NIBE-BIAWAR HK 200M User manual

15.02.2017

25957

HK 200M

Installation manual

Indoor unit

cooperating with air

heat pumps

HK 200M

HK 200M

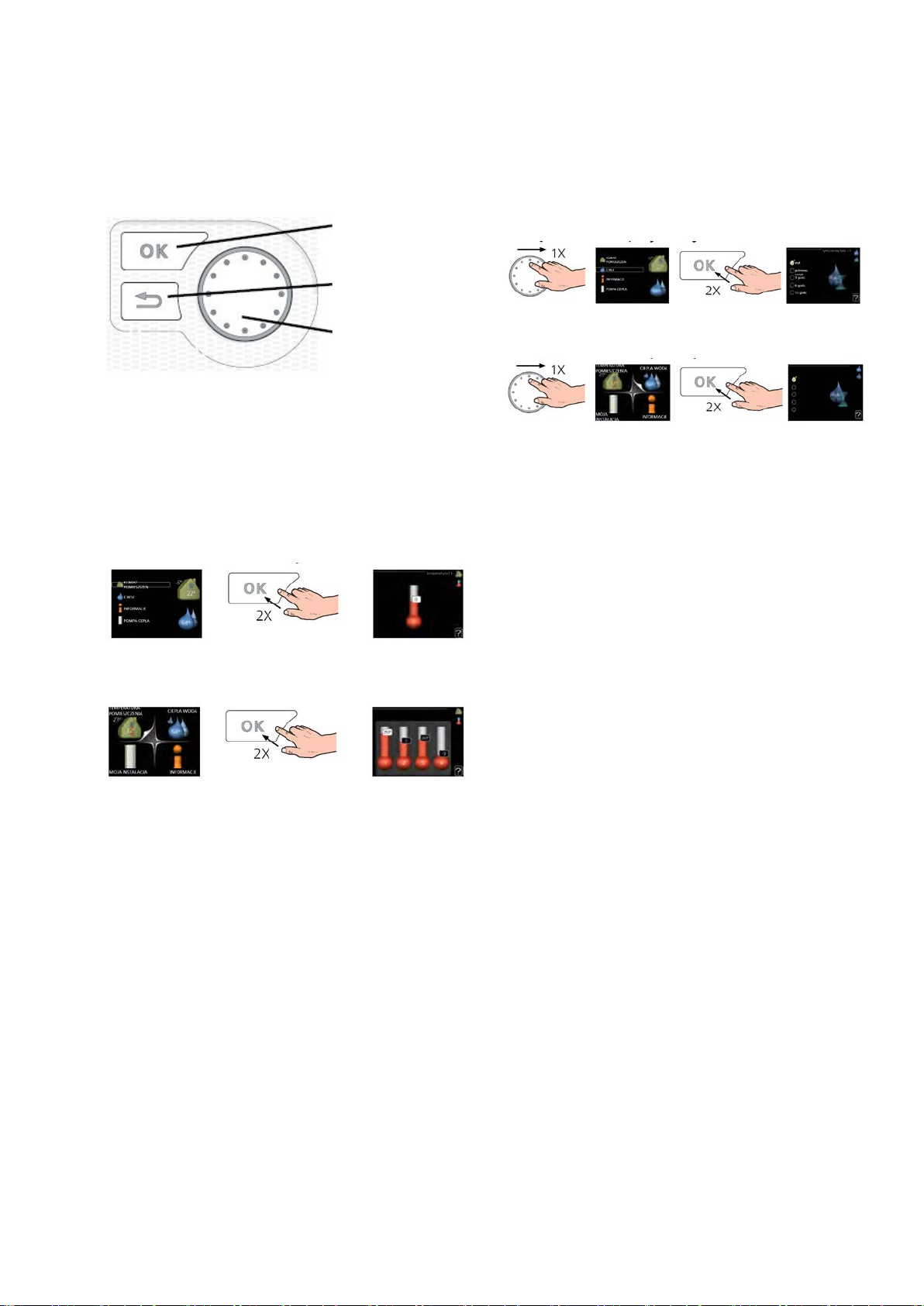

Navigation

Room temperature setting

Detailed description of button functions to be found in

section Display.

Moving about the menu and inputting various settings

has been specied in the Menu Selection section.

The room temperature setting mode is selected by

pressing the OK button twice from the start mode lev-

el in the main menu. More information to be found in

section Room temperature setting.

SMO 20

SMO 40

In order to temporarily increase hot water volume rst

turn the control knob to mark menu 2 (icon present-

ing water drop) and press the OK button twice. More

information to be found in section Setting hot water

output

If there are any distortions to the heat comfort, before

contacting the installation technician, you can per-

form some activities yourself.Appropriate instructions

can be found in section Cancelling the settings.

Increase hot water volume

If the heat comfort is distorted

Ok button

(conrm/select)

Back Button (back/

cancel/exit)

Regulation knob

(move/increase/decrease)

Abbreviated manual

SMO 20

SMO 40

3List of contents |HK 200M

List of contents

1 Important information _______ 4

Safety information4

2 Supply and handling ________ 6

Transport ______________________________ 6

Assembly ______________________________ 6

Supplied elements _______________________ 6

Cover removal __________________________ 6

3 Construction of the internal mod-

ule _________________________ 7

4 Pipe connections ___________ 9

General information ______________________ 9

Dimensions and pipe connections __________ 12

Connection of inner unit__________________ 13

Connection options______________________ 15

5 Electrical connections ______ 16

General information _____________________ 16

Connections___________________________ 17

Settings ______________________________ 24

6 Start-up and regulation _____ 25

Preparations___________________________ 25

Filling and venting ______________________ 25

Start-up and acceptance _________________ 26

7 Control __________________ 27

Display _______________________________ 27

System menu__________________________ 27

8 Maintenance service _______ 28

Servicing activities ______________________ 28

9 Distorted heat comfort______ 29

10 Accessories _____________ 29

11 Technical data____________ 30

Dimensions and layout of connections ______ 31

Technical data _________________________ 31

Diagram of electrical connections __________ 32

4HK 200M

1 Important information

Information regarding

safety Serial number

Symbols

Marking

HK 200M features the CE mark and re protection

IP21.

The CE mark con rms that NIBE-BIAWAR has taken

care for product conformity with applicable regula-

tions of relevant EU Directives. The CE is required

for most products sold in the EU, regardless of their

place of manufacture.

IP21 means that items with the diameter greater or

equal to 12.5 mm cannot permeate inside causing

damage, and that the product has been secured

against vertically falling water drops.

The device can be operated by children aged over

8 and persons with physical, sensory, or mental dis-

abilities, and without any experience or knowledge

about its operation, if supervised or trained in safe

operation, and if they understand the risks related

to its operation. The device must not serve as a toy

for children. Activities related to cleaning and basic

maintenance must not be performed by unsupervised

children.

Rights to introduce structural changes reserved.

©NIBE-BIAWAR 2016

This manual contains installation and maintenance proce-

dures for specialists.

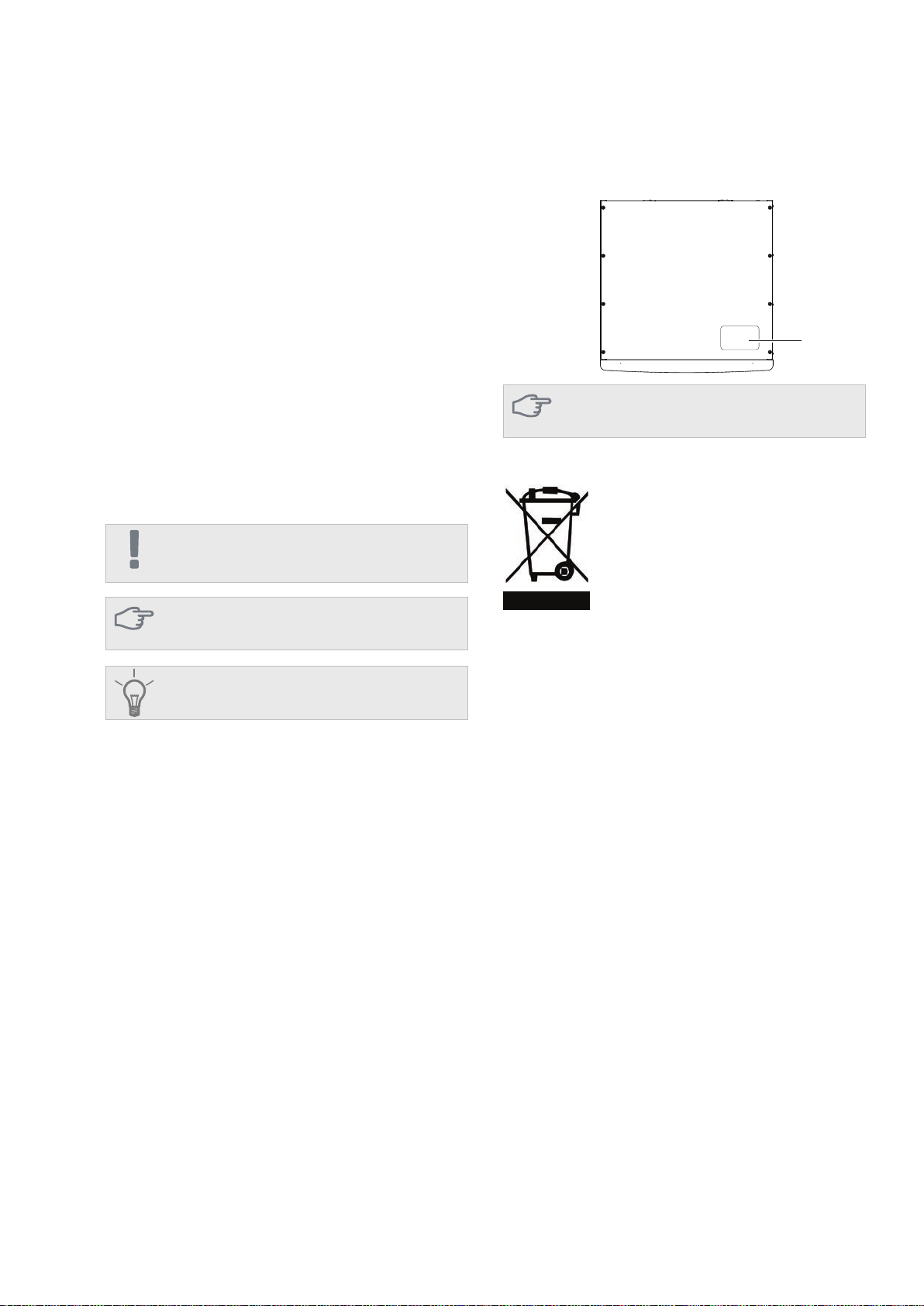

The serial number is located at the top of HK 200M.

IMPORTANT

This symbol informs about the risk to the device or a

person

CAUTION

This symbol points to important information to be not-

ed when operating the device.

ADVICE

This symbol shall mean tips to make product operation

easier.

CAUTION

When contacting the installation technician, always

provide the product serial number (14 digits).

Serial

number

Waste disposal

Information for particular countries

Disposal of the packaging shall be the

responsibility of the installation techni-

cian installing the product, or a special

waste management facility.

Incorrect disposal of the product by the user is sub-

ject to administrative penalties under applicable reg-

ulations.

Installation manual

This installation manual must be submitted to the Cli-

ent.

Do not dispose of decommissioned prod-

ucts together with regular household

wastes. Hand them over to a specialist

facility.

dealing with waste disposal or salesperson offering

such services.

Chapter 1 | Important information

5HK 200M

Description Notes Signature Date

Heating medium

Installation rinsing

Installation venting

Diaphragm expansion vessel

Particulate lter

Safety valve

Cut-off valves

Pressure in the heating system

Connection according to the

drawing

Hot water

Cut-off valves

Mixing valve

Safety valve

Power supply

Communication connection

Circuit fuses

Fuses,

internal module

Building fuses

temperature sensor

outdoor

Room sensor

Energy meter

Emergency switch

Switch

differential

Thermostat emergency mode

setting

Miscellaneous

Connected to

Installation acceptance

The heating system must be accepted before start-up. Acceptance must be done by a person with appropriate

qualications. Complete the card in the operating manual by entering the installation data.

Checklist

Chapter 1 | Important information

6HK 200M

2 Supply and operation

Transport

Assembly

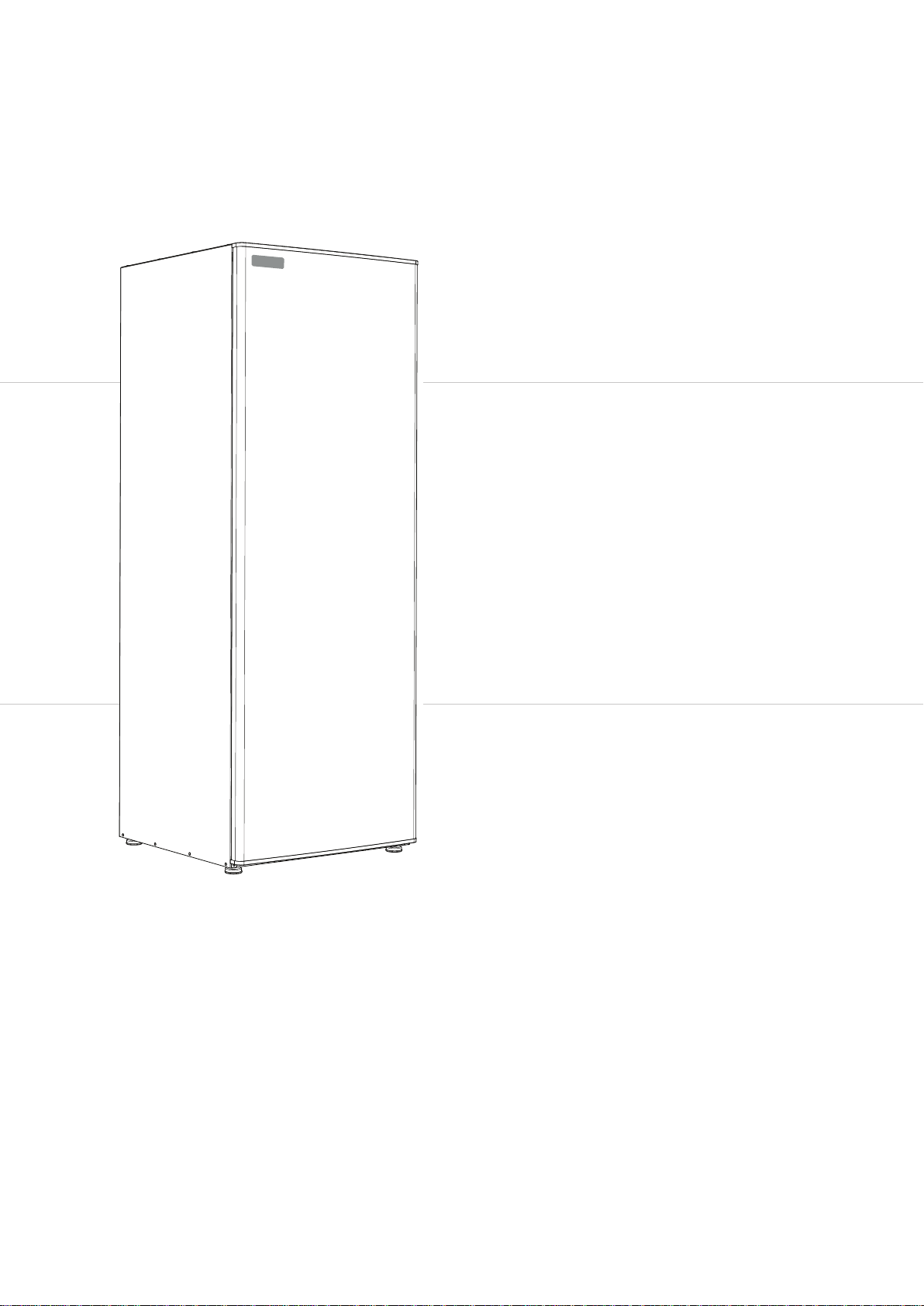

HK200M indor device must betransportedandstored

vertically in a dry place. HK 200M can be, however,

carefully placed on the rear side of the casing when

carrying the device into the building.

Leave 800 mm free space at the front of the mod-

ule. All maintenance works on HK 200M can be done

from the front.

Side covers are installed for permanent, therefore,

they cannot be disassembled.

• HK 200M must be set on a solid waterproof base

that would keep the weight of the indoor unit. The

regulated legs of the heat pump allow for levelling

and stable setting of the device.

• Because HK 200M is equipped with condensate

drain, the installation site of the indoor module

must be furnished with a oor drain with a dis-

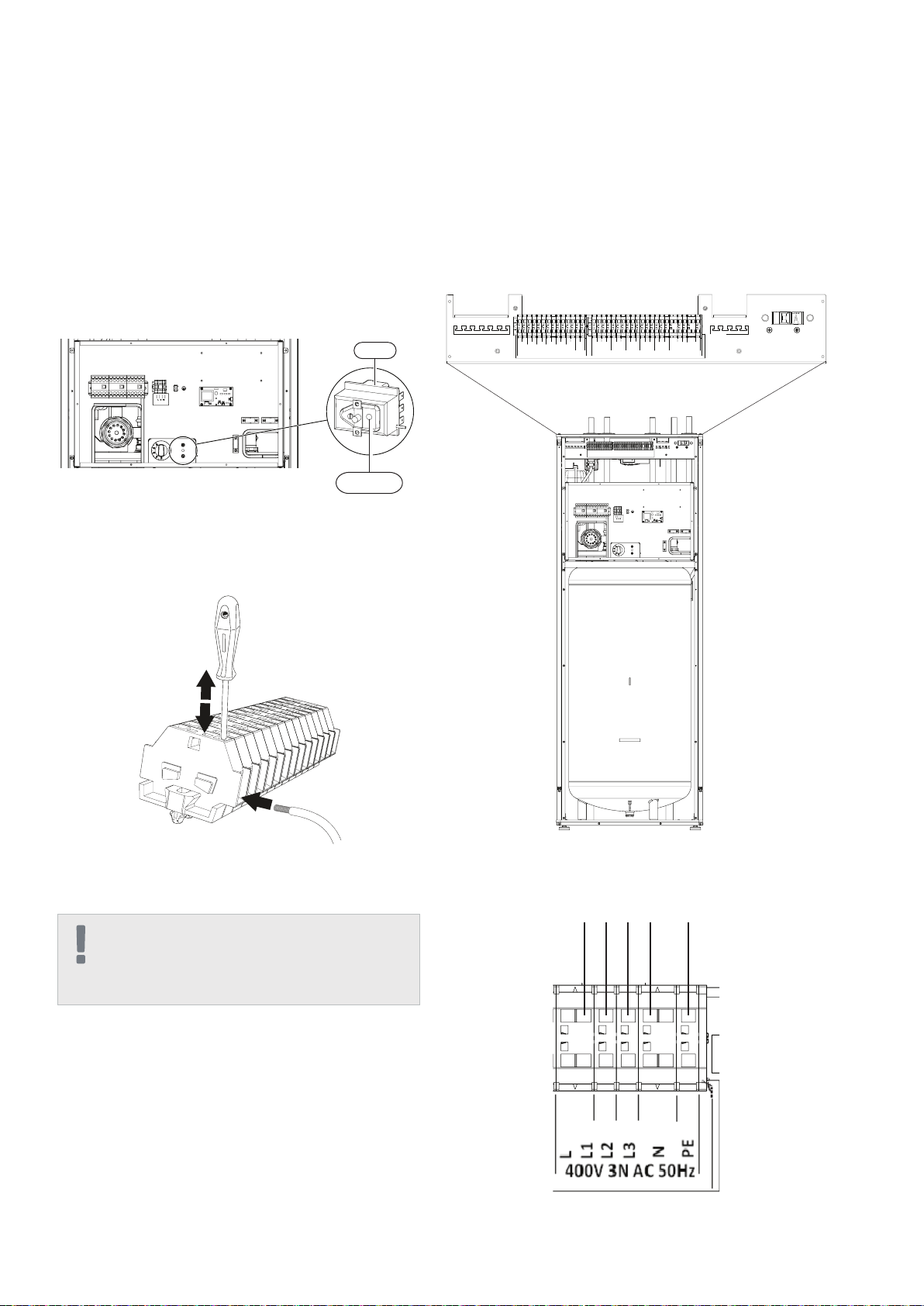

charge to the sewer system. 1. Remove screws at the bottom edge of the front

cover.

2. Tilt the cover at the bottom edge and lift.

Installation site

IMPORTANT

Leave 10 – 25 mm free space between the indoor

module and the back wall for cables and piping.

800 mm

Cover removal

1

2

Chapter 2 | Supply and operation

20-40 mm

Elements supplied

Safety valve

with a manometer

Wrench size 13

7HK 200M

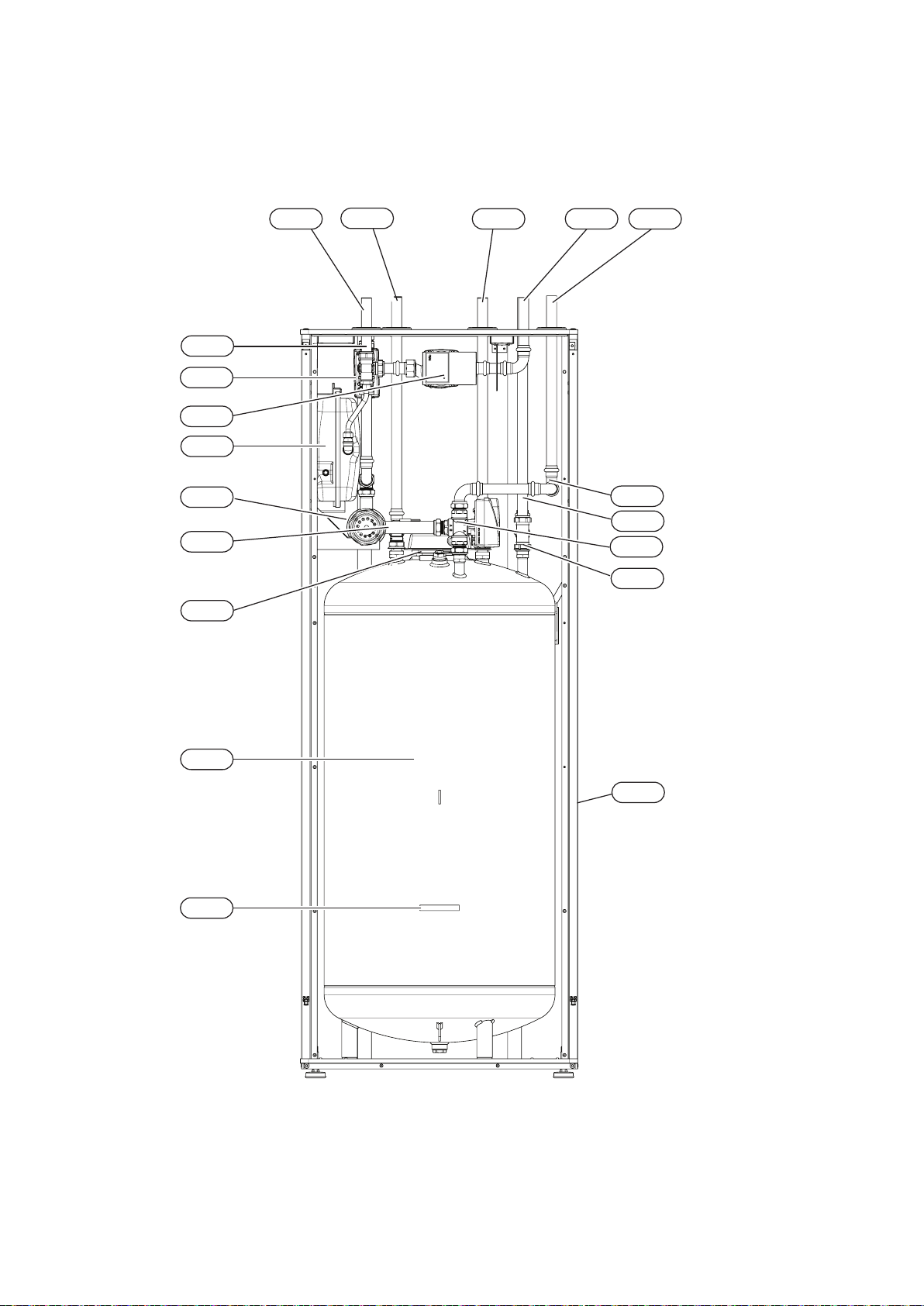

3 Indoor module structure

Chapter 3 | Indoor module structure

HK 200M

EB2

XL11

QN12

QN10

GP12

CM1

EB1

XL3 XL8

XL4 XL1

EB15

BT71

BT6

BT64

BT63

BT7

BT25

BT3

8HK 200M

EMERGENCY

Brown

Black

N

PWM

GND

K1

K2

K3

L

N

PE

BT64 BT63 BT25 BT71BT6

GP12

X1 X2

GP12

L

N

PE

PE

L3

L2

L1

L

N

SMO 400V 3N AC 50Hz

QN12

Brown

Black

N

QN10

BT7

F1

LEGEND

X1 X2

Chapter 3 | Indoor module structure

K1-K3

T1

X3

AA8

F3

Pipe connections

XL1 Connection, heating medium, supply

XL3 Connection, hot water

XL4 Connection, cold water

XL8 Connection, supply of the heating medi-

um from the external unit

XL11 Connection, safety group,

manometer

HVAC elements

CM1 Diaphragm expansion vessel, closed,

heat medium

QN10 Isolation valve, domestic hot water / cen-

tral heating

QN12 Isolation valve, cooling/heating

GP12 Circulation pump

Sensors

BT3 Temperature sensor, heating medium re-

turn

BT6 Temperature sensor, hot water loading

BT7 Temperature sensor, top of the hot water

heater

BT25 Temperature sensor, heating medium

supply

BT63 Temperature sensor, heating medium

supply downstream the submersible heat-

er

BT64 Temperature sensor, cooling medium

supply

BT71 Temperature sensor, heating medium re-

turn

Electrical elements

X1 Terminal block for low

voltage

X2 Terminal block for low

voltage

X3 Terminal block for high

voltage

K1-K3 Submersible heater contact

T1 Thermostat, standby mode

AA8 Titanium anode card

F3 Temperature limiter

F1 Circuit breaker

EB1 Submersible heater

Miscellaneous

EB15 HK 200M

PF3 Serial number

EB2 Hot water tank

9HK 200M

4 Pipe connections

General information

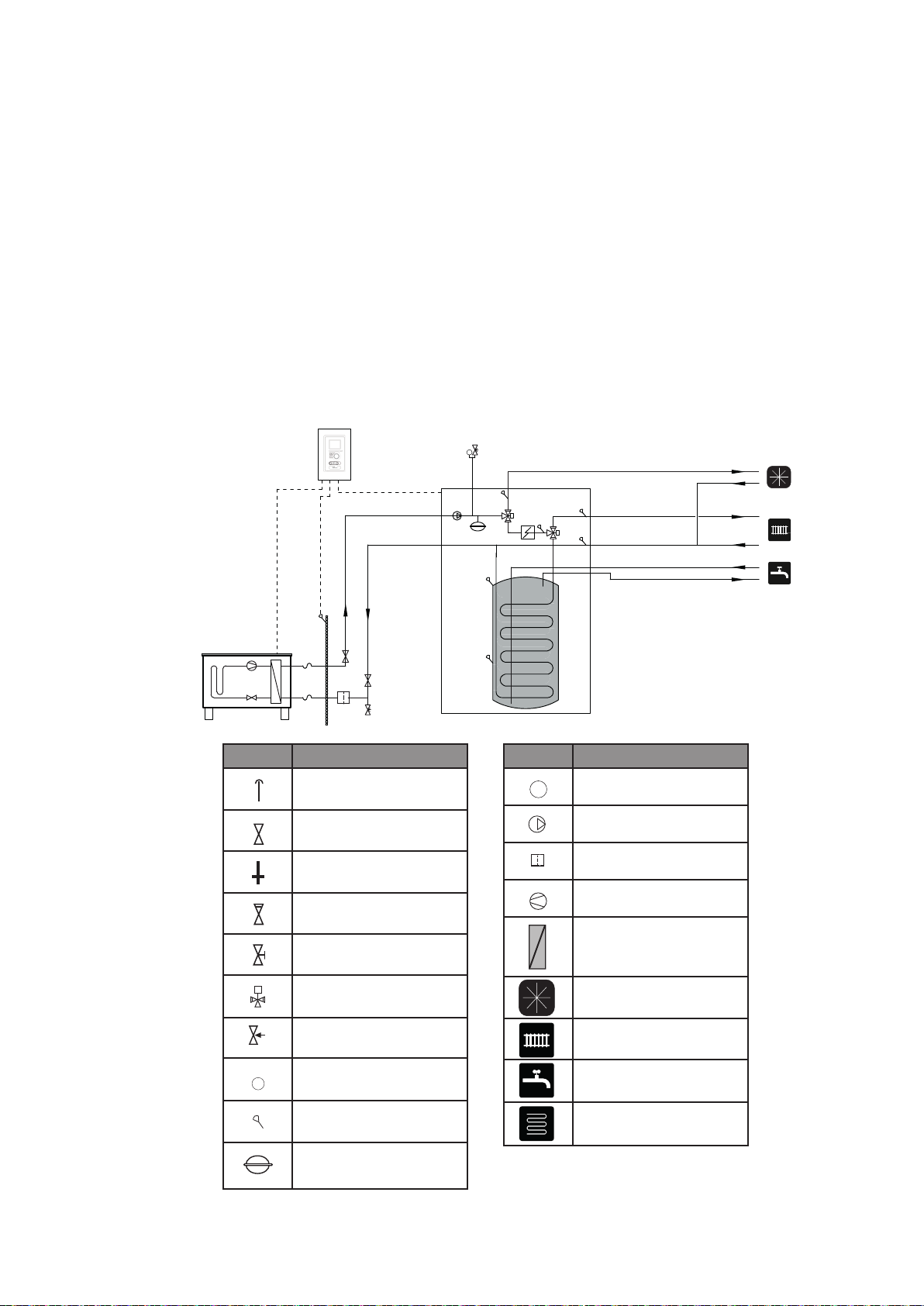

The piping installation must be executed according to

the applicable standards and directives.

HK 200M indoor unit, with NIBE Monoblock outdoor

air heat pump, and NIBE SMO controller form a com-

plete heating system.

The system can cooperate with a low- and medi-

um-temperature heating system. Recommended

temperature of the heating medium at minimum de-

signed outdoor temperature DOT must not exceed

55°C on supply, and 45°C on return circuit from the

heating system, whereas HK 200M can achieve even

65°C when using a ow-through heating module or

another peak heat source.

Excess medium owing out of the safety valve must

be discharged via a pipe to a oor drain. The over-

ow pipe must be slanted at the entire length from the

safety valve, and must be secured against freezing.

In order to achieve maximum system efciency, we

recommend the installation of HK 200M as close to

the heat pump as possible.

The HK 200M module is not equipped with cut-off

valves, which must be installed outside the indoor

module to make future maintenance easier. The HK

200M module can be connected to the central heat-

ing, cooling, and domestic hot water installation. In-

stall the supplied safety valve and the manometer.

HK 200M is equipped with a diaphragm expansion

vessel for a heating circuit of 10 I. Initial pressure of

the expansion vessel must be set appropriately to

the maximum height (H) between the vessel and the

highest heater, see the drawing. The initial pressure

of 0.5 bar (5 mvp) shall mean maximum permissible

height difference of 5 m.

If the standard initial pressure in the diaphragm ex-

pansion vessel is too low, it can be raised by lling the

vessel through the valve installed.

Any change to the initial pressure affects the dia-

phragm expansion vessel’s capacity to support the

increase in water volume.

IMPORTANT

All places in the heating system located high must be

equipped with vents.

IMPORTANT

Pipelines must be rinsed before connecting the indoor

module so that possible dirt does not damage its ele-

ments.

IMPORTANT

As long as heating circuits in the system have not been

led with the heating medium, do not set the switch

(SF1) in the SMO module in position “I” or “ ”. The

compressor in the heat pump and the ow-through

heating module can be damaged.

Capacities of the indoor unit and the

heating system

System requirements

The inner capacity of HK 200M for the purposes of

calculating the diaphragm expansion vessel in the

domestic hot water installation totals 180 l. The ca-

pacity of the diaphragm expansion vessel must con-

stitute at least 5% total capacity.

Minimum required conguration:

In order to assure correct operation, the capacity of

the heating system must meet the requirements for

the installation. If this condition has not been met, in-

stall an additional buffer tank. (NIBE UKV).

CAUTION

In this case a diaphragm expansion vessel of the

DHW installation must have the capacity of 10l. The

diaphragm expansion vessel at the domestic hot water

installation is not required. It is, however, required to

install a safety valve with opening pressure of 6 bar.

IMPORTANT

All connections require free ow, hence a discharge

valve must be installed.

Chapter 4 | Pipe connections

10 HK 200M

P

P

HK 200 S

HK 200 M

P

The HK 200M indoor unit is equipped with a coil water

heater, diaphragm expansion vessel , safety group,

electric heater, isolation valves, plate heat exchang-

er, metering instruments, and an electronic circulation

pump. Together with the heat pump NIBE Monoblok

and NIBE SMO module, it forms a complete heating

system.

The F2030, F2040 8 kW; F2040 12 kW, F2120 8

kW; F2120 12 kW, F2120 16 kW outdoor unit pro-

vides heat for heating the domestic hot water and

supplying the heating system while using free ener-

gy in the outdoor air, efciently operating within the

range of low temperatures up to -20°C.

The connection of the outdoor unit and indoor unit

HK 200M with a system of pipes lled with a cooling

medium secures the connection against freezing in

the event of any power outages. The control of sys-

tem operation is the function of SMO 20 or SMO 40

module.

Installation diagram

Chapter 4 | Pipe connections

Symbol Meaning

Vent

Cut-off valve

Water tap

Non-return valve

Balancing valve

Three-way valve

Safety valve

Thermometer

Temperature sensor

Diaphragm expansion

vessel

T

P

T

P

T

P

T

P

T

P

T

P

T

P

T

P

T

P

T

P

Symbol Meaning

Manometer

Circulation pump

Particulate lter

T

P

Compressor

T

P

Heat exchanger

Cooling

Central heating system

Domestic hot water

Heating systems

Floor heating

T

P

T

P

T

P

T

P

T

P

T

P

11HK 200M

Indoor HK 200M module

• It is recommended that the HK 200M module

should be installed in a room with a oor drain, at

best in a utility room or a boiler house.

• The oor must be solid, concrete at best.

• The HK 200M module must be set with its back

to the outer wall, at best in a room where noise is

not a problem. If possible, do not place the device

near a wall of a bedroom or another room where

noise might be a problem.

• The device can be leveled using regulated legs.

• Pipes must be led in such a way that they are not

adjacent to the bedroom or living room.

• Remember to leave about 800 mm free space at

the front and 500 mm over the device to provide

for future maintenance.

1. Connect HK 200M module to the heating system,

cold, and hot water pipelines.

2. Use hydraulic connections to connect the outdoor

and indoor unit.

3. Connect the current meter, outdoor temperature

sensor, centralized current control, and cables

between HK 200S, AMS 10 and SMO 20/40.

4. Connect power supply to module HK 200M.

5. Proceed according to start-up instructions in

chapter Start-up and regulation.

Recommended order of assembly

Chapter 4 | Pipe connections

12 HK 200M

Dimensions and pipe connections

Chapter 4 | Pipe connections

20-40

1600 95

XL11

XL10

XL3 XL5 XL4 XL2 XL1

XL9

XL8

PF3

300 155

45

95 90

120

85 65 55

600

610

315

70

Pipe connections

XL1 Connection, Heating medium supply

Ø22 mm

XL2 Connection, Heating medium return

Ø22 mm

XL3 Connection, hot water Ø22 mm

XL4 Connection, cold water Ø22 mm

XL5 Connection, circulation Ø15 mm

XL8 Connection, supply of the heating medi-

um from the external unit Ø22 mm

XL9 Connection, discharge of the heating me-

dium to the external unit Ø22 mm

XL10 Connection, cooling Ø22 mm

XL11 Connection, safety group

Ø22 mm, manometer

Other information

PF3 Serial number plate

65

13HK 200M

Compatible heat pumps

air/water by NIBE with module

HK 200M

Connection of the heating system

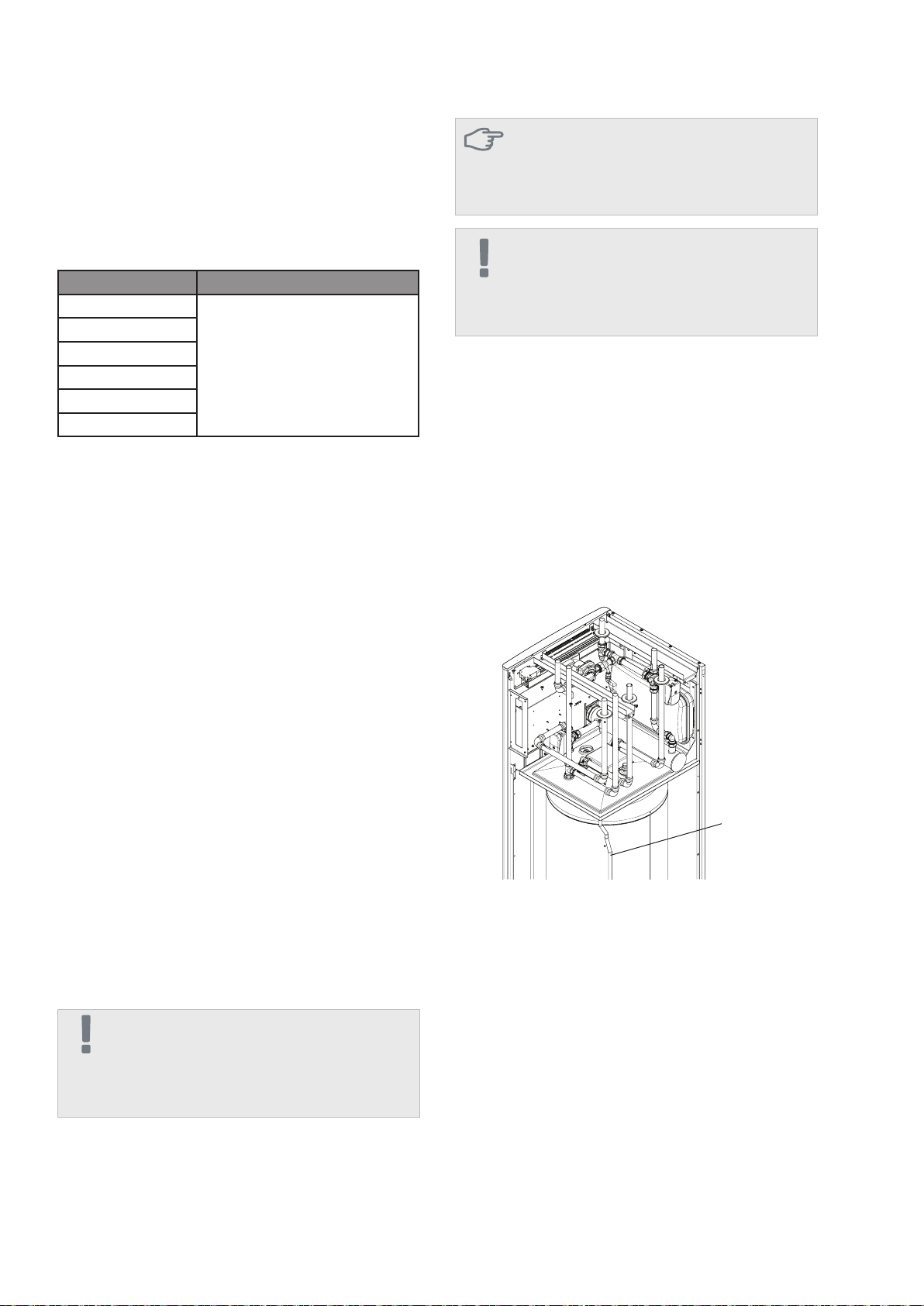

HK 200M indoor module can cooperate with Mono-

blok type outdoor units.

Compatible NIBE Monoblok heat pumps include:

An external heat source, e.g. a gas or oil boiler, can

be connected to (XL1) (input) and (XL2) (output) at

HK 200M.

The HK 200M module over the domestic hot water

tank features a drain tray from where condensate

is discharged via a hose. The hose drains all con-

densate away from the device to minimize the risk

of damage. If necessary, the hose can be extended.

Condensate

hose

Pipe connections of the heating system are to be

made at the top.

• All the required protections and cut-off valves

must be installed as close to the HK 200M mod-

ule as possible.

• Where necessary, install the vents.

• Safety valve with a nanometer at the central heat-

ing circuit and the safety valve at the hot water

system must be installed on relevant conductors

XL 11 and XL 4. In order to prevent ooding,

safety valve must be equipped with an over ow

pipe. The over ow pipe must be slanted at the

entire length from the safety valve, and must be

secured against freezing.

• When connecting to the installation where all

heaters have been equipped with thermostat

valves, install a discharge valve or remove sever-

al thermostats to assure appropriate ow.

IMPORTANT

The term “heating system”, as used in this installation

and operation manual, shall mean the heating or cool-

ing system supplied with a hot or cold medium from

the HK 200M module for heating or cooling purposes.

Connecting an external heat source

Condensate elimination

More information to be found at www.nibe.eu and

in relevant installation manuals for accessories used.

ChapterAccessories can serve to check the list of ac-

cessories to be used with HK 200M.

Chapter 4 | Pipe connections

Symbol Application

F2030

all versions

F2040 8 kW

F2040 12 kW

F2120 8kW

F2120 12kW

F2120 16kW

Connection of indoor unit

IMPORTANT

It is permitted that between the safety valve installed

on the pipe supplying cold water and XL4 connection,

there is a T-pipe with a drain valve and a T-pipe with a

diaphragm expansion vessel.

CAUTION

Directly on the pipe supplying cold water to the hot

water tank, safety valve must be absolutely installed

with opening pressure of 6 bar, which would protect

the tank against excessive pressure increase.

14 HK 200M

• The outdoor unit can be connected to the indoor

unit according to one of the system solutions to

be downloaded from website www.nibe.eu.

• The part of the outdoor unit with the indoor unit

that remains outdoors must be made using exi-

ble hoses supplied with the outdoor unit.

• We should install other elements supplied with

the outdoor unit.

• All outdoor pipes must be thermally insulated with

a pipe lining with at least 20mm thickness.

• Install cut-off and drain valves to allow for emp-

tying the outdoor unit in case of long power out-

ages.

• The supplied exible hoses act as vibration ab-

sorbers. Flexible hoses must be installed to form

elbows that would attenuate vibrations.

Connection between the outdoor and in-

door unit

Chapter 4 | Pipe connections

IMPORTANT

If the supply pump is controlled from the outside, it

must work even if the outdoor unit does not operate, to

prevent damage as a result of freezing.

15HK 200M

Connection to the heat pump

Connection when operating without a

heat pump

Connection of hot and cold water

All outdoor pipes must be thermally insulated with a

pipe lining with at least 20mm thickness.

HK 200M is not equipped with cut-off valves, which

must be installed outside the indoor module to make

future maintenance easier.

When connecting to the installation where all heaters/

oor heating pipes have been equipped with thermo-

stat valves, in order to assure appropriate ow, install

a discharge valve or a buffer in the parallel layout, or

remove several thermostats.

Connect the input pipe from the heat pump (XL8) to

output pipe XL9 of the heat pump.

The installation of the mixing valve is necessary

if factory settings are changed in a way where the

temperature can exceed 60°C. When changing the

factory settings, follow the national regulations in this

respect. The setting is entered in menu 5.1.1.

Connection of the heating system

The system can be extended by additional circuits ac-

cording to the capacity of the applied control module:

SMO 20 or SMO 40.

Additional accessories, capacity and connection

method have been specied in the manual for SMO

20 and SMO 40, in chapters Accessories and Elec-

trical connections.

Cooling system connection

Cooling is controlled by sensor BT64 and isolation

valve QN12. If cooling is needed, the isolation valve

changes the direction, and opens from the cooling

circuit side.

Optional connections

Chapter 4 | Pipe connections

P

P

P

P

P

HK 200 M

Connection options

16 HK 200M

5 Electrical connections

General information

The entire electrical equipment, apart from outdoor

temperature sensors, room sensors, and current in-

tensity meters, has been connected according to fac-

tory settings.

• Disconnect the indoor module before performing

tests of electrical system insulation in the build-

ing.

• If the building is equipped with a differential

switch, HK 200M must be equipped with a

separate switch.

• The diagram of indoor module connections can

be found in section „Diagram of electrical connec-

tions”.

• Do not lay communication and signal cables to

external contacts near high-voltage cables.

• Minimum cross-section of communication and

signal cables to external contacts must total 0.5

mm² with the length of up to 50 m, for example

EKKX or LiYY, or similar.

• Minimum cross-section of power supply cables

must total 0from 2.5 mm² to 4 mm².

• For cabling in HK 200M, use cable passes UB1

and UB2 (as marked in the drawing). In UB1 and

UB2, cables are input through the entire indoor

module from the back wall towards the front wall.

IMPORTANT

As long as the heating circuits have not been lled with

the heating medium, and if the central heating system

has not been vented, the switch (SF1) in SMO cannot

be set in positions „I” or „ ”. Otherwise, the tempera-

ture limiter, thermostat and ow-through heater can be

damaged.

X1 Terminal block for low

voltage

X2 Terminal block for high

voltage

X3 Terminal block for high

napięcia

K1-K3 Submersible heater contact

T1 Thermostat, standby mode

F3 Temperature limiter

AA8 Titanium anode card

F1 Circuit breaker

UB1 Cable pass

UB2 Cable pass

F3-SF2 Reset

X1

X2

LEGEND

Chapter 5 | Electrical connections

K1-K3

T1

X3

F1

AA8

F3

UB2 UB1

IMPORTANT

The electrical installation and maintenance service

must be performed under the supervision of a quali ed

power technician with relevant quali cations. Before

starting any maintenance works, power supply must

be cut off using an automatic switch. The electrical in-

stallation and cabling must be executed according to

applicable regulations.

IMPORTANT

If the power supply cable is damaged, it can only be

replaced by authorised service, its technician, or other

quali ed person, to avoid danger or damage.

17HK 200M

Temperature limiter (F3) is accessible behind the front

cover. Temperature limiter is reset by strong press-

ing of the button (F3-SF2) using a small screwdriver.

Press the button, max. 15 N (approx. 1.5 kg).

Resetting

Cable blockade

Use an appropriate tool to release/block cables in the

internal module clamps.

The power supply is to be connected to clamp (X2)

via the input at the back of the unit. The cable must be

dimensioned according to the applicable standards.

HK 200M must be connected to the power supply 400

V 3N AC 50Hz as speci ed on the clamp (X2).

Connection

Connections

IMPORTANT

In order to prevent interferences, do not lay unshielded

communication and/or signal cables to external con-

tacts at the distances lower than 20 cm from high-volt-

age cables.

Power supply connection

Temperature limiter

Temperature limiter (F3) cuts off the power supply of

the electrical heating module if the temperature in-

creases to the range of approximately 87 °C, and can

be reset manually.

F3

F3-SF2

L1 L2 L3 NPE

Circuit breaker

The system for automatic regulation of the heating,

circulation pump, and their cabling at HK 200M are

secured internally with a circuit breaker (F2).

Chapter 5 | Electrical connections

EMERGENCY

Brown

Black

N

PWM

GND

K1

K2

K3

L

N

PE

BT64 BT63 BT25 BT71BT6

GP12

X1 X2

GP12

L

N

PE

PE

L3

L2

L1

L

N

SMO 400V3N AC 50Hz

QN12

Brown

Black

N

QN10

BT7

2

1

3

18 HK 200M

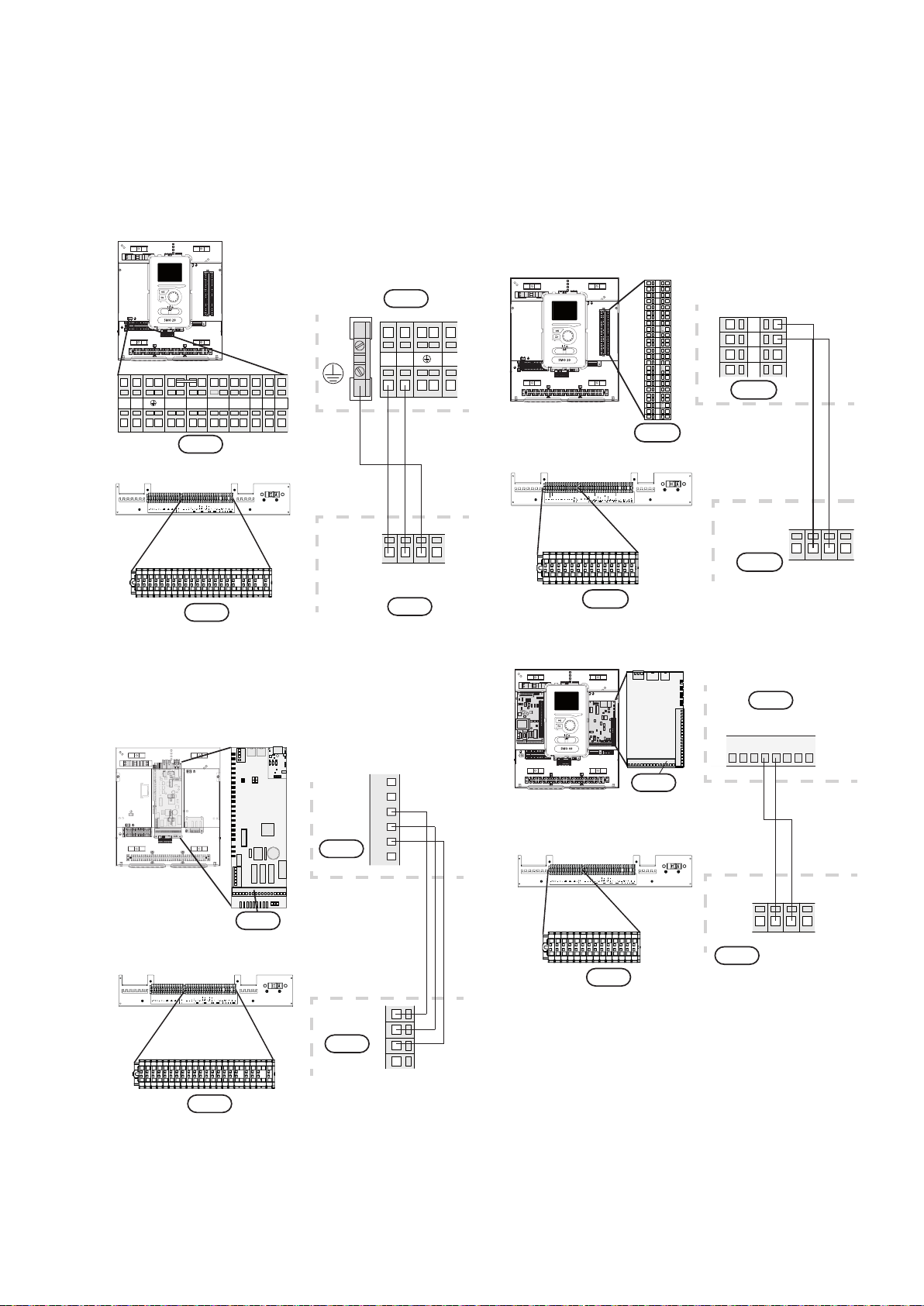

ConnectionsbetweenHK200MandSMO20/40

SMO 20/40 must be connected via the cut-off switch

with minimum contact-point gap of 3 mm. Minimum

cable cross-section is to be adjusted to the amperage

of fuses applied.

Connect the circulation pump (GP12) to clamps X4:5

(PE), X4:6 (N) and X4:7 (230 V) at the top board

(AA2), according to the drawing.

Power supply connection

Connecting the circulation pump

1NL

X1

LEK

L N 1 1 0 2 3 4PE

21 20 19 18 17 1615 14 13 12 11 10 9 8 7 6 5 4 3 2 1

X1

1 1NL 0 EP 2 3 4

X2

L

HK 200M

HK 200M

SMO 20

SMO 40

SMO 20/40

N PE

SMO

X2

PE

L

N

HK 200M

SMO20

SMO 40

987654

AA2-X4

X2

GP12

LEK

L N 1 1 0 2 3 4PE

AA2-X4

SMO20/40

L

N

PE

HK 200M

X2

Chapter 5 | Electrical connections

SMO 20

SMO 40

Connect the control signal (GP12) for SMO 20 to

clamps X2:1 (PWM) and X2:2 (GND), while for SMO

40 to clamps X4:8 and X4:7, according to the draw-

ing.

2

1

4

3

SMO

Externt

HK 200M

SMO20

SMO20

X2

PWM

GND

LEK

L N 1 1 0 2 3 4PE

21 20 19 18 17 1615 14 1312 11 10 9 8 7 6 5 4 3 2 1

X2

5

6

7

2

1

8

9

13

12

4

3

11

10

19

20

21

14

18

16

17

15

X1

PWM

GP12

GND

HK 200M

X1

Externt

HK 200M

SMO40

PWM

GND

X1

PWM

GND

5 467891011

AA3-X4

SMO40

L N 1 1 0 2 3 4PE

1 2 3 4

LEK AA3-X4

GP12

HK 200M

X1

19HK 200M Chapter 5 | Electrical connections

SMO 20

SMO 20

SMO 40

SMO 40

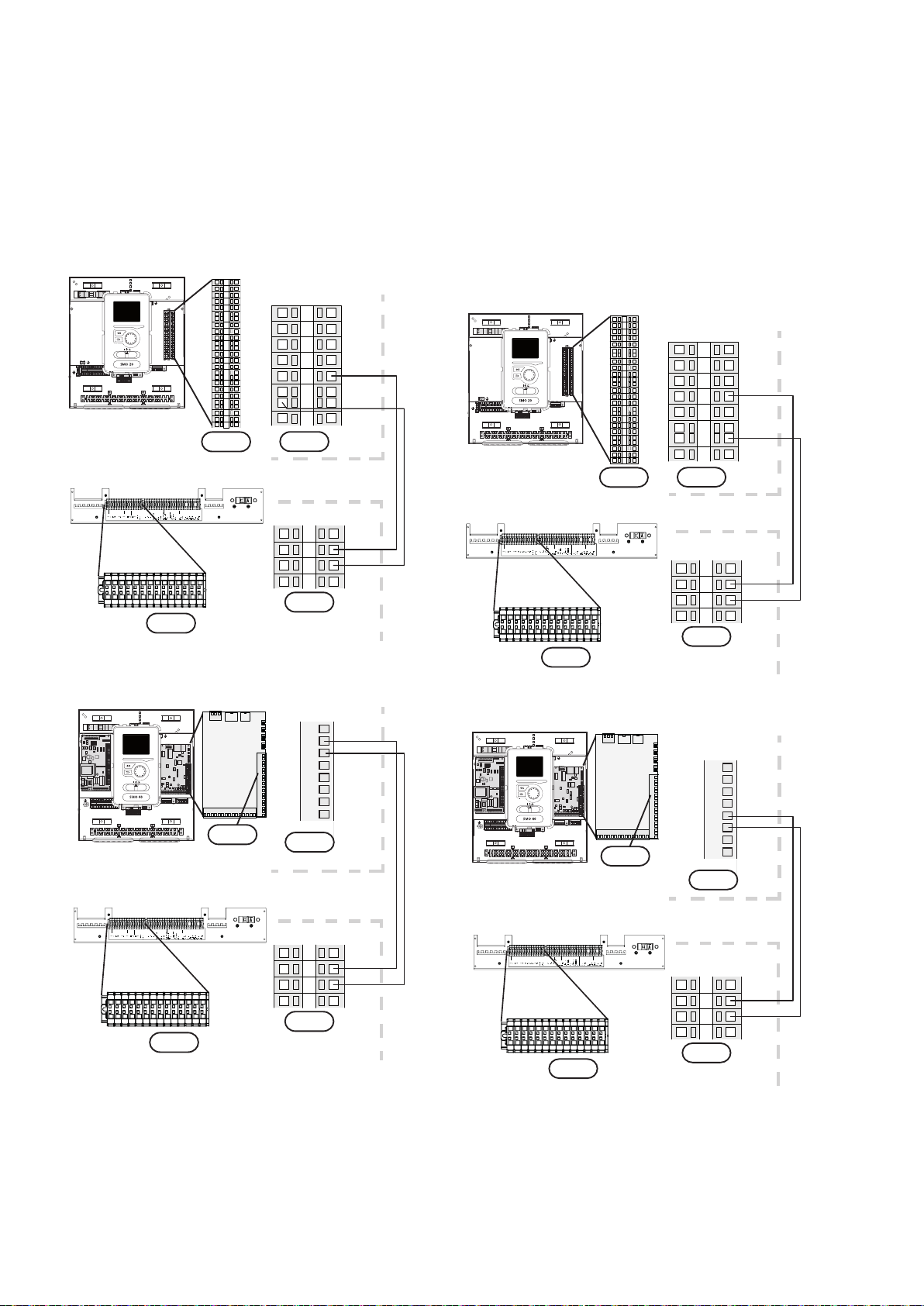

Temperature sensor, hot water loading DHW temperature sensor

Temperature sensor, hot water loading (BT6) is locat-

ed at the bottom part on the DHW heater.

The sensor must be connected - for SMO 20 to clamps

X2:5 and X2:6, while for SMO 40 to clamps X6:7 and

X6:8. Use a two-wire cable with the cross-section of

at least 0.5 mm².

Temperature sensor in the top part of the DHW heater

(BT7) indicates water temperature at the top part of

the tank.

The sensor must be connected - for SMO 20 to clamps

X2:4 and X2:6, while for SMO 40 to clamps X6:15

and X6:16.Use a two-wire cable with the cross-sec-

tion of at least 0.5 mm².

5

6

7

2

1

4

3

HK 200M

SMO20

X2

X1

BT6

LEK

L N 1 1 0 2 3 4PE

21 20 19 18 17 1615 14 13 12 11 10 9 8 7 6 5 4 3 2 1

X2

5

6

7

2

1

8

9

13

12

4

3

11

10

19

20

21

14

18

16

17

15

SMO20

HK 200M

X1

HK 200M

SMO40

X1

BT6

6

7

8

9

10

11

12

13

AA3-X6

SMO40

L N 1 1 0 2 3 4PE

1 2 3 4

LEK AA3-X6

HK 200M

X1

5

6

7

2

1

4

3

HK 200M

SMO20

X2

X1

BT7

LEK

L N 1 1 0 2 3 4PE

21 20 19 18 17 1615 14 13 12 11 10 9 8 7 6 5 4 3 2 1

X2

5

6

7

2

1

8

9

13

12

4

3

11

10

19

20

21

14

18

16

17

15

SMO20

HK 200M

X1

HK 200M

SMO40

X1

BT7

11

12

13

14

15

16

17

18

AA3-X6

SMO40

L N 1 1 0 2 3 4PE

1 2 3 4

LEK AA3-X6

HK 200M

X1

20 HK 200MChapter 5 | Electrical connections

Temperature sensor, on

supply pipeline

Temperature sensor on cooling supply (BT25) must

be connected for SMO 20 to clamps X2:8 and

X2:10, while for SMO 40 to clamps X6:5, X6:6. Use

a two-wire cable with the cross-section of at least 0.5

mm².

9

10

11

6

8

7

HK 200M

SMO20

X2

X1

LEK

L N 1 1 0 2 3 4PE

21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

X2

5

6

7

2

1

8

9

13

12

4

3

11

10

19

20

21

14

18

16

17

15

BT25

HK 200M

X1

HK 200M

SMO40

X1

BT25

4

5

6

7

8

9

10

11

AA3-X6

SMO40

L N 1 1 0 2 3 4PE

1 2 3 4

LEK AA3-X6

HK 200M

X1

SMO 20

SMO 40

Temperature sensor on the supply pipeline at

the heating module upstream the isolation valve

(QN10)

Temperature sensor on the pipeline downstream the

heating module (BT63) must be connected in SMO

20 to clamps X2:9 and X2:10, while in SMO 40 to

AUX clamps, e.g.: X6:13 and X6:14, and then turn on

sensor power supply - see SMO40 installation man-

ual. Use a two-wire cable with the cross-section of at

least 0.5 mm².

9

10

11

6

8

7

HK 200M

SMO20

SMO20

X2

X1

BT63

LEK

L N 1 1 0 2 3 4PE

21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

X2

5

6

7

2

1

8

9

13

12

4

3

11

10

19

20

21

14

18

16

17

15

SMO20

HK 200M

X1

HK 200M

SMO40

X1

BT63

L N 1 1 0 2 3 4PE

1 2 3 4

LEK AA3-X6

SMO40

7

8

9

10

11

12

13

14

AUX3

AUX2

AUX1

AA3-X6

HK 200M

X1

SMO 20

SMO 40

Table of contents

Other NIBE-BIAWAR Heat Pump manuals

Popular Heat Pump manuals by other brands

Hillphoenix

Hillphoenix CO2One manual

alphainnoTec

alphainnoTec LWC Series operating manual

Glowworm

Glowworm Envirosorb 5 installation manual

Grandaire

Grandaire R4H3 Series installation instructions

Sunsystem

Sunsystem TDA Series Installation and operation manual

OCEANAIRE

OCEANAIRE 2OACH1211 Engineering, installation and service manual

Daikin Altherma

Daikin Altherma EHVH04SU18CB6W installation manual

Trane

Trane Axiom GEHB Installation operation & maintenance

Trane

Trane 4TTR7 Series Installer's guide

HTW

HTW RSJ Series Owners and installation manual

Lennox

Lennox Magic-Pak PWC182 Installation and maintenance instructions

Toshiba

Toshiba HWT-601XWHM3W-ETR Service manual