3

1.5 Important information

Heat pumps must only be installed

and maintained by qualified con-

tractors.

Heat pump types

The description of individual functions var-

ies between the different heat pump types.

Therefore different types of heat pump are

determined, which are identified as

HP type 1, 2 or 3.

HP type 1: (Not this Heat Pump)

Heat pump with flammable refrigerant and

without internal secondary heater.

Rotary selector position 1, 2, 3, 9, A or B.

(WPWE .. KW and WPL .. KW)

HP type 2:

Heat pumps with safety refrigerant and in-

ternal second HS (Heat Source).

Rotary selector position 1.

(WPF 5 (S), 7 (S), 10, 13)

HP type 3:

Heat pumps with safety refrigerant and ex-

ternal second HS (Heat Source).

Rotary selector position 9.

(WPF 5 (S), 7 (S), 10, 13)

Never ...

process media which are not ex-

pressly approved

heat liquids other than heating water

install the equipment

a) outside

b) in rooms at risk from frost

c) in wet areas, e.g. bathrooms

d) in rooms at risk from heavy dust

contamination

e) in areas, where there is a risk of

explosions

operate the equipment

a) outside the stated temperature

limits

b) without minimum circulation

volume at the heat source and

heat reduction side

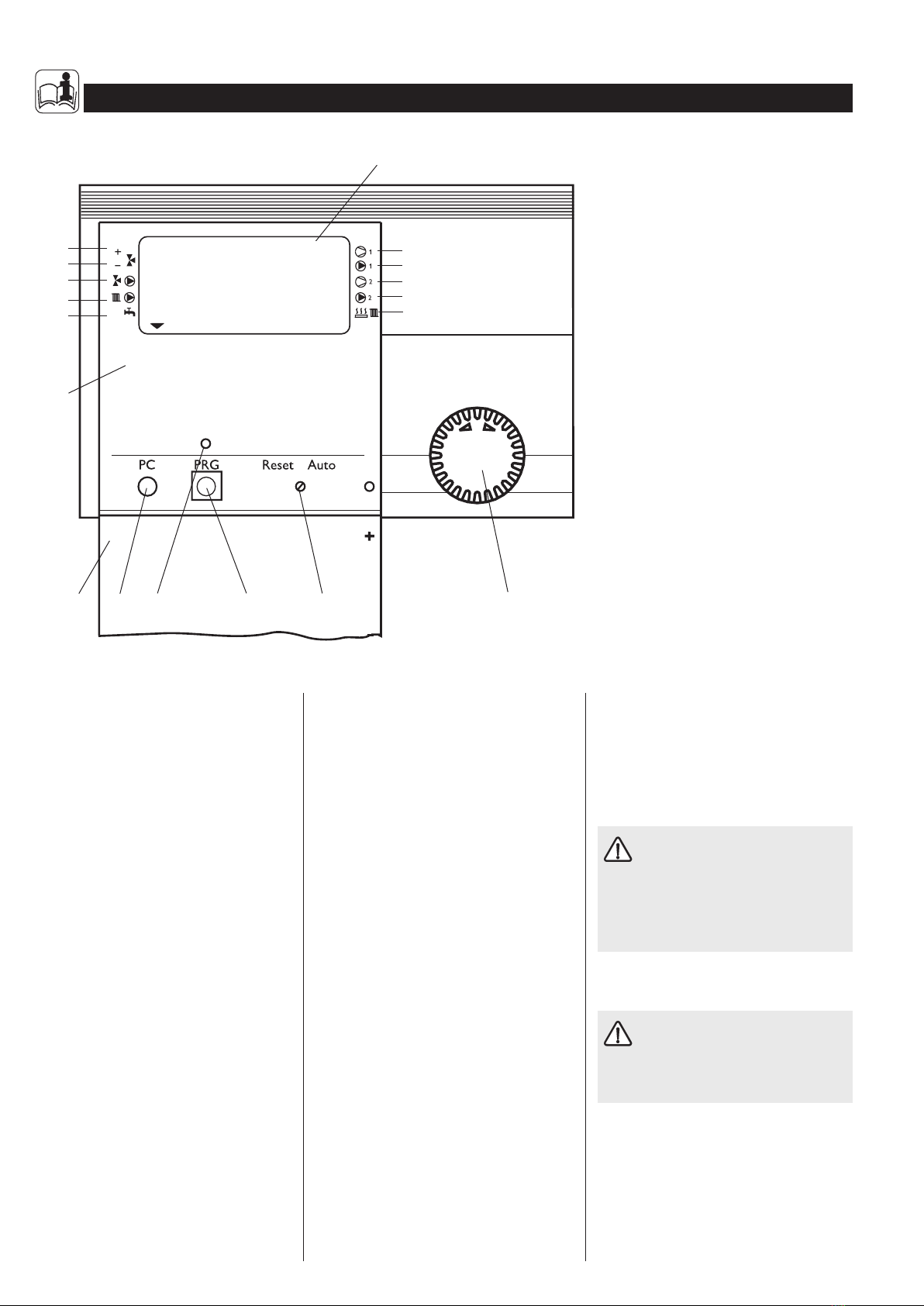

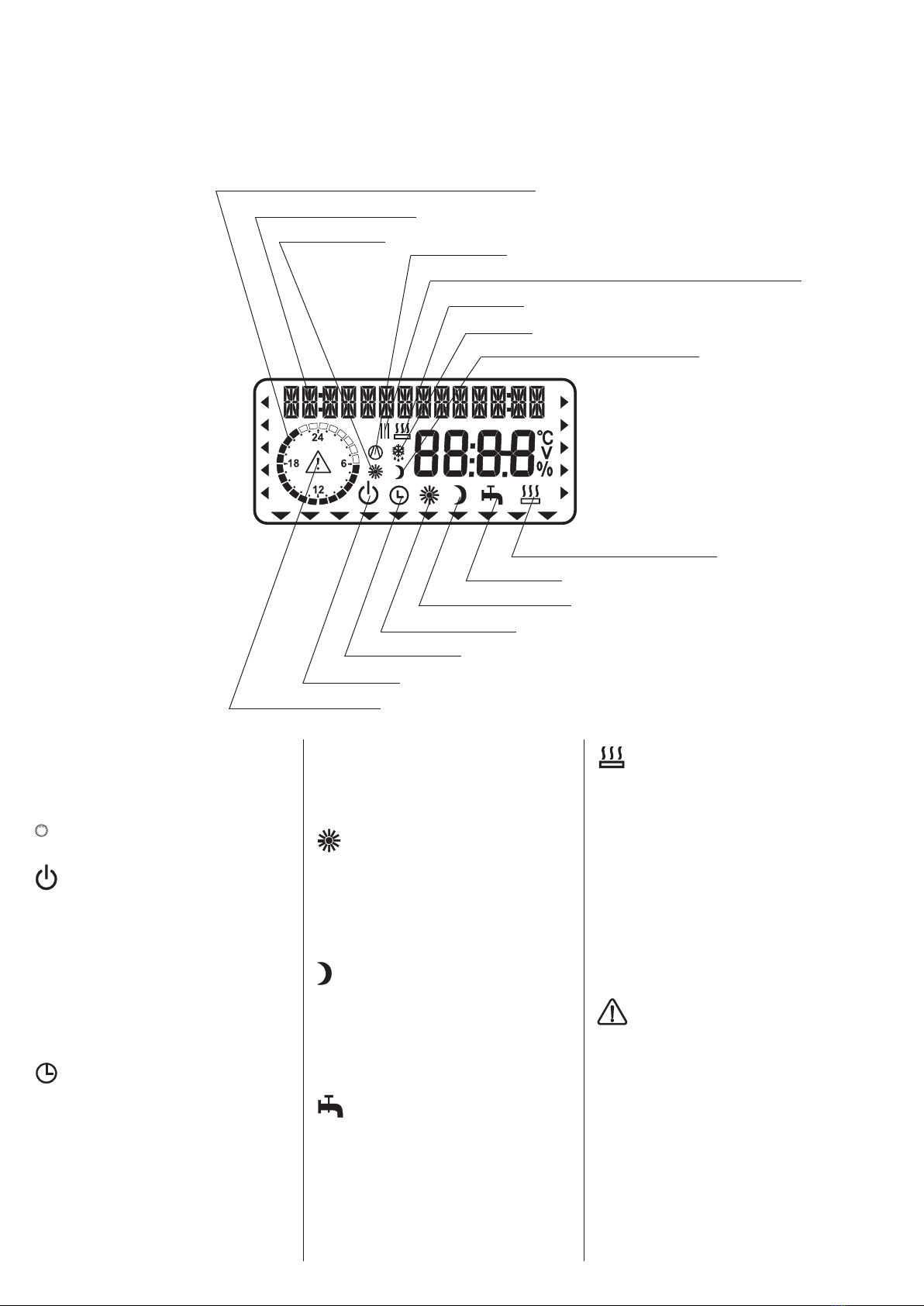

1.6 Operation

The operation is split over three control lev-

els. Control levels 1 and 2 are accessible to

users and contractors alike. Control level 3 is

only designed for qualified contractors:

Control level 1 (control flap closed)

This enables the adjustment of operating

modes, such as standby mode, programmed

operation, constant day or setback mode, etc.

(see section 1.8.1).

Vital facts in brief

Adjustments

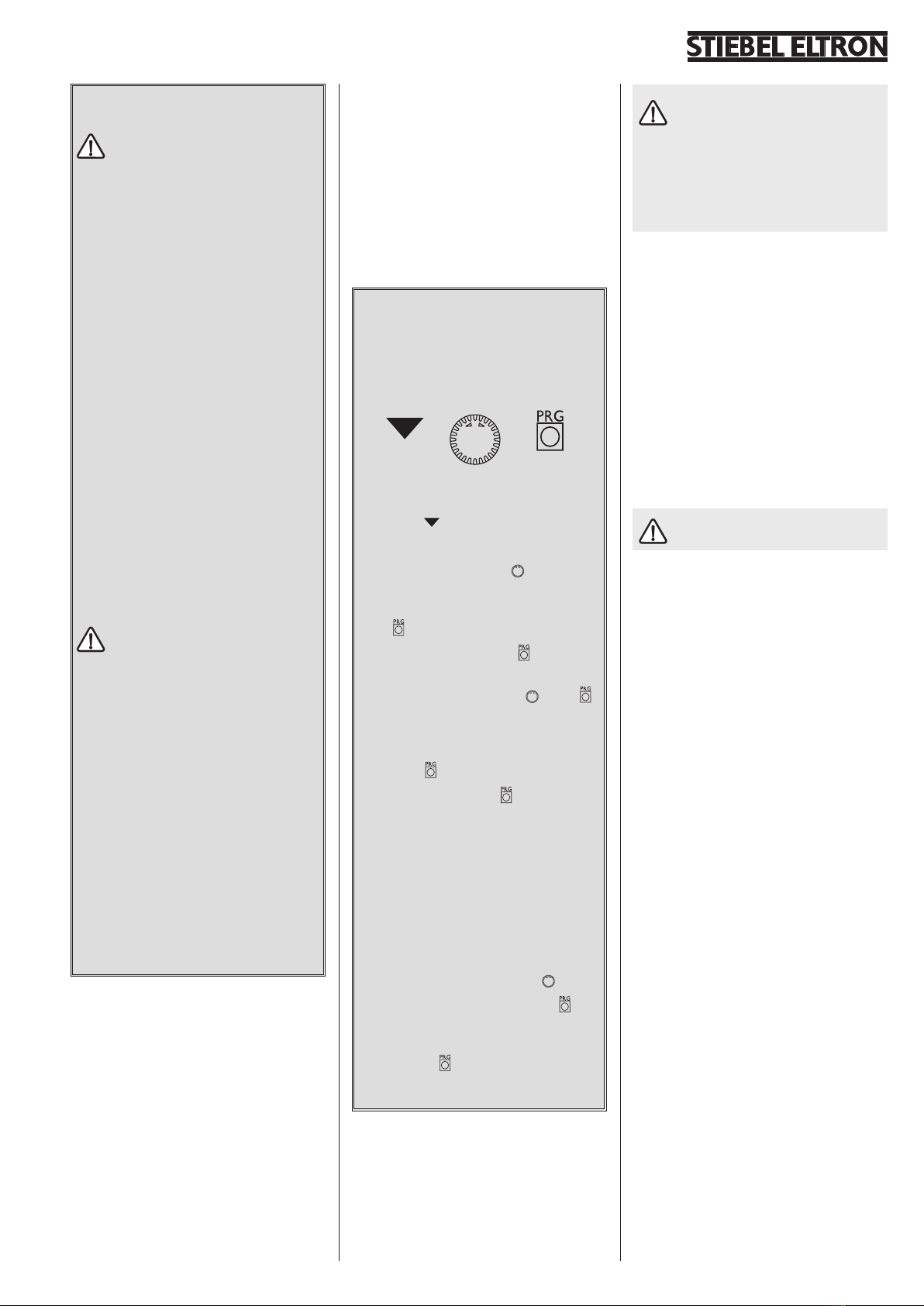

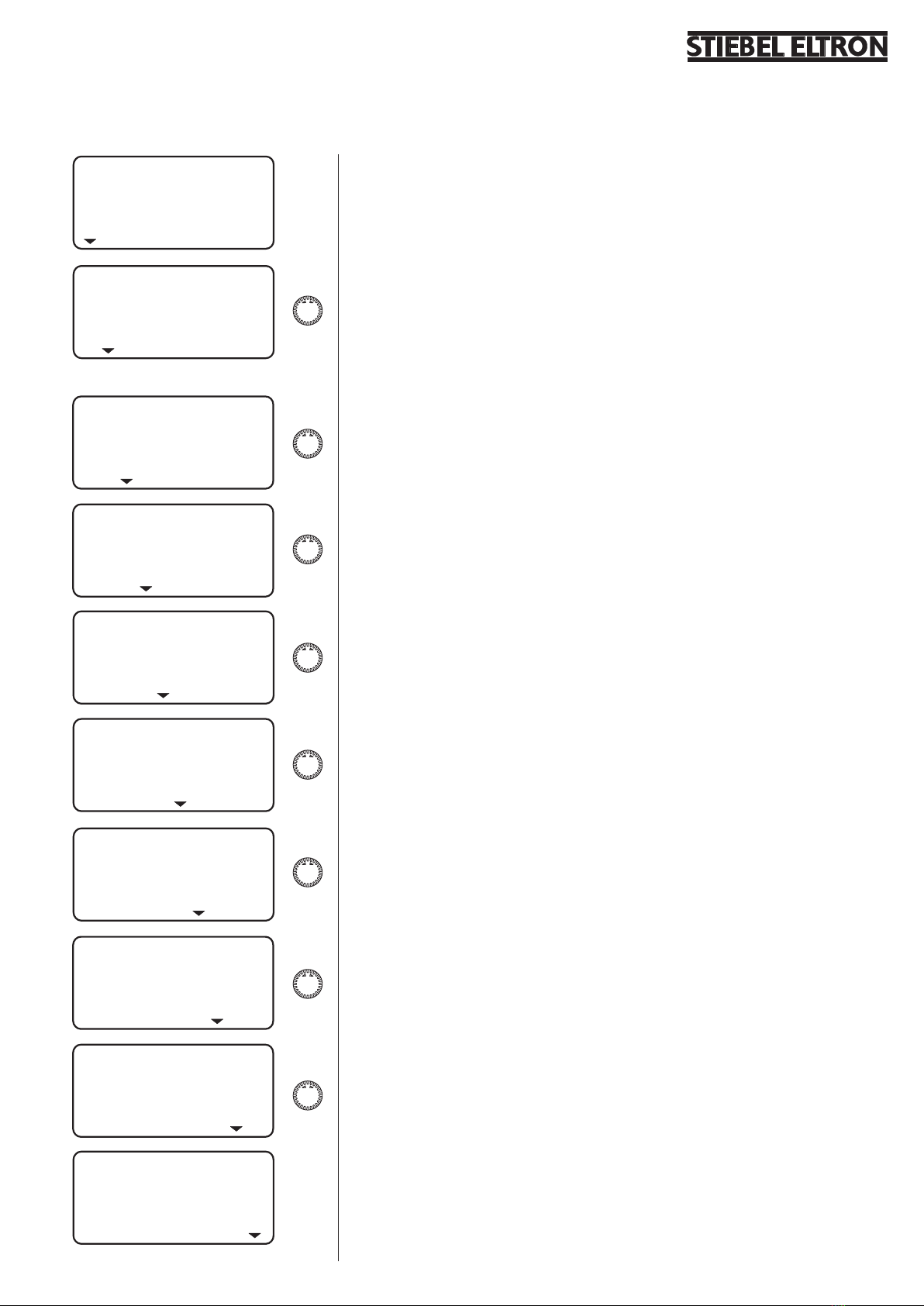

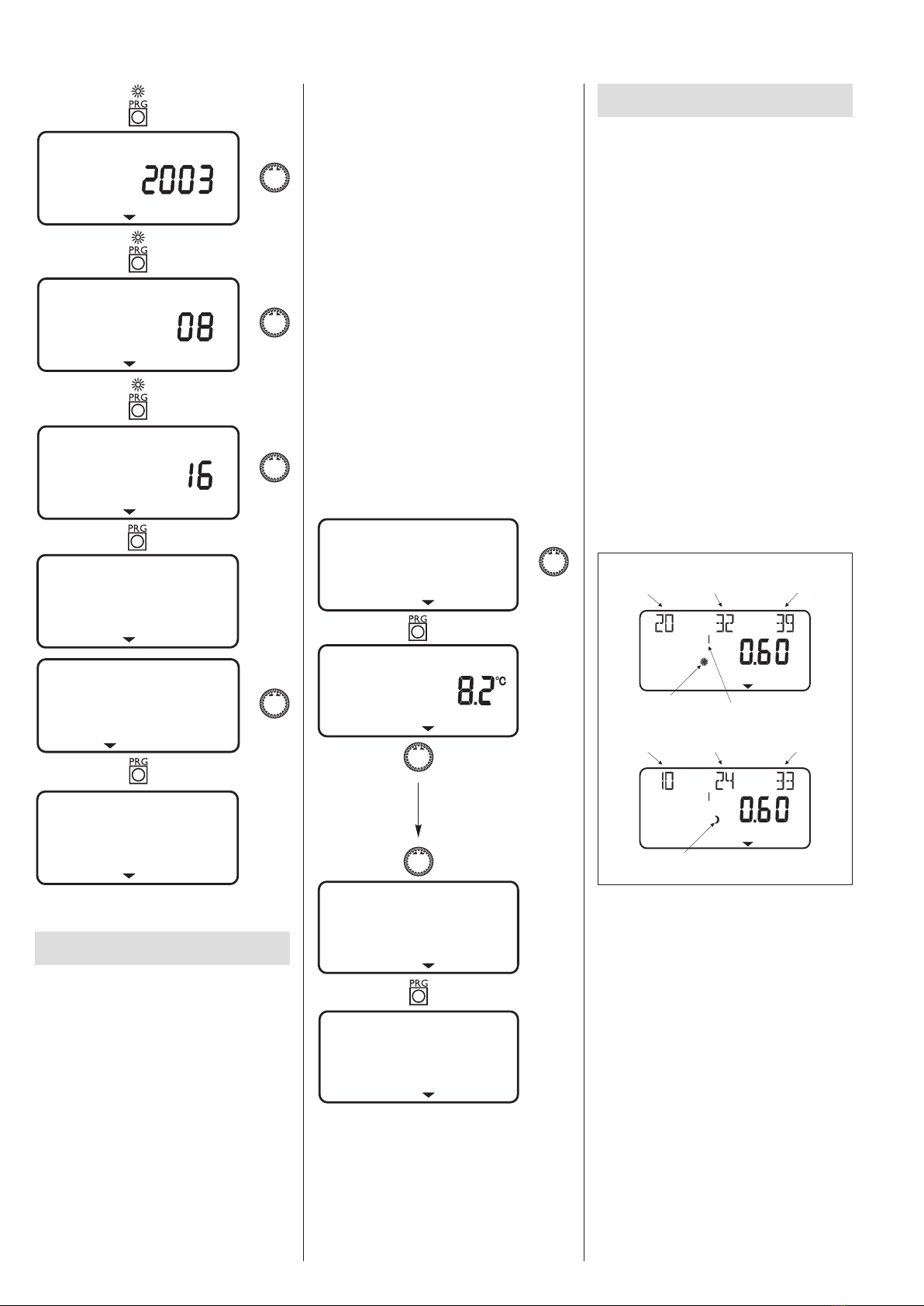

All adjustments follow the same pattern:

Opening the control flap toggles the man-

ager into programming mode. An indica-

tor symbol is shown at the bottom of

the display at system parameter ROOM

TEMP 1.

Turning the rotary selector allows you

to move the indicator to the system pa-

rameter you want to change.

Press to change the system parameter.

Whenever the red indicator above illu-

minates, you can modify the current value

by turning the rotary selector . Press

again; the illuminator then goes out and

the new set value has been saved. You can

modify further values for this menu item

by pressing , if the red indicator has not

been extinguished above .

The programming step can only be ter-

minated when the red indicator has gone

out.

Terminating the programming process

You can terminate the programming proc-

ess after entering and saving the require

menu point changes by closing the control

flap. However, if you want to make further

changes, turn the rotary selector until

the display shows BACK, then press

This will return you to the previous level.

Closing the control flap with illuminated in-

dicator above returns the manager into

its original position. The modified value will

not have been saved.

During commissioning, a system

check will be implemented, e.g. all

sensors that are currently connected, are

displayed upon request. Sensors not con-

nected before the system went 'live' are

not registered by the manager and are

therefore not displayed. The indicator sym-

bol skips the system parameter.

Example: The system parameters DHW

TEMP and DHW PROG will be skipped if,

during commissioning, the DHW cylinder sen-

sor was not connected. Values for these pa-

rameters can therefore not be programmed.

1.7 What to do if . . . ?

. . . there is no hot water or the heating sys-

tem stays cold:

Check the fuse/circuit breaker in your fuse

box. If it has blown/tripped, replace/reset the

fuse/MCB. Notify your local contractor if the

fuse/MCB blows/trips again.

Notify your local contractor in case

of all other faults.

Control level 2 (control flap open)

This enables system parameters, such as room

temperature, DHW temperature, heating pro-

grams, etc. to be adjusted (see section 1.8.2).

Control level 3 (for contractors only)

This level is protected by a code and should

only be used by contractors. At this level, heat

pump and system-specific details are deter-

mined (see section 2.10).