NI CB-2162 User manual

USER GUIDE

NI CB-2162

Single-Ended Digital I/O Accessory

The NI CB-2162 is a connector block and prototyping board for

National Instruments digital waveform generator/analyzer modules.

The NI CB-2162 provides an easy way to complete the following tasks:

• Terminate digital I/O (DIO) and control channels

• Connect to other devices for testing and debugging

• Develop and interface to prototype circuits

• Probe DIO and control channels

This guide explains how to set up and use the NI CB-2162 single-ended

DIO accessory.

Contents

What You Need to Get Started ............................................................... 2

Related Documentation........................................................................... 3

Parts Locator Diagram ............................................................................ 4

Installing Cables...................................................................................... 5

Connecting Signals ................................................................................. 6

Terminating Signals ................................................................................ 12

Using the NI CB-2162 Prototyping Area................................................ 15

Mounting the NI CB-2162 in an Enclosure ............................................ 17

Specifications .......................................................................................... 21

Where to Go for Support......................................................................... 22

NI CB-2162 User Guide 2 ni.com

What You Need to Get Started

To set up and use the NI CB-2162, you need the following items:

❑NI SHC68-C68-D2 or NI C68-C68-D4 cable assembly

❑Compatible NI digital waveform generator/analyzer module installed

in a PXI chassis, compact PCI chassis, or desktop PC

You also may need the following optional items:

❑Resistors and 10-pin single-inline packaged resistor networks for

pull-up/pull-down and series termination

❑The NI CB-2162 ships populated with a 0 Ωresistor. A 50 Ωresistor

also is included for optional STROBE/PFI 5 series termination.

❑30-gauge wire

❑Wire-wrap tool

❑1 × 2 header receptacle(s)

❑DC power supply for the prototyping area

❑CA-1000 (NI part number 777664-01), rack-mount side panels

(NI part number 777665-01), and an NI CB-2162 CA-1000 mounting

kit for mounting the NI CB-2162 in an enclosure

❑The documentation included with the digital waveform

generator/analyzer module and the driver software included with your

NI device

©National Instruments Corporation 3 NI CB-2162 User Guide

Related Documentation

National Instruments digital waveform generator/analyzer modules ship

with several documents designed to familiarize you with different aspects

of the module. The titles and location of the documents vary based on the

instrument driver that supports the NI device, but you should have the

following types of documentation:

• Getting Started Guide—This printed document should be the first

thing you read. Its purpose is to guide you through setting up the

digital waveform generator/analyzer module and configuring it to

generate or acquire your first samples.

• Help—This online document provides more in-depth information

about the hardware capabilities of the digital waveform

generator/analyzer module, theory of operation discussion, and

information on programming flow and software reference.

• Specifications—This printed document provides specifications for the

NI hardware.

Visit ni.com/manuals for the most current documentation.

You also may have documentation for any application development

environment (ADE) you are using.

NI CB-2162 User Guide 4 ni.com

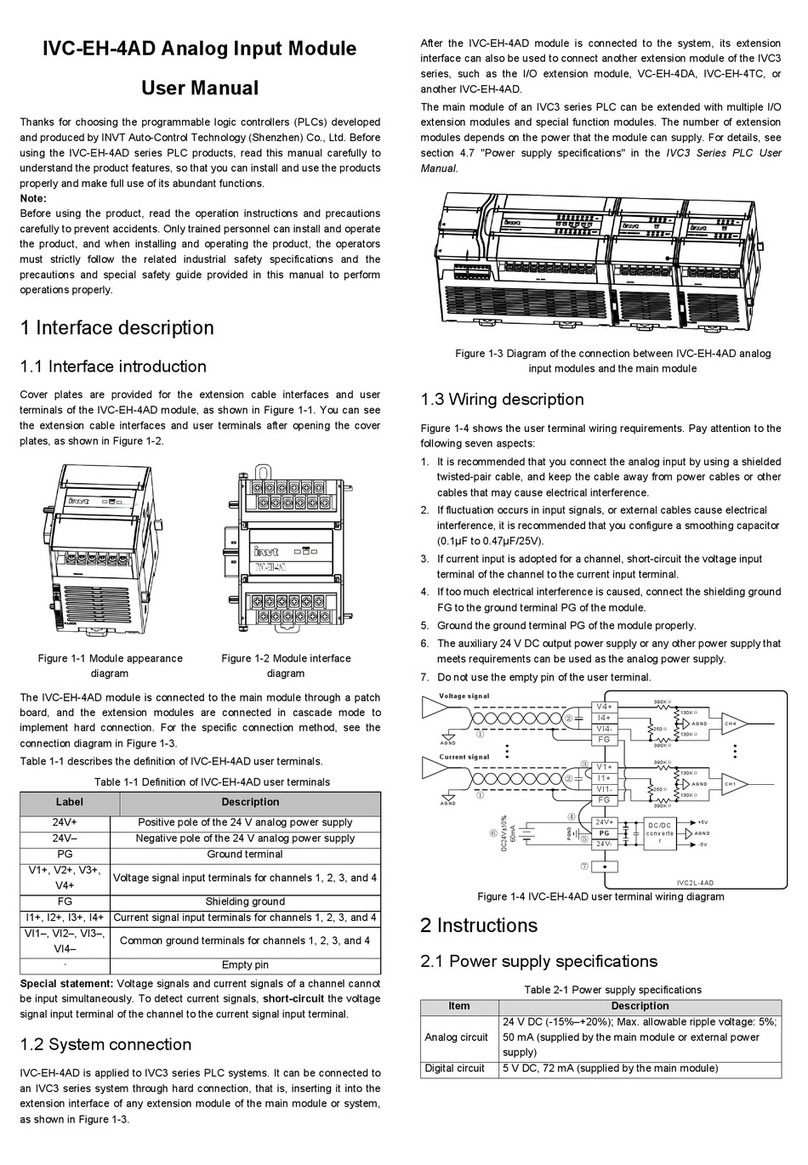

Parts Locator Diagram

Refer to Figure 1 to locate connectors and components on the NI CB-2162.

Figure 1. NI CB-2162 Parts Locator Diagram

1 68-Pin Digital Data & Control (DDC) Connector

2 Termination Sockets

3 Control and Ground Header Pairs

4 Prototyping Area Power Connectors

5 Prototyping Area Power LED

6 Prototyping Area Power and Ground Solder Pads

7 Prototyping Area

8 Labeling Strips

9 DIO and Ground Header Pairs

J15

1

J3

J4

4

3

2

9

7

5

8

6

4/DDC

CLKOUT 5/

STROBE

F6 F5 F4 F3 F2 F1

©National Instruments Corporation 5 NI CB-2162 User Guide

Installing Cables

A cable connects the NI CB-2162 to the digital waveform

generator/analyzer. Figure 2 shows how to install a cable.

Figure 2. Connecting a 68-Pin Digital Waveform Generator/Analyzer to the CB-2162

Refer to Figure 2 as you complete the following steps to install the

supported cable:

Caution Before connecting the cable, disconnect power from the module, accessory, and

any other connected hardware to prevent damage to the hardware and personal injury. NI is

not liable for damage resulting from improper connections.

1. Install NI-HSDIO or NI-DAQmx and the digital waveform

generator/analyzer by following the installation procedure in the

Getting Started Guide that shipped with your device.

1 PXI Chassis with NI Digital Waveform

Generator/Analyzer

2 Cable

3 NI CB-2162 Accessory

NI PXIe-6536

25 MHz Digital I/O

DIGITAL DATA & CONTROL

ACCESS ACTIVE

NI PXI-1042

3

2

J15

J3

J4

4/DDC

CLKOUT

5/

STROBE

F6 F5 F4 F3 F2 F1

1

NI CB-2162 User Guide 6 ni.com

Caution Before attaching any cables or accessories, install the digital waveform

generator/analyzer. Refer to the Getting Started Guide that shipped with your device for

instructions on installing the module.

2. Attach either end of the cable assembly to the DDC connector of the

digital waveform generator/analyzer module and secure the cable with

the captive screws on the cable connector.

3. Attach the other end of the cable assembly to the DDC connector of the

NI CB-2162 and secure them together with the captive screws on the

cable connector.

Connecting Signals

Each DIO, PFI, and clock channel of the digital waveform

generator/analyzer connects to a corresponding pin on the NI CB-2162.

Refer to Figure 1 for the location of these pins on the NI CB-2162.

Caution Before powering down the digital waveform generator/analyzer module, remove

power from the prototyping area of the NI CB-2162. NI is not liable for any damage

resulting from improper signal connections.

©National Instruments Corporation 7 NI CB-2162 User Guide

Figure 3 shows the DDC connector pinout of the NI CB-2162.

Figure 3. NI CB-2162 DDC Connector Pinout

Note Refer to the help file for your device for information about the number of available

DIO channels on your device. DIO <20..31> or PFI_0 may not be applicable to your

device. The function of DDC CLK OUT/PFI_4 and STROBE/PFI_5 may be unique to

your device.

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

DIO 31

GND

DIO 29

GND

DIO 27

GND

DIO 25

RESERVED

DIO 23

GND

DIO 21

GND

DIO 19

GND

DIO 17

GND

DIO 15

GND

DIO 13

GND

DIO 11

GND

DIO 9

GND

DIO 7

PFI 1

DIO 5

GND

DIO 3

PFI 3

DIO 1

GND

DDC CLK OUT/PFI_4

GND

DIO 30

GND

DIO 28

GND

DIO 26

GND

DIO 24

GND

DIO 22

GND

DIO 20

GND

DIO18

GND

DIO 16

GND

DIO 14

RESERVED/PFI_0

DIO 12

GND

DIO 10

GND

DIO 8

GND

DIO 6

RESERVED

DIO 4

GND

DIO 2

PFI 2

DIO 0

GND

STROBE/PFI_5

GND

NI CB-2162 User Guide 8 ni.com

Table 1 describes the DDC signals shown in Figure 3.

The NI CB-2162 provides connectivity to up to 32 of the single-ended

DIO channels of an NI digital waveform generator/analyzer. The 32 DIO

channels are divided into two bundles of 16 × 2 header pins. Each bundle

is grouped by signal and ground pairs. The ground pins provide ground

return paths for the DIO channels.

You can make connections to the DIO channels, the PFI channels,

DDC CLK OUT/PFI_4, or STROBE/PFI_5 on the NI CB-2162 using a

1 × 2 header receptacle, ribbon cable, a wire-wrap technique, or by

soldering directly to the pins. Examples of how to make these connections

are provided in the following sections.

Caution Connections that exceed any of the maximum ratings for the NI CB-2162 or the

NI digital waveform generator/analyzer module can damage the module and the computer.

Maximum input ratings are provided in the Specifications section and in the specifications

document that shipped with the digital waveform generator/analyzer. NI is not liable for

any damage resulting from such signal connections.

Table 1. DDC Connector Pinout Descriptions

DDC Pin Signal Description

DIO <0..31> Bidirectional digital data channels 0 through 31.

STROBE/PFI_5 External sample clock source for pattern

acquisition or general-purpose PFI*.

DDC CLK

OUT/PFI_4

Exported sample clock signal or general-purpose

PFI.

PFI <0..3> Programmable functional interface (PFI)

channels 0 through 3.

GND Ground reference for signals.

RESERVED These channels are reserved for system use.

Do not connect signals to these channels.

*Refer to your device documentation for support.

©National Instruments Corporation 9 NI CB-2162 User Guide

Using 1 × 2 Header Receptacles

Each signal and ground header pair is labeled on the NI CB-2162 and in

Figure 1. These header pairs are arranged so that you can make quick

connections using a 1 × 2 header receptacle to a coaxial cable assembly.

Note Header receptacle assemblies are not included with the NI CB-2162, but you can

create custom assemblies by purchasing parts from vendors such as 3M.

Connectivity is made by inserting the receptacle onto the appropriate

header pair. Refer to the receptacle documentation to assure that proper

connections are made to signal and ground.

Figure 4 shows how to make 1 × 2 header receptacle connections.

Figure 4. 1 × 2 Header Receptacle

1 1 × 2 Header Receptacle 2 Header Pin Pair

2

1

DIO

NI CB-2162 User Guide 10 ni.com

Using a Ribbon Cable

The header pairs on the NI CB-2162 are available for single wire probing.

You also can use 32-pin ribbon cables to easily connect a large number of

channels to other devices. Cable type and quality can dramatically affect

how well the signal integrity is maintained. NI recommends using short

twisted-pair ribbon cables.

Refer to the device or cable manufacturer for additional information on

proper connectivity to the NI CB-2162 signal and ground connections.

Figure 5 shows how to connect a ribbon cable to the accessory.

Figure 5. Using a Ribbon Cable with the NI CB-2162

J15

J5

J6

4/DDC

CLKOUT 5/

STROBE

F6 F5 F4 F3 F2 F1

©National Instruments Corporation 11 NI CB-2162 User Guide

Making a Wire-Wrap Connection

Make connections from the appropriate 1 × 1 header with a standard

wire-wrap tool and 30-gauge or similar wire. Strip the wire and insert it into

the receptacle end of the wire-wrap tool. Place the wire-wrap tool over the

appropriate header pair pin, and twist the tool around the header post. You

then can make connections to the device under test (DUT) as defined by the

device manufacturer. Connect the DIO channel and ground header pins for

each channel being used.

Figure 6 provides an illustration for making a wire-wrap connection.

Figure 6. Wire-Wrap Connections

1 Wire-Wrap Tool

2 Stripped Wire

3 Header Pin Receptacle

1

2

3

NI CB-2162 User Guide 12 ni.com

Terminating Signals

Termination of high-speed digital signals is necessary to prevent signal

reflections and to force signal channels to a known state when no signal

is present. Sockets for terminating resistors are connected to all DIO and

control channels on the NI CB-2162. These sockets are labeled in Figure 1.

Note Proper termination needs are application-specific. For some special considerations

for choosing resistor values, refer to the Terminating Control Channel Signals section.

Minimizing the Effects of Stubs

Stubs are unterminated tributaries from the original signal path. Stubs

decrease the signal quality of the system by adding reflections to the

transmission channels. To minimize the effect of stubs, termination is

placed at the end of the signal path.

If your signal transmission line ends on the NI CB-2162, you can use the

provided termination socket. If your signal terminates somewhere other

than the NI CB-2162, NI recommends terminating the transmission line

at the final signal destination.

Note Refer to the help file for your device for more information about proper signal

termination.

Terminating DIO Channel Signals

Table 2 shows the relationship between DIO channels and the termination

sockets.

Note Refer to the help file for your device for information about the number of available

DIO channels on your device. DIO <20..31> may not be applicable to your device.

You can use different resistor networks and jumper placements to terminate

the DIO channels in multiple configurations.

Table 2. DIO Termination Sockets

DIO Channels Termination Socket

DIO <0..7> J13

DIO <8..15> J15

DIO <16..23> J17

DIO <24..31> J19

©National Instruments Corporation 13 NI CB-2162 User Guide

Figure 7 shows the J13 connector as an example of this termination

scheme.

Figure 7. Termination Connectivity

Parallel Termination

Figure 8 shows a typical parallel resistor network.

Figure 8. Example of Parallel Resistor Network

You can implement a pull-up or pull-down termination using a parallel

configuration. Insert the 10-pin parallel resistor network into the

appropriate termination socket with the common pin of the resistor network

(pin 1 in Figure 8) connected to pin 1 of the socket, as shown in Figure 7.

With jumpers W<4..7> in place, pin 1 of J13, J15, J17, and J19 are all

pulled to ground. The signal can be alternately pulled up or terminated to

a nonground voltage if you remove the jumpers and apply power to the

jumper pin connected to pin 1 of the socket.

Alternatively, the common pin of the parallel resistor network shown

in Figure 7 can be inserted into pin 10 of the socket shown in Figure 8.

External power can then be applied to the connection point located below

pin 10 of the socket to provide proper termination.

Thevenin (Dual) Termination

In some applications, you might need to provide a Thevenin (dual)

termination or a pull-up and pull-down configuration. Figure 9 shows a

typical dual-termination resistor network, which can accomplish this task.

W4

TERMINATION

1

J13

110

NI CB-2162 User Guide 14 ni.com

Figure 9. Example of Dual-Termination Resistor Network

To implement this configuration, insert the 10-pin resistor network into the

J connector corresponding to the desired DIO channel. Make connections

to ground using a jumper to connect W4, W5, W6, and/or W7 with the

pull-down configuration mentioned previously. This jumper effectively

terminates the signal or pulls the signal to ground by a value provided by

R2 of Figure 9.

You can use the pull-up terminating resistance by connecting pin 10 of

the resistor network to the solder pads connected to pin 10 of the socket,

as shown in Figure 7. Connect external power to this solder point. Refer to

the resistor network manufacturer documentation for information on proper

pin labeling and resistor values.

Terminating Control Channel Signals

The control channel termination sockets are intended to accept standard

through-hole resistors. Refer to Figure 1 for the termination socket

locations. Table 3 lists the termination sockets for control channel

termination resistors.

Table 3. Control Channel Termination

Control Channel Termination Sockets Termination Type

STROBE/PFI_5 (W1) J1, J2 (F1) Series

DDC CLK OUT/PFI_4 (W2) J5, J6 (F2) Parallel (pull-down)

RESERVED/PFI_0 (F3) Parallel (pull-down)

PFI 1 (W3) J7, J8 (F4) Parallel (pull-down)

PFI 2 (W3) J9, J10 (F5) Parallel (pull-down)

PFI 3 (W3) J11, J12 (F6) Parallel (pull-down)

110

R2 R2 R2 R2 R2 R2

R1 R1 R1 R1 R1

R2

R1

R2

R1 R1

©National Instruments Corporation 15 NI CB-2162 User Guide

Notes Depending on the revision of your NI CB-2162, termination sockets may be

alternately referred to as the name in parenthesis.

Refer to the help file for your device for information about the function of DDC CLK

OUT/PFI_4 and STROBE/PFI_5.

The series termination socket for the STROBE/PFI_5 channel is intended

for use when the originating source of the signal being applied to the

STROBE/PFI_5 terminal of the DDC connector is near the 1 × 2

STROBE/PFI_5 control channel pin and has a source impedance of less

than 50 Ω

. In this case, you might want to add series resistance to raise the

total source impedance to 50 Ωto minimize reflections. This socket is

populated with a 0 Ωresistor before the NI CB-2162 is shipped.

Note To ensure proper high-speed operation, make sure that the connections from the

DIO pins to your device under test are matched in length.

When inserting a resistor into any of the control channel termination

sockets, first trim the leads of the resistor to an appropriate length and

ensure that the resistor fits securely into the socket.

Using the NI CB-2162 Prototyping Area

The NI CB-2162 prototyping area is designed to aid you in the following

tasks:

• Prototyping and testing circuits—Use the NI CB-2162 in conjunction

with an NI digital waveform generator/analyzer for prototyping,

evaluating, and testing custom circuits and/or components.

• Creating custom interfaces—Use the NI CB-2162 for creating custom

interfaces to other cables or devices. You can use the prototyping area

to mount and interface the integrated circuits (ICs) or connectors

required for your application.

• Prototyping a DUT load board—Use the NI CB-2162 as a simple DUT

interface board or as a prototype of a custom DUT load board.

The prototyping area is labeled in Figure 1. Also labeled in this diagram are

the erasable labeling strips for your notes as you use the prototyping area.

NI CB-2162 User Guide 16 ni.com

Connecting Power

Caution NI is not liable for any device damage or personal injury resulting from improper

connections that exceed the maximum specifications of the NI CB-2162.

To provide power to the prototyping area, connect VCC from a DC power

supply to J3 (red terminal) and ground to J4 (black terminal). Refer to the

Specifications section for the acceptable voltage ranges.

The green power LED is lit when a positive voltage is applied to the

NI CB-2162. However, if negative voltage is applied, the Power LED does

not light. The power connectors and LED for the prototyping area are

labeled in Figure 1.

Prototyping Circuits

The prototyping area of the NI CB-2162 consists of 304 through-hole

solder pads—208 isolated pads for component mounting and wire

connections, 48 pads connected to VCC,and 48 pads connected to

ground—and space for attaching surface-mount components.

Refer to the Specifications section and to the NI digital waveform

generator/analyzer modules specifications for information on the voltage

limitations on circuits created in the prototyping area.

Replacing Components

The NI CB-2162 does not use replaceable fuses. If you need to replace the

LED, choose a replacement that meets the specifications described in the

Specifications section.

©National Instruments Corporation 17 NI CB-2162 User Guide

Mounting the NI CB-2162 in an Enclosure

You may want to mount the NI CB-2162 in an enclosure to reduce radio

interference or for convenience when using the NI CB-2162 in a

rack-mount system.

You can purchase a CA-1000 (777664-01) and an NI CB-2162 CA-1000

Mounting Kit (192065-01) for mounting your NI CB-2162 in an enclosure.

The mounting kit contains a VHDCI panelette and three screws. The

CA-1000 includes the standoffs that are required to attach the NI CB-2162

to the bottom of the CA-1000.

If you want to rack-mount the NI CB-2162 after it is installed in the

CA-1000, you can purchase rack-mount side panels (777665-01).

To install the NI CB-2162 in the CA-1000, complete the following steps:

1. Remove the jackscrews and washers from the NI CB-2162

DDC connector, as shown in Figure 10.

Figure 10. Remove Jackscrews from DDC Connector

Note You will not need the washers to mount the NI CB-2162 in the CA-1000. Save the

washers in case you ever need to remove the NI CB-2162 from the CA-1000 and use the

NI CB-2162 outside the enclosure.

1 Jackscrews 2 Washers 3 NI CB-2162

3

2

1

NI CB-2162 User Guide 18 ni.com

2. Remove the eight 4-40 × 1/4 in. flathead Phillips-head screws from the

top cover of the CA-1000, as shown in Figure 11.

3. Remove the top cover.

Figure 11. Remove Cover from CA-1000 Enclosure

Refer to Figure 12 as you complete the following steps.

4. Screw the standoffs onto the threaded screws in the locations shown in

Figure 12.

5. Position the NI CB-2162 on the standoffs of the CA-1000.

6. Secure the NI CB-2162 in the bottom of the CA 1000 using two of the

screws provided in the NI CB-2162 CA-1000 Mounting Kit.

7. Place the lower edge of the VHDCI panellete in the groove at the

bottom of the enclosure opening.

8. Tilt the VHDCI panelette top back into the enclosure.

1 CA-1000 Enclosure 2 Top Cover 3 4-40 x 1/4 in. Screws

1

2

3

©National Instruments Corporation 19 NI CB-2162 User Guide

9. Secure the VHDCI panelette with one of the panhead screws included

with the CA-1000 kit.

10. Reattach the DDC connector jackscrews through the opening in the

I/O panelette.

Figure 12. Secure the NI CB-2162 and Attach the I/O Panelette

1 DDC Screws

2 VHDCI Panelette

3 CA 1000

4 Standoffs

5 NI CB-2162

4

5

2

1

3

NI CB-2162 User Guide 20 ni.com

11. Replace the top cover of the CA-1000 by replacing the screws you

removed in step 2. Refer to Figure 11 for an illustration.

12. Install I/O panelettes in the unused panelette openings, as shown in

Figure 13. The panelettes in the following figure are blank, but you can

purchase many other types of I/O panelettes from NI. For more

information on the other I/O panelettes, go to ni.com and search for

I/O Connector Panelettes.

Figure 13. Install Blank I/O Panelettes

The NI CB-2162 is now installed in the CA-1000 enclosure.

1 I/O Panelettes 2Screws

1

2

Table of contents

Other NI I/O System manuals