NGH GF150R5 Administrator Guide

1

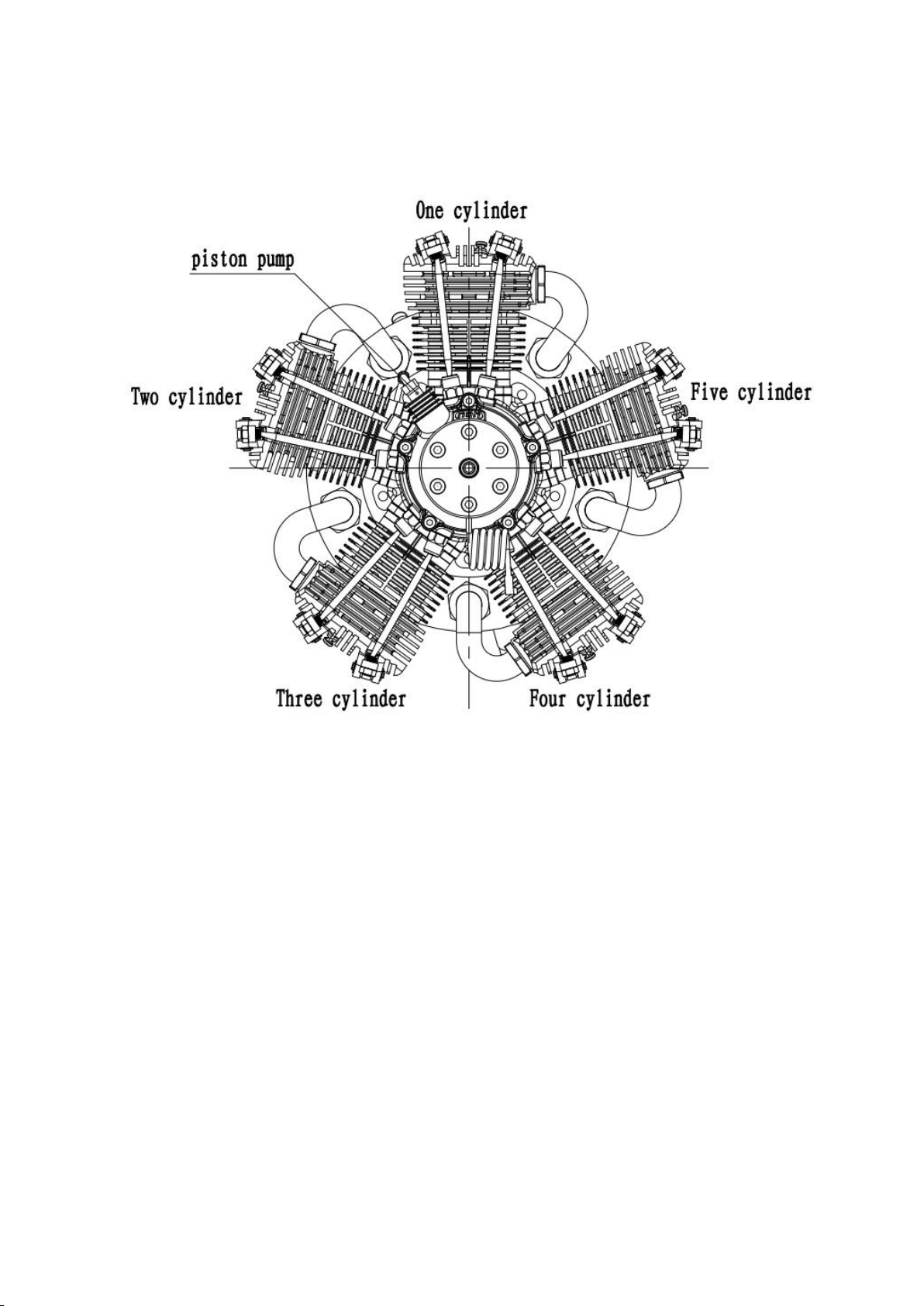

GF150R5 Five-cylinder of radial configuration/4-stroke RC gasoline egnine

Operation instruction manual

Thank you for purchasing NGH products. This product is a Five-cylinder of radial configuration four-stroke gasoline engine specially designed

by NGH engineers for the model enthusiasts and the user of UAVs. It has high-rise stability, the output torque , ultralow vibration, sufficient

combustion of mixed gas, low fuel consumption, low noise, high wear resistance, and power to weight ratio greater. The structure is tight and

the appearance is exquisite. It is very suitable for the real aircraft and long-endurance UAV power during World War II, and we hope that this

engine will give you a pleasant and safe flight experience.

Security Warning and Instruction:

Please kindly read this operating manual carefully before operating and maintaining the engine to familiarize you with the performance.

Improper operation may damage the engine and even cause great loss to private property and personal injury.

The engine is a precision product developed and manufactured by NGH. The operator needs to have some common sense of internal

combustion engine and basic mechanical knowledge, and must be cautious in the operation; please do not use any accessories that are not

approved by our company when repairing and maintaining the engine. Please kindly read the manual carefully and follow the instructions in

the manual to ensure use it correctly and avoid danger before assembling, debugging and using the engine.

Age recommendation: RC engines are not toys! Not suitable for the children under 15 years old.

This engine is designed for the radio-controlled model aircraft and long-endurance Uavs. If you use this engine for any other purpose, we are

not responsible for ensuring its stability and safety. When installing engines on RC models, please read the RC model manual carefully. The

RC model manual contains helpful advice when installing engines.

• NGH and its distributors are not responsible for the property damage and the injury caused by negligent use.

• Please keep away from the rotating area of the propeller when operating the engine.

• Do not wear loose clothing when go near the engine or propeller.

• Do not start the engine on the ground of loose materials such as dirt、gravel、ropes、sand、etc.

• Operate the engine in a good ventilated environment, as the engine may produce harmful carbon monoxide gas during the operation.

• Make sure that the propeller is firmly fixed to the engine crankshaft before each flight and also make sure that all parts are in place and

fastened.

• When running or debugging the engine, stand on the back of the propeller, and make sure to keep your face and body out of the path which

the propeller blades pass. Do not allow others to stand in front or on the side of the propeller.

• Make sure that small parts are out of the reach of children to prevent children from swallowing.

• Please always check whether the nut fastening the propeller is locked.

• Gasoline is flammable. Be careful of sparks which come into contact with the engine (eg fire stars, battery chargers, etc.) causing fires.

• Stop and cool the engine before touching or refueling it. The surface of the running engine is hot enough to cause burns and other injuries.

• Before flying, be sure to check for loose bolts. When installing the muffler, screw the muffler into the thread of the engine exhaust until it

stops, it is recommended to use screw glue.

• Make sure the engine and muffler have cold air passing through the aircraft fairing environment to ensure engine cooling.

The product specifications:

Type:Five-cylinder of radial configuration/4-stroke air-cooled gasoline engine(It’s only use for fixed wing model airplane and long-endurance UAV)

Bore:36mm

Stroke:29.4mm

The dimensions:149.55cc(5 x 29.91cc)

Carburetor:Walbro WT

The maximum power:8.2 HP/6500rpm

Range of the speeds:1000-6500rpm

Igniter:NGH automatic advance angle R5 igniter (RoHS and CE certificate)

Igniter power supply:DC 6V-9.6V/1000mAH

Spark plug:CM6

Fuel: 92# unlead gasoline + Fully synthetic 2T lubricants

Lubricating ratio: Gasoline:Lubricating = 35:1

Recommended propeller:26x16、28x14 30x12(two-bladed)

23x16 26x14(three-bladed)

Engine Weight: 4.6kg

Igniter weighta: 0.43kg

2

Carburetor Settings & adjustment :

The Walbro carburetor used by NGH-GF150R5 Five-cylinder of radial

configuration/4-stroke RC gasoline egnine is matched with perfect idle stability

and acceleration sensitivity; It is better to remove all remaining fuel from the

carburetor after a set of flights is completed. The fuel is cleaned to prevent aging

of the carburetor rubber parts. The specific method: Start the engine without

connecting the fuel pipe until the fuel in the carburetor is exhausted.

Set up the carburetor:

①—Choke:Close it before the first start the engine, and quickly rotating propeller to suck the fuel in the tank, and the engine has a

detonation sound and then turn it on.

②—The throttle control arm:Infinitely adjustable-speed device, control the turning speed of the engine.

③—The nozzle:Connect the oil tank and supply the fuel to engine.

④—High speed needle(H):After fully open the throttle control arm ②, adjust the high speed needle to achieve the best high speed.

⑤—Idling speed needle(L):Put ②return to the initial position, adjust the idling speed needle to obtain a satisfactory low speed.

⑥—Idle mixture adjustment screw:Adjusting the fuel and air mixing ratio at idle, it actually control the initial position of ②,

adjust ⑥and ⑤will obtain the better idling speed.

Note: the carburetor's initial Settings are factory Settings and do not need to be adjusted when the engine starts for the first time.

The factory setting status:

④—High speed needle, completely close (clockwise) and then exit (counterclockwise) 1.5 rings;

⑤—Idle speed needle, Fully closed (clockwise) and then exit (counterclockwise) 1.5 rings;

⑥—Idle mixture adjustment screw, The throttle control arm at the other end of the limit pawl near the screw cone about 0mm.

Adjust Carburetor:

When you need to adjust the carburetor after your engine runs, please adjust it based on the factory settings:

Please use a high quality tachometer to judge your adjustment results when adjusting the carburetor. This tachometer is necessary for you to

buy one.

First adjust the high-speed oil needle: Turn the throttle to the maximum position when the engine is running, adjust the high-speed oil needle,

watch the change of the tachometer, adjust the engine speed to the maximum value per minute, and the engine works at a stable high-speed

state (Note: Don't let the engine run lean for a long time, it is a big damage to the engine.)

Adjust the idle speed needle: return the throttle to the idle position, adjust the idle speed needle and watch the change of the tachometer. Let

the engine run at a steady idle state (recommended 26x16 wood 2 blade propeller idle speed at 1100rpm), if necessary, adjust with the idling

mixture adjustment screw to ensure the steady engine idling and smooth acceleration; if the engine is hard to start at idle speed (Exclude CDI

igniter power shortage, too much fuel in combustion chamber, spark plug problems, etc), it means that the air-fuel ratio (A/F) at idle is low.

Please adjust the idle mixture adjustment screw to increase the air ratio, or adjust the idle oil needle to reduce the fuel quantity, so that the

air-fuel ratio is at an appropriate ratio. (Tip: The larger the size of the propeller the engine carries, the lower the ideal idle speed that can be

achieved.)

When the engine high speed and idle speed adjustment is completed, try to run the engine acceleration performance.

First let the engine to run 10 seconds at idling and then quickly move the throttle control arm at full throttle position, there will be the

following three situations:

A. The acceleration of the engine is very responsive and the smooth transition to the highest speed. It indicates that the engine is well adjusted.

B. Engine acceleration has a cough performance, gradually transition to the highest speed, illustrate the idle speed needle set relatively rich oil,

the idle speed needle to make a small adjustment (clockwise rotation), and then try again, try to accelerate the reaction constant adjustment

until the engine reaches your request.

C. Rapid throttle when the engine suddenly stopped running, this shows that the idle speed needle set relatively lean oil, the idle speed needle

to make a small adjustment (anticlockwise rotation), and then try again, try to accelerate the reaction constant adjustment until the engine

reaches your requirements.

3

The Fuel Tank Connecting:

Valve clearance adjustment:

Note: when adjusting valve clearance, please remove the gear box cover from the back cover and adjust valve clearance according to the mark

on the gear.

The first adjustment of the valve clearance is after the engine has been running for 4 hours. It is necessary to adjust the valve clearance after

every 8 hours of flight. Before adjusting the valve clearance, it should be checked that the valve mechanism moves flexibly and freely without

jamming. Due to the thermal expansion of the metal material, the adjustment of the valve clearance should be performed after the engine is

completely cooled. When adjusting the valve clearance, the valve clearance should be adjusted during the compression stroke of the engine

(both intake and exhaust valves are fully closed). Rotate the propeller manually, and correspond to the TDC mark points on the large and

small gears corresponding to the front and rear cylinder positions. In this position, insert the plug (thickness 0.06 - 0.1mm) between the rocker

arm and the valve and then adjust with a hexagonal wrench. After adjusting the clearance, tighten the hex nut (Note: Hexagon nuts should not

be screwed too tight)

Valve clearance adjustment is one of the most important aspects of four-stroke engine maintenance. Excessive valve clearance affects the

performance of the engine, aggravating the wear of the tappet and the cam, causing the camshaft to produce an abnormal sound; Small valve

clearance(or no clearance) will also affect the performance of the engine, resulting in loose valve closure, compression stroke leakage, engine

hard to start, etc.

Engine installation:

NGH-GF150R5 Five-cylinder of radial configuration/4-stroke egnine is installed on a suitable RC aircraft with mounting base,installation

should be firm and reliable . It can effectively reduce the vibration of the four-stroke engine at high speed.

Note: Please ensure that the back of the firewall of the RC aircraft is equipped with a metal flat washer or a pawl nut to prevent the

bolt from falling into the plywood. Please kindly always check for loose bolts before flying.

4

Connection of CDI electronic igniter:

When connecting the CDI electronic igneer, please pay attention to the number marked on the CDI control box, which should correspond to

the order of the engine cylinder number. It should not be connected incorrectly, otherwise the engine will not run.

Sequence of five cylinders

5

When the indicator light is red, the magnet is reset, and when the indicator light is green, the corresponding cylinder is ignited.

Engine starting:

1. Firmly install the connected engine on the RC aircraft, lock the propeller, keep the carburetor in the factory setting state, connect the spark

plug, electronic igniter, sensor, fill the fuel inlet tank, and turn on the power and radio control equipment.

2. Turn off the power of the electronic igniter and turn off the choke valve of the carburetor. Rotate the engine propeller quickly and suck the

fuel into the carburetor. Don’t inhale too much fuel, Too much fuel will flood the spark plug and making it difficult to start the engine.

3. Open the choke door of the carburetor, turn on the power supply of the electronic igniter, use the motor starter to start the engine, and the

engine starts to work. At this time, enthusiasts can adjust the carburetor according to their own needs, according to the above steps to adjust

the carburetor.

Warning: make sure all bystanders, especially children, stay at least 50 meters away from the rotating engine.

Engine Break-in:

Please use high quality full synthetic 2T oils, gasoline and machine oil with mixing ratio 35:1. NGH is recommended to use smaller size

propellers at first break-in and follow-up about 10 times in flight. Keep medium speed running for 30 minutes (no more than 5000rpm) after

started engine, then high speed running (5500 rpm) for 3 minutes, at last medium speed running for 10 minutes, high speed running for 3

minutes, reciprocating 3-5 times complete break-in. Breaking in engine carefully will increase its life. Please make sure the engine got the

complete break-in before you use the larger load propeller.

6

Engine cooling:

If engine is installed in the fairing, there must be enough air coming in to cool the engine, and make sure there is enough air circulation in the

fairing.

Reference data: The exit area should be 3-5 times the inlet area to ensure adequate cooling, and if necessary, the rear cylinder should be

diverted to keep the rear tank cool.

Engine Trouble Removal:

If the engine is difficult to start, idle or idle speed is unstable, please check: whether the electric circuit and oil line of engine is trouble,

whether the engine leaks air, whether the electronic ignition works or its power supply is adequate, whether the spark plug flame out. If

necessary, replace with a new spark plug.

If the engine finds that a cylinder is not working at low speed, you only need to increase the throttle slightly to make the cylinder to work

properly that does not work.

Engine Maintenance:

In order to reduce the fuel consumption and extend the life of the engine, please adjust the engine’s highest speed and make engine run in the

output maximum speed of 90% once the gas pedal full opened, If the load is large (the diameter and pitch of the propeller are large), the speed

will be lower and the fuel consumption will be higher; if the load is small, the speed will be high, but the fuel consumption will be less; Please

make sure to empty the fuel in the carburetor after each flight, otherwise it’ll cause the rubber of carburetor aging and affect the engine

performance; Please clean periodically the carbon deposition on the spark plug and keep the gap from 0.7mm to 0.8mm between the electrodes;

If it’s difficult to start the engine, idle speed unstable or it is flameout during high speed operation, and there is carbon deposits in the spark

plug, please replace the spark plugs; Please clean the engine surface after used each time, it can make the engine to get better cooling; The

carburetor may be blocked seriously if you use different brands or types of lubricating oil together, you need select a better fuel filter;

Long-term low-speed operation will cause the spark plug to deposit carbon; Regularly check the fuel system to ensure no oil leakage and no

air leakage.

Engine Guarantee:

If the NGH engine has performance defects caused by the defects of process, material and manufacturing, we certify that: Change for free

within one year and Guarantee within two years since the date you purchased. Please note the guarantee is only for the original purchaser, not

including: normal wear for engine; damage caused by the failure of maintenance; damage for engine over speed operation caused by using

small propeller; Bearing rust; Crash; Use inappropriate fuel; Damage caused by foreign bodies; Damage caused by unreasonable installation or

operating environment; Damage caused by improper dismantle; Damage caused by any modification.

Web: www.nghengine.com

E-mail: ngh@ncdmoly.com

Skype: blue-sky-tan

Packing list:

Number

Drawing number

Name

quantity

Remarks

1

GF150R5

Engine

1

2

CDI electronic igniter

1

3

CM-6

CM-6 Spark plug

5

4

Valve clearance adjustment plug sheet

1

5

Operation instruction manual

1

6

Logo paster

1

7

Table of contents

Other NGH Engine manuals