9HK 200S

HK 200S-6

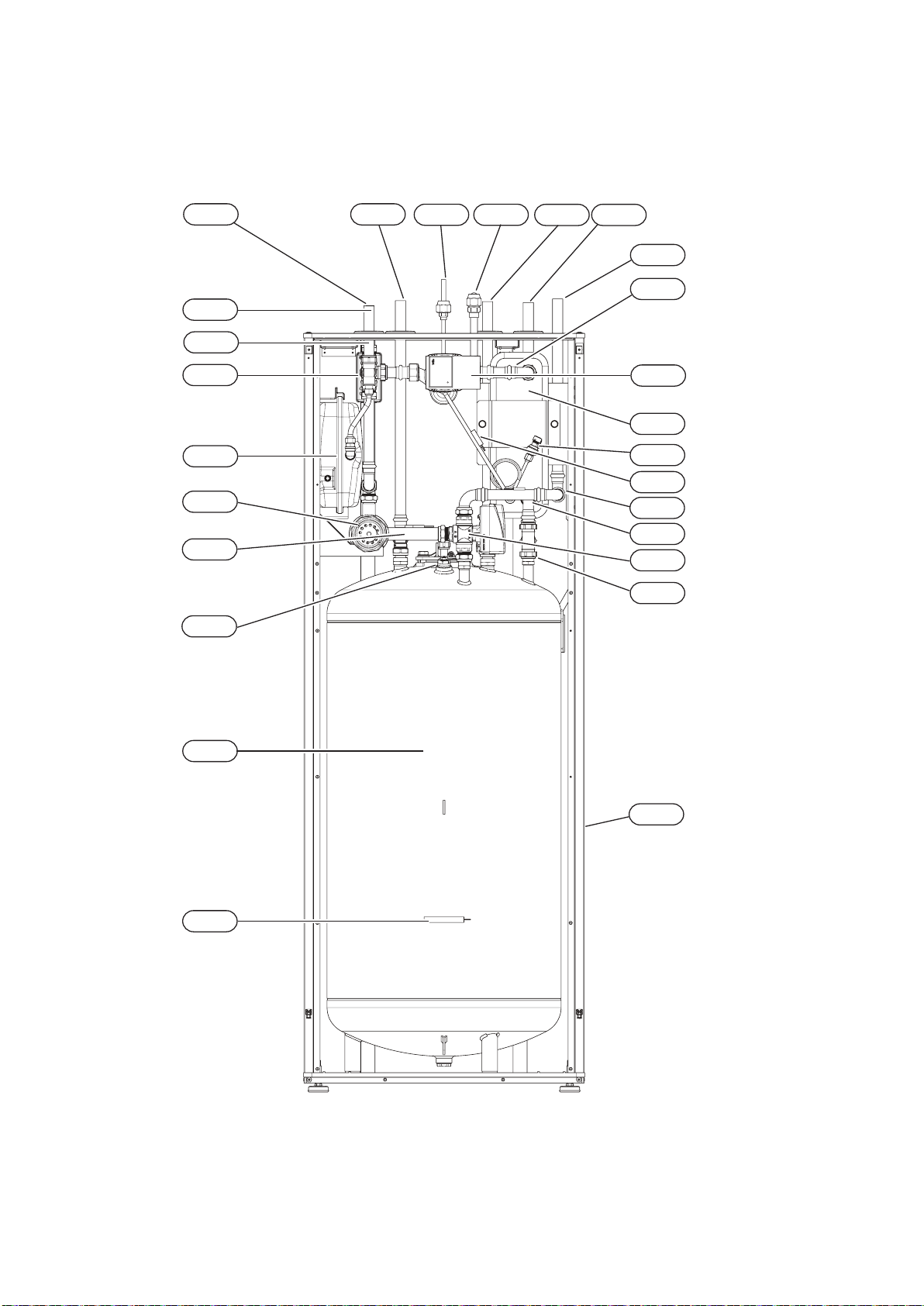

4 Pipe connections

General pipe connections

The piping installation must be executed according to

the applicable standards and directives.

HK 200S / HK 200S-6 indoor unit NIBE SPLIT out-

door air heat pump, and controller NIBE SMO form a

complete heating system.

The system can cooperate with a low- and medium-

temperature heating system. Recommended temper-

ature of the heating medium at minimum designed

outdoor temperature DOT must not exceed 55°C on

supply, and 45 °C on return circuit from the heating

system, whereas HK 200S / HK 200S-6 can achieve

even 65 °C when using a ow-through heating mod-

ule or another peak heat source.

Excess medium owing out of the safety valve must

be discharged via a pipe to a oor drain. The over-

ow pipe must be slanted at the entire length from the

safety valve, and must be secured against freezing.

In order to achieve maximum system efciency, we

recommend the installation of HK 200S / HK 200S-6

as close to the heat pump as possible.

The HK 200S / HK 200S-6 module is not equipped

with cut-off valves, which must be installed outside

the indoor module to make future maintenance eas-

ier. The HK 200S / HK 200S-6 module can be con-

nected to the central heating, cooling, and domestic

hot water installation. Install the supplied safety valve

and the manometer.

HK 200S / HK 200S-6 is equipped with a diaphragm

expansion vessel for a heating circuit of 10 I. Initial

pressure of the expansion vessel must be set appro-

priately to the maximum height (H) between the ves-

sel and the highest heater, see the drawing. The ini-

tial pressure of 0.5 bar (5 mvp) shall mean maximum

permissible height difference of 5 m.

If the standard initial pressure in the diaphragm ex-

pansion vessel is too low, it can be raised by lling the

vessel through the valve installed.

Any change to the initial pressure affects the dia-

phragm expansion vessel’s capacity to support the

increase in water volume.

IMPORTANT

All places in the heating system located high must be

equipped with vents.

IMPORTANT

Pipelines must be rinsed before connecting the indoor

module so that possible dirt does not damage its ele-

ments.

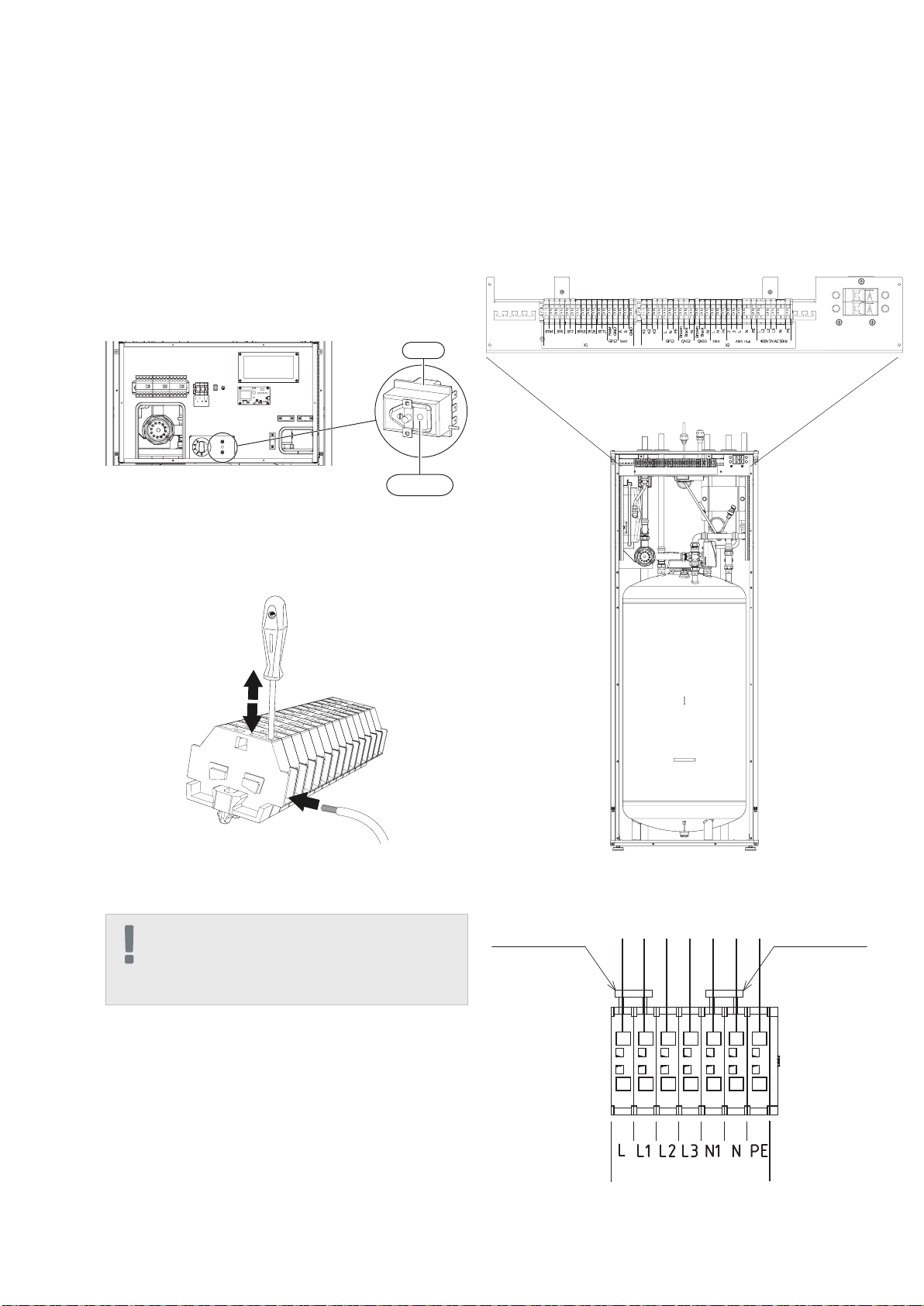

IMPORTANT

As long as heating circuits in the system have not been

lled with the heating medium, do not set the switch

(SF1) in the SMO module in position “I” or “ ”. The

compressor in the heat pump and the ow-through

heating module can be damaged.

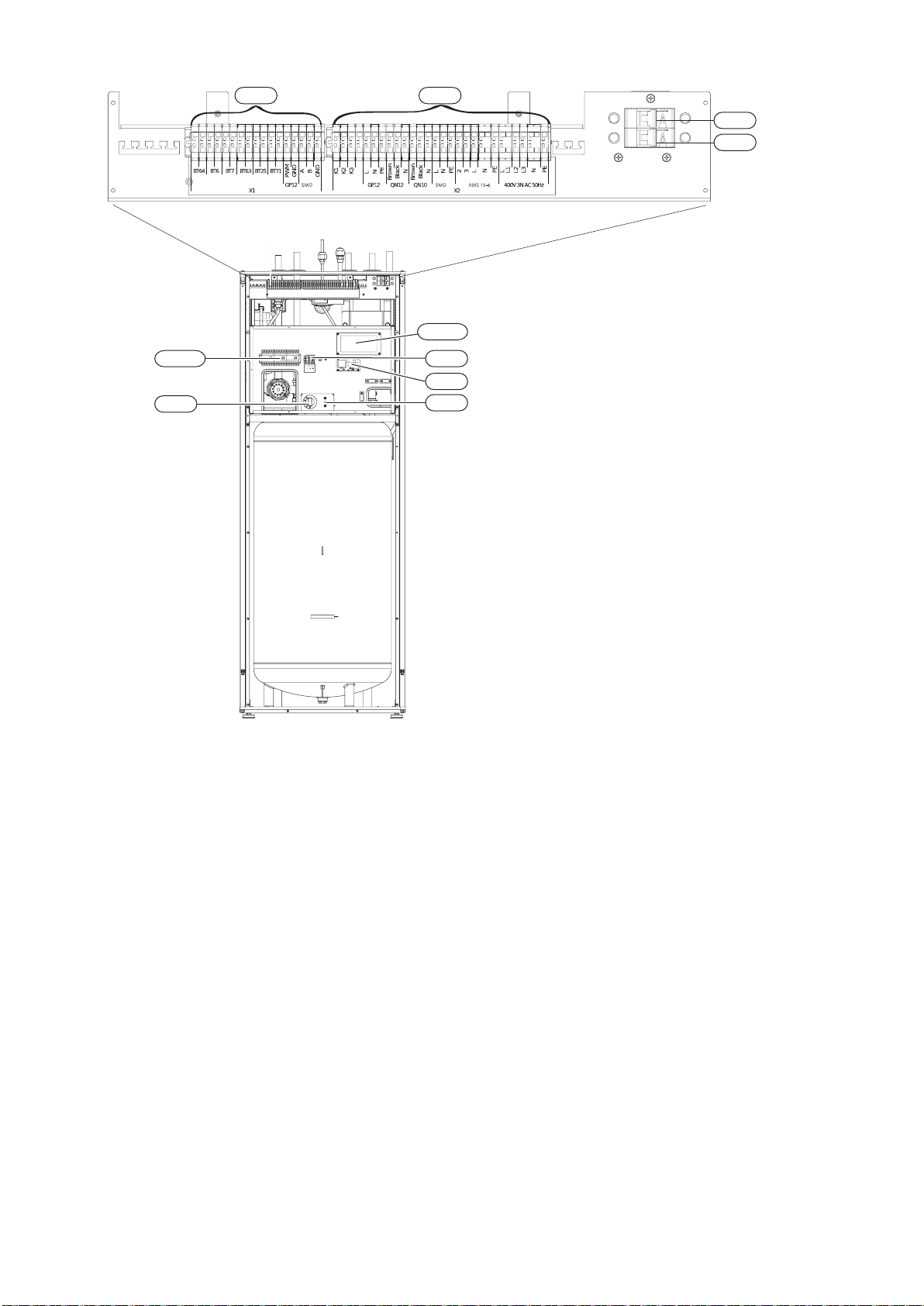

Capacities of the indoor unit and the

heating system

System requirements

The inner capacity of HK 200S / HK 200S-6 for the

purposes of calculating the diaphragm expansion

vessel in the domestic hot water installation totals

180 l. The capacity of the diaphragm expansion ves-

sel must constitute at least 5% total capacity.

Minimum required conguration:

In order to assure correct operation, the capacity of

the heating system must meet the requirements for

the installation. If this condition has not been met, in-

stall an additional buffer tank.

CAUTION

In this case a diaphragm expansion vessel of the

DHW installation must have the capacity of 10l. The

diaphragm expansion vessel at the domestic hot water

installation is not required. It is, however, required to

install a safety valve with opening pressure of 6 bar.

IMPORTANT

All connections require free ow, hence a discharge

valve must be installed.

Chapter 4 | Pipe connections