Nexys A7 User manual

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 1/30

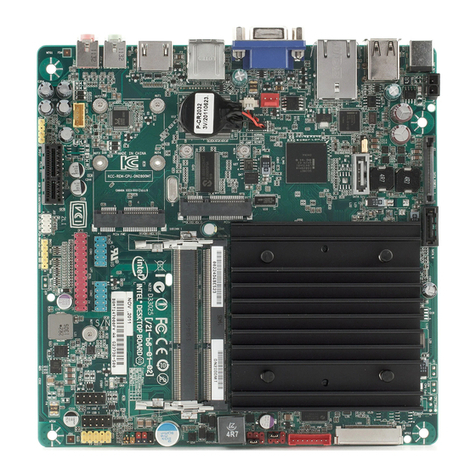

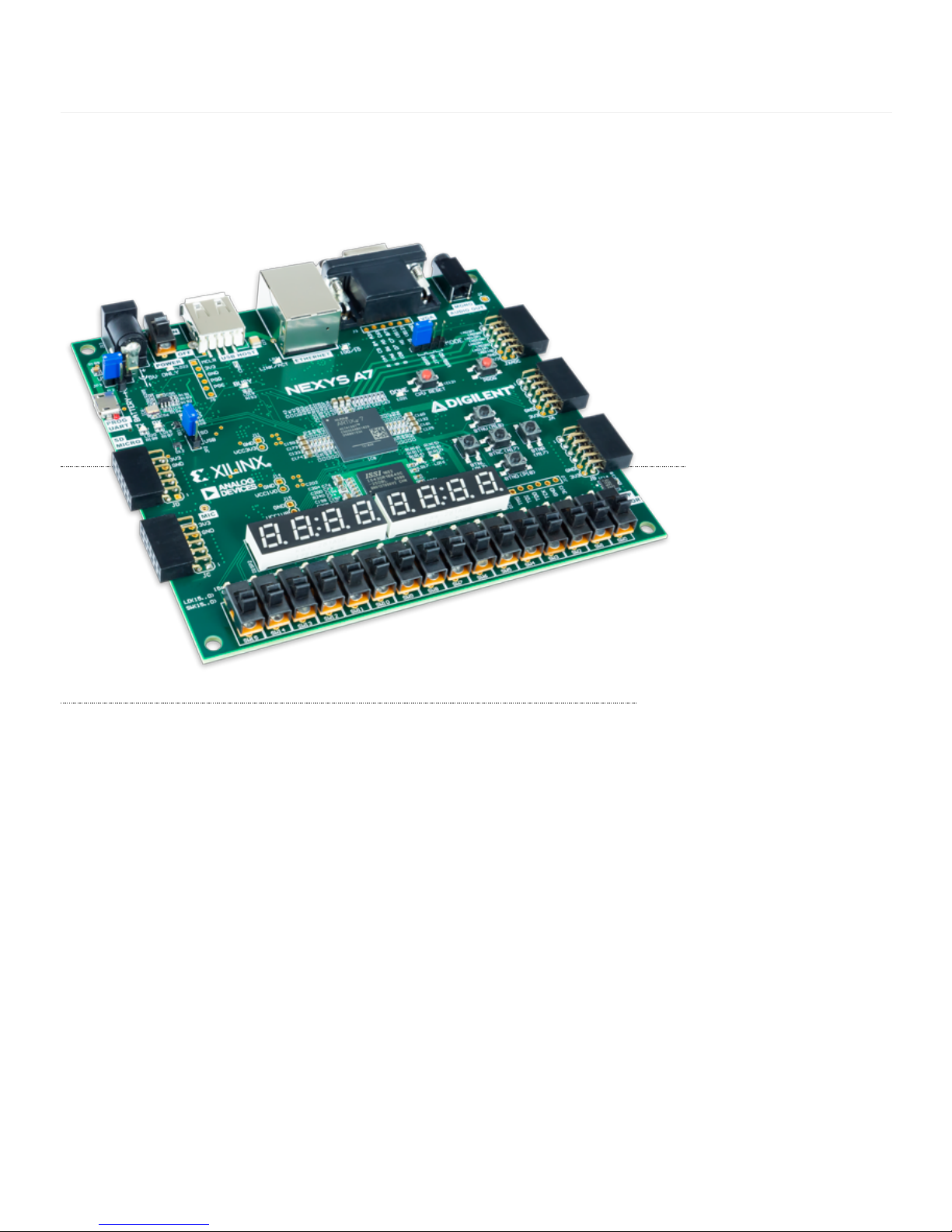

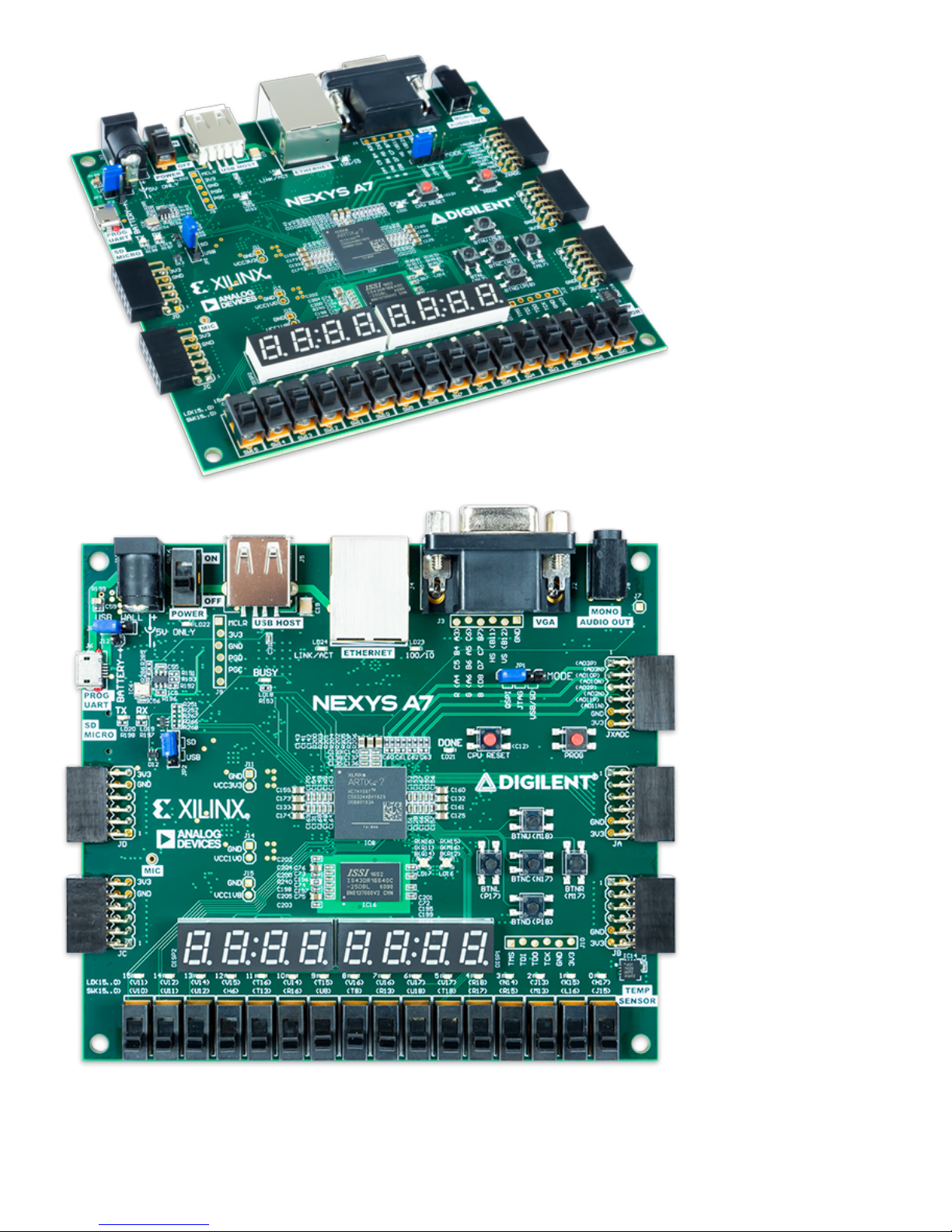

The Nexys A7 board is a complete, ready-to-use digital circuit development platform based on the latest Artix-7™ Field Programmable

Gate Array (FPGA) from Xilinx®. With its large, high-capacity FPGA, generous external memories, and collection of USB, Ethernet, and

other ports, the Nexys A7 can host designs ranging from introductory combinational circuits to powerful embedded processors. Several

built-in peripherals, including an accelerometer, temperature sensor, MEMs digital microphone, a speaker amplifier, and several I/O devices

allow the Nexys A7 to be used for a wide range of designs without needing any other components.

(https://reference.digilentinc.com/_media/reference/programmable-logic/nexys-a7/nexys-a7-obl-600.png)

Nexys A7 Reference Manual

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 2/30

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 3/30

Artix-7 FPGA

15,850 Programmable logic slices, each with four 6-input LUTs and 8 flip-flops (*8,150 slices)

Features

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 4/30

1,188 Kbits of fast block RAM () (*600 Kbits)

Six clock management tiles, each with phase-locked loop (PLL)

240 DSP slices (*120 DSPs)

Internal clock speeds exceeding 450 MHz ()

Dual-channel, 1 MSPS internal analog-digital converter (XADC)

Memory

128MiB DDR2

Serial Flash

microSD card slot

Power

Powered from USB or any 4.5V-5.5V external power source

USB and Ethernet

10/100 Ethernet PHY

USB-JTAG programming circuitry

USB-UART bridge

USB HID Host for mice, keyboards and memory sticks

Simple User Input/Output

16 Switches

16 LEDs

Two RGB LEDs

Two 4-digit 7-segment displays

Audio and Video

12-bit VGA output

PWM audio output

PDM microphone

Additional Sensors

3-axis accelerometer

Temperature sensor

Expansion Connectors

Pmod connector for XADC signals

Four Pmod connectors providing 32 total FPGA I/O

The Nexys A7 is compatible with Xilinx’s Vivado® Design Suite as well as the ISE® toolset, which includes ChipScope™ and EDK. Xilinx

offers free WebPACK™ versions of these toolsets, so designs can be implemented at no additional cost. The Nexys A7 is not supported by

the Digilent Adept Utility.

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 5/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/nexys-a7-callout.png?id=reference%3Aprogrammable-

logic%3Anexys-a7%3Areference-manual)

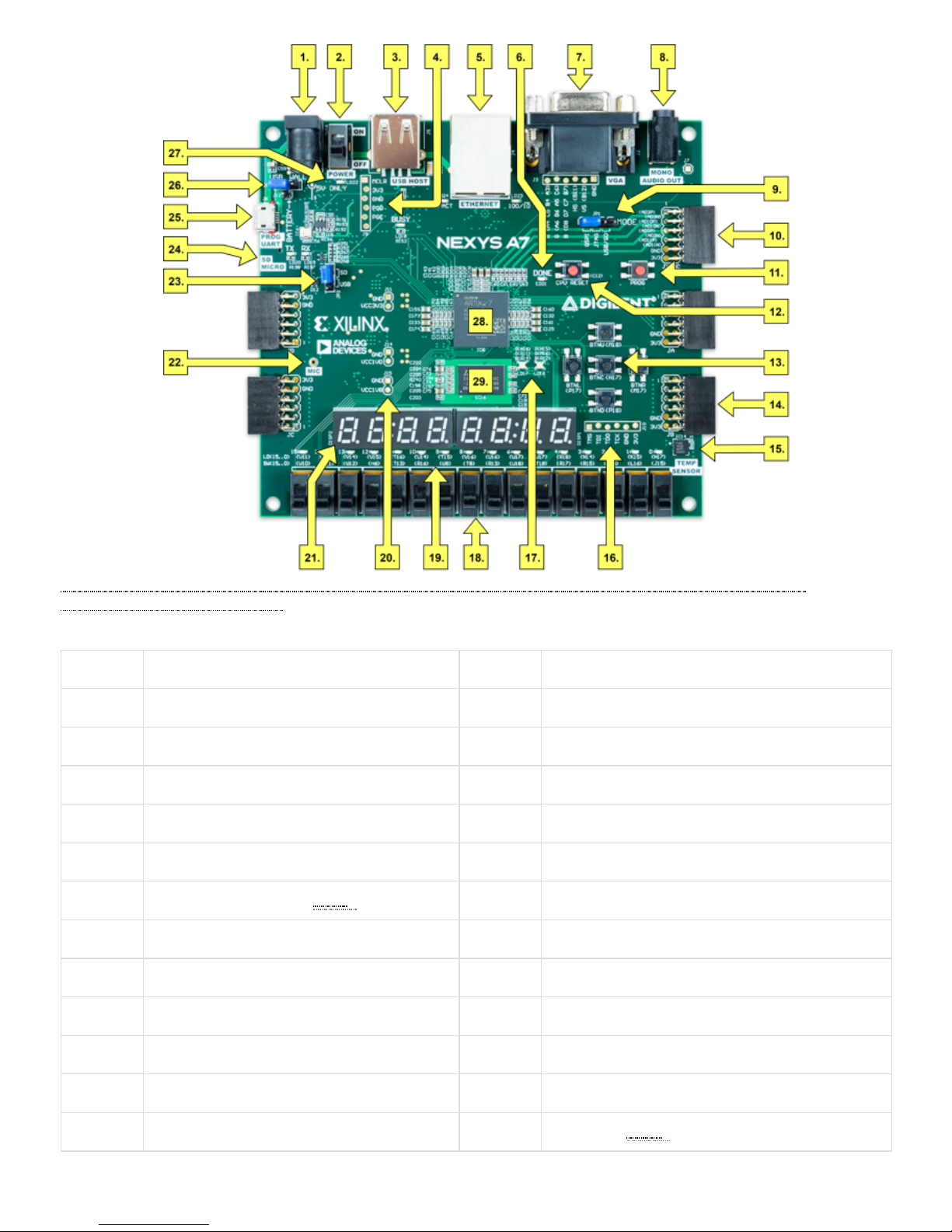

Figure 1. Nexys A7 Feature Callout

Callout Component Description Callout Component Description

1Power jack 16 JTAG port for (optional) external cable

2Power switch 17 Tri-color (RGB) LEDs

3USB host connector 18 Slide switches (16)

4PIC24 programming port (factory use) 19 LEDs (16)

5Ethernet connector 20 Power supply test point(s)

6FPGA programming done LED () 21 Eight digit 7-seg display

7VGA connector 22 Microphone

8Audio connector 23 External configuration jumper (SD / USB)

9Programming mode jumper 24 MicroSD card slot

10 Analog signal Pmod port (XADC) 25 Shared UART/ JTAG USB port

11 FPGA configuration reset button 26 Power select jumper and battery header

12 CPU reset button (for soft cores) 27 Power-good LED ()

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 6/30

13 Five pushbuttons 28 Xilinx Artix-7 FPGA

14 Pmod port(s) 29 DDR2 memory

15 Temperature sensor

The Nexys A7 can be purchased with either a XC7A100T or XC7A50T FPGA loaded. These two Nexys A7 product variants are referred to

as the Nexys A7-100T and Nexys A7-50T, respectively. When Digilent documentation describes functionality that is common to both of

these variants, they are referred to collectively as the “Nexys A7”. When describing something that is only common to a specific variant, the

variant will be explicitly called out by its name.

The only difference between the Nexys A7-100T and Nexys A7-50T is the size of the Artix-7 part. The Artix-7 FPGAs both have the same

capabilities, but the XC7100T has about a 2 times larger internal FPGA than the XC750T. The differences between the two variants are

summarized below:

Product Variant Nexys A7-100T Nexys A7-50T

FPGA Part Number XC7A100T-1CSG324C XC7A50T-1CSG324I

Look-up Tables (LUTs) 63,400 32,600

Flip-Flops 126,800 65,200

Block RAM () 1,188 Kb 600 Kb

DSP Slices 240 120

Clock Management Tiles 6 5

The Nexys A7 is a rebrand of the Nexys 4 DDR board, which is an incremental update to the Nexys 4 board.

The only difference between the Nexys A7 and Nexys 4 DDR is the addition of the Nexys A7-50T variant of the Nexys A7, which has a

smaller gate array. The Nexys A7-100T variant is functionally identical to the Nexys 4 DDR.

Users of the Nexys A7 may find resources produced for the Nexys 4 DDR helpful, which can be found at the Nexys 4 DDR's Resource

Center (https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/start).

The major improvement from the Nexys 4 to the Nexys 4 DDR is the replacement of the 16 MiB Cellular RAM () with a 128 MiB DDR2

SDRAM memory. Furthermore, to accommodate the new memory, the pin-out of the FPGA banks changed as well.

The audio output (AUD_PWM) needs to be driven open-drain as opposed to push-pull on the Nexys 4.

The Nexys A7 board can receive power from the Digilent USB-JTAG port (J6) or from an external power supply. Jumper JP3 (near the

power jack) determines which source is used.

Purchasing Options

Board Revisions

Migrating from Nexys 4 DDR

Migrating from Nexys 4

Functional Description

1 Power Supplies

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 7/30

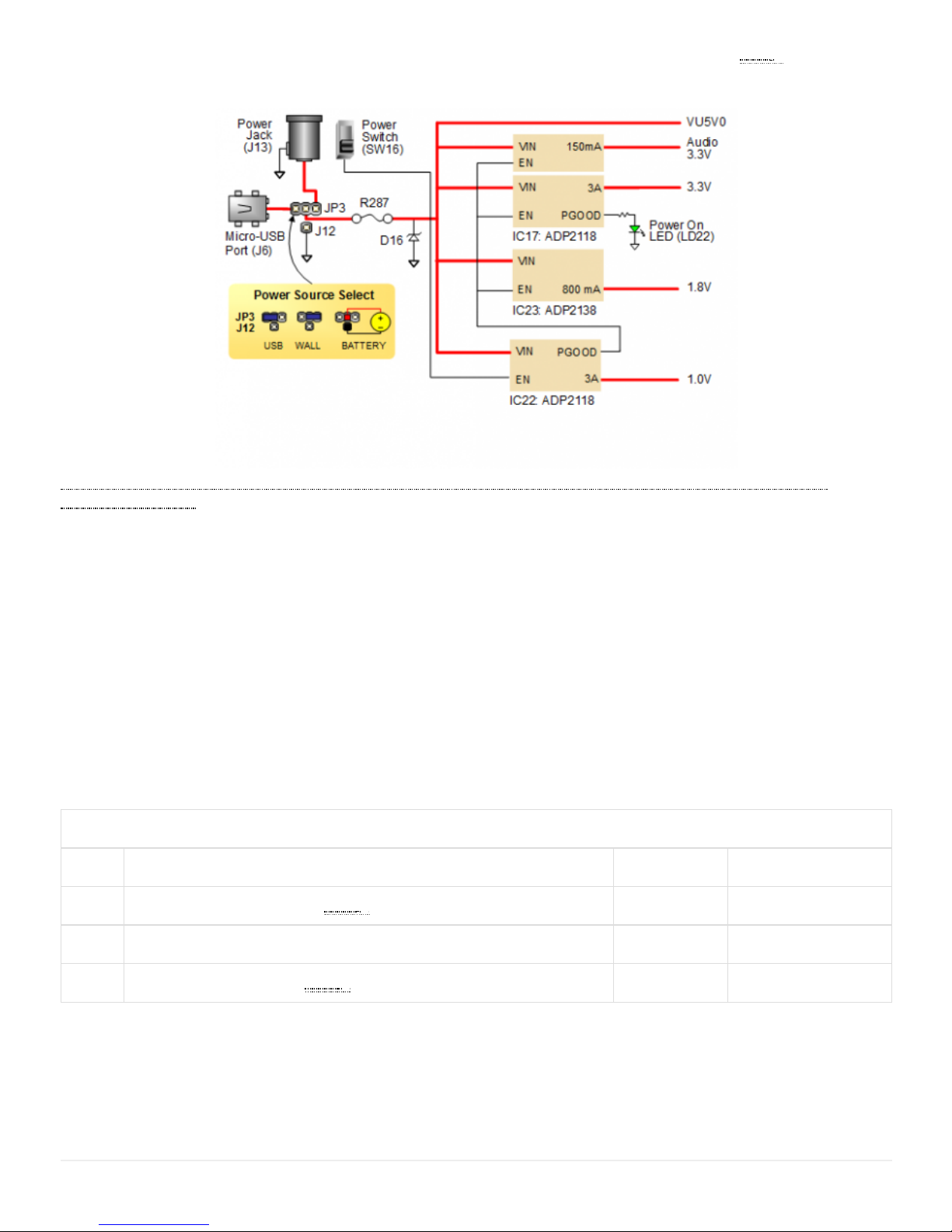

All Nexys A7 power supplies can be turned on and off by a single logic-level power switch (SW16). A power-good LED () (LD22), driven

by the “power good” output of the ADP2118 supply, indicates that the supplies are turned on and operating normally. An overview of the

Nexys A7 power circuit is shown in Figure 1.1.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4d.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 1.1 Nexys A7 Power Circuit

The USB port can deliver enough power for the vast majority of designs. Our out-of-box demo draws ~400mA of current from the 5V

input rail. A few demanding applications, including any that drive multiple peripheral boards, might require more power than the USB port

can provide. Also, some applications may need to run without being connected to a PC’s USB port. In these instances, an external power

supply or battery pack can be used.

An external power supply can be used by plugging into to the power jack (JP3) and setting jumper J13 to “wall”. The supply must use a

coax, center-positive 2.1mm internal-diameter plug, and deliver 4.5VDC to 5.5VDC and at least 1A of current (i.e., at least 5W of power).

Many suitable supplies can be purchased from Digilent, through Digi-Key, or other catalog vendors.

An external battery pack can be used by connecting the battery’s positive terminal to the center pin of JP3 and the negative terminal to the

pin labeled J12, directly below JP3. Since the main regulator on the Nexys A7 cannot accommodate input voltages over 5.5VDC, an external

battery pack must be limited to 5.5VDC. The minimum voltage of the battery pack depends on the application: if the USB Host function

(J5) is used, at least 4.6V needs to be provided. In other cases, the minimum voltage is 3.6V.

Voltage regulator circuits from Analog Devices create the required 3.3V, 1.8V, and 1.0V supplies from the main power input. Table 1.1

provides additional information. Typical currents depend strongly on FPGA configuration and the values provided are typical of medium

size/speed designs.

Table 1.1 Nexys A7 power supplies.

Supply Circuits Device Current (max/typical)

3.3V FPGA I/O, USB ports, Clocks, RAM () I/O, Ethernet, SD slot, Sensors, Flash IC17: ADP2118 3A/0.1 to 1.5A

1.0V FPGA Core IC22: ADP2118 3A/ 0.2 to 1.3A

1.8V DDR2, FPGA Auxiliary and RAM () IC23: ADP2118 0.8A/ 0.5A

The Nexys A7 features overcurrent and overvoltage protection on the input power rail. A 3.5A fuse (R287) and a 5V Zener diode (D16)

provide a non-resettable protection for other on-board integrated circuits, as displayed in Figure 2. Applying power outside of the specs

outlined in this document is not covered by warranty. If this happens, either or both might get permanently damaged. The damaged parts

are not user-replaceable.

1.1 Protection

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 8/30

After power-on, the Artix-7 FPGA must be configured (or programmed) before it can perform any functions. You can configure the FPGA

in one of four ways:

1. A PC can use the Digilent USB-JTAG circuitry (portJ6, labeled “PROG”) to program the FPGA any time the power is on.

2. A file stored in the nonvolatile serial (SPI) flash device can be transferred to the FPGA using the SPI port.

3. A programming file can be transferred to the FPGA from a micro SD card.

4. A programming file can be transferred from a USB memory stick attached to the USB HID port.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4e.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 2.1 Nexys A7 DDR Configuration Options

Figure 2.1 shows the different options available for configuring the FPGA. An on-board “mode” jumper (JP1) and a media selection jumper

(JP2) select between the programming modes.

The FPGA configuration data is stored in files called bitstreams that have the .bit file extension. The ISE or Vivado software from Xilinx

can create bitstreams from VHDL, Verilog®, or schematic-based source files (in the ISE toolset, EDK is used for MicroBlaze™ embedded

processor-based designs).

Bitstreams are stored in SRAM-based memory cells within the FPGA. This data defines the FPGA’s logic functions and circuit connections,

and it remains valid until it is erased by removing board power, by pressing the reset button attached to the PROG input, or by writing a

new configuration file using the JTAG port.

An Artix-7 100T bitstream is typically 30,606,304 bits and can take a long time to transfer. The time it takes to program the Nexys A7 can

be decreased by compressing the bitstream before programming, and then allowing the FPGA to decompress the bitstream itself during

configuration. Depending on design complexity, compression ratios of 10x can be achieved. Bitstream compression can be enabled within

the Xilinx tools (ISE or Vivado) to occur during generation. For instructions on how to do this, consult the Xilinx documentation for the

toolset being used. After being successfully programmed, the FPGA will cause the “DONE” LED () to illuminate. Pressing the “PROG”

button at any time will reset the configuration memory in the FPGA. After being reset, the FPGA will immediately attempt to reprogram

itself from whatever method has been selected by the programming mode jumpers.

The following sections provide greater detail about programming the Nexys A7 using the different methods available.

The Xilinx tools typically communicate with FPGAs using the Test Access Port and Boundary-Scan Architecture, commonly referred to as

JTAG. During JTAG programming, a .bit file is transferred from the PC to the FPGA using the onboard Digilent USB-JTAG circuitry (port

J6) or an external JTAG programmer, such as the Digilent JTAG-HS2, attached to port J10. You can perform JTAG programming any time

after the Nexys A7 has been powered on, regardless of what the mode jumper (JP1) is set to. If the FPGA is already configured, then the

existing configuration is overwritten with the bitstream being transmitted over JTAG. Setting the mode jumper to the JTAG setting (seen in

Figure 3) is useful to prevent the FPGA from being configured from any other bitstream source until a JTAG programming occurs.

Programming the Nexys A7 with an uncompressed bitstream using the on-board USB-JTAG circuitry usually takes around five seconds.

JTAG programming can be done using the hardware server in Vivado or the iMPACT tool included with ISE and the Lab Tools version of

Vivado. The demonstration project available at www.digilentinc.com (http://www.digilentinc.com) gives an in-depth tutorial on how to

program your board.

2 FPGA Configuration

2.1 JTAG Configuration

2.2 Quad-SPI Configuration

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 9/30

Since the FPGA on the Nexys A7 is volatile, it relies on the Quad-SPI flash memory to store the configuration between power cycles. This

configuration mode is called Master SPI. The blank FPGA takes the role of master and reads the configuration file out of the flash device

upon power-up. To that effect, a configuration file needs to be downloaded first to the flash. When programming a nonvolatile flash device,

a bitstream file is transferred to the flash in a two-step process. First, the FPGA is programmed with a circuit that can program flash

devices, and then data is transferred to the flash device via the FPGA circuit (this complexity is hidden from the user by the Xilinx tools).

This is called indirect programming. After the flash device has been programmed, it can automatically configure the FPGA at a subsequent

power-on or reset event as determined by the mode jumper setting (see Figure 3). Programming files stored in the flash device will remain

until they are overwritten, regardless of power-cycle events.

Programming the flash can take as long as four to five minutes, which is mostly due to the lengthy erase process inherent to the memory

technology. Once written however, FPGA configuration can be very fast—less than a second. Bitstream compression, SPI bus width, and

configuration rate are factors controlled by the Xilinx tools that can affect configuration speed. The Nexys A7 supports x1, x2, and x4 bus

widths and data rates of up to 50 MHz () for Quad-SPI programming.

Quad-SPI programming can be done using the iMPACT tool included with ISE or the Lab Tools version of Vivado.

You can program the FPGA from a pen drive attached to the USB Host port (J5) or a microSD card inserted into J1 by doing the following:

1. Format the storage device (Pen drive or microSD card) with a FAT32 file system.

2. Place a single .bit configuration file in the root directory of the storage device.

3. Attach the storage device to the Nexys A7.

4. Set the JP1 Programming Mode jumper on the Nexys A7 to “USB/SD”.

5. Select the desired storage device using JP2.

6. Push the PROG button or power-cycle the Nexys A7.

The FPGA will automatically configure with the .bit file on the selected storage device. Any .bit files that are not built for the proper Artix-7

device will be rejected by the FPGA.

The Auxiliary Function Status, or “BUSY” LED (), gives visual feedback on the state of the configuration process when the FPGA is not

yet programmed:

When steadily lit, the auxiliary microcontroller is either booting up or currently reading the configuration medium (microSD or pen

drive) and downloading a bitstream to the FPGA.

A slow pulse means the microcontroller is waiting for a configuration medium to be plugged in.

In case of an error during configuration, the LED () will blink rapidly.

When the FPGA has been successfully configured, the behavior of the LED () is application-specific. For example, if a USB keyboard is

plugged in, a rapid blink will signal the receipt of an HID input report from the keyboard.

The Nexys A7 board contains two external memories: a 1Gib (128MiB) DDR2 SDRAM and a 128Mib (16MiB) non-volatile serial Flash

device. The DDR2 modules are integrated on-board and connect to the FPGA using the industry standard interface. The serial Flash is on a

dedicated quad-mode (x4) SPI bus. The connections and pin assignments between the FPGA and external memories are shown below.

The Nexys A7 includes one Micron MT47H64M16HR-25:H DDR2 memory component, creating a single rank, 16-bit wide interface. It is

routed to a 1.8V-powered HR (High Range) FPGA bank with 50 ohm controlled single-ended trace impedance. 50 ohm internal

terminations in the FPGA are used to match the trace characteristics. Similarly, on the memory side, on-die terminations (ODT) are used for

impedance matching.

For proper operation of the memory, a memory controller and physical layer (PHY) interface needs to be included in the FPGA design.

There are two recommended ways to do that, which are outlined below and differ in complexity and design flexibility.

The straightforward way is to use the Digilent-provided DDR-to-SRAM adapter module which instantiates the memory controller and uses

an asynchronous SRAM bus for interfacing with user logic. This module provides backward compatibility with projects written for older

Nexys-line boards featuring a CellularRAM instead of DDR2. It trades memory bandwidth for simplicity.

More advanced users or those who wish to learn more about DDR SDRAM technology may want to use the Xilinx 7-series memory

interface solutions core generated by the MIG (Memory Interface Generator) Wizard. Depending on the tool used (ISE, EDK or Vivado),

the MIG Wizard can generate a native FIFO-style or an AXI4 interface to connect to user logic. This workflow allows the customization of

several DDR parameters optimized for the particular application. Table 3.1 below lists the MIG Wizard settings optimized for the Nexys

A7.

2.3 USB Host and Micro SD Programming

3 Memory

3.1 DDR2

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 10/30

Table 3.1.1 DDR2 settings for the Nexys A7.

Setting Value

Memory type DDR2 SDRAM

Max. clock period 3000ps (667Mbps data rate)

Recommended clock period (for easy clock generation) 3077ps (650Mbps data rate)

Memory part MT47H64M16HR-25E

Data width 16

Data mask Enabled

Chip Select pin Enabled

Rtt (nominal) – On-die termination 50ohms

Internal Vref Enabled

Internal termination impedance 50ohms

Although the FPGA, memory IC, and the board itself are capable of the maximum data rate of 667Mbps, the limitations in the clock

generation primitives restrict the clock frequencies that can be generated from the 100 MHz () system clock. Thus, for simplicity, the next

highest data rate of 650Mbps is recommended.

The MIG Wizard will require the fixed pin-out of the memory signals to be entered and validated before generating the IP core. For your

convenience, an importable UCF file is provided on the Digilent website to speed up the process.

For more details on the Xilinx memory interface solutions, refer to the 7 Series FPGAs Memory Interface Solutions User Guide (ug586)¹.

FPGA configuration files can be written to the Quad-SPI Flash (Spansion part number S25FL128S), and mode settings are available to

cause the FPGA to automatically read a configuration from this device at power on. An Artix-7 100T configuration file requires just less

than four MiB (mebibyte) of memory, leaving about 77% of the flash device available for user data. Or, if the FPGA is getting configured

from another source, the whole memory can be used for custom data.

The contents of the memory can be manipulated by issuing certain commands on the SPI bus. The implementation of this protocol is

outside the scope of this document. All signals in the SPI bus except SCK are general-purpose user I/O pins after FPGA configuration.

SCK is an exception because it remains a dedicated pin even after configuration. Access to this pin is provided through a special FPGA

primitive called STARTUPE2.

NOTE: Refer to the manufacturer’s data sheets² and Xilinx user guides³ for more information.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4f.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 3.2.1 Nexys A7 DDR SPI Flash Pin-out

3.2 Quad-SPI Flash

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 11/30

¹ Zynq-7000 SoC and 7 Series Devices Memory Interface Solutions from Xilinx

(http://www.xilinx.com/support/documentation/ip_documentation/mig_7series/v2_1/ug586_7Series_MIS.pdf)

² Spansion S25FL032P_00 Datasheet (https://www.spansion.com/Support/Datasheets/S25FL032P_00.pdf)

³ 7-Series FPGAs Configuration User Guide from Xilinx

(http://www.xilinx.com/support/documentation/user_guides/ug470_7Series_Config.pdf)

The Nexys A7 board includes an SMSC 10/100 Ethernet PHY (SMSC part number LAN8720A) paired with an RJ-45 Ethernet jack with

integrated magnetics. The SMSC PHY uses the RMII interface and supports 10/100 Mb/s. Figure 4.1 illustrates the pin connections

between the Artix-7 and the Ethernet PHY. At power-on reset, the PHY is set to the following defaults:

RMII mode interface

Auto-negotiation enabled, advertising all 10/100 mode capable

PHY address=00001

Two on-board LEDs (LD23 = LED2, LD24 = LED1) connected to the PHY provide link status and data activity feedback. See the PHY

datasheet for details.

EDK-based designs can access the PHY using either the axi_ethernetlite (AXI EthernetLite) IP core or the axi_ethernet (Tri Mode Ethernet

MAC) IP core. A mii_to_rmii core (Ethernet PHY MII to Reduced MII) needs to be inserted to convert the MAC interface from MII to

RMII. Also, a 50 MHz () clock needs to be generated for the mii_to_rmii core and the CLKIN pin of the external PHY. To account for

skew introduced by the mii_to_rmii core, generate each clock individually, with the external PHY clock having a 45 degree phase shift

relative to the mii_to_rmii Ref_Clk. An EDK demonstration project that properly uses the Ethernet PHY can be found on the Nexys A7

product page at www.digilentinc.com (http://www.digilentinc.com).

ISE designs can use the IP Core Generator wizard to create an Ethernet MAC controller IP core.

NOTE: Refer to the LAN8720A data sheet¹ for further information.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4g.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 4.1 Pin Connections between the Artix-7 and the Ethernet PHY

¹ SMSC LAN8720A Datasheet from Microchip (http://ww1.microchip.com/downloads/en/DeviceDoc/8720a.pdf)

The Nexys A7 board includes a single 100 MHz () crystal oscillator connected to pin E3 (E3 is a MRCC input on bank 35). The input clock

can drive MMCMs or PLLs to generate clocks of various frequencies and with known phase relationships that may be needed throughout a

design. Some rules restrict which MMCMs and PLLs may be driven by the 100 MHz () input clock. For a full description of these rules and

of the capabilities of the Artix-7 clocking resources, refer to the “7 Series FPGAs Clocking Resources User Guide” available from Xilinx.

4 Ethernet PHY

5 Oscillators/Clocks

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 12/30

Xilinx offers the Clocking Wizard IP core to help users generate the different clocks required for a specific design. This wizard will properly

instantiate the needed MMCMs and PLLs based on the desired frequencies and phase relationships specified by the user. The wizard will

then output an easy-to-use wrapper component around these clocking resources that can be inserted into the user’s design. The clocking

wizard can be accessed from within the Project Navigator or Core Generator tools.

The Nexys A7 includes an FTDI FT2232HQ USB-UART bridge (attached to connector J6) that allows you use PC applications to

communicate with the board using standard Windows COM port commands. Free USB-COM port drivers, available from

www.ftdichip.com (http://www.ftdichip.com) under the “Virtual Com Port” or VCP heading, convert USB packets to UART/serial port data.

Serial port data is exchanged with the FPGA using a two-wire serial port (TXD/RXD) and optional hardware flow control (RTS/CTS).

After the drivers are installed, I/O commands can be used from the PC directed to the COM port to produce serial data traffic on the C4

and D4 FPGA pins.

Two on-board status LEDs provide visual feedback on traffic flowing through the port: the transmit LED () (LD20) and the receive LED ()

(LD19). Signal names that imply direction are from the point-of-view of the DTE (Data Terminal Equipment), in this case the PC.

The FT2232HQ is also used as the controller for the Digilent USB-JTAG circuitry, but the USB-UART and USB-JTAG functions behave

entirely independent of one another. Programmers interested in using the UART functionality of the FT2232 within their design do not

need to worry about the JTAG circuitry interfering with the UART data transfers, and vice-versa. The combination of these two features

into a single device allows the Nexys A7 to be programmed, communicated with via UART, and powered from a computer attached with a

single Micro USB cable.

The connections between the FT2232HQ and the Artix-7 are shown in Figure 6.1.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4h.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 6.1 Nexys A7 FT2322HQ Connections

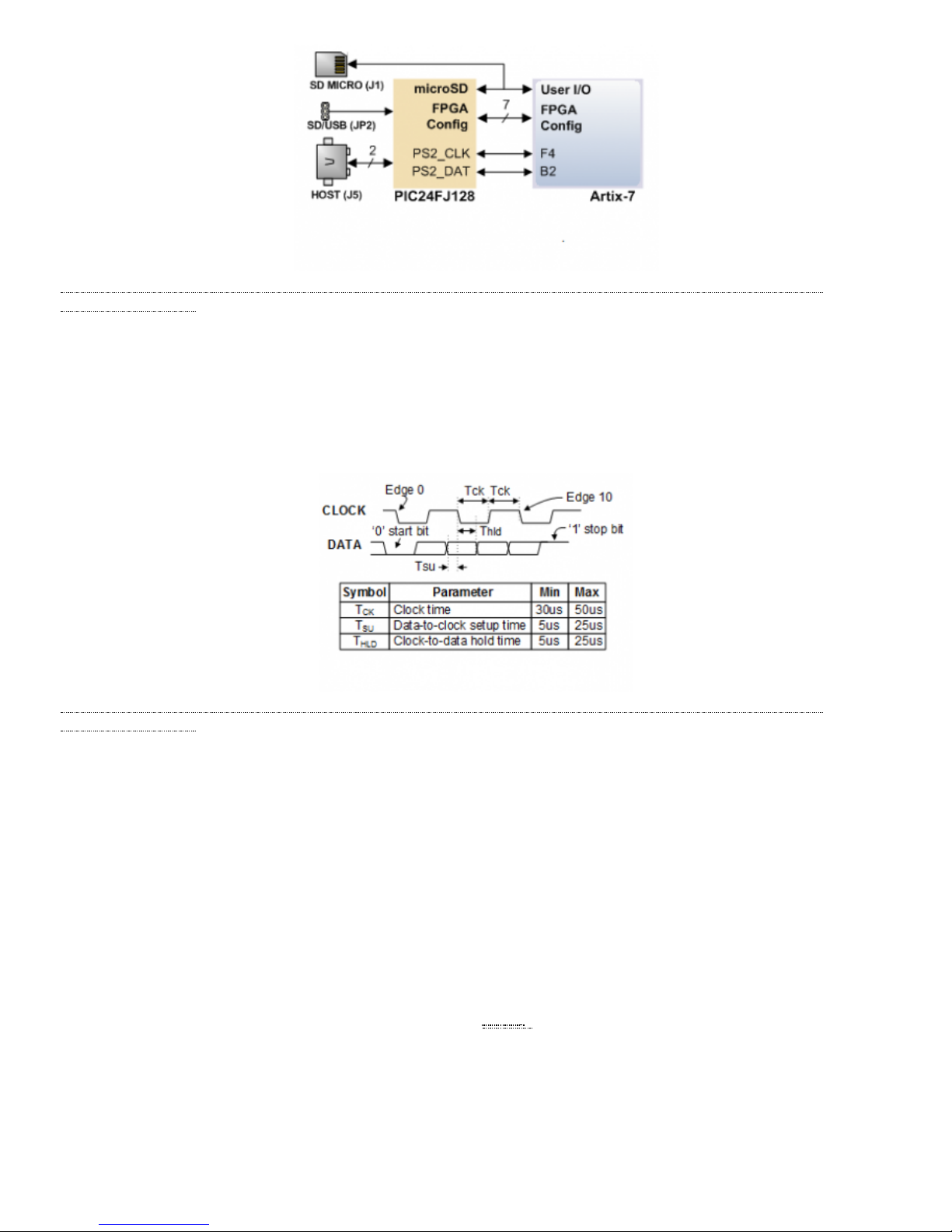

The Auxiliary Function microcontroller (Microchip PIC24FJ128) provides the Nexys A7 with USB Embedded HID host capability. After

power-up, the microcontroller is in configuration mode, either downloading a bitstream to the FPGA, or waiting to be programmed from

other sources. Once the FPGA is programmed, the microcontroller switches to application mode, which is USB HID Host in this case.

Firmware in the microcontroller can drive a mouse or a keyboard attached to the type A USB connector at J5 labeled “USB Host”. Hub

support is not currently available, so only a single mouse or a single keyboard can be used. Only keyboards and mice supporting the Boot

HID interface are supported. The PIC24 drives several signals into the FPGA – two are used to implement a standard PS/2 interface for

communication with a mouse or keyboard, and the others are connected to the FPGA’s two-wire serial programming port, so the FPGA

can be programmed from a file stored on a USB pen drive or microSD card.

6 USB-UART Bridge (Serial Port)

7 USB HID Host

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 13/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4i.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 7.1 Nexys A7 PIC24 Connections

The Auxiliary Function microcontroller hides the USB HID protocol from the FPGA and emulates an old-style PS/2 bus. The

microcontroller behaves just like a PS/2 keyboard or mouse would. This means new designs can re-use existing PS/2 IP cores. Mice and

keyboards that use the PS/2 protocol use a two-wire serial bus (clock and data) to communicate with a host. On the Nexys A7, the

microcontroller emulates a PS/2 device while the FPGA plays the role of the host. Both the mouse and the keyboard use 11-bit words that

include a start bit, data byte (LSB first), odd parity, and stop bit, but the data packets are organized differently, and the keyboard interface

allows bi-directional data transfers (so the host device can illuminate state LEDs on the keyboard). Bus timings are shown in Figure 7.1.1.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4j.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 7.1.1 PS/2 Device-to-Host Timing Diagram

The clock and data signals are only driven when data transfers occur; otherwise, they are held in the idle state at high-impedance (open-drain

drivers). This requires that when the PS/2 signals are used in a design, internal pull-ups must be enabled in the FPGA on the data and clock

pins. The clock signal is normally driven by the device, but may be held low by the host in special cases. The timings define signal

requirements for mouse-to-host communications and bi-directional keyboard communications. A PS/2 interface circuit can be implemented

in the FPGA to create a keyboard or mouse interface.

When a keyboard or mouse is connected to the Nexys A7, a “self-test passed” command (0xAA) is sent to the host. After this, commands

may be issued to the device. Since both the keyboard and the mouse use the same PS/2 port, one can tell the type of device connected using

the device ID. This ID can be read by issuing a Read ID command (0xF2). Also, a mouse sends its ID (0x00) right after the “self-test

passed” command, which distinguishes it from a keyboard.

PS/2-style keyboards use scan codes to communicate key press data. Each key is assigned a code that is sent whenever the key is pressed. If

the key is held down, the scan code will be sent repeatedly about once every 100ms. When a key is released, an F0 key-up code is sent,

followed by the scan code of the released key. If a key can be shifted to produce a new character (like a capital letter), then a shift character

is sent in addition to the scan code and the host must determine which ASCII () character to use. Some keys, called extended keys, send an

E0 ahead of the scan code (and they may send more than one scan code). When an extended key is released, an E0 F0 key-up code is sent,

followed by the scan code. Scan codes for most keys are shown in Figure 7.2.1.

7.1 HID Controller

7.2 Keyboard

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 14/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4k.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 7.2.1 Keyboard Scan Codes

A host device can also send data to the keyboard. Table 7.2.1 shows a list of some common commands a host might send.

The keyboard can send data to the host only when both the data and clock lines are high (or idle). Because the host is the bus master, the

keyboard must check to see whether the host is sending data before driving the bus. To facilitate this, the clock line is used as a “clear to

send” signal. If the host drives the clock line low, the keyboard must not send any data until the clock is released. The keyboard sends data

to the host in 11-bit words that contain a ‘0’ start bit, followed by 8-bits of scan code (LSB first), followed by an odd parity bit, and

terminated with a ‘1’ stop bit. The keyboard generates 11 clock transitions (at 20 to 30 KHz) when the data is sent, and data is valid on the

falling edge of the clock.

Table 7.2.1. Keyboard Commands

Command Action

ED Set Num Lock, Caps Lock, and Scroll Lock LEDs. Keyboard returns FA after receiving ED, then host sends a byte to set

LED () status: bit 0 sets Scroll Lock, bit 1 sets Num Lock, and bit 2 sets Caps lock. Bits 3 to 7 are ignored.

EE Echo (test). Keyboard returns EE after receiving EE

F3 Set scan code repeat rate. Keyboard returns F3 on receiving FA, then host sends second byte to set the repeat rate.

FE Resend. FE directs keyboard to re-send most recent scan code.

FF Reset. Resets the keyboard.

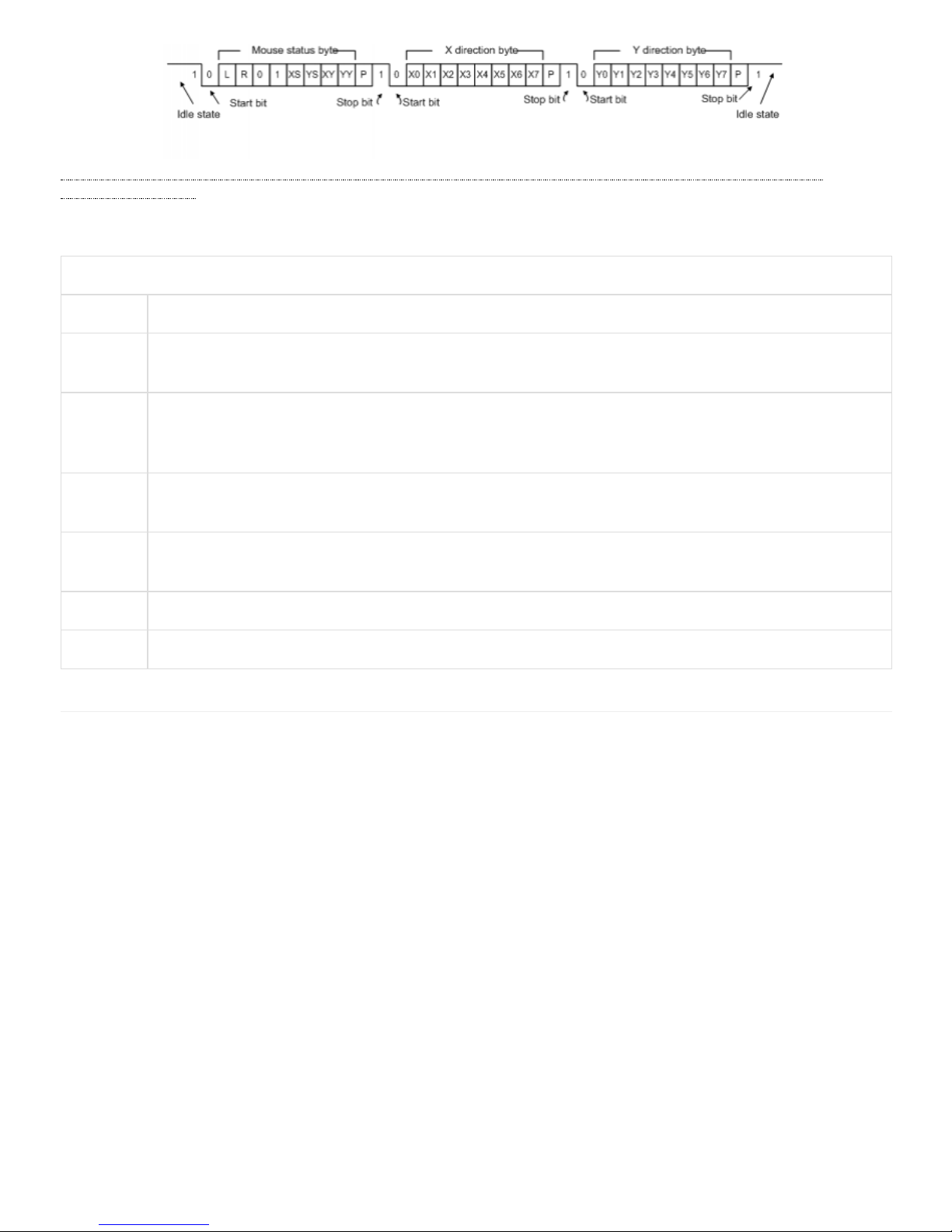

Once entered in stream mode and data reporting is enabled, the mouse outputs a clock and data signal when it is moved; otherwise, these

signals remain at logic ‘1.’ Each time the mouse is moved, three 11-bit words are sent from the mouse to the host device, as shown in Figure

7.3.1. Each of the 11-bit words contains a ‘0’ start bit, followed by 8 bits of data (LSB first), followed by an odd parity bit, and terminated

with a ‘1’ stop bit. Thus, each data transmission contains 33 bits, where bits 0, 11, and 22 are ‘0’ start bits, and bits 11, 21, and 33 are ‘1’ stop

bits. The three 8-bit data fields contain movement data, as shown in Figure 7.3.1. Data is valid at the falling edge of the clock, and the clock

period is 20 to 30 KHz.

The mouse assumes a relative coordinate system wherein moving the mouse to the right generates a positive number in the X field, and

moving to the left generates a negative number. Likewise, moving the mouse up generates a positive number in the Y field, and moving

down represents a negative number (the XS and YS bits in the status byte are the sign bits – a ‘1’ indicates a negative number). The

magnitude of the X and Y numbers represent the rate of mouse movement; the larger the number, the faster the mouse is moving (the XV

and YV bits in the status byte are movement overflow indicators. A ‘1’ means overflow has occurred). If the mouse moves continuously, the

33-bit transmissions are repeated every 50ms or so. The L and R fields in the status byte indicate Left and Right button presses (a ‘1’

indicates the button is being pressed).

7.3 Mouse

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 15/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4l.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 7.3.1 Mouse Data Format

The microcontroller also supports Microsoft® IntelliMouse®-type extensions for reporting back a third axis representing the mouse wheel,

as shown in Table 7.3.1.

Table 7.3.1. Microsoft IntelliMouse-Type Extensions, Commands, and Actions.

Command Action

EA Set stream mode. The mouse responds with “acknowledge” (0xFA) then resets its movement counters and enters stream

mode.

F4 Enable data reporting. The mouse responds with “acknowledge” (0xFA) then enables data reporting and resets its

movement counters. This command only affects behavior in stream mode. Once issued, mouse movement will

automatically generate a data packet.

F5 Disable data reporting. The mouse responds with “acknowledge” (0xFA) then disables data reporting and resets its

movement counters.

F3 Set mouse sample rate. The mouse responds with “acknowledge” (0xFA) then reads one more byte from the host. This

byte is then saved as the new sample rate, and a new “acknowledge” packet is issued.

FE Resend. FE directs mouse to re-send last packet.

FF Reset. The mouse responds with “acknowledge” (0xFA) then enters reset mode.

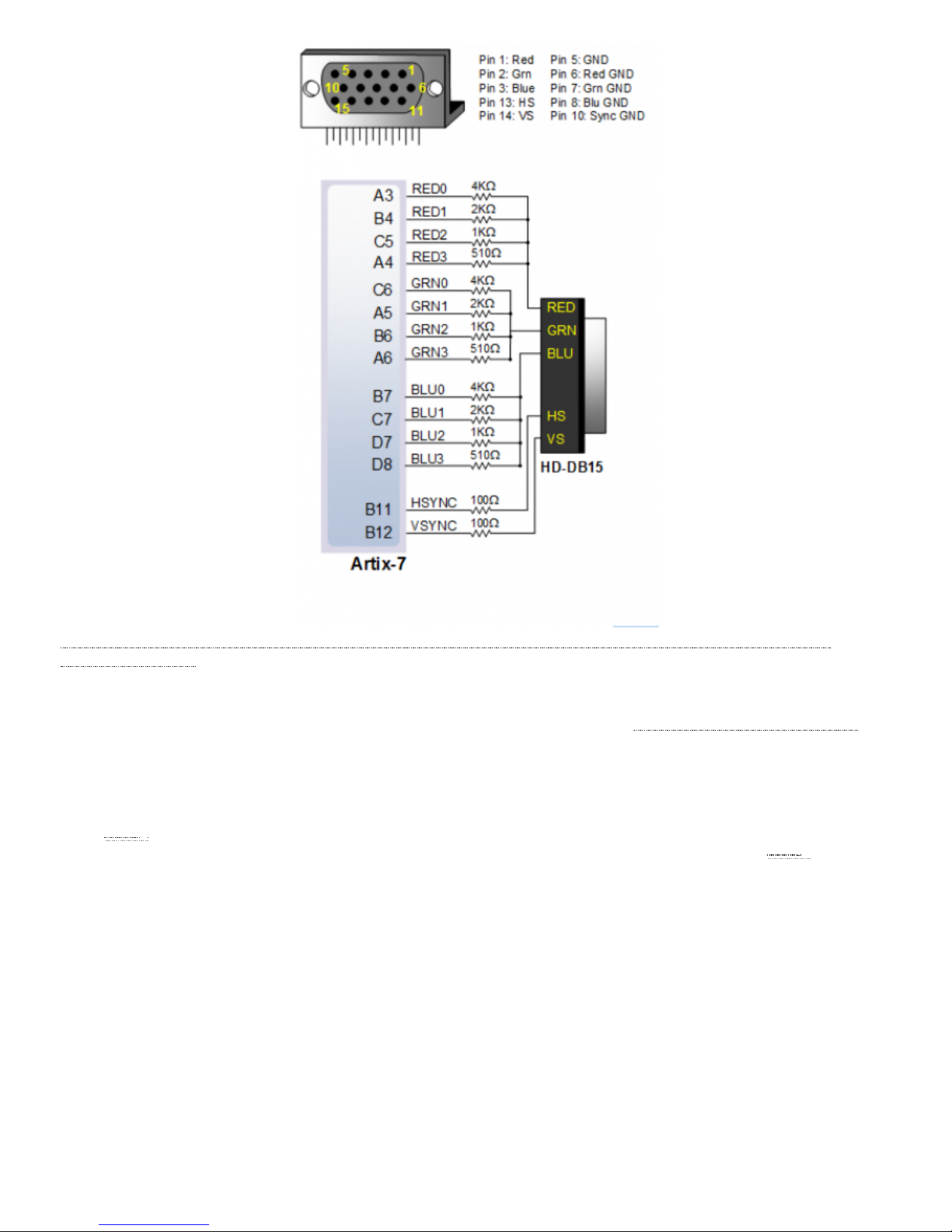

The Nexys A7 board uses 14 FPGA signals to create a VGA port with 4 bits-per-color and the two standard sync signals (HS – Horizontal

Sync, and VS – Vertical Sync). The color signals use resistor-divider circuits that work in conjunction with the 75-ohm termination

resistance of the VGA display to create 16 signal levels each on the red, green, and blue VGA signals. This circuit, shown in Figure 8.1,

produces video color signals that proceed in equal increments between 0V (fully off) and 0.7V (fully on). Using this circuit, 4096 different

colors can be displayed, one for each unique 12-bit pattern. A video controller circuit must be created in the FPGA to drive the sync and

color signals with the correct timing in order to produce a working display system.

8 VGA Port

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 16/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4m.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 8.1 Nexys A7 VGA Interface

VGA signal timings are specified, published, copyrighted, and sold by the VESA® organization ( www.vesa.org (http://www.vesa.org)).

The following VGA system timing information is provided as an example of how a VGA monitor might be driven in 640 by 480 mode.

NOTE: For more precise information, or for information on other VGA frequencies, refer to documentation available at the

VESA website.

CRT-based VGA displays use amplitude-modulated moving electron beams (or cathode rays) to display information on a phosphor-coated

screen. LCD () displays use an array of switches that can impose a voltage across a small amount of liquid crystal, thereby changing light

permittivity through the crystal on a pixel-by-pixel basis. Although the following description is limited to CRT displays, LCD () displays have

evolved to use the same signal timings as CRT displays (so the “signals” discussion below pertains to both CRTs and LCDs). Color CRT

displays use three electron beams (one for red, one for blue, and one for green) to energize the phosphor that coats the inner side of the

display end of a cathode ray tube (see Figure 8.1.1).

8.1 VGA System Timing

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 17/30

Modern VGA displays can accommodate different resolutions, and

a VGA controller circuit dictates the resolution by producing

timing signals to control the raster patterns. The controller must

produce synchronizing pulses at 3.3V (or 5V) to set the frequency

at which current flows through the deflection coils, and it must

ensure that video data is applied to the electron guns at the correct

time. Raster video displays define a number of “rows” that

corresponds to the number of horizontal passes the cathode makes

over the display area, and a number of “columns” that corresponds

to an area on each row that is assigned to one “picture element,” or

pixel. Typical displays use from 240 to 1200 rows and from 320 to

1600 columns. The overall size of a display and the number of

rows and columns determines the size of each pixel.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4n.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 8.1.1 Color CRT Display

Electron beams emanate from “electron guns,” which are finely-pointed heated cathodes placed in close proximity to a positively charged

annular plate called a “grid.” The electrostatic force imposed by the grid pulls rays of energized electrons from the cathodes, and those rays

are fed by the current that flows into the cathodes. These particle rays are initially accelerated towards the grid, but they soon fall under the

influence of the much larger electrostatic force that results from the entire phosphor-coated display surface of the CRT being charged to

20kV (or more). The rays are focused to a fine beam as they pass through the center of the grids, and then they accelerate to impact on the

phosphor-coated display surface. The phosphor surface glows brightly at the impact point, and it continues to glow for several hundred

microseconds after the beam is removed. The larger the current fed into the cathode, the brighter the phosphor will glow.

Between the grid and the display surface, the beam passes through the neck of the CRT where two coils of wire produce orthogonal

electromagnetic fields. Because cathode rays are composed of charged particles (electrons), they can be deflected by these magnetic fields.

Current waveforms are passed through the coils to produce magnetic fields that interact with the cathode rays and cause them to transverse

the display surface in a “raster” pattern, horizontally from left to right and vertically from top to bottom, as shown in Figure 8.1.2. As the

cathode ray moves over the surface of the display, the current sent to the electron guns can be increased or decreased to change the

brightness of the display at the cathode ray impact point.

Information is only displayed when the beam is moving in the “forward” direction (left to right and top to bottom), and not during the time

the beam is reset back to the left or top edge of the display. Much of the potential display time is therefore lost in “blanking” periods when

the beam is reset and stabilized to begin a new horizontal or vertical display pass. The size of the beams, the frequency at which the beam

can be traced across the display, and the frequency at which the electron beam can be modulated determine the display resolution.

Video data typically comes from a video refresh memory; with one

or more bytes assigned to each pixel location (the Nexys A7 uses

12 bits per pixel). The controller must index into video memory as

the beams move across the display, and retrieve and apply video

data to the display at precisely the time the electron beam is

moving across a given pixel.

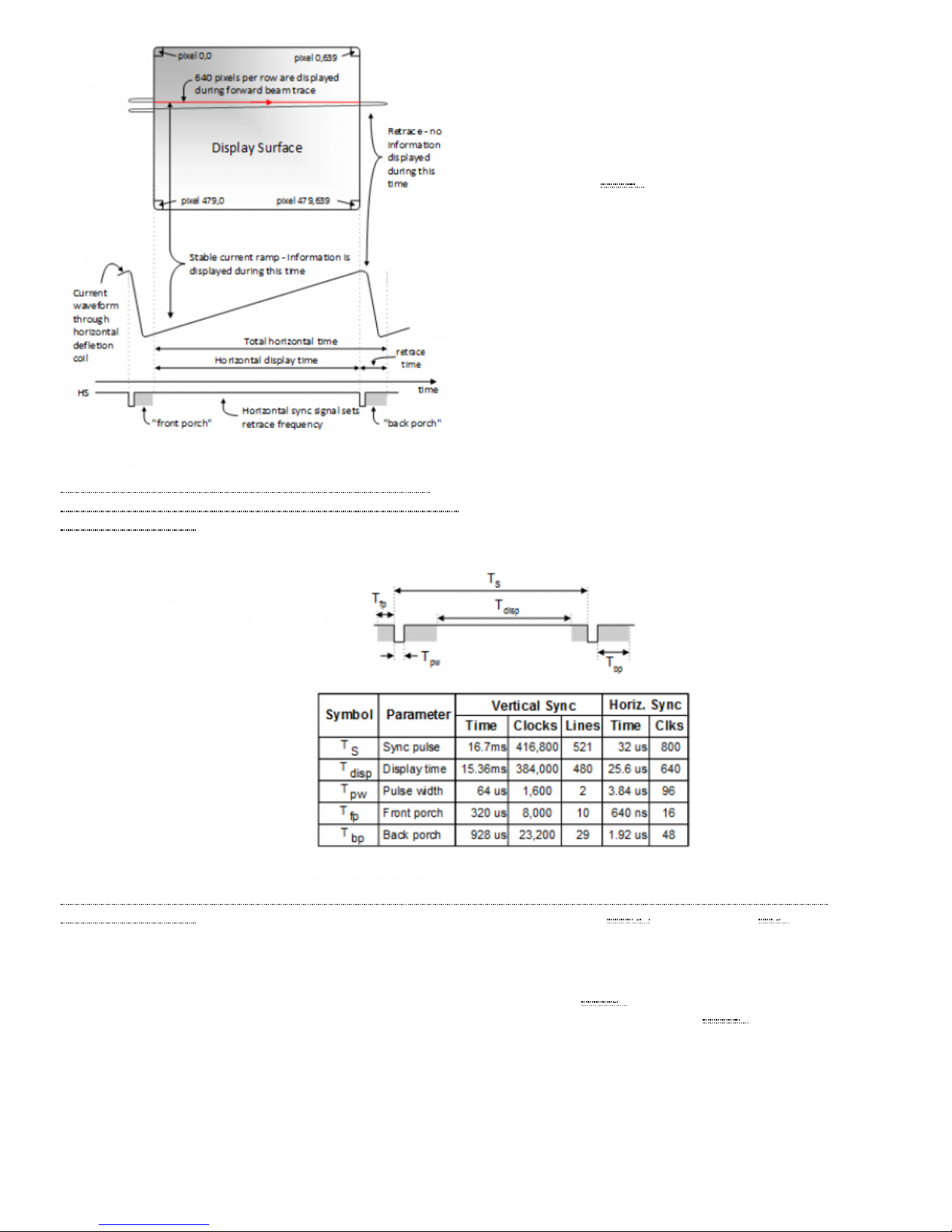

A VGA controller circuit must generate the HS and VS timings

signals and coordinate the delivery of video data based on the pixel

clock. The pixel clock defines the time available to display one

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 18/30

(https://reference.digilentinc.com/_detail/reference/programmable-

logic/nexys-a7/n4o.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual)

Figure 8.1.2 VGA Horizontal Synchronization

pixel of information. The VS signal defines the “refresh” frequency

of the display, or the frequency at which all information on the

display is redrawn. The minimum refresh frequency is a function of

the display’s phosphor and electron beam intensity, with practical

refresh frequencies falling in the 50Hz to 120Hz range. The

number of lines to be displayed at a given refresh frequency defines

the horizontal “retrace” frequency. For a 640-pixel by 480-row

display using a 25 MHz () pixel clock and 60 +/-1Hz refresh, the

signal timings shown in Figure 8.1.3 can be derived. Timings for

sync pulse width and front and back porch intervals (porch

intervals are the pre- and post-sync pulse times during which

information cannot be displayed) are based on observations taken

from actual VGA displays.

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4p.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 8.1.3 Signal Timings for a 640-Pixel by 480-Row Display Using a 25 MHz () Pixel Clock and 60 Hz () Vertical Refresh

A VGA controller circuit, such as the one diagrammed in Figure 8.1.4, decodes the output of a horizontal-sync counter driven by the pixel

clock to generate HS signal timings. You can use this counter to locate any pixel location on a given row. Likewise, the output of a vertical-

sync counter that increments with each HS pulse can be used to generate VS signal timings, and you can use this counter to locate any given

row. These two continually running counters can be used to form an address into video RAM (). No time relationship between the onset of

the HS pulse and the onset of the VS pulse is specified, so you can arrange the counters to easily form video RAM () addresses, or to

minimize decoding logic for sync pulse generation.

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 19/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4q.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 8.1.4 VGA Display Controller Block Diagram

The Nexys A7 board includes two tri-color LEDs, sixteen slide switches, six push buttons, sixteen individual LEDs, and an eight-digit

seven-segment display, as shown in Figure 9.1. The pushbuttons and slide switches are connected to the FPGA via series resistors to

prevent damage from inadvertent short circuits (a short circuit could occur if an FPGA pin assigned to a pushbutton or slide switch was

inadvertently defined as an output). The five pushbuttons arranged in a plus-sign configuration are “momentary” switches that normally

generate a low output when they are at rest, and a high output only when they are pressed. The red pushbutton labeled “CPU RESET,” on

the other hand, generates a high output when at rest and a low output when pressed. The CPU RESET button is intended to be used in

EDK designs to reset the processor, but you can also use it as a general purpose pushbutton. Slide switches generate constant high or low

inputs depending on their position.

9 Basic I/O

12/25/2018 Nexys A7 Reference Manual [Reference.Digilentinc]

https://reference.digilentinc.com/reference/programmable-logic/nexys-a7/reference-manual 20/30

(https://reference.digilentinc.com/_detail/reference/programmable-logic/nexys-a7/n4r.png?id=reference%3Aprogrammable-logic%3Anexys-

a7%3Areference-manual) Figure 9.1 General Purpose I/O Devices on the Nexys A7

The sixteen individual high-efficiency LEDs are anode-connected to the FPGA via 330-ohm resistors, so they will turn on when a logic high

voltage is applied to their respective I/O pin. Additional LEDs that are not user-accessible indicate power-on, FPGA programming status,

and USB and Ethernet port status.

The Nexys A7 board contains two four-digit common anode seven-segment LED () displays, configured to behave like a single eight-digit

display. Each of the eight digits is composed of seven segments arranged in a “figure 8” pattern, with an LED () embedded in each segment.

Segment LEDs can be individually illuminated, so any one of 128 patterns can be displayed on a digit by illuminating certain LED ()

segments and leaving the others dark, as shown in Figure 9.1.1. Of these 128 possible patterns, the ten corresponding to the decimal digits

are the most useful.

9.1 Seven-Segment Display

Table of contents