Hillphoenix CO2One User manual

CO2One

CO2Condensing Unit Manual

DECEMBER 2021

I

DISCLAIMER

This manual is designed to provide only general information. If advice

about a particular system or component is needed, consult your

supervisor or a senior technician. Any applicable specification sheets,

data sheets, handbooks, and instructions for this installation provided by

Hillphoenix should only be consulted for information including, without

limitation, material regarding the design, installation, maintenance,

care, warnings relating to, and proper uses of Hillphoenix products as

they pertain to this installation. Any information pertaining to products

referred to in this manual that are not provided by Hillphoenix is in no

way intended to be authoritative or in any way ensured to be accurate.

INFORMATION CONTAINED WITHIN THIS MANUAL, IS PROVIDED “AS

IS,” WITH ALL FAULTS, WITH NO REPRESENTATIONS OR WARRANTIES

OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, QUALITY OF INFORMATION,

QUIET ENJOYMENT, AND TITLE/ NONINFRINGEMENT. HILLPHOENIX

SPECIFICALLY DISCLAIMS ALL LIABILITY FOR ERRORS OR OMISSIONS

IN, OR THE MISUSE OR MISINTERPRETATION OF, ANY INFORMATION

CONTAINED IN THIS MANUAL. HILLPHOENIX DOES NOT WARRANT THE

ACCURACY, COMPLETENESS OR TIMELINESS OF THE INFORMATION

CONTAINED IN THIS MANUAL.

Copyright©2021

Rev: Ver 1.0 November 26, 2021

II

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Important Notices

Hillphoenix emphasizes important information in installation and operations manuals with alert symbols. These

symbols, and text, call attention to potential dangers to personal health and safety – as well as to equipment

damage – if the instructions in this manual are not followed carefully.

Hillphoenix industrial Hillphoenix industrial refrigeration systems should only be installed and serviced by trained

refrigeration systems should only be installed and serviced by trained and qualied technicians who have

experience working with industrial refrigeration systems.

ATTENTION!ATTENTION!

Indicates important information that is

critical to proper system performance.

CAUTION!CAUTION!

Indicates the threat of potential injury if

all instructions are not followed carefully.

DANGER!DANGER!

Indicates an immediate threat of serious injury or

death if all instructions are not followed carefully.

Experienced installers and technicians not only assure that customers enjoy optimum and technicians not

only assure that customers enjoy optimum system performance, but that potential problems and unforeseen

circumstances system performance, but that potential problems and unforeseen circumstances encountered

during the installation process are either avoided or addressed in the most encountered during the installation

process are either avoided or addressed in the most effective and efcient way possible. For a list of Hillphoenix-

authorized installation and effective and efcient way possible. For a list of Hillphoenix-authorized installation

and service contractors, including our own AMS Group, visit our website at www.hillphoenix. com.

III

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

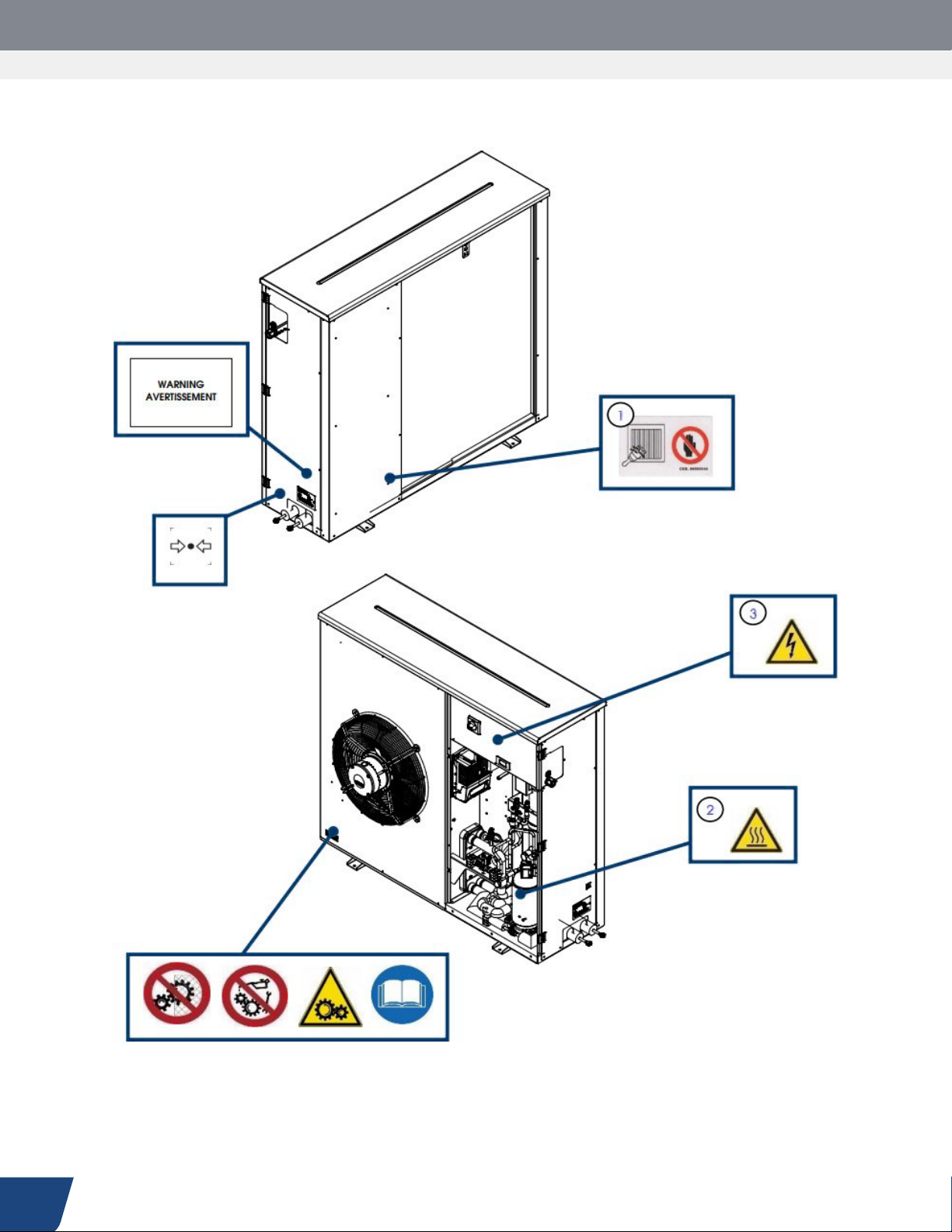

Safety Labels

The warning labels shown in the table below are present on the equipment.

PLATE DESCRIPTION

Indicates that it is forbidden to remove the safety devices and protections

installed; it is usually accompanied by the explanatory wording: DO NOT

REMOVE THE PROTECTIVE DEVICES.

Indicates that it is forbidden to perform any type of maintenance (including

lubrication and cleaning) near moving parts; usually, it is accompanied by

the explanatory wording: DO NOT REPAIR OR ADJUST WHILE THE MACHINE

IS RUNNING.

Signals the danger due to the presence of mobile parts near the area of the

partly completed machinery where it is positioned.

Signals the danger of electrical voltage.

Signals the danger of hot surfaces.

Signals that it is mandatory to read the manual/assembly instructions.

Warns against touching the parts in near the area where it is afxed.

System or component pressurized

System contains refrigerant under high pressure. Do not tamper with it.

It must be serviced by qualied persons only.

The refrigerator is for use with R744 (carbon dioxide) system components

where the design pressure of the refrigerator is not less than the design

pressure of the associated components.

WARNING: more than one source of electrical supply. Disconnect all sources

before servicing.

IV

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

1. On all the air exchangers present in the equipment

2. On each surface subject to high temperatures

3. On each energized part

Position of the Pictograms

V

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Hillphoenix, Inc. - All rights reserved

These assembly instructions are intended for users of CO2One and for the instruction of the technicians

involved in installation and maintenance. The instructions, drawings, tables, and anything else contained in

this instruction manual are of a reserved technical nature and cannot be reproduced and/or disclosed, either

completely or partially, without the specic written authorization of Hillphoenix.

The installation and maintenance technicians are explicitly prohibited from disseminating the information

contained and from using this manual for purposes other than for those strictly related to efcient maintenance

of the equipment.

Hillphoenix cannot be held responsible or liable for damages caused by incorrect use of the documentation.

In order to avoid actions that could cause danger to persons, it is important to read and understand all the

documentation accompanying the equipment.

Manufacturer’s Name Hillphoenix, Inc.

Address 2016 Gees Mill Road

Conyers, GA 30013

Telephone 770-285-3264

Fax 770-285-3080

VI

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

General Information

This manual covers general installation, operation, maintenance, and troubleshooting of a Hillphoenix industrial

refrigeration system. It can serve as a useful resource for understanding the system and its operation.

Receiving Equipment

Receiving Equipment Inspect all arriving equipment carefully. In the event of shipping damage and/or shortages,

contact the Hillphoenix Service Parts Department at 800-283-1109.

Missing Items

Missing Items Hillphoenix carefully inspects all systmes and products before shipping to ensure the highest

level of quality. There may be occasions however, when a particular item or part is not included when the

system or product is shipped. Any claim for missing items must be made to Hillphoenix within 48 hours of

receipt of the equipment.

Technical Support

Technical Support For technical support issues regarding this unit, contact the Hillphoenix Refrigeration Technical

Support at 770-285-3061.

Ordering Equipment Parts

Contact Hillphoenix OEM Genuine Parts at 833-3PARTS1 (833-372-7871) if any

additional parts are needed during installation or any time afterwards for the

system. If a part does not have a barcode, the following can assit in ordering the

right part:

• Model number and serial number of the part

• Size of the part, if applicable

• Whether the part is for a left-handed or a right -handed application

• Quantity of parts required

• Ship-to location for parts delivery

If Hillphoenix decides that a part must be returned, a Return Material Authorization number will be provided to

complete the process.

VII

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

12

VIII

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

General Conditions

The manufacturer, Hillphoenix, Inc., guarantees the equipment produced by the manufacturer itself as being free

from material and processing defects for a period that is agreed upon when the contract for the sale of the same

unit is concluded.

The parts subject to wear and all the tools and consumables supplied by the manufacturer together with the

equipment are excluded from the warranty.

Actions That Invalidate the Warranty

Any attempt to disassemble, modify, or tamper with a component of the equipment by the user or by

unauthorised personnel entails invalidating of the warranty and exempts the manufacturer from any

responsibility for any damage to persons or property deriving from such tampering. The manufacturer is also

deemed to be exempted from any liability with invalidation of the warranty relating to the equipment in the

following cases:

• Use contrary to that described in Proper and Improper Use of the Equipment in Section 2: Safety Introduction

• Use contrary to local codes and ordinances

• Installation under conditions other than those specied in Section 4: Transport and Installation

• Iinstallation not compliant with the specications provided in Section 4: Transport and Installation

• Full or partial failure to comply with the instructions provided in this instruction manual

• Non- or incorrect maintenance

• Use of spare parts which are not original or not specied by the manufacturer

Assistance

This instruction manual does not replace the experience of trained and qualied installers, users, and

maintenance technicians.

Hillphoenix provides telephone support as well as documentation covering the installation, use, and maintenance

of the equipment.

WARNING: If in any doubt about the correct interpretation of the instructions provided in these

assembly instructions, contact the Hillphoenix Technical Support team for clarication.

Provide the name, model, and serial number of the equipment when requesting assistance.

IX

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Table of Contents

Section 1: Overview................................................ 1

Introduction .....................................................................1

Proprietary Information ...........................................................1

Contents of the Assembly Instructions ...............................................2

Conventions and Definitions .......................................................3

Section 2: General Safety Information ................................ 5

Engineering Criteria ..............................................................5

Devices and Solutions for Protection ................................................6

Residual Risks ...................................................................7

Proper and Improper Use of the Equipment ...........................................7

Incorporation Statement ..........................................................8

General Warnings and Rules of Conduct .............................................8

Section 3: Description of the Equipment ............................. 10

Identification Plate ..............................................................13

Section 4: Transport and Installation ................................ 16

Environmental Requirements .....................................................16

Power Supplies and Utilities ......................................................16

Transport and Handling ..........................................................17

Installation .....................................................................19

Preparation for Startup...........................................................34

Storage ........................................................................46

Uninstalling ....................................................................46

Section 5: Maintenance ........................................... 47

Maintenance and Cleaning .......................................................48

Safety Valve Operation ...........................................................51

Section 6: Troubleshooting ........................................ 52

Section 7: Appendices ............................................ 54

1

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 1: Overview

CO2One Condensing Unit

Section 1: Overview

Introduction

These assembly instructions are an integral part of the CO2One product (identied in this document as the

equipment or unit) produced by Hillphoenix, Inc.; they will need to be included in the documentation for the

equipment when it is installed.

These instructions have been written to provide the technicians involved in the installation and maintenance of

the equipment with the essential information and instructions to operate correctly and safely.

ATTENTION: Needing to be easily and immediately available, these instructions must be kept in a

place that is known and accessible to all.

The purchaser may request a copy of this document (for example, in case of damage to the original

document) with a written request to Hillphoenix Technical Support (see Request for Assistance later

in this section), and agrees to return the damaged copy.

Proprietary Information

These assembly instructions contain condential proprietary information. All rights reserved.

These instructions may not be reproduced or photocopied, in whole or in part, without the prior written consent of

the manufacturer. Only the purchaser to whom the instructions have been provided may use this documentation

with the equipment and only for the purposes of installation and maintenance of the equipment to which the

instructions refer.

The manufacturer declares that the information contained in these instructions is consistent with the technical

and safety specications of the equipment to which the instructions refer. The drawings, diagrams, and technical

data shown are updated at the date of publication of this document and are valid only for the equipment to which

they have been attached.

The manufacturer reserves the right to apply changes or improvements to this documentation without prior notice.

The manufacturer assumes no responsibility for direct or indirect damage to persons, property, or pets resulting

from use of this material or of the equipment in conditions other than those provided for.

2

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 1: Overview

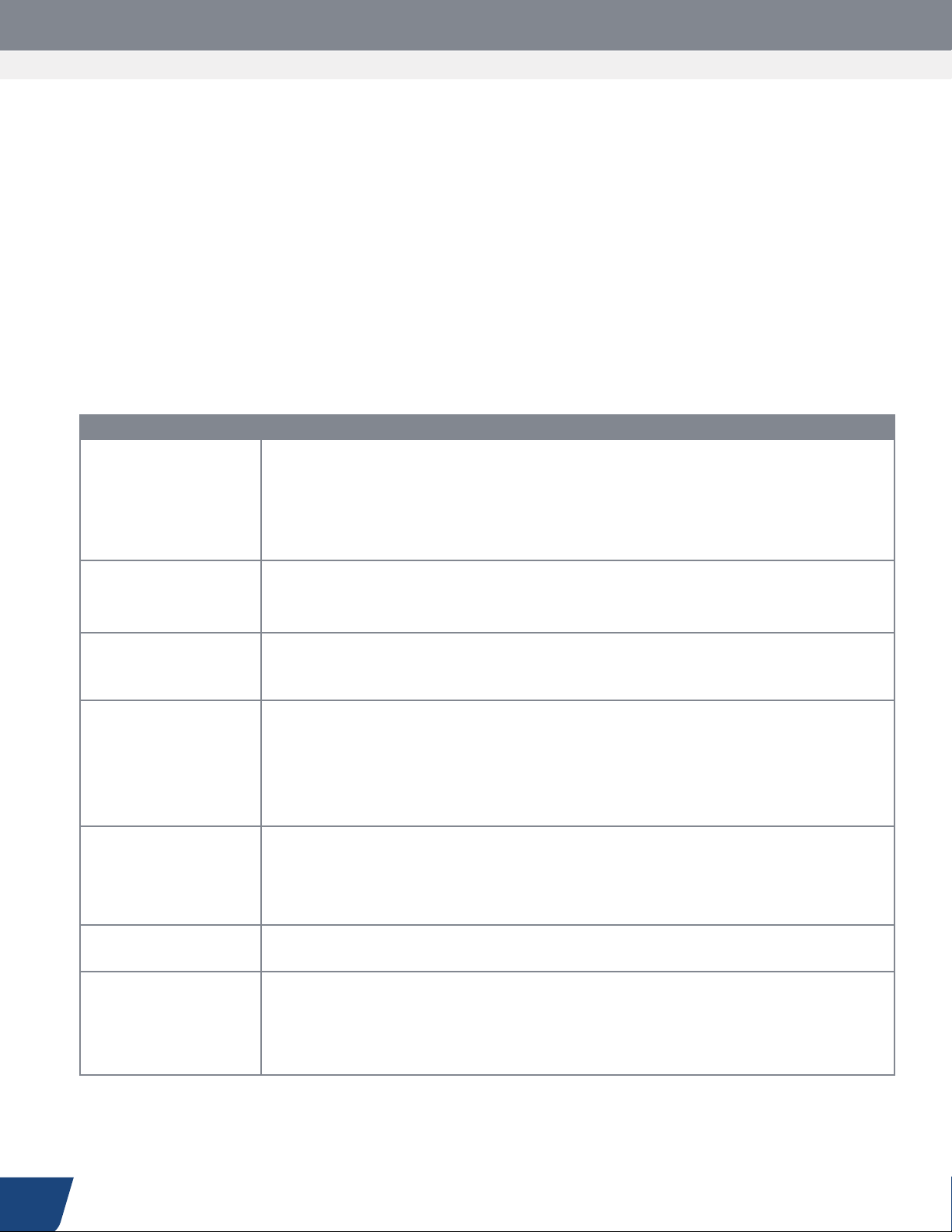

SECTION CONTENT

Section 1

General information

• Description of the assembly instructions, their structure, and the

conventions used

• Denition of the terms used

• Denition of the relationship between the manufacturer and the purchaser/

user (in terms of warranty and assistance conditions)

Section 2

General Safety

Information

• Presentation of general indications regarding the equipment and guidance for the

protection of operating personnel

• Presentation of the residual risks present

Section 3

Description of

the Equipment

• Description of the equipment

• Presentation of the main technical data concerning the equipment

Section 4

Transport and

Installation

• Description of the methods of lifting and handling the equipment

• Description of the installation methods, electrical connections, and commissioning

of the equipment

• Description of optimal storage of the equipment

• Description of uninstallation of the equipment

Section 5

Maintenance and

Dismantling

• Description of the verication and control procedures of the parts and components

of the equipment (in particular, of the parts most subject to wear)

• Description of the procedures for the designated personnel to clean the equipment

• Instructions for disassembling, demolishing, and disposing of the equipment

Section 6

Troubleshooting

• List of possible malfunctions of the equipment and related solutions

Section 7

Appendices

• Technical datasheets of the possible versions of the equipment

• Refrigeration diagram

• Documentation of components tted to the equipment

• Declaration of incorporation

Contents of the Assembly Instructions

These instructions are intended for technicians to understand and correctly install the equipment. These

instructions also provide guidance for:

• Correct transportation and installation of the equipment

• Performing correct cleaning, adjustment, and maintenance of the equipment

• Drawing attention to the most important safety and accident-prevention rules

Carefully read all sections to understand the indications provided in these instructions and to properly operate

the equipment. For easier searching through the contents, refer to the following table containing a description of

the topics addressed in the sections.

3

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 1: Overview

Conventions and Definitions

The assembly instructions for the uninstalled equipment were divided into sections to enable, for each life phase

of the equipment (transportation, installation, maintenance, and decommissioning), readily available information

necessary for the user of the equipment.

The entire documentation relating to the equipment was prepared in accordance with current safety regulations.

The conguration of certain elements or devices described or represented in the documents may differ from

that of the equipment in the specic setup created according to particular requirements or safety regulations;

in this case, certain descriptions, references, or best practices may have a generic character while retaining

their effectiveness.

Dimensional drawings and photographs are provided as a reference for easier understanding of the text.

Denitions

P.P.E.: The acronym for Personal Protective Equipment.

DANGEROUS AREA: Any area inside or near the equipment that presents a risk to the health and safety of an

exposed person.

USER: Any person (entrepreneur/company) who adequately uses the equipment or who entrusts its use to

persons instructed on its proper operation.

EXPOSED PERSON: Any person wholly or partially present in a dangerous zone or near such areas.

MECHANICAL MAINTENANCE WORKER: A qualied technician allowed to work on any mechanical component to

carry out the necessary adjustments, repairs, and maintenance.

The mechanical maintenance operator is not permitted to carry out maintenance on powered electrical plants.

MAINTENANCE ELECTRICIAN: A qualied technician in charge of electrical works (adjustment, maintenance,

repairs) and, when necessary, works inside powered electric cabinets and the junction boxes.

HANDLING PERSONNEL: Qualied personnel who carry out the tasks of handling the equipment or the materials

used if these tasks require the use of lifting devices.

MANUFACTURER’S TECHNICIAN: Qualied technician provided by the manufacturer of the equipment to carry

out operations of a complex nature in particular situations or when agreed with the user.

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

4

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 1: Overview

Personal Protection Equipment and Rules of Conduct

For each of the procedures described in these instructions, mandatory protective measures and safety guidelines

are specied for the safety of any personnel operating the equipment.

Editorial Conventions

The layout of these instructions allows easy readability of the contents with the use of bulleted and numbered

lists, as indicated below:

•This symbol identies a generic bulleted list or list in points consisting of simple actions (the order

in which the actions are presented is not mandatory but recommended).

1. A numbered explanatory list of a complex procedure is identied (the order in which the actions

are presented is mandatory to correctly and safely perform the work in question).

Italic text Italicized text is used, in particular, for:

• Cross-references; the cross references used in these instructions are expressed in the

following form: “Paragraph/Table” with the number and, in general, the specication “of the

section” with the number and name of that section (when it is not specied it is implied that

the paragraph or the table belong to the current section).

• Technical and specialized terms, the rst time they appear in the text.

Bold text Bold text is used to highlight words, phrases, or parts of the procedure.

Personal Protective Equipment (PPE)

This paragraph indicates the graphic symbols used in these instructions to indicate the need to use certain PPE.

SYMBOL DESCRIPTION

Indicates the need to use head protectors suitable for performing the described procedure.

Indicates the need to use protective gloves suitable for performing the described procedure

(possibly of the dielectrics type for work performed on the electrical system).

Indicates the need to use protective clothing suitable for performing the described procedure.

Indicates the need to use safety shoes suitable for performing the described procedure.

Indicates the need to use protective goggles to perform the described procedure.

5

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 2: Safety Introduction

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 2: General Safety Information

Engineering Criteria

The equipment has been designed in compliance with the standards indicated in the table below.

STANDARD NAME

UL 60335-1

Safety of Household and Similar Appliances, Part 1: General Requirements,

Edition 6,

Issue Date 2016-10-31

CAN/CSA-C22.2 No. 60335-1:16, Second Edition, Issue Date 2016-10-31

UL 60335-2-89

Household and Similar Electrical Appliances - Safety - Part 2-89: Particular

Requirements for Commercial Refrigerating Appliances with an Incorporated or

Remote Refrigerant Unit or Compressor, Edition 1, Issue Date 2017-09-29

CAN/CSA-C22.2 No. 60335-2-89:17, First Edition, Issue Date 2017-09-29

These standards are designed to reduce or eliminate risk of malfunction, damage, or injury to the greatest

extent possible.

The components used have been carefully chosen from those available on the market; the equipment is

comprised of materials that involve no risks to the health and safety of persons. All parts supplied by third parties

are UL-certied (when envisaged) and comply with the relevant directives of reference. All components have been

strictly controlled in accordance with the quality standards prescribed by the current regulations.

For the necessary warning and protection measures related to residual risks, see Residual Risks in Section 2:

Safety Introduction.

6

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 2: Safety Introduction

Devices and Solutions for Protection

Passive Safety Devices

The equipment includes the following safety devices and features:

• Fixed guards close to the moving parts

• External fairing with xed access doors (if equipped)

• Safety signs corresponding to the guards on the equipment

Active Safety Devices

The equipment includes the following active safety devices:

• Maximum safety pressure switch for each automatic reset compressor (PSH) or for specic versions with

safety pressure switch for each manual reset compressor (PZH)

• Safety valve on the MT and LT circuit low-pressure side (if equipped)

• Safety valve(s) on the intermediate receiver

• Safety valve on the high-pressure side, (if equipped)

The valve calibration is shown on the valves themselves and is based on the EN 13136 standard.

ATTENTION: It is strictly forbidden to modify the calibration of the safety pressure switch and/or to

inhibit its operation.

Protection Systems

The system is equipped with protections to safeguard against anomalous situations affecting either the pressure

or voltage circuits.

Notications

The unit is equipped, in addition to the signals and instruments installed on the electrical panel, with indicator lights

on the inside. To access them, it may be necessary to remove one or more covering panels. For further information,

refer to the wiring diagram and to the documentation attached to this manual.

ATTENTION: Operating the equipment with the panel removed should only be performed by

authorized/qualied personnel. Observe all safety precautions and use the necessary PPE. At

the end of such operation, always carefully replace all panels removed.

ATTENTION: All work requiring access to the compressor compartment and machine display

can be done with power on and the right-hand compartment door open.

ATTENTION: DO NOT access the gas cooler zone by opening the fan panel with power on.

ATTENTION: DO NOT access the electrical enclosure with power on.

ATTENTION: DO NOT work on the inverter or the electronic components with power on.

7

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 2: Safety Introduction

Residual Risks

To avoid any dangerous condition for persons or damage to the equipment caused by residual risks, i.e., those

risks that persist despite all provisions implemented, or potential risks which were not obvious, Hillphoenix

recommends that maintenance personnel and all personnel in charge of operating the equipment strictly follow

the warnings indicated on the following pages.

ATTENTION: Always comply with the signs and indications of the plates applied to the equipment

and operate exclusively according to the instructions provided in this instruction manual.

ATTENTION: All work to be performed on the equipment must be performed by qualied, trained, and

properly equipped personnel.

Residual risk of asphyxiation

To avoid leaks of gases that are dangerous to human health, install the unit in a dry, protected, and sufciently-

ventilated place in compliance with local codes and ordinances.

Residual risk of burns

Before carrying out any work on the equipment, make sure that the hot surfaces have cooled down; wear

protective gloves to avoid burns.

Proper and Improper Use of the Equipment

The equipment discussed in these assembly instructions has been designed and constructed exclusively for

refrigeration. The equipment is congured to use only R744 (CO2) refrigerant gas.

The equipment is designed to use only the refrigerant specied above. It is therefore important to use the

equipment in compliance with regulations applicable to the refrigerant uid for which it was designed and built

and as received from Hillphoenix.

The equipment has been designed and built to operate in environments with no potentially explosive atmosphere.

The equipment must be adequately protected from weather and environmental conditions.

As a precautionary measure, keep powder extinguishers in the vicinity of the equipment. To prevent the

possibility of re, keep the equipment clear of plastic pieces, oil, solvents, paper, and rags.

Use of the equipment for unauthorized purposes may cause harm to persons or damage to the unit itself and is

therefore considered improper use for which Hillphoenix is not responsible.

8

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 2: Safety Introduction

DANGER: The user MUST conrm the type and quantity of gas contained in the equipment to ensure

proper operation.

ATTENTION: It is essential to consult Hillphoenix prior to any unapproved use.

DANGER: All work involving R744 (CO2) refrigerant must be carried out only by qualied technicians

trained to work with this type of refrigerant.

General Warnings and Rules of Conduct

In order to avoid any risk to persons or damage to the equipment, it is advisable to strictly follow the warnings

and general rules of conduct reported here.

DANGER: The manufacturer disclaims any liability for any damage to property and/or persons

arising from work performed by unqualied, untrained, or unauthorized personnel.

• Personnel in charge of operating the equipment must be adequately trained to avoid risk of damage or injury,

and must work in a comfortable environment with the best possible safety and hygiene conditions.

• Prior to using the equipment, ensure that any hazardous safety conditions have been rectied and that no

personnel are present in the danger area near the unit.

• After removing the packaging, make sure all equipment parts are intact; otherwise contact the dealer.

• Before using the equipment, ensure that all guards or other protections are tted and that all safety devices

are present and working.

• Carefully read the labels on the unit; do not cover them and replace them immediately if damaged.

• Do not place containers of liquids on the unit.

• Consult these instructions for the safety provisions in force and the specic Personal Protective Equipment

(PPE) to implement for staff safety; in particular, the staff responsible for the equipment must wear suitable

clothing, avoiding or paying due attention to:

• Loose clothing

• Wide sleeves

• Ties or draping scarves

• Necklaces, bracelets, and rings

9

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 2: Safety Introduction

• Staff responsible for maintenance of the equipment must be aware of all the procedures outlined in Section

5: Maintenance and must have adequate technical training to correctly interpret the instructions and

diagrams attached to these instructions and to perform maintenance on the equipment.

• The area where the maintenance procedures are carried out must always be clean, dry, and with the

appropriate equipment always available and operating efciently.

• If it is necessary to perform maintenance procedures in the vicinity of electrical components, operate with dry

hands and use dielectric gloves.

• If the equipment is installed in a position not easily accessible to the operator, it is necessary to have suitable

structures to allow access to the components being serviced.

DANGER: It is necessary to ensure that the power supply is disconnected before starting any type

of maintenance on the unit or on its components or accessory equipment. If this is not possible, it

is necessary to take precautions to ensure safe working conditions in the area of the equipment.

DANGER: The leaking of refrigerant gas after the safety valve is engaged may result in damage to

property and/or injury to persons.

DANGER: Tampering with or unauthorized replacement of one or several parts of the equipment and

the use of accessories, tools, and consumables other than those indicated by the manufacturer may

result in an accident.

DANGER: The R744 (CO2) refrigerant is colorless and odorless. Its presence in the environment can

cause asphyxiation. All work must be performed in the presence of gas presence detectors and in

compliance with local codes and ordinances.

ATTENTION: All work involving R744 (CO2) refrigerant must be carried out only by qualied

technicians trained to operate with this type of refrigerant.

ATTENTION: All work involving R744 (CO2) refrigerant must be carried out in the presence of gas

presence detectors.

ATTENTION: All materials with an environmental impact must be disposed of according to the

regulations in force. If necessary, use specialist facilities for their disposal.

10

Hillphoenix Refrigeration Systems

CO2One Condensing Unit

Section 3: Description of the Equipment

Section 3: Description of the Equipment

The condensing units described in this document are designed for use in commercial refrigeration. These

condensing unit systems are intended for use in locations where heat can be released outside of the building in

which they are installed..

The condensing units are compact, low-noise systems that are also suitable for outdoor use.

The unit is designed and optimized to work with CO2 (R744).

The operating modes can be transcritical or subcritical depending on the conditions of the external environment.

The electronic control, with appropriate logics, allows the equipment to always operate in conditions of maximum

efciency in different environmental conditions and cold demand. It also manages lubrication and any alarms by

signaling them on the electronic control terminal.

Depending on the model, for the condensing unit, units can be provided with a single fan-motor, or with a

double fan.

All models are equipped with the following refrigerator accessories:

• Compressor(s) driven by inverter

• Control valves

• Intermediate receiver

• Dehydrating lter and liquid indicator

• On-board gas cooler

• Electrical panel with relative electronic control

In low-temperature refrigeration models, a desuperheater (intercooler) is incorporated in the gas cooler battery.

All models also have a crankcase heater that prevents the accumulation of liquid in the lower area of the

compressor during downturn periods. The unit is always enclosed in a self-supporting housing made of steel

varnished with epoxy powder and is equipped with electrical equipment with a main disconnecting switch (the

power supply wire that must be connected to the switch is not supplied).

The following variants are possible:

• Only for medium-temperature units

• Only for low--temperature units

Table of contents

Other Hillphoenix Heat Pump manuals

Popular Heat Pump manuals by other brands

Carrier

Carrier 38YKB Product data

Novelan

Novelan LA Series operating manual

Ferroli

Ferroli EGEA 200 LT User, installation, and maintenance manual

Daikin

Daikin 3 H HT F installation manual

Daikin

Daikin EHVH08SU26CB6W User reference guide

Viessmann

Viessmann VITOCAL 060-A Operating Instructions for the System User

Lennox

Lennox HSXA15 SERIES installation instructions

Trane

Trane 4TWR3 Installer's guide

Solaris

Solaris SunPump MACHRW010W Installation instructions manual

ANTEK

ANTEK AIR MAGNA 100 Installation and maintenance instructions

DeDietrich

DeDietrich MIV-4S AWHP 6 MR-3 user guide

Hubbell

Hubbell PBX Series Installation, operation and maintenance manual