NI 9203 Manual

CALIBRATION PROCEDURE

NI 9203

This document contains the verification and adjustment procedures for the NI 9203. Refer to

ni.com/calibration for more information about calibration solutions.

Contents

Software.................................................................................................................................... 1

Documentation.......................................................................................................................... 1

Test Equipment..........................................................................................................................2

Test Conditions..........................................................................................................................2

Initial Setup............................................................................................................................... 3

Verification................................................................................................................................3

Accuracy Verification....................................................................................................... 3

Adjustment................................................................................................................................ 5

Gain Accuracy Adjustment...............................................................................................5

Offset Accuracy Adjustment.............................................................................................6

EEPROM Update......................................................................................................................7

Reverification............................................................................................................................7

Accuracy Under Calibration Conditions...................................................................................7

Worldwide Support and Services.............................................................................................. 8

Software

Calibrating the NI 9203 requires the installation of NI-DAQmx 9.2 or later on the calibration

system. You can download NI-DAQmx from ni.com/downloads. NI-DAQmx supports

LabVIEW, LabWindows™/CVI™, C/C++, C#, and Visual Basic .NET. When you install NI-

DAQmx, you only need to install support for the application software that you intend to use.

Documentation

Consult the following documents for information about the NI 9203, NI-DAQmx, and your

application software. All documents are available on ni.com, and help files install with the

software.

•NI cDAQ-9174/9178 Quick Start— NI-DAQmx installation and hardware setup.

•NI 9203 Getting Started Guide and NI 9203 Datasheet—NI 9203-specific information,

specifications, and calibration interval.

•NI-DAQmx Readme—Operating system and application software support in NI-DAQmx.

•LabVIEW Help—LabVIEW programming concepts and reference information about

NI-DAQmx VIs and functions.

•NI-DAQmx C Reference Help—Reference information for NI-DAQmx C functions and

NI-DAQmx C properties.

•NI-DAQmx .NET Help Support for Visual Studio—Reference information for

NI-DAQmx .NET methods and NI-DAQmx .NET properties, key concepts, and a C

enum to .NET enum mapping table.

Test Equipment

Table 1 lists the equipment recommended for the performance verification and adjustment

procedures. If the recommended equipment is not available, select a substitute using the

requirements listed in Table 1.

Table 1. Recommended Equipment

Equipment Recommended Model Requirements

Calibrator Fluke 5700A If this instrument is unavailable, use a high-precision

current source with an accuracy <100 ppm.

Chassis NI cDAQ-9178 —

Test Conditions

The following setup and environmental conditions are required to ensure the NI 9203 meets

published specifications.

• Keep connections to the NI 9203 as short as possible. Long cables and wires act as

antennae, picking up extra noise that can affect measurements.

• Verify that all connections to the NI 9203 are secure.

• Use shielded copper wire for all cable connections to the NI 9203. Use twisted-pairs wire

to eliminate noise and thermal offsets.

• Maintain an ambient temperature of 23 °C ±5 °C. The NI 9203 temperature will be

greater than the ambient temperature.

• Keep relative humidity below 80%.

• Allow a warm-up time of at least 10 minutes to ensure that the NI 9203 measurement

circuitry is at a stable operating temperature.

2| ni.com | NI 9203 Calibration Procedure

Initial Setup

Complete the following steps to set up the NI 9203.

1. Install NI-DAQmx.

2. Make sure the NI cDAQ-9178 power source is not connected.

3. Install the module in slot 8 of the NI cDAQ-9178 chassis. Leave slots 1 through 7 of the

NI cDAQ-9178 chassis empty.

4. Connect the NI cDAQ-9178 chassis to your host computer.

5. Connect the power source to the NI cDAQ-9178 chassis.

6. Launch Measurement & Automation Explorer (MAX).

7. Right-click the device name and select Self-Test to ensure that the module is working

properly.

Verification

The following performance verification procedures describe the sequence of operation and test

points required to verify the NI 9203 and assume that adequate traceable uncertainties are

available for the calibration references.

Accuracy Verification

Complete the following procedure to determine the As-Found status of the NI 9203.

1. Remove all connections to the NI 9203.

2. Acquire and average samples for offset error.

a. Create and configure an AI current channel according to Table 2.

Table 2. NI 9203 AI Current Channel Configuration

Input Range Range Scaled Units Terminal Configuration

Min Max

Unipolar 0.000 0.020 Amps RSE

Bipolar -0.020 0.020 Amps RSE

b. Configure the AI current channel timing according to Table 3.

Table 3. NI 9203 Timing Configuration

Samples Per Channel Acquisition Mode Rate (S/s)

10k Finite 20k

c. Start the task.

d. Read samples from the NI 9203.

NI 9203 Calibration Procedure | © National Instruments Corporation | 3

e. Average the samples.

f. Clear the task.

3. Compare the average sample to the offset test limits in Tables 4 and 5.

Table 4. NI 9203 As-Found Offset Test Limits

Input Range Range (A) Test Point As-Found Limits

Min Max Location Value (A) Lower Limit (A) Upper Limit (A)

Unipolar 0.000 0.020 Min 0.000000 -0.000004 0.000004

Bipolar -0.020 0.020 Mid 0.000000 -0.000015 0.000015

Table 5. NI 9203 As-Left Offset Test Limits

Input Range Range (A) Test Point As-Left Limits

Min Max Location Value (A) Lower Limit (A) Upper Limit (A)

Unipolar 0.000 0.020 Min 0.000000 -0.000003 0.000003

Bipolar -0.020 0.020 Mid 0.000000 -0.000003 0.000003

4. Repeat steps 2 and 3 for both ranges.

5. Repeat steps 2 through 4 for each channel.

6. Set the calibrator to Standby mode (STBY).

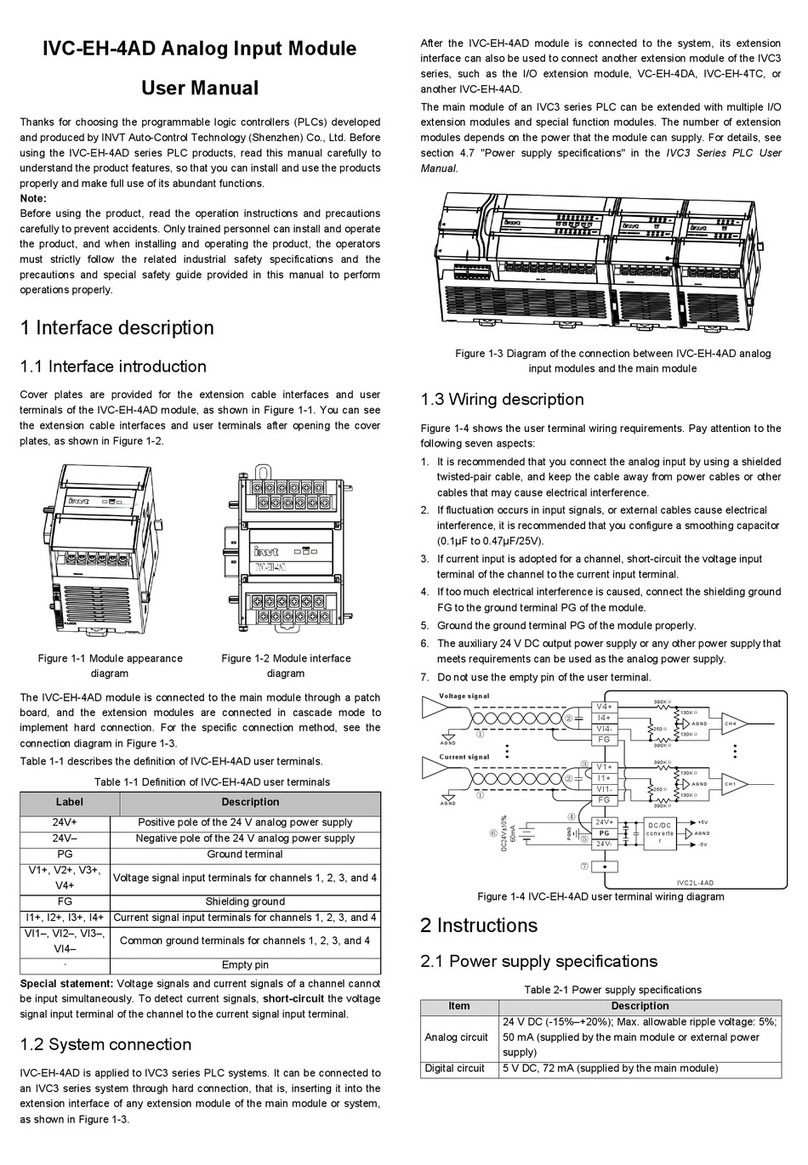

7. Connect the NI 9203 to the calibrator. Refer to Figure 1 for a connection diagram.

Figure 1. Accuracy Connections for the NI 9203

NI 9203Calibrator

COM

AIx

HI

LO

Guard

NI 9203Calibrator

COM

AIx

HI

LO

1 2

1. Connections when using a calibrator with a guard connection.

2. Connections when using a calibrator with no guard connection.

Note If the calibrator outputs are truly floating, connect the negative output to

a quiet earth ground as well as COM to give the entire system a ground

reference.

8. Set the calibrator to Operate mode (OPR).

9. Set the calibrator current to a Test Point value indicated in Tables 6 and 7.

10. Compare the average sample to the gain test limits in Tables 6 and 7.

4| ni.com | NI 9203 Calibration Procedure

Table 6. NI 9203 As-Found Gain Test Limits

Input Range Range (A) Test Point As-Found Limits

Min Max Location Value (A) Lower Limit (A) Upper Limit (A)

Unipolar 0.000 0.020 Max 0.020000 0.019979 0.020021

0.000 0.020 Min 0.010000 0.009988 0.010013

Bipolar -0.020 0.020 Max 0.020000 0.019969 0.020031

-0.020 0.020 Min -0.020000 0.020031 -0.019969

Table 7. NI 9203 As-Left Gain Test Limits

Input Range Range (A) Test Point As-Left Limits

Min Max Location Value (A) Lower Limit (A) Upper Limit (A)

Unipolar 0.000 0.020 Max 0.020000 0.019988 0.020012

0.000 0.020 Min 0.010000 0.009993 0.010007

Bipolar -0.020 0.020 Max 0.020000 0.019988 0.020012

-0.020 0.020 Min -0.020000 -0.020012 -0.019988

11. Repeat steps 9 and 10 for each Test Point in Tables 6 and 7.

12. Set the calibrator to Standby mode (STBY).

13. Disconnect the NI 9203 from the calibrator.

14. Repeat steps 7 through 13 for each channel on the NI 9203.

Adjustment

The following performance adjustment procedure describes the sequence of operation required

to adjust the NI 9203.

Gain Accuracy Adjustment

Complete the following procedure to adjust the gain accuracy performance of the NI 9203.

1. Set the calibrator to Standby mode (STBY).

2. Connect the NI 9203 to the calibrator. Refer to Figure 1 for a connection diagram.

3. Adjust the NI 9203.

a. Initialize a calibration session on the NI 9203. The default password is NI.

b. Input the external temperature in degrees Celsius.

NI 9203 Calibration Procedure | © National Instruments Corporation | 5

c. Call and configure the NI 9203 get C Series adjustment points function according to

Table 8 to obtain an array of recommended calibration currents for both the Unipolar

and Bipolar Input Range.

Table 8. Get Adjustment Points Configuration

Input Range Range (A)

Min Max

Unipolar 0.000 0.020

Bipolar -0.020 0.020

d. Set the calibrator to a reference value determined by the array of recommended

calibration currents.

e. Set the calibrator to Operate mode (OPR).

f. Call and configure the NI 9203:Gain adjustment function according to Table 9 to

adjust the gain for both the Unipolar and Bipolar ranges.

Table 9. Gain Adjustment Configuration

Input Range Range Physical Channel Reference Value

Min Max

Unipolar 0.000 0.020 cDAQMod8/aixThe reference value from the array of

adjustment points.

Bipolar -0.020 0.020 cDAQMod8/aixThe reference value from the array of

adjustment points.

g. Set the calibrator to Standby mode (STBY).

h. Repeat steps d through g for each calibration current in the array.

i. Disconnect the calibrator from the NI 9203.

j. Close the calibration session.

4. Repeat steps 2 and 3 for each channel on the NI 9203.

Offset Accuracy Adjustment

Complete the following procedure to adjust the offset accuracy performance of the NI 9203.

1. Remove all connections to the NI 9203.

2. Adjust the NI 9203.

a. Initialize a calibration session on the NI 9203. The default password is NI.

b. Input the external temperature in degrees Celsius.

c. Call and configure the NI 9203:Offset adjustment function according to Table 10 to

adjust the offset for both the Unipolar and Bipolar ranges.

6| ni.com | NI 9203 Calibration Procedure

Table 10. Offset Adjustment Configuration

Input Range Range Physical Channel

Min Max

Unipolar 0.000 0.020 dDAQMod8/ai3

Bipolar -0.020 0.020 dDAQMod8/ai3

d. Close the calibration session.

EEPROM Update

When an adjustment procedure is completed, the NI 9203 internal calibration memory

(EEPROM) is immediately updated.

If you do not want to perform an adjustment, you can update the calibration date and onboard

calibration temperature without making any adjustments by initializing an external calibration,

setting the C Series calibration temperature, and closing the external calibration.

Reverification

Repeat the Verification section to determine the As-Left status of the device.

Note If any test fails Reverification after performing an adjustment, verify that you

have met the Test Conditions before returning your device to NI. Refer to Worldwide

Support and Services for assistance in returning the device to NI.

Accuracy Under Calibration Conditions

The values in the following table are based on calibrated scaling coefficients, which are stored

in the onboard EEPROM.

The following accuracy table is valid for calibration under the following conditions:

• Ambient temperature 23 °C ±5 °C

• NI 9203 installed in slot 8 of an NI cDAQ-9178 chassis

• Slots 1 through 7 of the NI cDAQ-9178 chassis are empty

NI 9203 Calibration Procedure | © National Instruments Corporation | 7

Table 11. NI 9203 Accuracy Under Calibration Conditions

Input Range As-Found As-Left*

Percent of

Reading

(Gain Error)

Percent of

Range**

(Offset Error)

Percent of

Reading

(Gain Error)

Percent of

Range**

(Offset Error)

Unipolar 0.082% 0.020% 0.042% 0.015%

Bipolar 0.084% 0.034% 0.042% 0.008%

* As-left limits are applicable immediately after adjustment.

** Range equals 21.5 mA for Unipolar and 43 mA (±21.5 mA) for Bipolar.

Note For operational specifications, refer to the most recent NI 9203 Datasheet

online at ni.com/manuals.

Worldwide Support and Services

The NI website is your complete resource for technical support. At ni.com/support, you have

access to everything from troubleshooting and application development self-help resources to

email and phone assistance from NI Application Engineers.

Visit ni.com/services for information about the services NI offers.

Visit ni.com/register to register your NI product. Product registration facilitates technical

support and ensures that you receive important information updates from NI.

NI corporate headquarters is located at 11500 North Mopac Expressway, Austin, Texas,

78759-3504, USA. For up-to-date contact information for your location, visit ni.com/contact.

Information is subject to change without notice. Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for

information on NI trademarks. Other product and company names mentioned herein are trademarks or trade names of their

respective companies. For patents covering NI products/technology, refer to the appropriate location: Help»Patents in your

software, the patents.txt file on your media, or the National Instruments Patent Notice at ni.com/patents. You can find

information about end-user license agreements (EULAs) and third-party legal notices in the readme file for your NI product. Refer

to the Export Compliance Information at ni.com/legal/export-compliance for the NI global trade compliance policy and how

to obtain relevant HTS codes, ECCNs, and other import/export data. NI MAKES NO EXPRESS OR IMPLIED WARRANTIES AS

TO THE ACCURACY OF THE INFORMATION CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR ANY ERRORS. U.S.

Government Customers: The data contained in this manual was developed at private expense and is subject to the applicable

limited rights and restricted data rights as set forth in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2008—2020 National Instruments Corporation. All rights reserved.

372674D-01 August 5, 2020

Other manuals for 9203

1

Table of contents

Other NI I/O System manuals