NHP XTerra Series Manual

XTERRA SERIES

Horizontal and Vertical,

Single and Dual Stage Geothermal Heat Pumps:

FORCAIR

AQUA2

SOURC3

TERRA SERIES

ENERGY EXTRACTION SYSTEM

TABLE OF CONTENTS

Serial Number Breakdown 2

Model Descriptions 2

Physical Data & Dimensions 3

General Information 6

Closed Loop Applications 7

Open Loop Applications 10

HydronicHeat 12

Storage Tanks 13

Electrical 16

Thermostats 17

Desuperheater 21

StartUp 23

Troubleshooting 24

Warranty 26

INSTALLATION

And Maintenance Manual

NORTHERN HEAT PUMP

XTERRA SERIES

Horizontal and Vertical,

Single and Dual Stage Geothermal Heat Pumps:

FORCAIR

AQUA2

SOURC3

TABLE OF CONTENTS

Serial Number Breakdown 2

Model Descriptions 2

Physical Data & Dimensions 4

General Information 7

Closed Loop Applications 8

Open Loop Applications 11

Hydronic Heat 13

Storage Tanks 14

Electrical 17

Thermostats 18

Desuperheater 22

StartUp 24

Troubleshooting 25

Warranty 27

TERRA SERIES

ENERGY EXTRACTION SYSTEM

Page 2

MODEL # DESCRIPTION

SERIAL # DESCRIPTION

XL 08 01 A 1000 A

BILL OF MFG

YEAR OF MFG

MONTH OF MFG

MFG LOCATION

A=SOUTH RAILWAY PLANT

SEQUENTIAL NUMBER

FUTURE USE

A=LINE NUMBER

RA VE 502 - C 1 3 1

UNIT DESIGNATION

R=RESIDENTIAL

UNIT TYPE

A=STANDARD

M=MULTI

D=DUAL COMPRESSOR

S=SPECIAL

W=HEAT ONLY

T=TWO SPEED

P=MINI

UNIT STYLE

W=HYDRONIC

V=VERTICAL

D=DOWNFLOW

H=HORIZONTAL

S=SPLIT

REFRIGERANT TYPE

E=R410A REFRIGERANT

F=R22 REFRIGERANT

NORMAL SIZE

X 1000 BTU/H

DESUPERHEATER OPTION

1=NONE

2=PARTIAL DESUPERHEATER

3=FULL TIME

BLOWER TYPE

1=None

2=Standard PSC 3 Speed Blower

3=ECM Blower

CONFIGURATION

1=LEFT SIDE RETURN (STD)

2=RIGHT SIDE RETURN

3=NONE

HEAT EXCHANGER

C=COPPER

F=S.S. FLATPLATE

H=CUPRO HYDRONIC LOOP

N=CUPRO NICKEL

RESIDENTIAL MODEL # DESCRIPTION

POWER SUPPLY

1=208/230V 1Ph

2=208/230V 3Ph

3=575V 3Ph

4=460/480V 3PH

5=220/240V 1PH 50HZ

6=380V 3PH 50HZ

Page 3

SERIAL # DESCRIPTION

XL 08 01 A 1000 A

BILL OF MFG

YEAR OF MFG

MONTH OF MFG

MFG LOCATION

A=SOUTH RAILWAY PLANT

SEQUENTIAL NUMBER

FUTURE USE

A=LINE NUMBER

CD WE 114 2 - C 1 1

UNIT DESIGNATION

C=COMMERCIAL

UNIT TYPE

A=STANDARD

M=MULTI

D=DUAL COMPRESSOR

S=SPECIAL

W=HEAT ONLY

T=TWO SPEED

P=MINI

UNIT STYLE

W=HYDRONIC

V=VERTICAL

D=DOWNFLOW

H=HORIZONTAL

S=SPLIT

REFRIGERANT TYPE

E=R410A REFRIGERANT

F=R22 REFRIGERANT

NORMAL SIZE

X 1000 BTU/H DESUPERHEATER OPTION

1=NONE

2=PARTIAL DESUPERHEATER

3=FULL TIME

BLOWER TYPE

1=None

2=Standard PSC 3 Speed Blower

3=ECM Blower

HEAT EXCHANGER

C=COPPER

F=S.S. FLATPLATE

H=CUPRO HYDRONIC LOOP

N=CUPRO NICKEL

COMMERCIAL MODEL # DESCRIPTION

POWER SUPPLY

1=208/230V 1Ph

2=208/230V 3Ph

3=575V 3Ph

4=460/480V 3PH

5=220/240V 1PH 50HZ

6=380V 3PH 50HZ

XTerra Physical Data - R22

MODEL RA*F36 RA*F48 RA*F61 RA*F68

Compressor -1 Each SCROLL

Factory Charge R22 -(oz) 72 80 88 96

PSC Fan Motor & Blower

Fan Motor Type/Speeds PSC/3 PSC/3 PSC/3 PSC/3

Fan Motor HP 0.5 0.5 0.75 0.75

Blower Wheel Size Dia. x W 9x9 9x9 10x10 10x10

ECM Fan Motor & Blower –OPTIONAL

Fan Motor Type ECM ECM ECM ECM

Fan Motor HP 0.5 0.5 0.75 1.0

Water Connection Size

Residential Class 3/4” 3/4” 3/4” 3/4

HWG Water Connection Size

Residential Class 3/4” 3/4” 3/4” 3/4”

FORCAIR/SOURC3 Vertical (Upflow and Downflow)

Air Coil Dimensions H x W 20x20 20x20 20x28 20x28

Air Coil Total Face Area ft2 2.7 2.7 3.8 3.8

Air Coil Tube Size (in) 3/8 3/8 3/8 3/8

Air Coil Fin Spacing (fpi) 12 12 12 12

Air Coil Number of Rows 5 5 5 5

Filter Standard 1” Disposable 20x24 20x24 22x30 22x30

Filter Optional Electrostatic 1” 20x24 20x24 22x30 22x30

Weight– Packaged (lbs) 280 330 375 395

Width of Cabinet 28” 28” 28” 28”

Height 53” 53” 53” 53”

Depth 27” 27” 27” 27”

Horizontal

Air Coil Dimensions HxW 20x20 20x20 20 x 28 20 x 28

Air Coil Total Face Area ft2 2.7 2.7 3.8 3.8

Air Coil Tube Size (in) 3/8 3/8 3/8 3/8

Air Coil Fin Spacing (fpi) 12 12 12 12

Air Coil Number of Rows 5 5 5 5

Filter Standard 1” Disposable 20x24 20x24 22x30 22x30

Filter Optional Electrostatic 1” 20x24 20x24 22x30 22x30

Weight– Packaged (lbs) 290 340 380 400

Width of Cabinet 26” 26” 26” 26”

Height 25” 25” 25” 25”

Depth 58” 58” 58” 58”

AQUA2 Hydronic

Width of Cabinet 27” 27” 27” 27”

Height 25.5” 25.5” 25.5” 25.5”

Depth 28” 28” 28” 28”

Weight– Packaged (lbs) 200 220 235 255

All units have rubber compressor mountings and thermostatic expansion valves.

Data Subject To Change Without Notice.

Page 4

Page 5

XTerra Physical Data - R410A SINGLE STAGE COMPRESSOR

MODEL RA*E36 RA*E50 RA*E57 RA*E70

Compressor -1 Each SCROLL

Factory Charge R22 -(oz) 72 80 88 96

PSC Fan Motor & Blower

Fan Motor Type/Speeds PSC/3 PSC/3 PSC/3 PSC/3

Fan Motor HP 0.5 0.5 0.75 0.75

Blower Wheel Size Dia. x W 9x9 9x9 9x9 10x10

ECM Fan Motor & Blower –OPTIONAL

Fan Motor Type ECM ECM ECM ECM

Fan Motor HP 0.5 0.5 0.75 1.0

Water Connection Size

Residential Class 3/4” 3/4” 3/4” 3/4

HWG Water Connection Size

Residential Class 3/4” 3/4” 3/4” 3/4”

FORCAIR Vertical (Upflow and Downflow)

Air Coil Dimensions H x W 20x20 20x20 20x28 20x28

Air Coil Total Face Area ft2 2.7 2.7 3.8 3.8

Air Coil Tube Size (in) 3/8 3/8 3/8 3/8

Air Coil Fin Spacing (fpi) 12 12 12 12

Air Coil Number of Rows 5 5 5 5

Filter Standard 1” Disposable 20x24 20x24 22x30 22x30

Filter Optional Electrostatic 1” 20x24 20x24 22x30 22x30

Weight– Packaged (lbs) 280 330 375 395

Width of Cabinet 28” 28” 28” 28”

Height 53” 53” 53” 53”

Depth 27” 27” 27” 27”

Horizontal

Air Coil Dimensions HxW 20x20 20x20 20 x 28 20 x 28

Air Coil Total Face Area ft2 2.7 2.7 3.8 3.8

Air Coil Tube Size (in) 3/8 3/8 3/8 3/8

Air Coil Fin Spacing (fpi) 12 12 12 12

Air Coil Number of Rows 5 5 5 5

Filter Standard 1” Disposable 20x24 20x24 22x30 22x30

Filter Optional Electrostatic 1” 20x24 20x24 22x30 22x30

Weight– Packaged (lbs) 290 340 380 400

Width of Cabinet 26” 26” 26” 26”

Height 25” 25” 25” 25”

Depth 58” 58” 58” 58”

AQUA2 Hydronic

Width of Cabinet 27” 27” 27” 27”

Height 25.5” 25.5” 25.5” 25.5”

Depth 28” 28” 28” 28”

Weight– Packaged (lbs) 200 220 235 255

All units have rubber compressor mountings and thermostatic expansion valves.

Data Subject To Change Without Notice.

Page 6

XTerra Physical Data - R410A DUAL STAGE COMPRESSOR

MODEL RT*E30 RT*E40 RT*E51 RT*E60

Compressor -1 Each SCROLL

Factory Charge R22 -(oz) 72 80 96 96

PSC Fan Motor & Blower

Fan Motor Type/Speeds PSC/3 PSC/3 PSC/3 PSC/3

Fan Motor HP 0.5 0.5 0.5 0.75

Blower Wheel Size Dia. x W 9x9 9x9 9x9 10x10

ECM Fan Motor & Blower—OPTIONAL

Fan Motor Type ECM ECM ECM ECM

Fan Motor HP 0.5 0.5 0.5 0.75

Water Connection Size

Residential Class 3/4” 3/4” 3/4” 3/4

HWG Water Connection Size

Residential Class 3/4” 3/4” 3/4” 3/4”

FORCAIR/SOURC3 Vertical (Upflow and Downflow)

Air Coil Dimensions H x W 20x20 20x20 20x28 20x28

Air Coil Total Face Area ft2 2.7 2.7 3.8 3.8

Air Coil Tube Size (in) 3/8 3/8 3/8 3/8

Air Coil Fin Spacing (fpi) 12 12 12 12

Air Coil Number of Rows 5 5 5 5

Filter Standard 1” Disposable 20x24 20x24 22x30 22x30

Filter Optional Electrostatic 1” 20x24 20x24 22x30 22x30

Weight– Packaged (lbs) 280 330 375 395

Width of Cabinet 28” 28” 28” 28”

Height 53” 53” 53” 53”

Depth 27” 27” 27” 27”

Horizontal

Air Coil Dimensions HxW 20x20 20x20 20 x 28 20 x 28

Air Coil Total Face Area ft2 2.7 2.7 3.8 3.8

Air Coil Tube Size (in) 3/8 3/8 3/8 3/8

Air Coil Fin Spacing (fpi) 12 12 12 12

Air Coil Number of Rows 5 5 5 5

Filter Standard 1” Disposable 20x24 20x24 22x30 22x30

Filter Optional Electrostatic 1” 20x24 20x24 22x30 22x30

Weight– Packaged (lbs) 290 340 380 400

Width of Cabinet 26” 26” 26” 26”

Height 25” 25” 25” 25”

Depth 58” 58” 58” 58”

AQUA2 Hydronic

Width of Cabinet 27” 27” 27” 27”

Height 25.5” 25.5” 25.5” 25.5”

Depth 28” 28” 28” 28”

Weight– Packaged (lbs) 200 220 235 255

All units have rubber compressor mountings and thermostatic expansion valves.

Data Subject To Change Without Notice.

GENERAL INFORMATION

XTERRA Series Geothermal heat pumps are designed to

provide maximum efficiency and reliability. Solid and simple

electric controls allow for low maintenance and built in safety

protection. When properly installed and maintained you can

trust Northern Heat Pump.

Page 7

VERTICAL UNIT LOCATION AND MOUNTING

Locate the unit in an indoor area where the ambient

temperature will remain above 7°C. NHP provides 3

removable panels for ease of servicing; front, right and rear

side. Allow enough room to remove panels and for filter

maintenance. Units should be mounted on a vibration

absorbing pad (rubber or extruded polystyrene) slightly

larger than the base to provide isolation between the floor

and the unit. (figure # 1) Water supply should not be hard

plumbed directly with copper pipe as this could transfer any

vibration to living space.

VERTICAL CONDENSATE DRAIN

Vertical FORCAIR and SOURC3 units must have a

condensate drain installed to remove moisture from the

evaporating pan when air conditioning. Vertical forced air

models have an internal trap built into the unit. The

connection must satisfy local plumbing codes. To ensure

free condensate flow the drain line must slope away from

the unit.

Install the condensate drain line into an open drain. (Figure

# 1)

MOVING AND STORAGE

Units should be stored in original packaging in a clean dry

area. Store and move units in normal upright position. Do

not stack units.

SAFETY

Service of refrigerant based equipment can be hazardous

due to system pressure and high voltage electrical energy.

Only trained and qualified service personnel can install,

repair or service refrigerant equipment. The installation

must meet all local electric, plumbing, heating and air

conditioning codes.

WARNING:

Turn off the main switches before performing

service or maintenance to this unit. Electric

shock can cause personal injury.

3/4 FPT Condensate

Drain

Slope away from

unit

Rubber pad

or extruded

polystyrene

HORIZONTAL MOUNTING

Horizontal units may be mounted on any surface that

can support their weight. Typically they are

suspended by threaded rods attached to the unit by

using corner hanging brackets (See Figure # 2).

If the unit is set on an attic floor or similar situation, an

anti-vibration pad similar to the vertical units should be

used to help isolate any noise. All installations should

conform to local codes. Allow enough space to

access electrical panels, compressor compartment

and filter rack.

Figure # 2Figure # 1

INITIAL INSPECTION

Be certain to inspect all cartons and crates as units

are received before signing the freight bill. Verify that

all items received have no physical damage. Report

any damages or shortages on the freight bill. The

purchaser is responsible for filing the necessary

claims with the carrier. Concealed or hidden damages

not discovered until removing packaging must be

reported to the carrier within 15 days of receipt.

WARNING:

Before driving screws into the cabinet check on the inside

of the unit to make sure the screws will not hit any

electrical or refrigeration lines.

HORIZONTAL CONDENSATE DRAIN

Horizontal units are not internally trapped: An

external trap is required. Two drain connections are

located at the radiator end of the cabinet. Use either

connection and plug the remaining connection. Each

unit must also include its own vent for condensate.

(Figure # 3)

The condensate drain incorporates a 3/4” FPT port.

A drain line attached to this port must slope away from

unit and must be properly vented.

Horizontal units should be pitched slightly towards the

drain end by minimum 1/4” to help condensate drain.

DUCTING SYSTEM

All XTERRA Series models include a return duct air

flange and filter rack. Both return and supply ducts

should be isolated with a flexible connection to

minimize vibration transfer to the ducting.

To further reduce noise, both return and supply duct

can be internally insulated the first few feet with duct

board.

Note: Undersized ducting on new or retrofitted

systems can not only increase air noise, it can affect

heat transfer to the building and unit performance.

Size duct to appropriate blower outputs and

building needs.

ELECTRICAL

All electrical and wiring must comply with local code.

Power supplied to the unit must be within the

operating range on the unit’s description and rating

plate.

Condensate Drain

Vent

Slope away

from unit

Condensate Trap

3” drop

Figure # 3

Horizontal

Unit

Page 8

CLOSED LOOP APPLICATIONS

A closed loop system re-circulates the same water/

antifreeze solution through a closed system of under-

ground high-density polyethylene pipe. As the solution

passes through the pipe it collects heat (in the heating

mode) that is being transferred from the relatively warm

surrounding soil through the pipe and into the relatively

cold solution. The solution is circulated back to the heat

pump that extracts its heat and then returns to the

ground to absorb more heat from the earth.

The XTERRA Series heat pumps are designed to oper-

ate on either vertical or horizontal closed loop appli-

cations. ( Figures 4 & 5 ) Vertical loops are typically in-

stalled with a well drilling rig up to 200 feet deep or more.

Horizontal systems are typically installed with excavating

or trenching equipment approximately six to eight feet

deep, depending on geographic location and length of

pipe used. Earth loops must be sized properly for each

particular geographic area and individual capacity re-

quirements. Contact your local installer for loop sizing

requirements in your area.

Vertical Loop

Figure #5

Figure #4

Horizontal Loop

Once closed loops are completed, they must be pressure

tested to ensure integrity.

Once pressure is tested, loop must be purged of all foreign

debris and filled with fluid. All air must be removed at this

time by flushing the system.

Table # 1 shows approximate fluid volumes:

DO NOT Mix more than 25% propylene glycol with water

to achieve a lower than –9°C freeze protection. (See Table

#2) A more concentrated mixture cannot be pumped through

the earth loop at low temperatures. Lack of antifreeze will

cause unit shutdown problems during cold weather

operation (longest unit run time) when the loop temperatures

fall below the freeze protection of the antifreeze. Flow rate

requirements for closed loop solutions are higher than open

loop systems because water temperatures supplied to the

heat pump are generally lower. Typically 2.0 to 3.0 gallons

per minute (GPM) per ton are required for proper

operation of the heat pump and the earth coupled heat

exchanger.

WARNING:

Do NOT use calcium as anti-freeze. Follow IGSHPA

recommendations for the appropriate type and

amount of anti-freeze.

Antifreeze Percentages by Volume

Methanol

25%

21%

18%

16%

10%

100% USP Food Grade

Propylene Glycol

38%

30%

25%

22%

15%

Ethanol 22%

20% 18% 14% 10%

Minimum Temp. for Freeze Protection

-12°C -9°C -8°C -6°C -4°C

Type (10°F) (16°F) (17°F) (21°F) (25°

F)

Table #2

Pipe Size Volume

Polyethylene 3/4” IPS SDR 11 2.8

1” IPS SDR 11 4.5

1-1/4” IPS SDR 11 8.0

1-1/2” IPS SDR 11 10.9

2” IPS SDR 11 18.0

Rubber Hose 1” 3.9

Copper 1” 4.1

1.25” 6.4

1.5” 9.2

Table #1

Approximate Fluid Volume (gal) per 100” of pipe

LOOP PUMP SELECTION

Select a loop circulation pump based upon the gpm

required and total system pressure drop.

Refer to Table # 3.

Pressure/Temperature (P/T) plugs should be installed in

the adaptor elbow on the entering and leaving water line of

the heat pump on a closed system (Figure# 6) A

thermometer can be inserted into the P/T ports to check

entering and leaving water temperatures. A pressure

gauge can also be inserted into these P/T ports to

determine the pressure differential between the entering

and leaving water. This pressure differential can then be

compared to the engineering specifications data to

determine the flow rate of the system.

1” Brass Barb

Heat Pump Adaptor Elbow

P/T Port Plug

3/4 MPT

Figure # 6

Unit LOOP PD PD

Size GPM (FT) (PSI)

3 Ton 4.0 2.7 1.2

8.0 11.3 4.9

4 Ton 6.0 6.2 2.7

11.0 24.2 10.5

5 Ton 8.0 11.5 5.0

13.0 34.6 15.0

6 Ton 10.0 19.6 8.5

14.0 45.7 19.8

Data and specifications may change without notice

Heat Exchanger Pressure Drop

Table # 3

LAKE OR POND LOOPS

Closed loop systems may also be used in lakes or rivers to

supply a heat source to the heat pump.

Typically a loop consisting of geothermal pipe can be

designed and placed in an area not much deeper than 15ft

with some water currents present. In any lake or pond,

municipal and area by-laws must be observed in regards to

a lake or pond loop. The use of an environmentally friendly

loop fluid like ethanol should be considered if the loop was

ever damaged. Consult a IGSHPA certified installer for

proper lake or pond loop design.

WARNING:

Loop design is extremely important for proper heat pump operation. Incorrect loop design will

reduce heat pump efficiency, cause poor performance OR may render the loop unusable. Contact a

IGSHPA certified geothermal loop contractor for proper installations.

Page 9

FLUSHING AND FILLING THE SYSTEM USING 3 WAY

VALVES

Step 1

Use water and a high volume head circulator pump to flush

air and debris and to fill the loop system.

- Refer to recommendations provided by IGSHPA when

choosing a pump for the flushing process.

- It is recommended that pump suction be from the bottom

of a large volume container. Use a suction line strainer to

prevent debris discharged into the container from being

recycled to the system.

Step 2

Pump water into the system by connecting the pump

discharge hose to one (not both) of the 1” NPT water

connections located on the sides of the module.

Connect a return hose to the opposite side of the module to

discharge debris and air as water is added to the loop.

Step 3

Rotate the module valves as shown in step 3 diagram:

Step 4

Start the pump. Add anti-freeze and water to the container

as needed so that no air enters the system. This will push

any air out of the loop. If flushing assembly is equipped with

valves to reverse flow direction, do so occasionally to help

remove trapped air. When bubbles cease in the return hose

container, the earth loop has been completely flushed.

Step 5

Flush the heat pump. To do so, simply rotate the valves as

shown in step 5 diagram while the pump is running. Flush

the heat pump using the same procedure as used to flush

the earth loop.

Pressurizing The System

Step 6

After flushing and filling the system, rotate the module valve

discharging into the flush container as shown in step 6A

diagram to pressurize the loop. Then turn the valves as in

step 6B.

Step 7

Turn off the flush cart pump. The system should remain

pressurized. Release excess pressure by rotating either

module valve to allow a small amount of water to pass

through and out of the system and into the container. Some

initial loss of pressure can be expected and is due to the

expansion of the earth loop pipe under pressure. The

pressure will stabilize if the system has no leaks.

Step 8

Flushing, filling and pressurization should be complete.

Start the loop pump module circulators.

Page 10

To Earth Loop From Earth Loop

From

Flush

Cart

To

Flush

Cart

Step 3

From Heat PumpTo Heat Pump

Step 5 To

Flush

Cart

From

Flush

Cart

Step 9

Troubleshoot. If for some reason the circulators are not

operating, power off and diagnose the problem.

Step 10

Using a single water pressure gauge, measure the pressure

drop at the pressure/temperature plugs across the heat

pump heat exchanger. Compare the measurement with the

flow versus the pressure drop table (Table#3) and determine

the actual flow rate. If the flow rate is low, recheck the

selection of the loop pump module model for sufficient

capacity. If the model is correct, there is likely trapped air or

a restriction in the flow circuit.

System pressure should increase rapidly as the flush pump

works to force more water into the system. Additional

flushing of the loop is needed if the water level in the loop

falls. This shows that there is air in the system.

System operating pressures should be between 10 to 40

PSI.

From Heat Pump To Heat Pump

To Earth Loop From Earth Loop

Step 6B

From Heat PumpTo Heat Pump

Step 6A

From

Flush

Cart

Pressurize Loop

OPEN SYSTEM APPLICATIONS

An open system gets its name from the open discharge of

water after it has been used by the heat pump. A well must

be available that can supply all of the water requirements of

the heat pump along with any other water requirements

drawing off that same well. The well must be capable of

supplying the heat pumps required flow rated for up to 24

hours per day for the coldest winter day.

Figure # 7 shows the necessary components for water

piping of an open system. First a bladder type pressure tank

with a “draw down” of at least 1-1/2 to 2 times the well pump

capacity must be installed on the supply side of the heat

pump to prevent short cycling the well pump. Shut off

valves and boiler drains on the entering and leaving water

lines are necessary for future maintenance. A screen

strainer is placed on the supply line with a mesh size of 40

to 60 and enough surface area to allow for particle buildup

between cleanings. Pressure temperature (P/T) plugs are

placed in the supply and discharge lines so that

thermometers or pressure gauges can be inserted into the

water stream. On the well water discharge side of the heat

pump a flow control/shut off valve must be mounted to

regulate the maximum water flow through the unit. Remove

handle to prevent accidental change of flow.

A solenoid valve is then installed and wired to X & Y terminal

on the heat pump. (See page 15 in Electrical Section) This

valve will open when the unit is running and close when the

unit stops.

A visual flow meter is then installed to allow visual inspection

of the flow requirements. The flow meter can also be useful

in determining when maintenance is required. Schedule 40

PVC piping, copper tubing, polyethylene or rubber hose can

be used for supply and discharge water lines. Limit rubber

hose to 10ft. to prevent excessive pressure drop. Make sure

line sizes are large enough to supply the required flow with a

reasonable pressure drop (generally 1” diameter).

Water discharge is generally made to a drain field, stream,

pond, surface discharge, tile line, or storm sewer.

CAUTION: Using a drain field requires soil conditions and

adequate sizing to assure rapid percolation or the required

flow rates will not be achieved. Consult local codes and

ordinances to assure compliance. DO NOT discharge water

to a septic system. The heat pump should never be

operated with flow rates less than specified. Operation of

the unit with less than required flow rate or no flow may

result in freezing water in the water to refrigerant heat

exchanger. This will cause the unit to shut down on low-

pressure lockout. If the unit locks out, verify that the unit has

the required flow and reset the unit by shutting off power to

the unit for one minute. DO NOT continually reset the unit; if

the unit locks out more than once call your service

professional. Continued reset of the unit can freeze water

inside the water coil to the point of rupturing the water coil.

Open Loop Freeze Protection Switch

Heat pump installations on open loop systems, using a non-

antifreeze protected water source during the heating mode

require the use of a water coil freeze protection switch. If

the water supply to the heat pump is interrupted for any

reason, continued operation of the compressor will cause

the water remaining in the water-to-refrigerant heat

exchanger to freeze and rupture. The freeze protection

switch (low pressure switch) will shut the unit down before

freezing can occur and protect the heat pump against flow

loss and damage.

Water Coil Maintenance

Water quality is a major concern for open systems.

Problems can occur from scaling, particle buildup,

suspended solids, corrosion, pH levels outside the 7-9

ranges, or biological growth. If poor water quality is known

to exist in your area a cupro-nickel water coil may be

required when ordering the system, or installing a closed

loop system may be the best alternative. Water coil

cleaning on an open loop system may be necessary on a

regular basis.

Page 11

Figure # 7 Open System Diagram

Expansion Tank/Water Supply Strainer

Shut Off

Valves

Boiler Drains

Visual Flow meter

Solenoid

Shutoff

Valve

Supply Return Well

In

Out

Adaptor Elbow

With PT Plugs

Page 12

Depending on the specific water quality issue, the water

coil can be cleaned by the following methods:

Chlorine Cleaning (Bacterial Growth)

1. Turn thermostat to “Off” position.

2. Connect a circulating pump to hose bibs on entering

water and leaving waterside of heat exchanger.

3. Using a five-gallon pail of water add chlorine bleach

mixture. The chlorine should be strong enough to kill

the bacteria. Suggested initial mixture is 1 part

chlorine bleach to 4 parts water.

4. Close shut off valves upstream and downstream of heat

exchanger.

5. Open hose bibs to allow circulation of bleach solution.

6. Start pump and circulate solution through heat

exchanger for 15 minutes to one hour. Solution should

change color to indicate the chlorine is killing the

bacteria and removing it from the heat exchanger.

7. Flush used solution down the drain by adding fresh

water supply. Flush until leaving water is clear.

8. Repeat procedure until solution runs clear through the

chlorine circulation process.

9. Flush entire heat pump system with water.

This procedure can be repeated annually,

semiannually, or as often as it takes to keep bacteria

out of the heat exchanger, or when bacteria appears in

a visual flow meter to the point the flow cannot be

read.

Miradic Acid Cleaning

(Difficult Scaling and Particle Buildup Problems)

Consult installer due to dangerous nature of

acids.

Iron out solutions and de-scaling products are also useful.

HYDRONIC HEAT EXCHANGE

Radiant Floor Heating

Hydronic side heat exchangers can be a variety of different

types. Probably the most popular form of hydronic heat

exchanger is radiant floor heat tubing. Radiant floor heating

gives excellent comfort and very high efficiencies by

supplying low temperature water to the floor slab and

keeping the heat concentrated evenly near the floor.

Radiant floor heating systems heat the occupants and

surfaces directly with radiant energy not by heating air that

transfers the heat to the occupants.

Radiant floor heating usually consists of tubing laid in the

slab. The amount and spacing of the tubing is calculated to

meet the capacity of the space being heated. To optimize

the efficiency, the fluid temperature inside the tubing should

be maintained as low as possible. The type of floor covering

and the spacing of the pipe in the floor have the greatest

effect on operating fluid temperature.

NHP designs its hydronic heat pump line using a

46°C (115°F) leaving water design point. This leaving water

temperature is the ideal maximum fluid temperature for

radiant floor systems. Operating temperatures higher than

this would result in less efficient operation and possibly an

uncomfortable condition.

High static pressure fan coils work well with hydronic heat

pumps. These systems, produced by Unico System, Space

Pak and others, provide heating and cooling for houses

without ductwork. They use a high static pressure blower to

supply air through small diameter chase ways to the living

space. The blower passes through a water-to-air coil which

is coupled to a water-to-water heat pump to provide heating

and cooling. These systems work nicely on retrofit

applications where ductwork isn’t available or wanted.

When sizing the fan coil, keep in mind maximum

recommended water temp. LWT 46°C (115°F) . However,

running the heat pump continuously will result in very high

operating pressure and may shorten the life of the unit.

Base Board Heating

Cast iron radiators have been used successfully. If these

radiators are rated for an output of 70 Btuh/square inch at

130°F the system should still operate at the standard 115°F

HYD LWT of the water-to-water heat pump. Some

installations may require additional use of an air handler or

more aggressive finned tube to provide enough heat during

the colder weather.

Other Applications

Open loop hydronic applications (Figure # 8)such as

outdoor swimming pools, hot tubs, whirlpools, tank heating,

etc. are easily sized and based on heat exchanger operating

temperature and flow. Often sizing a heat pump to these

applications comes down to recovery time; the larger the

heat pump (within reason to avoid short cycling), the faster

the system recovery time. Note: Installing a plate heat

exchanger between the heat pump and an open system is

required when corrosive fluid is used in the open loop,

especially on swimming pools where pH imbalance can

damage the heat pump.

Other forms of closed loop systems such as indoor

swimming pools, pretreated fresh air systems, snow melt,

and valance heating/cooling systems are also very common

with water-to-water heat pumps. The sizing of the heat

pump to these systems is more precise and information from

the system manufacture is required. Note: Expect the

maximum operating temperature of an indirect coupled

application to be approximately 12°C below the maximum

operating temperature of the heat pump.

Systems must be constructed to all appropriate codes and

according to accepted plumbing practices.

Should NHP heat pumps be installed in an industrial

application in Europe, the unit will be “fitted with means for

disconnection from the supply mains having a contact

separation in all poles that provide full disconnection under

overvoltage category III, the instructions state that means for

disconnection must be incorporated in the fixed wiring in

accordance with the wiring rules” in Europe.

Fan Coils

Fan coils can be used with NHP hydronic AQUA2 heat

pumps in the heating and cooling mode. In many cases

radiant floor heating and fan coil cooling are used together.

Fan coils also provide dehumidification. Dehumidification

rates can be adjusted by varying the fan coil operating

temperature and air flow.

Fan coils are available in many different sizes and

configurations making them very flexible to your particular

application. Note: When selecting fan coil units for cooling

use, make sure they include condensate drain pans.

Fan coils are sized for capacity at specific water temperature

and flow rate combinations. Their sizing is also based on air

temperatures, airflow rates (which remain constant based on

fan speed selection and static pressure differential), and

humidity conditions. The fan coils are then matched to the

heat pump at a common system flow rate and operating

temperature to provide the overall system capacity to a

space load.

Page 13

In

Out

Supply

Earth Heat Exchanger

Pump Module

SOURC3

Individual Zones

Heat Load

Zone Supply Valves

Zone Return Lines

Pump

Expansion Tank

Hydronic

Hot Water

Storage

Tank

Figure # 8

Pump

Conceptual Drawing Only

STORAGE TANKS

Coupling the heat pump to the space conditioning heat

exchanger through a water storage tank is recommended

(Figure # 9). In fact, the only instance where these storage

tanks are not recommended, is when the heat pump is

coupled to a large heat exchanger capable of absorbing the

entire heating or cooling capacity of the heat pump

requiring high discharge water temperatures. Insulated hot

water heaters are commonly used for storage tanks.

Individual Zones

Heat Load

Zone Supply Valves

Zone Return Lines

Pump

Expansion Tank

Hydronic Hot

Water

Storage

Tank

Figure # 9

Heat

Pump

Pump

Conceptual Drawing Only

In applications that use multiple smaller zones,

storage tanks absorb the relatively large amount of

energy supplied by the compressor to provide longer

run times and less compressor cycling for the heat

pump. Storage tanks also serve to dispense energy in

small amounts so that the conditioned zones have

time to absorb heat without short cycling.

When properly sized, a storage tank eliminates many

problems with multiple zone hydronic systems. These

problems include;

1) Excessive leaving water temperature if a single

zone cannot dissipate heat quickly enough.

2) Flow reduction through the heat pump when only

one zone is calling which can occur because the

pump is normally sized to provide the heat pumps

required flow with all zones calling. When sizing

storage tanks to the heat pump, a good rule of

thumb is 10 gallons of storage tank per ton of

hydronic capacity.

The tank temperature can be controlled with a simple Aqua

stat or a set point controller.

CAUTION

For proper operation adequate water flow must be

achieved through heat pump heat exchangers.

Page 14

CIRCULATION FLUID

The fluid circulating through the hydronic side of the

geothermal heat pump system is the transfer medium for

the heating and cooling being supplied to the conditioned

space. Selection of this fluid is very important. Water is

the most readily available fluid but has the draw back of

expansion during freezing which can damage the system.

Antifreeze must be used wherever the possibility of

freezing exists from the environment or from use of the unit

in the cooling mode. A propylene glycol based antifreeze

and water solution is recommended. Freeze protection for

the hydronic side fluid down to –7 degrees Celsius (20%

propylene glycol) by volume in water is recommended for

most indoor applications.

(Table # 4) Using over 40% solution in hydronic side

applications can cause pumping problems due to high

viscosity.

The water being added to the system should have 100

PPM grains hardness or less. If poor water conditions exist

on the site, softened water is recommended, or acceptable

water should be brought in. Bacteria or algae’s growth in

the water is a possibility, especially bacteria or algae that

thrive at the particular temperatures produced in the

heating system. This growth can cause buildup on hydronic

side heat exchanger surfaces reducing the efficiency of the

system or causing the heat pump to run at higher head

pressures and cut out.

EXPANSION TANKS

Expansion tanks must be used in the hydronic side of the

water-to-water system to absorb the change in pressure of

the closed system due to the change in temperature when

heat is supplied to the system. Diaphragm-type expansion

tanks should be used. The diaphragm in these tanks is filled

with pressurized air which expands or contracts to maintain

constant overall system pressure as the fluid in the system

expands with increasing temperature. Use diaphragm tanks

that are compatible with glycol-based antifreeze fluids (butyl

rubber diaphragms will slowly dissolve with glycol-based

antifreezes). Expansion tanks should be installed in the

system near the suction of the circulator whenever possible.

This maintains positive pressure at the circulator and

reduces the highest working pressure of the system.

Antifreeze Percentages by Volume

Methanol

25%

21%

18%

16%

10%

100% USP Food Grade Propylene Glycol

38%

30%

25%

22%

15%

Ethanol 22%

20% 18% 14% 10%

Type Minimum Temp. for Freeze Protection

-12°C -9°C -8°C -6°C -4°C

(10°F) (16°F) (17°F) (21°F) (25°F)

Table # 4

HYDRONIC SIDE CIRCULATORS

Hydronic circulator pumps transfer the energy supplied by

water-to-water heat pumps to the space conditioning

exchanger. (Figure # 11) When selecting a circulator be

sure to select a pump with the ability to supply the required

flow rate at the system pressure drop. The circulator

supplying the heat pump should be placed in the water

supply line entering the unit to provide the best pump

performance. Individual zone pumps should also be

installed in the supply line to the heated zones.

Small circulator pumps can be used. If these pumps are

impedance protected they do not require additional fusing if

powered directly from the heat pump. If impedance

protected pumps are not used, inline fuses should be

supplied according to code.

A common problem with circulator pumps is trapped air in

the system. This air accumulates in the suction port of the

circulator pump causing cavitations in the pump that leads

noisy operation and premature pump failure. Air can be

eliminated by completely purging the system or by placing

an air separator in the plumbing lines.

The entire system must be purged of air during initial

installation and pressurized to a 20 to 30 psi static pressure

to avoid air entering the system. This initial static pressure

may fluctuate when going from the heating to cooling modes

but should always remain above zero. If a leak in the

system allows the static pressure to drop, the leak must be

repaired to assure proper system operation. If air

continually enters the loop; corrosion, bacteria, or pump

cavitations may occur.

The hydronic side circulator supplying the heat pump should

be controlled to run only when the heat pump is also

running.

Page 15

ELECTRICAL SERVICE

The main electrical service should be fusible and capable of

providing the amperes required by the unit at nameplate

voltage. All wiring shall comply with the national electrical

code and/or any local codes that may apply. Access to the

line voltage contactor is gained through the electrical

knockouts provided on either sides of the heat pump next to

the front corner.

WARNING: The unit must be properly grounded!

WIRING HYDRONIC PUMPS

When supplying water pumps off the system power supply,

use impendence protected motors. The module can be

wired directly to the contactor and grounded in the

grounding lug. A relay (RP) and terminal block (BP) are

supplied in the electrical box for the hydronic side pumps.

The relay will start the pump with a call from the aqua stat

on SOURC3 units. The pump relay is activated by power to

G on the terminal strip (BT) of hydronic units (wire G to X).

The use of impedance-protected pumps eliminates the need

for additional fusing. Do not connect more than a 1/3-horse

power pump to the internal pump relay.

If larger pumps are required or impedance protected pumps

are not used, a separate power supply is required. To start

this pump use a 24-volt relay controlled from the Y and X

terminals.

24-VOLT CONTROL CIRCUIT

Transformer

An electrical diagram is provided to operate all control

features of the heat pump. The transformer can be quickly

overloaded when using it for additional control equipment

like zone valves or fan coil relays.

On more complicated control systems transformer capacity

is used up quickly.

If the systems external controls require more than

40 VA of power from the transformer an external transformer

must be used. The heat pump’s transformer can generally

power simpler control systems consisting of a few relays or

zone valves (depending of course on the VA draw of the

components).

The SOURC3 heat pump requires at least two temperature

controls. The first is a forced air heat pump thermostat

connected directly to the terminal strip. This thermostat

controls forced air heating and cooling as any thermostat

would. The second control is a aqua stat, which is powered

from R on the terminal strip, through the aqua stat, and back

to H on the low voltage thermostat block in the heat pump.

ELECTRICAL

The aqua stat tells the heat pump when hydronic side water

heating is required and when the hydronic side is satisfied.

The SOURC3 combination heat pump can only run one

mode at a time (one thermostat must have priority over the

other). Any number or types of thermostats, aqua stats, or

switches can be used with an independent power supply

(typically a 24 volt transformer) to activate specific zone

controls. These zone controls are normally either a zone

pump or zone valves. End switches on the zone valves can

be used to pass a signal to a pump relay when the zone

valve is open. The pump relay then activates a common

pump, which supplies any number of zones.

NOTE: A common maximum aqua stat set point is

46°C (115°F). The tank will then shut down when it reaches

46°C however the leaving water temperature from the heat

pump is actually higher (near the maximum operating

temperature). The Aqua stat maximum set point should limit

the head pressure of the heat pump to 325 psi.

If the thermostat is equipped with an anticipator it should be

set to its lowest setting to avoid interfering with heat pump

operation.

Digital Timer

The timer performs the following functions which control the

compressor operation: system lockout, compressor anti-

short cycle, and a five minute delay after power is applied.

System lockout occurs if the high pressure and low pressure

switches open. The timer blocks the signal from the

thermostat to the contactor to energize the compressor.

This lockout condition means that the unit has shut itself

down to protect itself, and will not come back on until power

has been disconnected (circuit breaker) to the heat pump.

Problems that could cause a lockout situation include:

1. Water flow problems

2. Air flow problems

3. Internal heat pump operation problems

4. Cold ambient air temperature conditions

If a lockout condition exists, the heat pump should not be

reset more than once and a service technician should be

called immediately. The cause of the lockout must be

determined or repeated reset damage may occur to the

system.

The anti-short cycle function puts a time-out period of ten

minutes on the compressor before re-starting. This function

protects the compressor from repeated on/off operation in

the event of a loose wire or faulty controller.

Page 16

Page 17

SOURC3 Wiring Diagram Figure #12

FORCAIR Wiring Diagram Figure #11

Thermostat/Aqua stat

Consult the instructions in the thermostat box for proper

mounting and thermostat operation.

CAUTION:

Improper wiring of controls may result in transformer

burnout.

Power is supplied to the thermostat by connecting the R and

X terminals to the heat pump terminal strip. The Y terminal

energizes the compressor. The unit is put into the cooling

mode when the thermostat energizes the O terminal which

operates the reversing valve. A compressor lockout is

indicated by the L terminal, which is used to power the

lockout LED on a thermostat or an external 24-volt lockout

light.

On hydronic AQUA2 and SOURC3 units the pump relay (RP)

is connected to the circulation pump high voltage connection

block (BP). The hydronic side circulation pump receives

power from BP, which is energized by RP. Running a jumper

wire from Y to G on the terminal strip (BP) of a hydronic unit

will bring the circulation pump on seconds before the

compressor to prove water flow. The hydronic pump relay

(RP) on a SOURC3 unit energizes automatically when the

system runs in the hydronic mode.

Page 18

R

G

O

Y

W2A

W2

L

X

H

E

24 Volt Power

Fan

Reversing Valve

Compressor

Second Stage Auxiliary

Second Stage Electric

Lockout Indicator

Common

Hydronic (Sourc3)

Emergency Relay

Block Terminal – Thermostat

Block terminals have the following input functions:

AQUA2 Wiring DiagramFigure #13

Second Stage Duct Heater - SOURC3 Model

Since the SOURC3 model can run in either forced air mode

or hydronic mode, second stage must be wired through W2

and W2A as shown below:

Second Stage Duct Heater - FORCAIR Model

A second stage electric duct heater can be added in

conjunction with a XTERRA Series heat pump to help

supplement heat if required. This duct heater can also act

as an emergency backup if the heat pump should fault for

any reason.

A two stage thermostat is required to activate the second

stage. On a FORCAIR model heat pump, wire the second

stage as shown below:

A simple, single stage heating aqua stat on a storage

tank or wall mounted thermostat may be all that is

required for simple heat only systems. This

thermostat closes and passes power to the Y terminal

(H terminal for SOURC3 units), energizing the

compressor and circulation pumps in the heating

mode. When mounting aqua stats inside storage

tanks. Always use submergible or submersible type

aqua stats.

A cooling aqua stat can be mounted on the water

supply line. This aqua stat acts as a low limit switch,

which shuts the heat pump down when the cooling

water reaches a set minimum temperature (e.g. 2°C).

Changeover from heating to cooling can be achieved in two

ways:

1) With a manual toggle switch to select the

control aqua stat (heating or cooling)

2) A cooling thermostat which powers the coil of

a single pole/double throw relay which selects

the heating aqua stat (normally closed

contacts) or cooling aqua stat (normally open

contacts). NOTE: Always wire the system to shut

down (anti-short cycle) between a heating and cooling

changeover mode. Nuisance trip-outs may occur

from changing modes on the “fly”.

Page 19

Forced Air or Hydronic Priority SOURC3 Model

The XTERRA Series SOURC3 heat pump is capable of

either priority forced air or hydronic water heating. The unit

is set to priority forced air at the factory. To set the unit to

priority hydronic water heating: Move the Red wire (G— #8

RE) from the “G” terminal to terminal “E” as shown below:

24 Volt Power

Fan

Reversing Valve

Compressor

Second Stage Auxiliary

Second Stage Electric

Lockout Indicator

Common

Hydronic (Sourc3)

Emergency Relay

R

G

O

Y

W2A

W2

L

X

H

E

Call From

Thermostat

Duct Heater Relay

Red Wire RE #8

Forced Air

Priority

Hydronic

Priority

OR

R

G

O

Y

W2A

W2

L

X

H

E

24 Volt Power

Fan

Reversing Valve

Compressor

Second Stage Auxiliary

Second Stage Electric

Lockout Indicator

Common

Hydronic (SOURC3)

Emergency Relay Red Wire RE #8

24 Volt Power

Fan

Reversing Valve

Compressor

Second Stage Auxiliary

Second Stage Electric

Lockout Indicator

Common

Hydronic (Sourc3)

Emergency Relay

R

G

O

Y

W2A

W2

L

X

H

E

Call From

Thermostat

Duct Heater Relay

Electrical Data R22

Xterra Series FORCAIR (V,H)

Compressor Without Pumps

Voltage Fan Total Min. Max. Fuse

Model (60 Hz) RLA LRA FLA FLA Ampac. Ckt Bkr.

16 208/230-1 10 41.0 2 12.0 14.5 20

18 208/230-1 10.7 45.0 2 12.7 15.4 20

22 208/230-1 12.1 54.0 2 14.1 17.1 30

24 208/230-1 13.6 63.0 2 15.6 19.0 30

36 208/230-1 17.9 100.0 4.3 22.2 26.7 40

208-3 11.4 77.0 4.3 15.7 18.6 30

48 208/230-1 24.4 150.0 4.3 28.7 34.8 50

208-3 16.4 91.0 4.3 20.7 24.8 40

575-3 6.4 37.0 4.3 10.7 12.3 15

61 208/230-1 32.1 148.0 5.0 37.1 45.1 70

208-3 19.3 137.0 5.0 24.3 29.1 40

575-3 7.9 50.0 5.0 12.9 14.8 20

68 208/230-1 32.1 176.0 5.0 37.1 45.1 70

208-3 20.7 156.0 5.0 25.7 30.9 50

575-3 8.2 54.0 5.0 13.2 15.3 20

Xterra Series AQUA2

Compressor Without Pumps

Voltage Pump/s Total Min. Max. Fuse

Model (60 Hz) RLA LRA FLA FLA Ampac. Ckt Bkr.

36 208/230-1 17.9 100.0 2.2 20.1 24.6 40

208-3 11.4 77.0 2.2 13.6 16.5 30

48 208/230-1 24.4 150.0 2.2 26.6 32.7 50

208-3 16.4 91.0 2.2 18.6 22.7 40

575-3 6.4 37.0 2.2 8.6 10.2 15

61 208/230-1 32.1 148.0 4.4 36.5 44.5 70

208-3 19.3 137.0 4.4 23.7 28.5 40

575-3 7.9 50.0 4.4 12.3 14.2 20

68 208/230-1 32.1 176.0 4.4 36.5 44.5 70

208-3 20.7 156.0 4.4 25.1 30.3 50

575-3 8.2 54.0 4.4 12.6 14.7 20

Special 208-3 18.9 146.0 11.4 30.3 35.0 40

575-3 6.7 60.0 2.2 8.9 10.6 15

400-3 9.5 73.0 2.2 11.7 14.1 20

Xterra Series SOURC3

Compressor 1/3 HP Without Pumps

Voltage Pump Fan Total Min. Max. Fuse

Model (60 Hz) RLA LRA FLA FLA FLA Ampac. Ckt Bkr.

36 208/230-1 17.9 100.0 2.2 4.3 22.2 26.7 40

208-3 11.4 77.0 2.2 4.3 15.7 18.6 30

48 208/230-1 24.4 150.0 2.2 4.3 28.7 34.8 50

208-3 16.4 91.0 2.2 4.3 20.7 24.8 40

575-3 6.4 37.0 2.2 4.3 10.7 12.3 15

61 208/230-1 32.1 148.0 2.2 5.0 37.1 45.1 70

208-3 19.3 137.0 2.2 5.0 24.3 29.1 40

575-3 7.9 50.0 2.2 5.0 12.85 14.8 20

68 208/230-1 32.1 176.0 5.0 37.1 69.2 77.2 70

208-3 20.7 156.0 2.2 5.0 25.7 30.9 50

575-3 8.2 54.0 2.2 5.0 13.2 15.3 20

*575vac units require dual voltage (208/230 voltage for pumps and blower).

Due to continuing product improvements data may change without notice.

Page 20

Table of contents

Popular Heat Pump manuals by other brands

Gree

Gree GPC12AL-K5NNA3A Service manual

Vagner Pool

Vagner Pool Rapid Series Installation and user manual

AES

AES Remora f6 manual

Johnson Controls

Johnson Controls HMH7 Series User's information manual

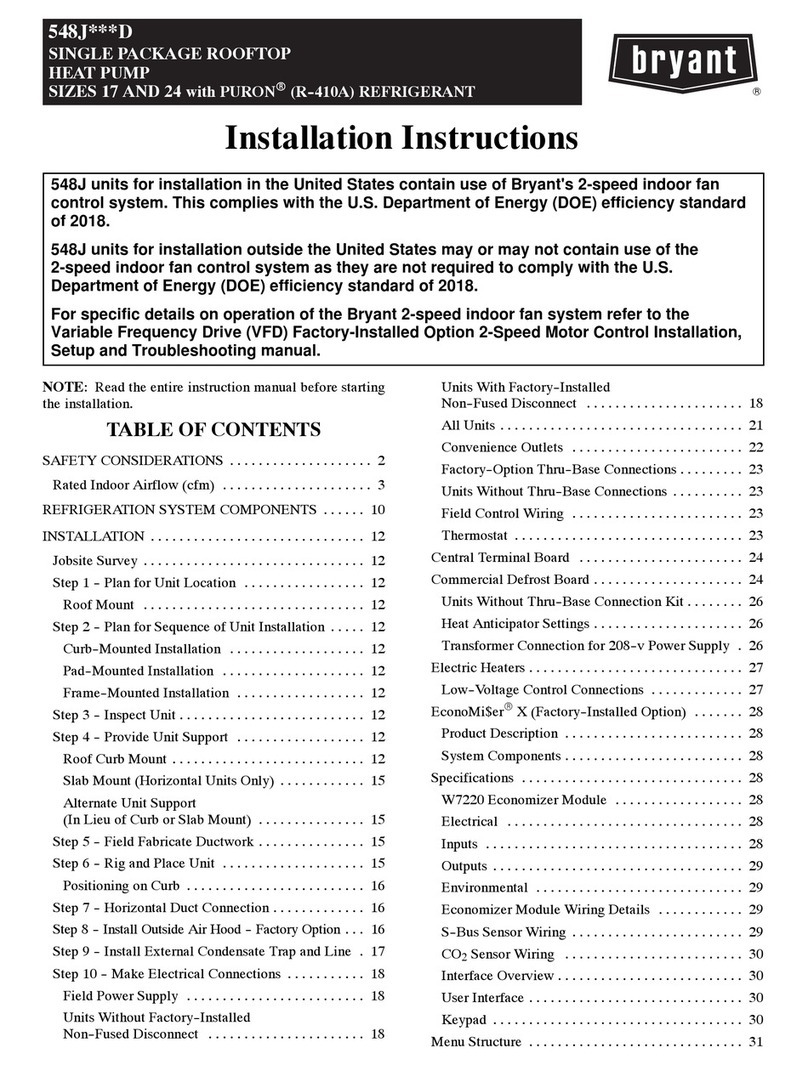

Bryant

Bryant 548J*D Series installation instructions

STIEBEL ELTRON

STIEBEL ELTRON WPF 5 Operating and installation instructions