PRECAUTIONS PRECAUTIONS

NEVER FREE-REV THE MOTOR Free-running your brushless

motor in a no-load condition can result in rotor failure and ESC

transistor damage & will void the product’s warranty!

• WATER & ELECTRONICS DON’T MIX Never allow water, moisture, or

other foreign materials to get inside motor, or on PCBs.

• NOVAK MOTORS & ESCs FOR BEST RESULTS Use Novak sensored

motors with Novak Brushless ESCs for best performance & protection. Only

use motors with the proper number of turns to match ESC’s rating.

Use of this brushless motor with non-Novak ESCs and ESCs that

advance motor timing can result in excessive current draw & severe

motor damage that will NOT be covered by the product’s warranty!

• DO NOT use Ballistic 550-Size 4.5T-5.5T motors above a 3S Li-Po pack.

• INSULATE EXPOSED WIRES Use heat shrink tubing to prevent shorts.

• NO SOLVENTS Do NOT expose the motor to any type of solvents.

• SET GEAR MESH PROPERLY Too tight of a gear mesh can result in

motor pinion shaft breakage--be sure to adjust mesh properly.

NEVER FREE-REV THE MOTOR Free-running your brushless

motor in a no-load condition can result in rotor failure and ESC

transistor damage & will void the product’s warranty!

• WATER & ELECTRONICS DON’T MIX Never allow water, moisture, or

other foreign materials to get inside motor, or on PCBs.

• NOVAK MOTORS & ESCs FOR BEST RESULTS Use Novak sensored

motors with Novak Brushless ESCs for best performance & protection. Only

use motors with the proper number of turns to match ESC’s rating.

Use of this brushless motor with non-Novak ESCs and ESCs that

advance motor timing can result in excessive current draw & severe

motor damage that will NOT be covered by the product’s warranty!

• DO NOT use Ballistic 550-Size 4.5T-5.5T motors above a 3S Li-Po pack.

• INSULATE EXPOSED WIRES Use heat shrink tubing to prevent shorts.

• NO SOLVENTS Do NOT expose the motor to any type of solvents.

• SET GEAR MESH PROPERLY Too tight of a gear mesh can result in

motor pinion shaft breakage--be sure to adjust mesh properly.

MOTOR MAINTENANCE MOTOR MAINTENANCE

• CHECK ALL MOTOR SCREWS for loosening at regular intervals, just like

other hardware on your vehicle. Note: The 3 main socket head screws

that hold the motor together may require tightening after a few runs of

the motor. Also check the 3 flat head screws securing the end cap on

the back of the motor.

• CHECK MOTOR BEARING WEAR after extensive use. The motor’s

closed design will keep most dirt & debris out, but some will get in

and eventually cause wear. If the shaft does not spin freely, you may

need bearing replacement

(replacement bearing accessory kits are available

from Novak)

. A small drop of light oil on the bearings periodically can

help extend bearing life--however, too much oil will attract dirt and will

cause problems, so apply sparingly.

• CLEAN INSIDE MOTOR periodically by removing front end bell,

removing the rotor, and blowing out the inside of the motor with

compressed air.

Be sure not to lose any small shim washers that may be

on the ends of the rotor shaft & keep them in the correct location.

• CHECK ALL MOTOR SCREWS for loosening at regular intervals, just like

other hardware on your vehicle. Note: The 3 main socket head screws

that hold the motor together may require tightening after a few runs of

the motor. Also check the 3 flat head screws securing the end cap on

the back of the motor.

• CHECK MOTOR BEARING WEAR after extensive use. The motor’s

closed design will keep most dirt & debris out, but some will get in

and eventually cause wear. If the shaft does not spin freely, you may

need bearing replacement

(replacement bearing accessory kits are available

from Novak)

. A small drop of light oil on the bearings periodically can

help extend bearing life--however, too much oil will attract dirt and will

cause problems, so apply sparingly.

• CLEAN INSIDE MOTOR periodically by removing front end bell,

removing the rotor, and blowing out the inside of the motor with

compressed air.

Be sure not to lose any small shim washers that may be

on the ends of the rotor shaft & keep them in the correct location.

SERVICE PROCEDURES

Consider changing out motor parts yourself. All of the Ballistic’s main components are

available as service items--Refer to ‘Accessories’ section or check out our website. In

most cases, replacing motor parts is less expensive than sending in your motor for service.

After reviewing instructions, tech section and how-to video section of website, if you feel

your motor requires service

(motor may appear to have failed when other problems exist)

, obtain

the most current product service options & pricing by one of the following methods:

WEBSITE:

Print a copy of the product SERVICE FORM from the SERVICE section of the

Novak website. Fill out the needed information & return it with the Novak product.

PHONE/E-MAIL: Contact our customer service department by phone or e-mail, and

we will supply you with current service options.

WARRANTY SERVICE:

You MUST CLAIM WARRANTY on product SERVICE FORM & include

a valid, itemized receipt with the purchase date on it, or an invoice from previous service

work. If warranty provisions have been voided, there will be a service fee.

ADDITIONAL NOTES:

•

Dealers/distributors are not authorized to replace products thought to be defective.

•

If a hobby dealer returns your product for service, submit a completed product SERVICE

FORM to dealer & make sure it’s included with items.

PRODUCT WARRANTY

Novak Brushless motors are guaranteed to be free from defects in materials or workmanship for a period of 120 days

from the original date of purchase (verified by dated, itemized sales receipt). Warranty does not cover incorrect instal-

lation, components worn by use, cross-connection of battery/motor power wires, overheating solder tabs, damage

resulting from thermal overload or operation above 175°F, use of excessive timing or overheating, splices or damage to

the sensor harness, damage from disassembling motor, tampering with internal electronics, allowing water, moisture,

or any other foreign material to enter motor or get onto the PC board, short-circuiting of motor by allowing exposed

wiring or solder tabs to cross-connect or ESC applying simultaneous power to more than one phase at a time from

switching to Brush Mode, free-revving motor, or any damage caused by a crash, flooding, or natural disaster. In no case

shall our liability exceed the product’s original cost. We reserve the right to modify warranty provisions without notice.

Because Novak R/C, Inc. has no control over the connection & use of motor or other related electronics, no liability may

be assumed nor will be accepted for damage resulting from the use of this product. Every motor is thoroughly tested and

cycled before leaving our facility and is, therefore, considered operational. This product is not a toy, and is not intended

for use by children under 14 years of age without the strict supervision of an adult. Use of this product in a uncontrolled

manner may result in physical damage or injuries. Take extra care when operating any remote control vehicle. By the act

of connecting/operating speed control, the user accepts all resulting liability.

• (949) 916-6044 • Monday-Thursday

©Novak R/C, Inc. California, U.S.A. • 55-3600-1.J • 4/2014

No part of these instructions may be reproduced without the written permission of Novak R/C, Inc.

All Rights Reserved. Novak motors are proudly designed in the U.S.A.

SERVICE PROCEDURES

Consider changing out motor parts yourself. All of the Ballistic’s main components are

available as service items--Refer to ‘Accessories’ section or check out our website. In

most cases, replacing motor parts is less expensive than sending in your motor for service.

After reviewing instructions, tech section and how-to video section of website, if you feel

your motor requires service

(motor may appear to have failed when other problems exist)

, obtain

the most current product service options & pricing by one of the following methods:

WEBSITE:

Print a copy of the product SERVICE FORM from the SERVICE section of the

Novak website. Fill out the needed information & return it with the Novak product.

PHONE/E-MAIL: Contact our customer service department by phone or e-mail, and

we will supply you with current service options.

WARRANTY SERVICE:

You MUST CLAIM WARRANTY on product SERVICE FORM & include

a valid, itemized receipt with the purchase date on it, or an invoice from previous service

work. If warranty provisions have been voided, there will be a service fee.

ADDITIONAL NOTES:

•

Dealers/distributors are not authorized to replace products thought to be defective.

•

If a hobby dealer returns your product for service, submit a completed product SERVICE

FORM to dealer & make sure it’s included with items.

PRODUCT WARRANTY

Novak Brushless motors are guaranteed to be free from defects in materials or workmanship for a period of 120 days

from the original date of purchase (verified by dated, itemized sales receipt). Warranty does not cover incorrect instal-

lation, components worn by use, cross-connection of battery/motor power wires, overheating solder tabs, damage

resulting from thermal overload or operation above 175°F, use of excessive timing or overheating, splices or damage to

the sensor harness, damage from disassembling motor, tampering with internal electronics, allowing water, moisture,

or any other foreign material to enter motor or get onto the PC board, short-circuiting of motor by allowing exposed

wiring or solder tabs to cross-connect or ESC applying simultaneous power to more than one phase at a time from

switching to Brush Mode, free-revving motor, or any damage caused by a crash, flooding, or natural disaster. In no case

shall our liability exceed the product’s original cost. We reserve the right to modify warranty provisions without notice.

Because Novak R/C, Inc. has no control over the connection & use of motor or other related electronics, no liability may

be assumed nor will be accepted for damage resulting from the use of this product. Every motor is thoroughly tested and

cycled before leaving our facility and is, therefore, considered operational. This product is not a toy, and is not intended

for use by children under 14 years of age without the strict supervision of an adult. Use of this product in a uncontrolled

manner may result in physical damage or injuries. Take extra care when operating any remote control vehicle. By the act

of connecting/operating speed control, the user accepts all resulting liability.

• (949) 916-6044 • Monday-Thursday

©Novak R/C, Inc. California, U.S.A. • 55-3600-1.J • 4/2014

No part of these instructions may be reproduced without the written permission of Novak R/C, Inc.

All Rights Reserved. Novak motors are proudly designed in the U.S.A.

ACCESSORIES ACCESSORIES

BALLISTIC

MOTOR INSTRUCTIONS

BALLISTIC

MOTOR INSTRUCTIONS

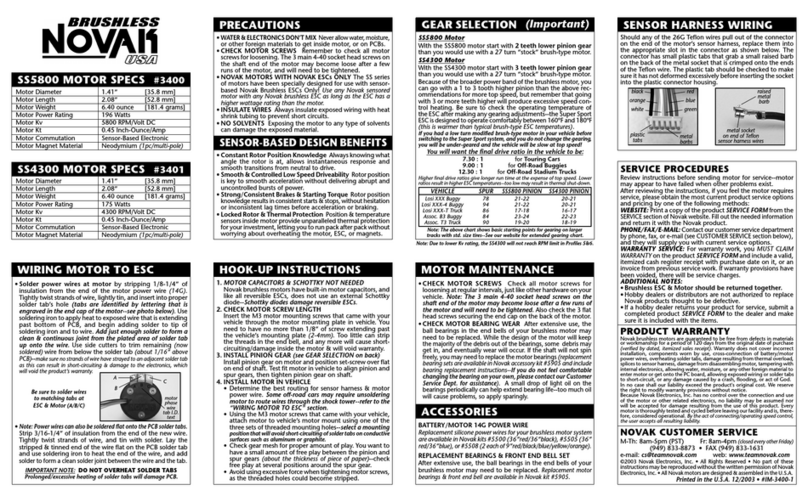

black

orange

white

black

orange

white

plastic

tabs plastic

tabs

red

blue

green

red

blue

green

metal

barbs metal

barbs

raised

metal

barb

raised

metal

barb

metal socket on end of

Teflon sensor harness wires metal socket on end of

Teflon sensor harness wires

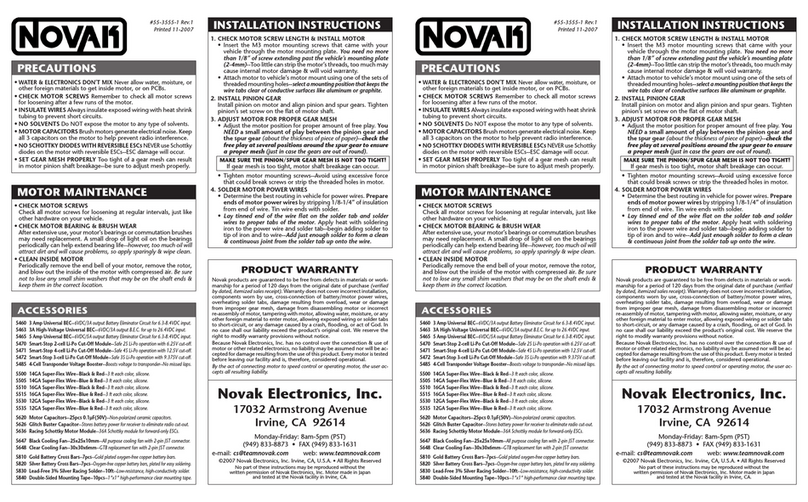

Should any of the 26G Teflon wires pull out of the motor’s sensor

harness connector, re-insert them in the connector’s appropriate

slot as shown below. There is a small plastic tab that grabs a small

raised barb on the back of the metal socket crimped onto the Teflon

wire’s end. Check the plastic tab to make sure it has not deformed

excessively before inserting the socket into the plastic connector

housing with the barb toward the plastic tabs.

Note: Remove or loosen the bearing cap to remove or insert a sensor harness.

Should any of the 26G Teflon wires pull out of the motor’s sensor

harness connector, re-insert them in the connector’s appropriate

slot as shown below. There is a small plastic tab that grabs a small

raised barb on the back of the metal socket crimped onto the Teflon

wire’s end. Check the plastic tab to make sure it has not deformed

excessively before inserting the socket into the plastic connector

housing with the barb toward the plastic tabs.

Note: Remove or loosen the bearing cap to remove or insert a sensor harness.

SENSOR HARNESS WIRING SENSOR HARNESS WIRING

5351 Brushless Shielded Sensor Harness--4”--Double-ended motor sensor harness.

5352 Brushless Shielded Sensor Harness--6”--Double-ended motor sensor harness.

5353 Brushless Shielded Sensor Harness--9”--Double-ended motor sensor harness.

5508

14GA Brushless Wire Set

--2 pieces each of 9” silicone blue, yellow, orange, black & red.

5509

16GA Brushless Wire Set

--2 pieces each of 9” silicone blue, yellow, orange, black & red.

5512 12GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

5514 14GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

5626 Glitch Buster Capacitor--Stores battery power for receiver to eliminate radio cut-out.

5647 Black Cooling Fan--25x25x10mm--All purpose cooling fan with 2-pin JST connector.

5649 Black Cooling Fan--25x25x10mm--Cooling fan with 2mm Mini plug installed.

5731

3.5mm Power Connectors/5 pair

--Gold plated low-loss connectors for 12-14G wire.

5741

4mm Power Connectors/5 pair

--Gold plated low-loss high-amp 12-14G connectors.

5831 Lead-Free 3% Silver Solder--6g--Low-resistance, high-conductivity solder.

5832 Lead-Free 3% Silver Solder--15g Tube--Low-resistance, high-conductivity solder.

5836 Heavy Duty Lead-Free 3% Silver Solder--25g Tube--Thicker 1.5mm solder.

5850

Heat Shrink Tubing Assortment--6pcs-

-6” pieces in 6 sizes from 1/16-3/8”--Black.

5851

Heat Shrink Tubing Assortment--24pcs

--6” pieces in 6 sizes from 1/16-3/8”--Black.

5852

Heat Shrink Tubing Assortment--40pcs

--1” pieces in 1/4” size--20 each of Red & Black.

5853 Heat Shrink Tubing Box Set--160pcs--4” pieces in 6 sizes from 1/16-3/8”--Black.

5861

Pro Solder Flux--10ml

--Liquid rosin flux for easy soldering of lead-free solders--Dropper bottle.

S5903

Motor Insulator Pack--Replacement paper disk, fiberglass cover & silicone grommet.

5909 Sintered 13mm Tuning Rotor--High-power 540 neodymium tuning rotor.

5925

Ballistic 540 Vented End Bell Kit

--

Front & rear end bells with machined cooling vents.

S5932 Motor Hardware Kit/540--Replacement motor screws & shim washers.

S5933 Motor Hardware Kit/550--Replacement motor screws & shim washers.

5935 Ceramic Ball Bearing/ABEC-5--Non-flanged rear 1/8”I.D. ceramic bearing.

5936 Ceramic Ball Bearing/ABEC-5--

Non-flanged front 3/16”I.D. ceramic bearing.

5937 Steel Ball Bearings/ABEC-3--Replacement rear 1/8”I.D. steel bearings.

5938 Steel Ball Bearings/ABEC-3--Replacement front

3/16”I.D.

steel bearings.

5939 Steel Ball Bearings/ABEC-3--Replacement 5mm

”I.D.

front steel bearings for 550.

5940

Ballistic Front End Bell/Closed & Bearing

--Black anodized/Ribbed/Bearing installed.

5941 Sintered 12.3mm Rotor--Replacement Ballistic 540 sintered neodymium rotor.

S5942 Timing/Sensor Assembly--Replacement timing & sensor section of 540/550 motor.

S5943

Bearing Cap/Back Bearing

--Replacement bearing cap with non-exposed, factory-installed bearing.

S5944 Back End Bell/Closed--Replacement back end bell of motor. Black anodized/Ribbed.

S5946

B

earing Cap/Ceramic Bearing

--Bearing cap/Non-exposed, installed ceramic bearing.

5947

Ballistic 550 Front End Bell/Bearing

--Black anodized/Ribbed/Factory-installed bearing.

5948 Ballistic 550 Rotor--Replacement 12.3mm high-power sintered neodymium rotor.

5950

Crawler Sintered Tuning Rotor

--14mm high-power sintered neodymium tuning rotor.

S6625 Ballistic Hand-Wound Stator--25.5T--Interchangeable Ballistic 25.5-turn stator.

5351 Brushless Shielded Sensor Harness--4”--Double-ended motor sensor harness.

5352 Brushless Shielded Sensor Harness--6”--Double-ended motor sensor harness.

5353 Brushless Shielded Sensor Harness--9”--Double-ended motor sensor harness.

5508

14GA Brushless Wire Set

--2 pieces each of 9” silicone blue, yellow, orange, black & red.

5509

16GA Brushless Wire Set

--2 pieces each of 9” silicone blue, yellow, orange, black & red.

5512 12GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

5514 14GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

5626 Glitch Buster Capacitor--Stores battery power for receiver to eliminate radio cut-out.

5647 Black Cooling Fan--25x25x10mm--All purpose cooling fan with 2-pin JST connector.

5649 Black Cooling Fan--25x25x10mm--Cooling fan with 2mm Mini plug installed.

5731

3.5mm Power Connectors/5 pair

--Gold plated low-loss connectors for 12-14G wire.

5741

4mm Power Connectors/5 pair

--Gold plated low-loss high-amp 12-14G connectors.

5831 Lead-Free 3% Silver Solder--6g--Low-resistance, high-conductivity solder.

5832 Lead-Free 3% Silver Solder--15g Tube--Low-resistance, high-conductivity solder.

5836 Heavy Duty Lead-Free 3% Silver Solder--25g Tube--Thicker 1.5mm solder.

5850

Heat Shrink Tubing Assortment--6pcs-

-6” pieces in 6 sizes from 1/16-3/8”--Black.

5851

Heat Shrink Tubing Assortment--24pcs

--6” pieces in 6 sizes from 1/16-3/8”--Black.

5852

Heat Shrink Tubing Assortment--40pcs

--1” pieces in 1/4” size--20 each of Red & Black.

5853 Heat Shrink Tubing Box Set--160pcs--4” pieces in 6 sizes from 1/16-3/8”--Black.

5861

Pro Solder Flux--10ml

--Liquid rosin flux for easy soldering of lead-free solders--Dropper bottle.

S5903

Motor Insulator Pack--Replacement paper disk, fiberglass cover & silicone grommet.

5909 Sintered 13mm Tuning Rotor--High-power 540 neodymium tuning rotor.

5925

Ballistic 540 Vented End Bell Kit

--

Front & rear end bells with machined cooling vents.

S5932 Motor Hardware Kit/540--Replacement motor screws & shim washers.

S5933 Motor Hardware Kit/550--Replacement motor screws & shim washers.

5935 Ceramic Ball Bearing/ABEC-5--Non-flanged rear 1/8”I.D. ceramic bearing.

5936 Ceramic Ball Bearing/ABEC-5--

Non-flanged front 3/16”I.D. ceramic bearing.

5937 Steel Ball Bearings/ABEC-3--Replacement rear 1/8”I.D. steel bearings.

5938 Steel Ball Bearings/ABEC-3--Replacement front

3/16”I.D.

steel bearings.

5939 Steel Ball Bearings/ABEC-3--Replacement 5mm

”I.D.

front steel bearings for 550.

5940

Ballistic Front End Bell/Closed & Bearing

--Black anodized/Ribbed/Bearing installed.

5941 Sintered 12.3mm Rotor--Replacement Ballistic 540 sintered neodymium rotor.

S5942 Timing/Sensor Assembly--Replacement timing & sensor section of 540/550 motor.

S5943

Bearing Cap/Back Bearing

--Replacement bearing cap with non-exposed, factory-installed bearing.

S5944 Back End Bell/Closed--Replacement back end bell of motor. Black anodized/Ribbed.

S5946

B

earing Cap/Ceramic Bearing

--Bearing cap/Non-exposed, installed ceramic bearing.

5947

Ballistic 550 Front End Bell/Bearing

--Black anodized/Ribbed/Factory-installed bearing.

5948 Ballistic 550 Rotor--Replacement 12.3mm high-power sintered neodymium rotor.

5950

Crawler Sintered Tuning Rotor

--14mm high-power sintered neodymium tuning rotor.

S6625 Ballistic Hand-Wound Stator--25.5T--Interchangeable Ballistic 25.5-turn stator.