NGH GF38 Operation manual

1

GF38 4-Stroke RCGasoline Engines

Owner sOperating Instruction Manual

Dearcustomer:

Thank you forpurchasing NGH GF38 4-stroke gasoline engine.the engine hasbeen developed by NGH engineers to

offer all hobbyists anew 4-stroke engine. You will be delightedwith stability,fuel economy,energy saving,

environmental protection, low noise, large torque output of your NGH GF38. Wehope that you will enjoy with your the

engine,and have many fun and safeflying experiences with its use.

Safety Instruction and WARNINGS!

Please read the instruction manual to become familiar with the features of the product before operating. Failure to

operatethe product correctly can result in damage to the product, personal property and causeserious injury.

GF38 engineis NGH R&D manufacturing precision products. Itmust be operated with caution and common senseand

requiressome basic mechanical ability.This product is not intended for use by children without direct adult supervision.

Don tattempt disassembly,use with incompatible components or augment product in any way without theapproval of

our company.It is to read and follow all the instructions and warnings in the manual, prior to assembly,setup oruse, in

order to operate correctly and avoid damage or serious injury.

Age Recommendation: RC engine is not a toy! Notforchildren under15 years.

The engine is designedfor use on amodel radio control airplane. If it is used for any purpose, we cannot be responsible

for its reliability of safety.

NGH or their dealers aren t responsiblefor any loss, injury or damage resulting from the miss-use of RC engine.

Keep away from the rotating propeller area while operating the engine.

Do not wear loose clothing near the engine or the propeller.

Do not operate the engine near loose material such as dirt, gravel, ropes, sand, etc.

Always run your model engine in awell-ventilated area. Model engines produce possibly harmful carbon monoxide

fumes.

Always ensure thatthe propelleris securely attachedto the engine shaft and all retaining fasteners are tightened

properly before each flight.

Always stand clearof and behind the propeller,ensure the face and body are far away from thepropeller blade after

trajectory. Never allow anyone, to be in front of orto the sides of the propeller when starting or running the engine.

Always ensure that small parts in the children can t touch place to prevent children from swallowing parts;

Always check the propeller nut tightening.

Gasoline is extremely flammable. Be careful of any sparks from electrical contacts such as fuel pumps, battery

charger, etc.

Allow your engine stop and cool before touching or fueling. The running engine of the surface temperature is high,

easy to cause burns and other personal injury.

Be sure to check whether there are loose bolts before flying.When install amuffler,the muffler in the threads ofthe

screw into the engine exhaust, until twist fixed, it is recommended to use screw glue.

Ensure the engine and muffler in aircraft fairing environment with cold air, make sure the engine cooling.

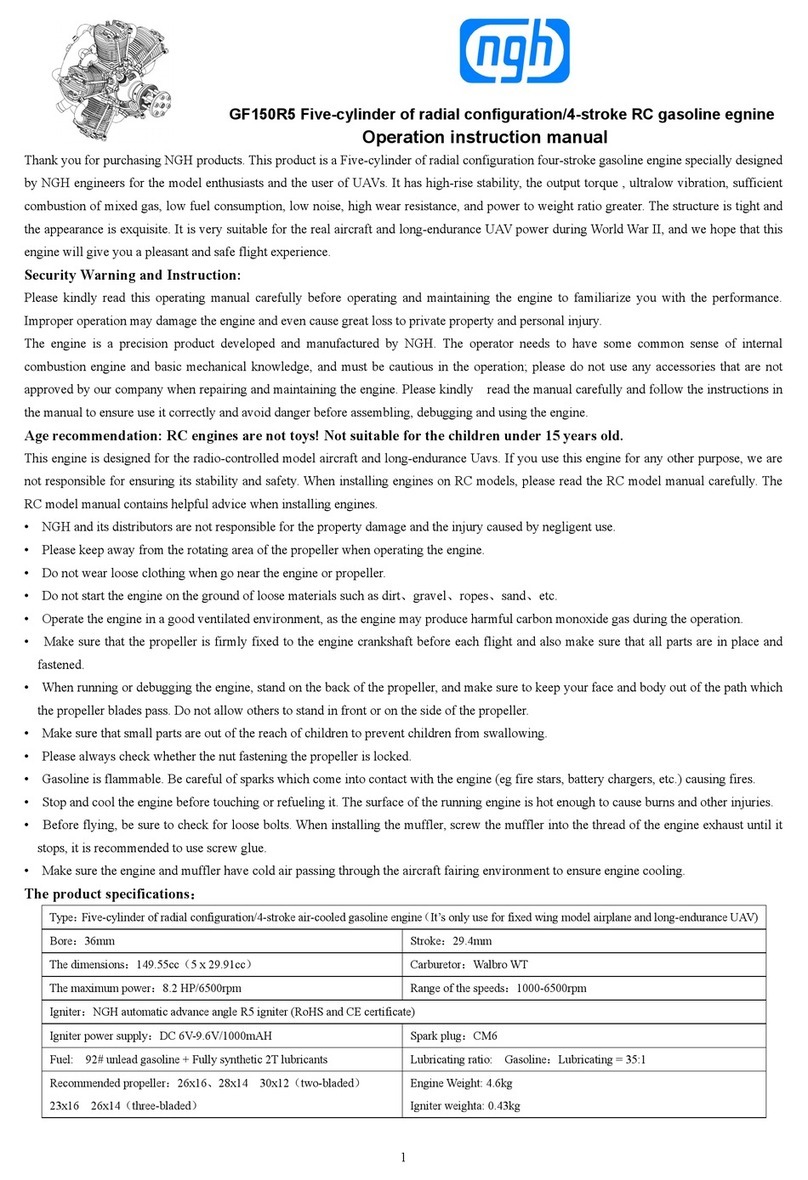

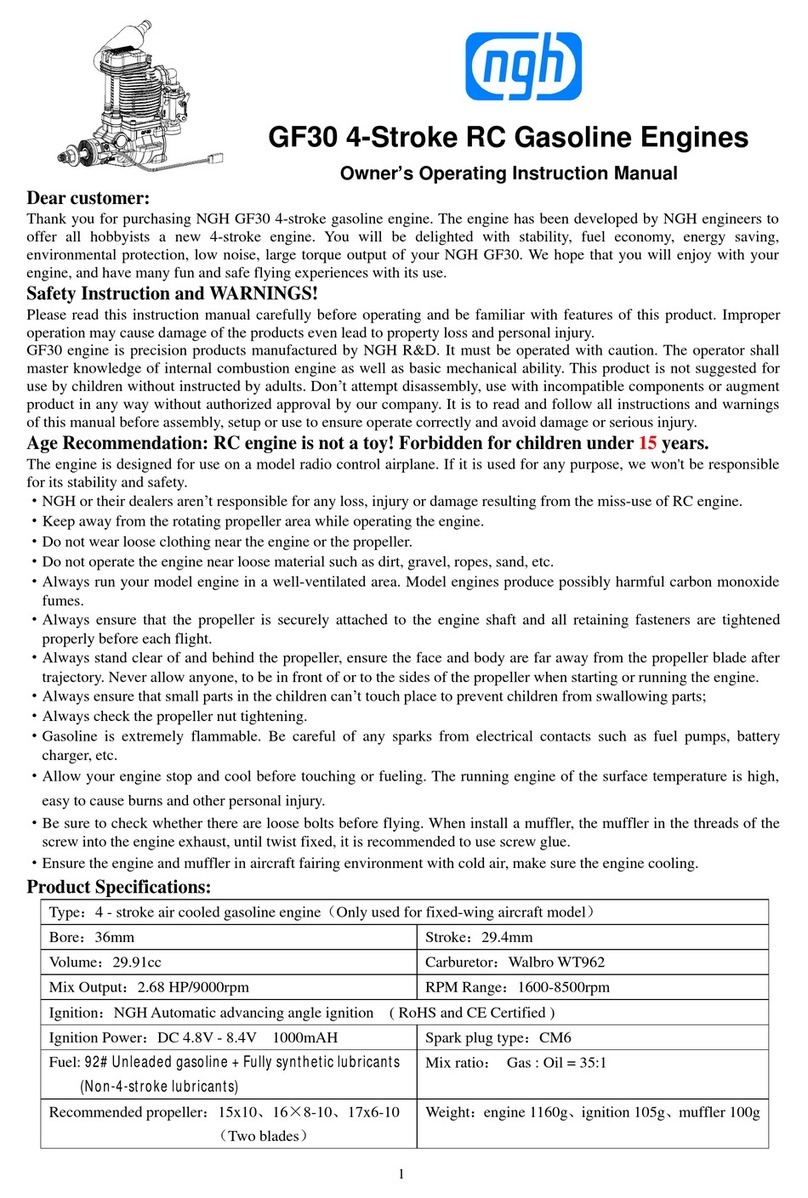

Product Specifications

Type:4 - stroke air cooled gasolineengine(Only used for fixed-wing aircraft model)

Bore:39mm Stroke:31.8mm

Volume:37.97cc Carburetor:Walbro WT1022

Mix Output:3.58 HP/8300rpm RPM Range:1600-8000rpm

Ignition:NGH Automatic advancing angle ignition (RoHS and CE Certified;Rcexl Manufactured)

Ignition Power:DC 4.8V- 8.4V1000mAH Spark plug type:CM6

Fuel: 93# Unleaded gasoline +Fully synthetic lubricants

(Non-4-stroke lubricants) Mixing ratio:oil :Lubrication = 35:1

Recommended propeller:18×8-10、19x8-10、20×8

(Two blades)Weight:engine 1310g、ignition 100g

2

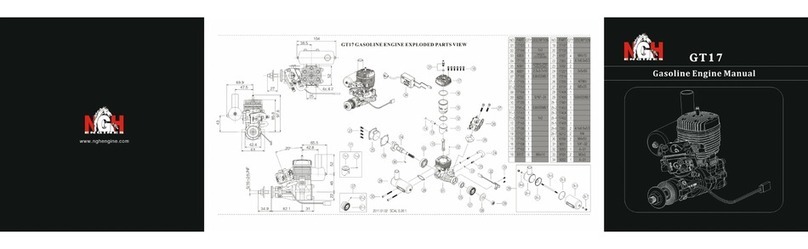

Installation of carburetorcomponents

Following theabovepictures connect the carburetor.Please attention the five ellipse holes and 90°of the mounting

bracket (F38264), and thesefive ellipse holes used to adjust position.Mounting bracket at 90 degrees can be intake

manifold (F38224) and the mounting surface integrity (If not 90°,it must be to adjust). Make sure the intake manifold

(F38224) will not rupture by pull down and up compressions.Above pictures ①-⑦are fastening screws. Please don't

take them all tighten at atime. Youshould adjust the mounting bracket position and make sure the intake manifold is

not subject to tension and extrusion,and then tight the fastening screws one by one (according the situation ⑦cannot

install ).

Carburetorsetup, adjust; Lubricated tube and pulse tube connection:

FIG.1FIG. 2

NGH-GF38 four-stroke gasoline engine used Walbro WT1022 carburetor is designedfor NGH unique. It has the perfect

stability of idle speed and acceleration sensitivity.

Always remove fuel from the carburetorafter flight. Not doing so will result in rubbercarburetor is components

deteriorating over time, causing loss of engine performance.

Methods: Start the engine without connecting the fuel pipe until we run out of fuel in the carburetor.

Setup Carburetor:

As shown in FIG. 1,

①—Choke:Close it before the first start the engine, and quickly rotating propeller, the fuel oil suction within the tank

into thecarburetor, when you start the engine should be open it.

②—The throttle control arm:Infinitely adjustable-speed device, control the turning speed of the engine.

③—Nozzle:Connect the oil tank and supply the fuel to engine.

④—High speed needle.:After fully open the throttlecontrol arm ②,adjust the high speed needle can get the best

high speed.

⑤—Idling speed needle:Put ②return to the initialposition, adjust the idling speed needle can obtain satisfactory

low speed.

⑥—Idle mixture adjustment screw:Adjusting the fueland air mixing ratio at idle, it actually control the initial

position of ②, adjust ⑥and ⑤will obtain the better idling speed.

The initial setup of the carburetor is factory settings, the engine first start don t need to adjust.

The factory setting status:

④—High speed needle, Fully closed (clockwise) before exiting(anticlockwise) 1.5-1.75 times;

⑤—Idle speed needle, Fully closed (clockwise) before exiting(anticlockwise) 1.5-1.75 times;

⑥—Idle mixture adjustmentscrew,The throttle control armat the other endof thelimit pawl near the screwcone

about 1mm.

3

Adjust Carburetor:

When the engine running, you want to adjust the carburetor, please adjust it based on factory Settings:

In the process of adjusting the carburetor,please use ahigh-quality tachometerto determineyour adjusted results, the

tachometer you need to buy one.

First adjust thehigh speed needle: Enginerun time will be turned on at full throttle position, adjust the high needle and

watch the change of the tachometer,makethe engine rpm reachthe max per minute.Engine work in astable high speed

(pleasenote: do not let the engine run boundary for along time,this is abig damage for engine). Adjust the idle speed

needle:The throttle return to the idle position, adjust the idle speed needle and watch the change of the tachometer.Let

the engine run in a stable state of idle speed (Advice 19x8 wooden propeller idle speed at 1800rpm).

When necessary and idle mixture adjustment screw joint adjustments to ensure the engine idle speed stability,smooth

acceleration; If the engine is idling start difficult (Exclude CDI ignition power shortage,excessive fuel combustion

chamber,sparkplug problems and so on).This shows that air-fuel ratio (A/F) is low at idling, please adjust idlemixture

adjustment screw,increaseair ratio, oradjust idling needle to reduce the amount of fuel, A/F ratio to achieve

appropriate proportion. ( Tip:The larger engine propeller,the more perfect lower idle speed you will get. )

When the engine high speedand idle speed adjustment is completed, try to run the engine acceleration performance.

First letthe engine to run 10 seconds at idling and thequickly move the throttle control armat full throttle position,

there will be the following three situations:

A. Engine speed is responsive and smooth transition to the highest speed, instructions for the adjustment of the engine is

very good.

B. Engine acceleration has acough performance, gradually transition to thehighest speed, illustrate theidle speed

needle set relatively rich oil, the idlespeed needle to make asmall adjustment (clockwise rotation), and then try again,

try to accelerate the reaction constant adjustment until the engine reaches yourrequest.

C. Rapid throttle when the enginesuddenly stopped running, this showsthatthe idle speed needle set relatively lean oil,

the idle speedneedle to make asmall adjustment (anticlockwise rotation),and then try again, try to accelerate the

reaction constant adjustment until the engine reaches your request.

Lubricated tube and Pulse tube connection:

Please according to as shown in FIG. 2 motioned connect, maintain the proper length of thetube, cut off the excess part.

The Fuel Tank Connecting:

As shown in figure

Fuel tank connection Valve clearance adjustment

Valve clearance Adjustment:

After approximately 2 hours flight, valve clearance adjustment may be necessary. Before adjusting valve clearance,

should check valve body to move freely, no clamping stagnation phenomenon. Due to the thermal expansion of metal m

aterials, valve clearance adjustment should be carried out after engine has cooled completely.Adjust the valves must be

in the engine s compression stroke (Intake and exhaust valves in a fully closed position). When adjustment is completed

, make sure you tighten the hexagonal nut.

How toadjust the valve clearance:

Remove the rocker arm cover and revolvethe propellerslowly clockwise by hand.The intake side rocker arm stops,

and by turning it, the piston reaches the compression top dead center (TDC).In this position, take asmall piece of paper

(thickness 0.06 - 0.1mm) into between rocker and valve. With a hexagonal wrench adjustment, after that, tighten the hex

nut (note the hexagonal nut should not be screwed too tight), as shown in the figure below.

The valve clearance is the most important factor in the maintenance of four-stroke engines, and operation with an

excess clearance will degrade performance. In particular,alarge gap aggravatesabrasion of the tappet and the cam and

also increases the unusual sound; asmall gap (or no gap )is also influence the performance of the engine, so that the

valve does not close tightly resulting the compression stroke air leaks.

4

Engine installation:

NGH 4-stroke engine mounted on a suitable RC aircraft has two common ways of installation, as shown below:

FIG. 3 FIG. 4

FIG.3: Rail bracket installation; FIG.4: Rear bracket installation.

Wesuggest that RC hobbyist use"FIG.3" installation. It can effectively reducethe high frequencyvibration of

four-stroke engine running at a high speed.

Notice: Please make sure to install afirewall on the back of RCaircraft using metal flat washer or ratchet nut to prevent

the pawl bolt into plywood. Be sure to check before you fly if there are loose bolts.

Rail bracket Rearbracket

Starting the engine:

1. According the engine connection method, install the engine on RC airplane and lock propellers.

Made the carburetor initial setup and connect the spark plug, electronic ignition and sensors,put the fuel into theoil

tank, connect the power and radio control equipment.

2. Will power offthe electronic igniter at this time, make the carburetor inlet port in afully closed position. Through the

motor starter rapidly rotating propeller engine make the fuel in the tank inhalation of carburetor,please pay attention

to the suction of fuel should not be too much, otherwise will drown the spark plug, theenginestart difficult.

3. Please open the carburetor throttle airinlet, power on the electronic igniter,then start the engine using themotor

starter,the engine will begin to work, the fans will adjust the carburetor according to your own need. According to

the above steps to adjust the carburetor adjustment.

Warning: Make sure all bystanders, especially children, at least 30 feet away from rotating engine.

Engine Break-in:

Please use thehigh quality synthetic oils, gasoline and machine oil smixing ratio is 35:1. NGH isrecommended to use

smallersize propellers at first break-in and follow-up about 10 times in flight. Keep medium speed running for 15

minutes(no more than4000rpm) after started engine, thenhigh speed running (6500 rpm) for 3minutes, again medium

speed running for 5minutes, high speed running for 3minutes, reciprocating 3-5 times complete break-in. Breaking in

enginecarefully will increaseits life.Please make sure the engine got the complete break-in beforeyou use the larger

load propeller.

Engine cooling:

If your engineis installed in the fairing, there must be air entering to cool theengineand ensure enough air flowing in

the faring. Reference data: Outlet area should be 3-5 times than the entrance area to ensure adequate cooling.

Engine FailureRemoval:

If the engine is difficult to start, idle speed and high speed unstable. Please check: whether the electric circuit and oil

line ofengineis trouble, whether the engine leaks air,whether the electronic ignition works or its power supply is

adequate, whether thespark plug flame out. If necessary, replace with a new spark plug.

5

Engine Maintenance:

To reduce thefuel consumption, extend engine slife, please adjust theengine shighest speed and make engine run in

the output maximum speed of 90% once the gas pedal full opened. If the loadis large (Propeller sdiameter and screw

pitch arebig ), the fuel must be adequate. If the load is small, the speedwill be high while the fuel consumption will be

less; Please make sureto empty the carburetor after each flight, otherwise it ll cause the rubber of carburetor aging to

affect the engine performance; Please clean the carbon deposition on the spark plug and keep the gap from 0.7mm to

0.8mm between the electrodes; If it sdifficult to start the engine, idle speedunstable or when high speed operation

flameout, please replace thespark plugs; Please clean the engine surface after used each time, it can make the engine

get better cooling; The carburetormay beblocked seriously if you use different brands or types of lubricating oil

together, you need select abetter fuel filter;If the enginelow speed work for along time, can lead to spark plug carbon

deposition; Regularly check the fuel system, make sure do not leak fuel, do not leak air.

Engine Guarantee:

If the NGH engine has performance defects caused by the defects of process, material and manufacturing, we certify

that: Change for free within one year and Guarantee within two years since the date you purchased. Please note the

guarantee is only forthe original purchaser, not including: Normal wear for engine;damage caused by the failureof

maintenance; damage for engineover speed operation caused by using small propeller; Bearing rust; Crash; Use

inappropriate fuel; Damagecaused by foreign bodies; Damage caused by unreasonable installation or operating

environment; Damage caused by improper dismantle; Damage caused by any modification.

Web:www.nghengine.com

E-mail: ngh@ncdmoly.com

Skype: blue-sky-tan

6

Table of contents

Other NGH Engine manuals

Popular Engine manuals by other brands

Vanguard

Vanguard 290000 Operator's manual

Oriental motor

Oriental motor World K Series operating manual

Oriental motor

Oriental motor US Series operating manual

Oriental motor

Oriental motor BMU Series operating manual

HunterDouglas

HunterDouglas M40 TE Instructions and warnings for installation and use

Farymann Diesel

Farymann Diesel K Series Repair manual

Kohler

Kohler Command Pro ECV850 Service manual

Briggs & Stratton

Briggs & Stratton 11000B Operator's manual

Kohler

Kohler K91 Service manual

Briggs & Stratton

Briggs & Stratton 12V800 Series Illustrated parts list

MTU

MTU Detroit Diesel 183 Series Technical publication

XTM Racing

XTM Racing 457 PRO user manual