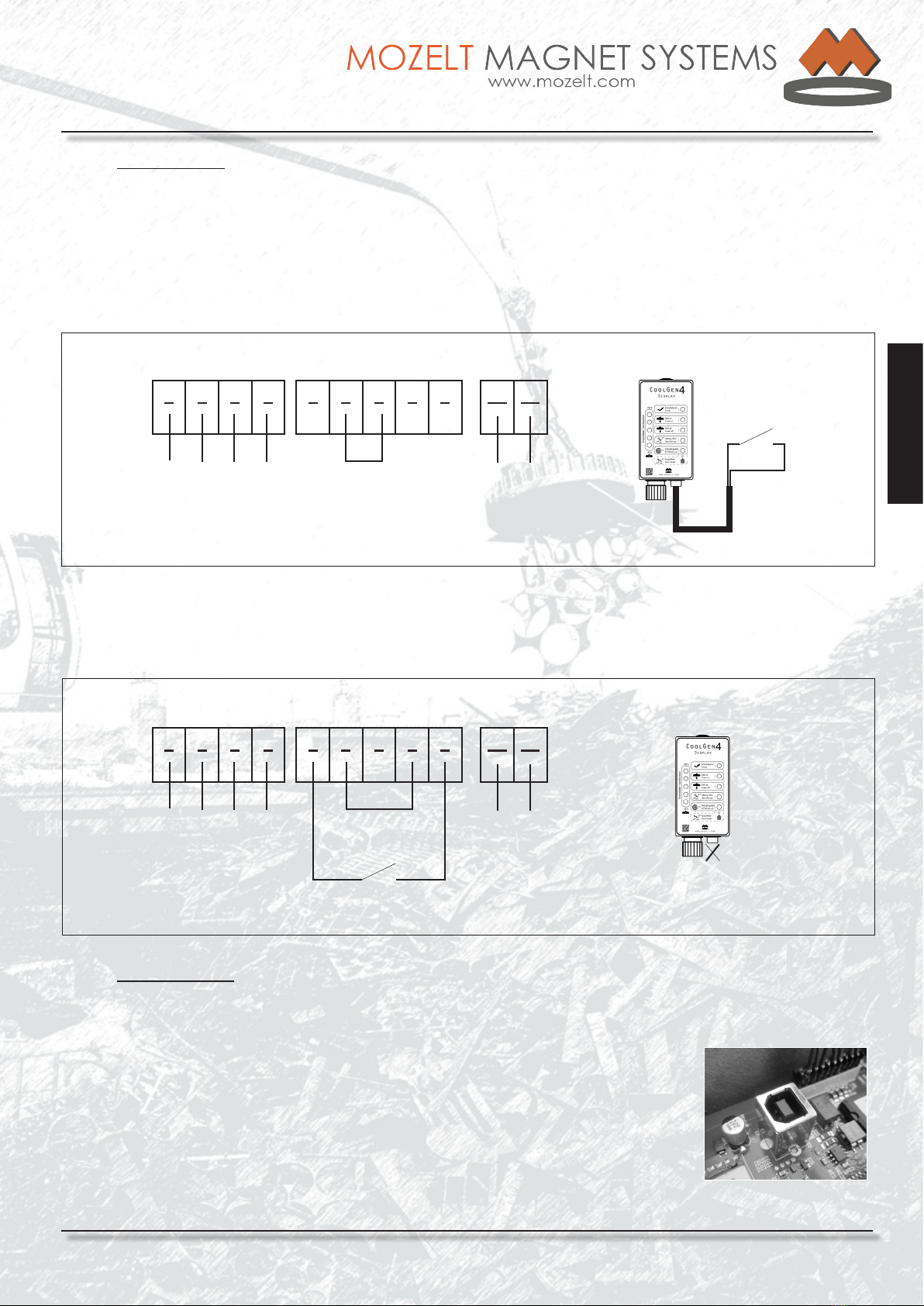

3.8.1 Start command via switch line on the MFD display

During run-up of the power generator, the electronics detects a signal at terminal 7.

Thus, the display pushbuon on the MFD is acvated and the pushbuon input at terminals 5 & 9 is deacvated.

3.8.2 Start Command via Terminal Block

During run-up of the power generator, the electronics detects the missing signal at terminal 7.

Thus, the display pushbuon is deacvated and the pushbuon input on terminals 5 & 9 acvated.

12 3 4 5678910 11

Hydraulic control

HydraBrain

Pushbuon wiring Temperature sensor

generator

Bridge Internal

Temperature

sensor

MFD Display

Keying signal

Keying signal

on the display

deacvated

3.9 USB Connecon

On the control card and MFD, there is an USB port. Both USB connecons are idencal and allow the following

funcons via the DriveSo service soware (see Annex DriveSo):

• Changing of the output voltage

• Changing of the ramps of the liing and detachment behaviour of the magnet

• Adjustments for sorng operaon

• Fault analysis

• Operang states (speed, temperature, operang hours, output voltage, etc.)

• Oscilloscope funcon

• Firmware updates

12 3 4 5678910 11

Hydraulic control

HydraBrain

Pushbuon wiring Temperature sensor

generator

See Annex

„HydraBrain“ Unit

Bridge Internal

Temperature

sensor

MFD Display

Switch line

Keying signal

Fig.: 10 | Terminal allocaon on the terminal block (pushbuon on MFD acvated)

Fig.: 11 | Terminal allocaon on terminal block (pushbuon on terminal block acvated)

Fig.: 12 | USB connecon on

the control card

See Annex

„HydraBrain“ Unit

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 13

English

English

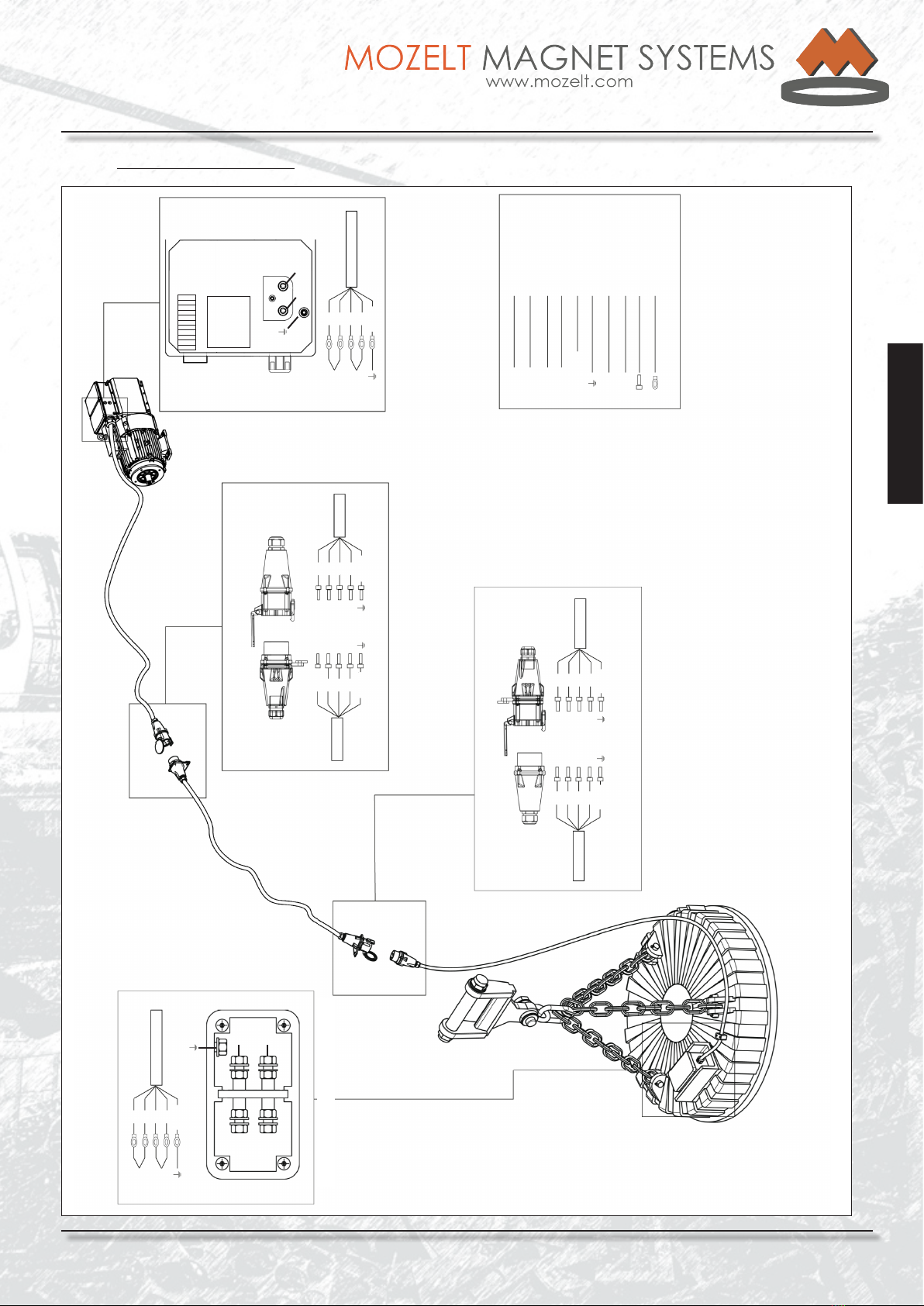

BK

GY

BN

BU

GNYE

1

2

3

4

GNYE

BK

BN

GY

BU

GNYE

BK

GY

BN

BU

GNYE

1

2

3

N

1

2

3

N

BK

BN

GY

BU

GNYE

BK

BN

GY

BU

GNYE

1

2

3

N

1

2

3

N

P1

P2

P1

P2

BK

BN

GY

BU

GNYE

P1

P2

Black

Brown

Grey

Blue

Green - Yellow

Protecve earth cond.

Pole 1

Pole 2

Adherent sleeves

Ring cable lugs

Legend

Plug-in connecon on the strut

Magnet connecon line | beam line

Oponal addional plug-in connecon on the beam Terminal box on the generator

Terminal box at the magnet

P1 P2

P1

P2

Fig.: 13 | Cable allocaon magnet system wiring system 230 V

3.10 Cable Allocaon 230 Volt

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 14

English

3.11 Dimensional Drawings Power Generator

Fig.: 14 | Power generator CG4 30 kW

Zahnwelle: W 30x2x30x14x9g DIN 5480

Spline Shaft: W 30x2x30x14x9g DIN 5480

Fig.: 15 | Power generator CG4 20 kW

Fig.: 16 | Power generator CG4 13 kW

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 15

English

English

4. Commissioning

The generator‘s internal electronic unit has been completely balanced at the works and does not require any

further adjustments and checks. Only the „MFD“ display is to be connected with the generator system via a 9-pole

cable, double-ended plug connecon.

To this display unit the release pushbuon is connected via the 3-pole plug. The magnet is connected via two

clamping bolts. Operaon is possible in both direcons of rotaon without rewiring.

4.1 Safety Notes

It is required that the user has familiarized himself with the operang instrucons before commissioning of the

power generator.

It is absolutely necessary to observe the following warning notes:

WARNING

During operaon of this power generator, dangerous voltage may occur which can cause death

or severe bodily injuries! Utmost care is advised during work on the power generator.

WARNING

• Only qualied maintenance and repair personnel are permied to examine and repair

the unit or parts of it.

• Never leave open or open terminal connecon spaces, covers and 230-volt plug-and-

socket devices on the power generator and magnet with the drive motor in operaon!

• Stand on an isolang mat (suitable for electrostacally sensive devices) and make

sure that this mat is not earthed before performing commissioning work on

the switch-on unit.

WARNING

Before start of work, verify isolaon from power supply. Make sure that no voltage is applied to

the magnet connecon. If this note is not observed, severe or even fatal bodily injuries may be

caused!

WARNING

• When working on the connected machine or supply leads to the machine, the power

generator should be shut down and locked out in O posion.

• According to VDE 1060, safety isolaon by locking the release pushbuon is not allowed.

• A safety isolaon blocks the power modules in the case of faults. However, with this

funcon it cannot be ensured that there is no residual voltage at the output terminals

and inside the power generator. Aer opening of the power generator, the

remaining residual voltage should be measured at the usually live parts. Before touching

electrical contacts make sure that no voltage is applied to voltage-carrying parts.

• Do not use any measuring equipment of which you know that it is in damaged or

defecve condion.

WARNING

Important!

In case of fault, modules potenal-free during operaon may carry voltage. Before start of work

on the equipment, make sure by measurement aer safety isolaon that the equipment is

deenergized. If this note is not observed severe or even fatal injuries may be caused.

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 16

English

The V-belt tension with belt drives is to be examined and,

if necessary, the belts are to be reghtened according to

regulaon.

Unless otherwise expressly stated, the diesel engine

of the mobile excavator is to be brought up to full

revoluons. The generator then runs within its operang

range. The yellow LED „Ready“ automacally appears on

the mul-funcon display MFD in the operator‘s cab.

Switching the power supply and/or the load liing

magnet on and o is usually accomplished with a switch

located in the handle. Depending on the type of device,

this must be energized with a separate switch in the

control console of the mobile excavator. For this purpose

also see the notes in the manual for the mobile excavator.

If the switching-on command is given, then the generator

CG 4 connects the voltage contactless through to the load

liing magnet. If the command is given to switch o, then

the generator automacally leads to its demagnezaon.

During the process of demagnezing, whereby the

magnet releases its load (approx. 1 sec), no renewed

switching-on command can be given.

Switching-on of the installaon is only possible, if a load

liing magnet is aached to the system.

Switching on the magnet:

Operate the buon in the control lever 1 x.

In addion to the yellow LED „Ready“, the green LED

„Power on“ lights up in the mul-funcon display.

Switching o the magnet:

Operate the same buon in the control lever again only

1 x. The already illuminated green LED „Power on“ now

goes out and a red LED with „Power o“ lights up.

Aer the load has been dropped, this goes out

automacally. The permanently illuminated LED „Ready“

during the shiing processes indicates that a renewed

procedure is now possible and that the power can be

switched on. Breakdowns are indicated by illuminated

red LEDs.

The meaning and eliminaon of such disturbances are

explained using gurave illustraons and texts under -

Breakdown indicators on the MFD -.

Make sure that ...

• the person supervising the trial run is qualied

and competent to carry out, and supervise,

the mechanical and electrical installaon.

• the nominal values of the power generator

correspond to the operang condions.

• the power generator is securely xed.

• the power generator is adequately venlated.

Safety measures shall be properly adhered to!

4.2 Operang instrucons

When working with the load liing magnet, the pernent

industrial safety and accident prevenon regulaons are

to be observed.

In addion, liing magnet operaon may only be started,

if the operator knows the „Safety Regulaons Magnet

Operaon“ (see Table of Contents).

Before start-up of the power supply CG 4, the operator

should ensure that the 230V cable system is in an

opcally perfect condion. Plugs and plug connectors are

to be examined for ghtness of t, the anchoring device

of the magnet connecng cable is to be examined for

perfect funcon.

WARNING

Before start-up, subject the complete

system to a visual inspecon!

WARNING

Before start-up, check correct seang

of the V-belts!

WARNING

Connect only liing magnets to the

system! For other electrical consumers,

operaon is not allowed!

WARNING

Before start of all work on the enre

system, shut down the drive motor!

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 17

English

English

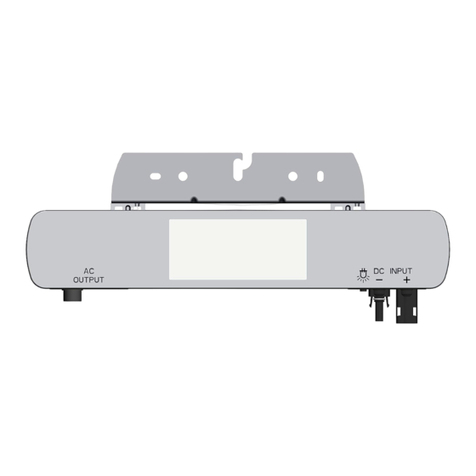

4.3 Operaonal indicators MFD

Indicaon: - LED 1 (yellow), „Ready“

Note: Generator is waing for switching-on command.

1

Generator running in the working range

Fig.: 17 | MFD signals Ready for operaon

Indicaon: - LED 1 (yellow), „Ready“

- LED 2 (green), „Power on“

Note: Magnet liing material.

1

Aer switching-on command given via operang switch, the magnet lis

Fig.: 18 | MFD signals an acvated magnet

2

Indicaon: - LED 1 (yellow), „Ready“

- LED 3 (red), „Power o“

Note: Magnet releases the material.

1

Aer switching-o command given via operang switch, magnet releases

load

Fig.: 19 | MFD signals throwing-o of

the material

3

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 18

English

Indicaon: - LED 1 (yellow) „Ready“,

- LED 2 (green, ashing) „Power on“.

Note: - Magnet lis material. The power generator operates in the

sorng mode .

1

Aer the start command has been given via the operang pushbuon, the

magnet lis

Fig.: 20 | MFD signals an acvated

magnet in the sorng mode

2

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 19

English

English

4.4 Fault indicators MFD

Faults are oen indicated by red LED.

Indicaon: LED 1 (yellow), „Ready“.

Possible cause : - Interrupon in switch cable

- Operang switch defecve

- Control cable defecve

Aer switching-on command given via operang switch, no funcon

1

Fig.: 21 | Starng command does not respond

Aer giving the start command via the operang pushbuon, „line interrupt“

is displayed

4

Fig.: 22 | MFD signals „Line interrupt“

Indicaon: LED 4 (red), „Line interrupt“.

Possible cause: - Line interrupon in the 230V circuit

- Magnet not, or incorrectly, connected

- Magnet, line or plug-and-socket device defecve

Note: The power generator is to be immediately shut

down unl the fault has been corrected.

The fault indicaon can only be cancelled by

shutdown of the power generator.

Aer giving the shutdown command via the operang pushbuon LEDs 1 to 5

are ashing

Fig.: 23 | MFD signals short circuit

Indicaon: LED 1 -5 (ashing).

Possible cause: - Short circuit in the 230V wiring system

- Full earth fault of the magnet

- Magnet too much power for the power supply

Note: The power generator is to be immediately shut

down unl the fault has been corrected.

The fault indicaon can only be cancelled by

shutdown of the power generator

1

2

3

4

5

MOZELT GmbH & Co. KG

Load liing magnet devices

Technical manual: CoolGen 4

Copyright: MOZELT GmbH & Co. KG, D-47269 Duisburg Edition: August 2014 Rev.: 00

Page 20

English

No LED indicator recognizable, possibly also

all LED lights up.

- Cable damage / power breakdown in the

control cable.

Generator runs within its working range, however, no funcon is

recognizable or all LED light up

Fig.: 24 | MFD has no funcon / all LED

light up

Indicaon:

Possible cause:

LED 1 (yellow), „Ready“,

LED 5 (red, ashing), „R.P.M not o.k.“.

The display „R.P.M not o.k.“ ashes and the indicaon „Ready“ is on

5

Fig.: 25 | MFD signals „R.P.M not o.k.“

Indicaon:

Possible cause: The power generator runs at overspeed.

Shut down motor immediately and have the

speed checked to prevent damage to the power

generator!

WARNING

The display „R.P.M not o.k.“ lights up

Fig.: 26 |MFD signals underspeed

Indicaon:

Possible cause:

Note:

only LED 5 (red), „R.P.M not o.k.“, possibly

also ashing.

The power generator runs at underspeed.

Have the speed checked!

LED 5 (steady light), speed of 1650 - 2000 rpm

LED 5 (ashing), speed of 2000 - 2350 rpm

5

1

Table of contents

Popular Inverter manuals by other brands

Mitsubishi Electric

Mitsubishi Electric FR-F820-00046 instruction manual

SolaX Power

SolaX Power X1 Series user manual

Mastervolt

Mastervolt Whisper 6 user manual

Orbio

Orbio 5000-Sc Operator's manual

AE Conversion

AE Conversion INV315-50EU Assembly and operating instructions

Generac Power Systems

Generac Power Systems Guardian 004188-1 owner's manual