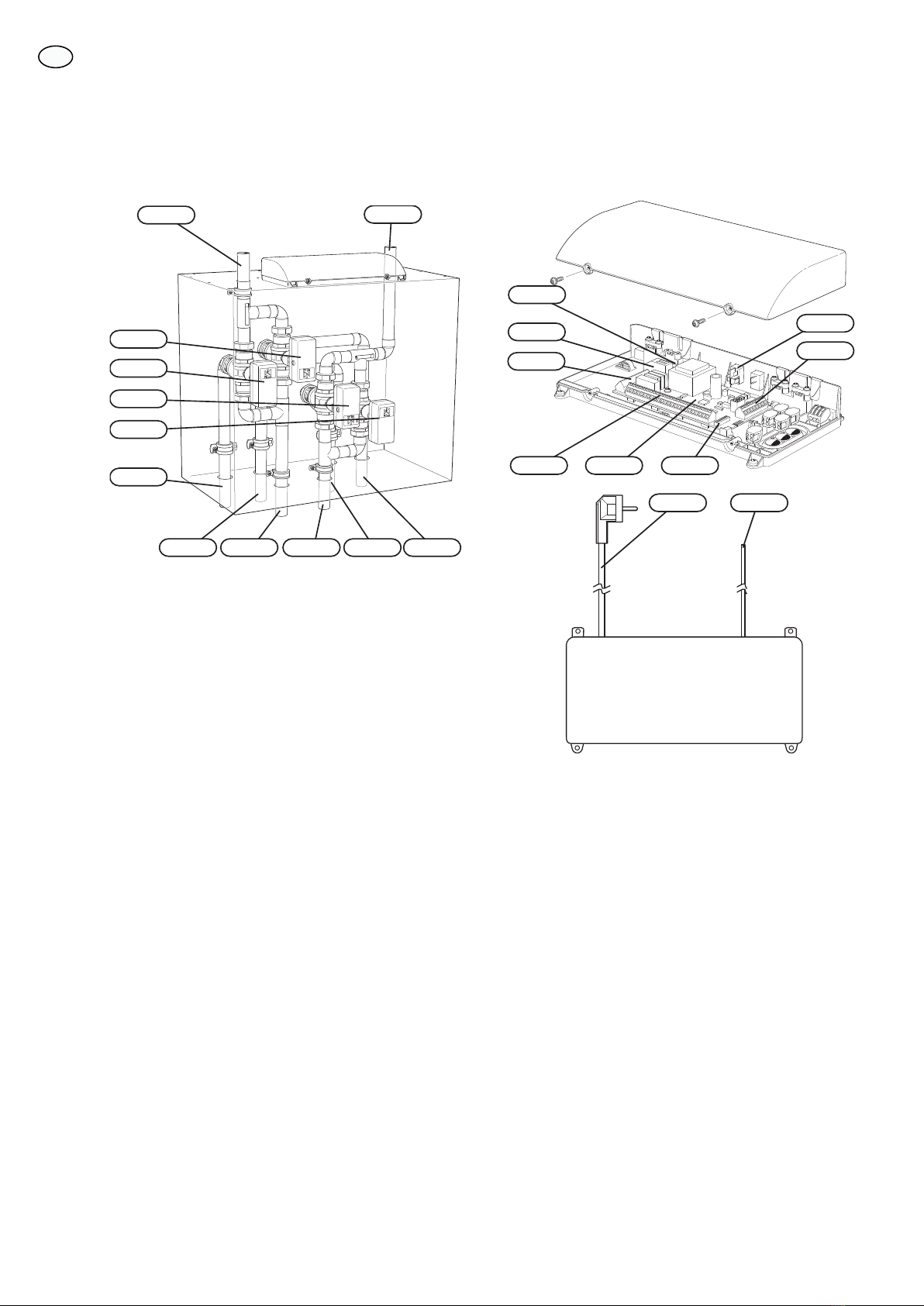

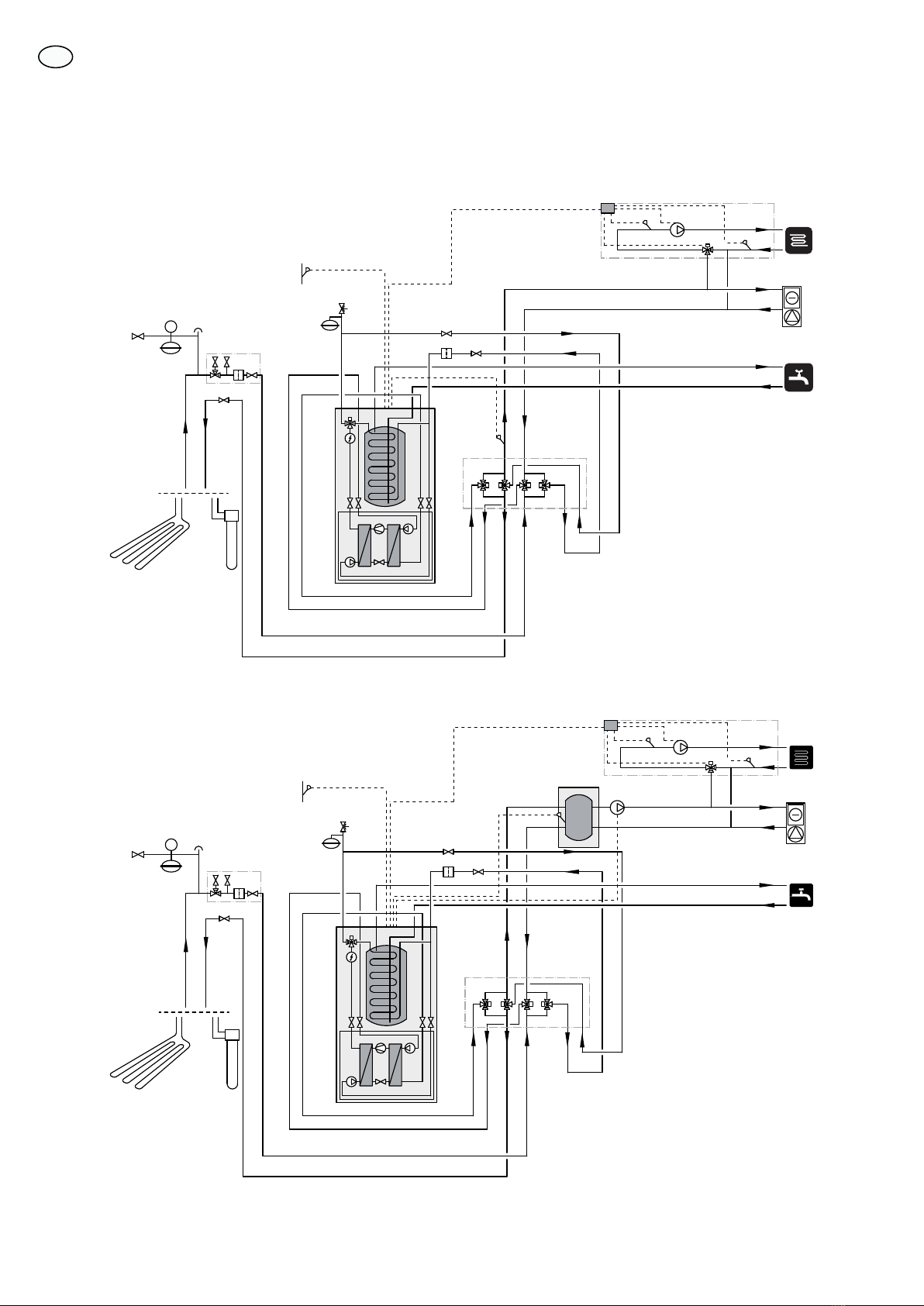

Pipe connections

General

Pipe installation must be carried out in accordance with

current norms and directives. HPAC 40 can only operate

up to a return temperature of about 50 °C and an outgo-

ing temperature of about 65 °C from the heat pump.

When the heat pump is not equipped with shut off valves;

these must be installed outside the heat pump to facilitate

any future servicing.

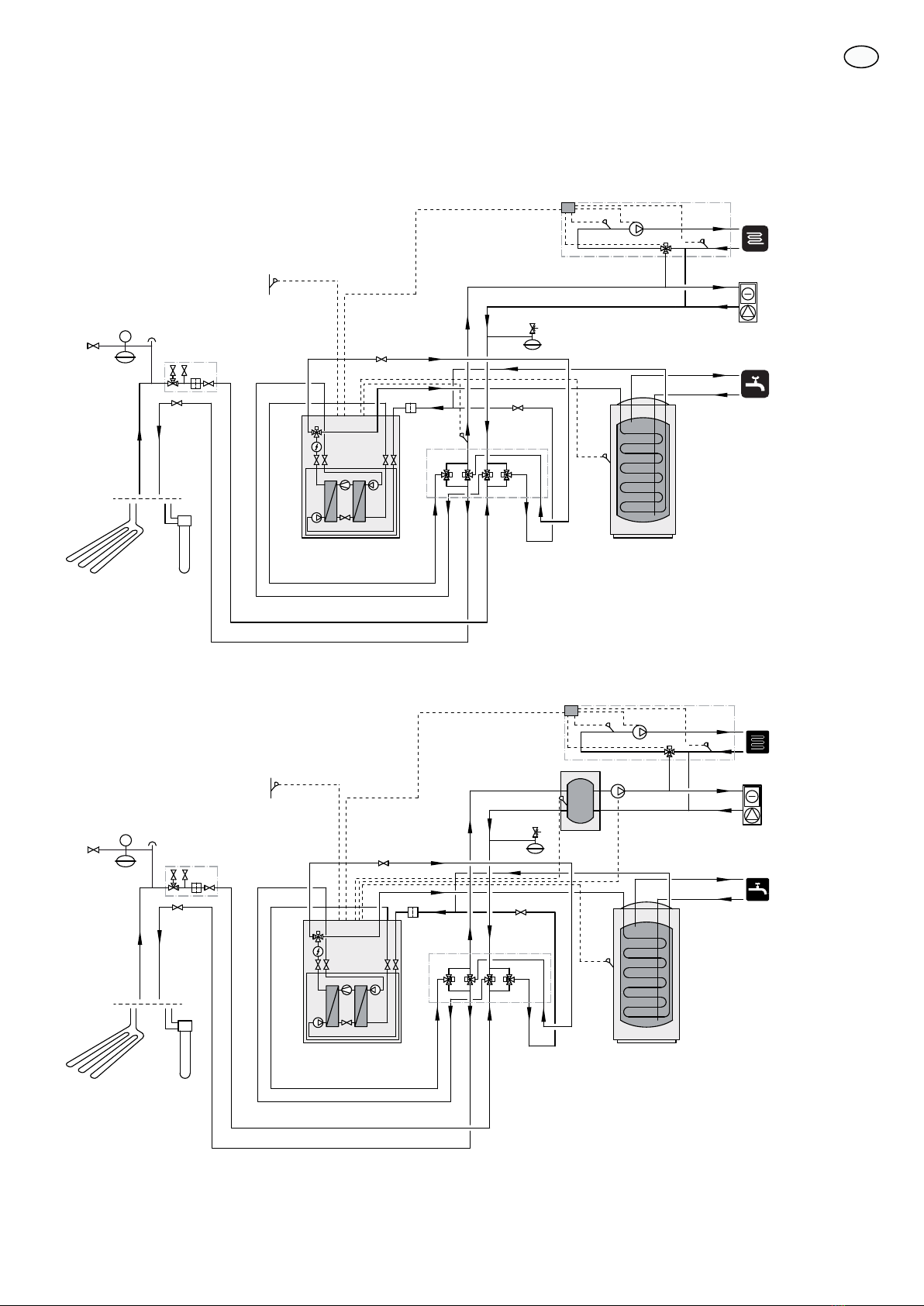

The fluid in the building's distribution system is the same

as in the surface soil/rock collector, if no other heat ex-

changer is connected.

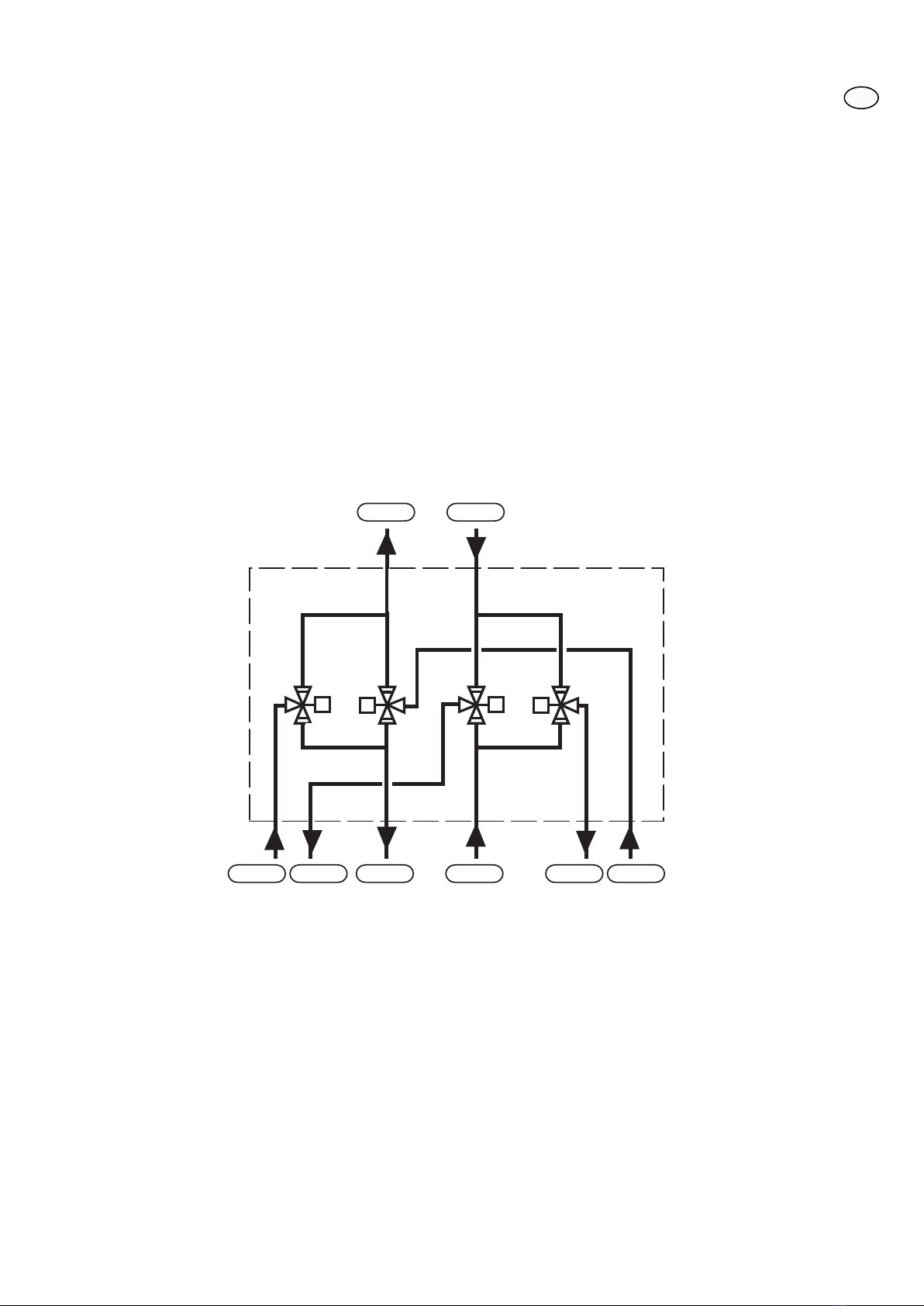

Pipe connection, the building’s climate sy-

stem

Connect the heat pump to HPAC 40 and, where applic-

able, hot water heating.

Pipe connections are made at the bottom and top of

HPAC 40. All required safety devices, shut-off valves (in-

stalled as close to the cooling module as possible), and

particle filter (supplied with the heat pump) are to be fit-

ted in such a way that HPAC 40 is also protected.

If HPAC 40 is connected to a system with thermostats on

all convectors, a bypass valve must be fitted, or a thermo-

stat must be removed to ensure sufficient flow.

Pipe connection, collector side

The length of the collector hose varies depending on the

rock /surface soil conditions and on the climate system.

Ensure the collector hose rises constantly towards the

heat pump to avoid air pockets. If this is not possible,

airvents should be used.

The climate system must be supplied with two pressure

expansion vessels.

All the system's pipes must be condensation insulated

except the pipes to the water heater.

If the temperature of the brine system can fall below 0

°C this must be protected against freezing through the

mixture of propylene glycol (NOTE! Not ethanol). The

mixing ratio should be approximately 25 % propylene

glycol and the remainder water. As a guideline for the

volume calculation, use 1 litre of ready mixed brine per

meter of collector hose, (for 40 x 2.4 PN 6.3 PEM hose).

The installation should be marked with the antifreeze

used.

Install shut off valves as close to the heat pump as pos-

sible. Fit a particle filter to the incoming pipe.

In the case of connection to an open groundwater system,

an intermediate frost-protected circuit must be provided,

because of the risk of dirt and freezing in the evaporator.

This requires an extra heat exchanger. In addition, the

ground water flow must be sufficiently large for all com-

ponents.

NOTE

This system solution means that the brine will

also circulate through the heating system.

Check that all component parts are designed

for the brine in question.

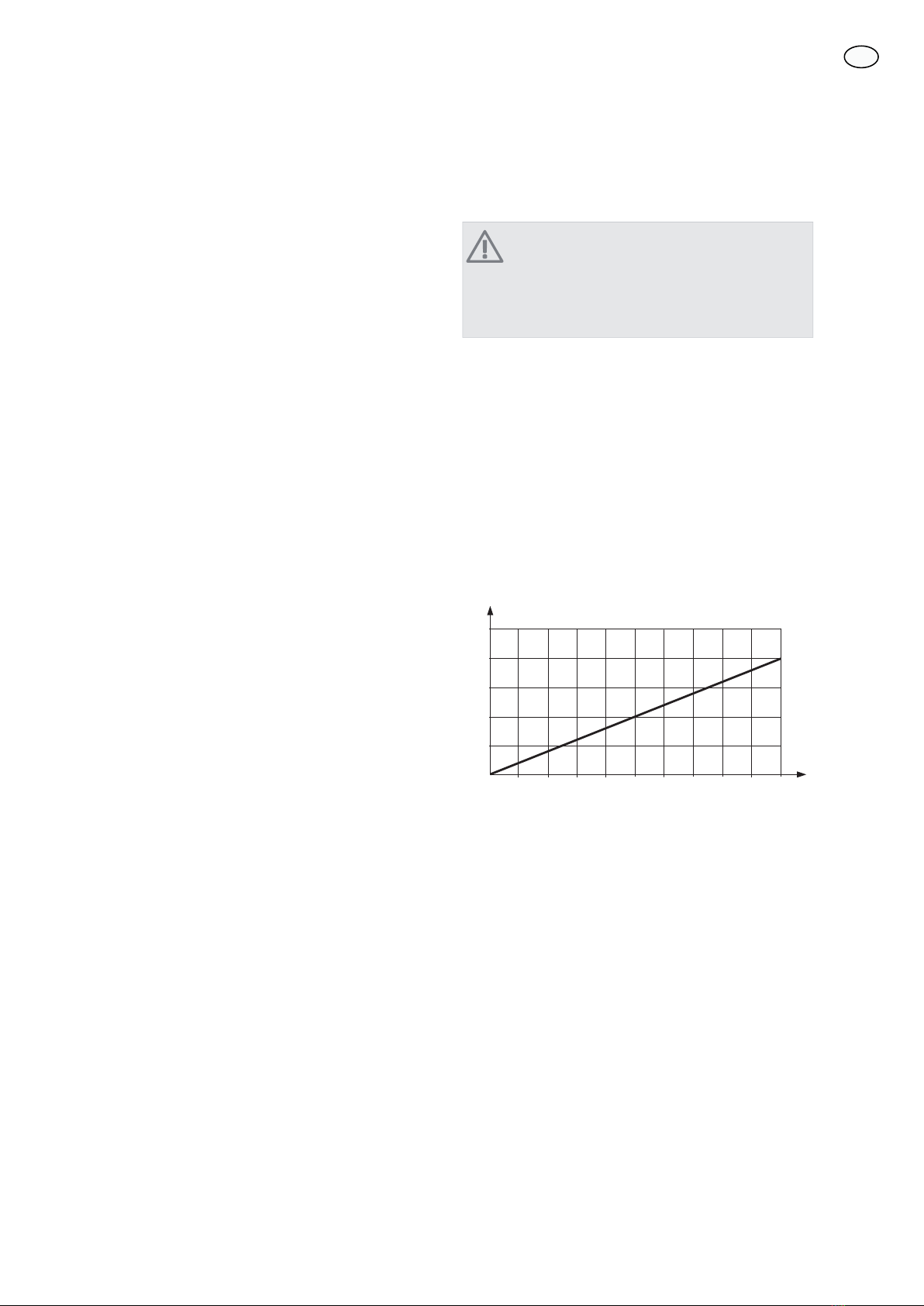

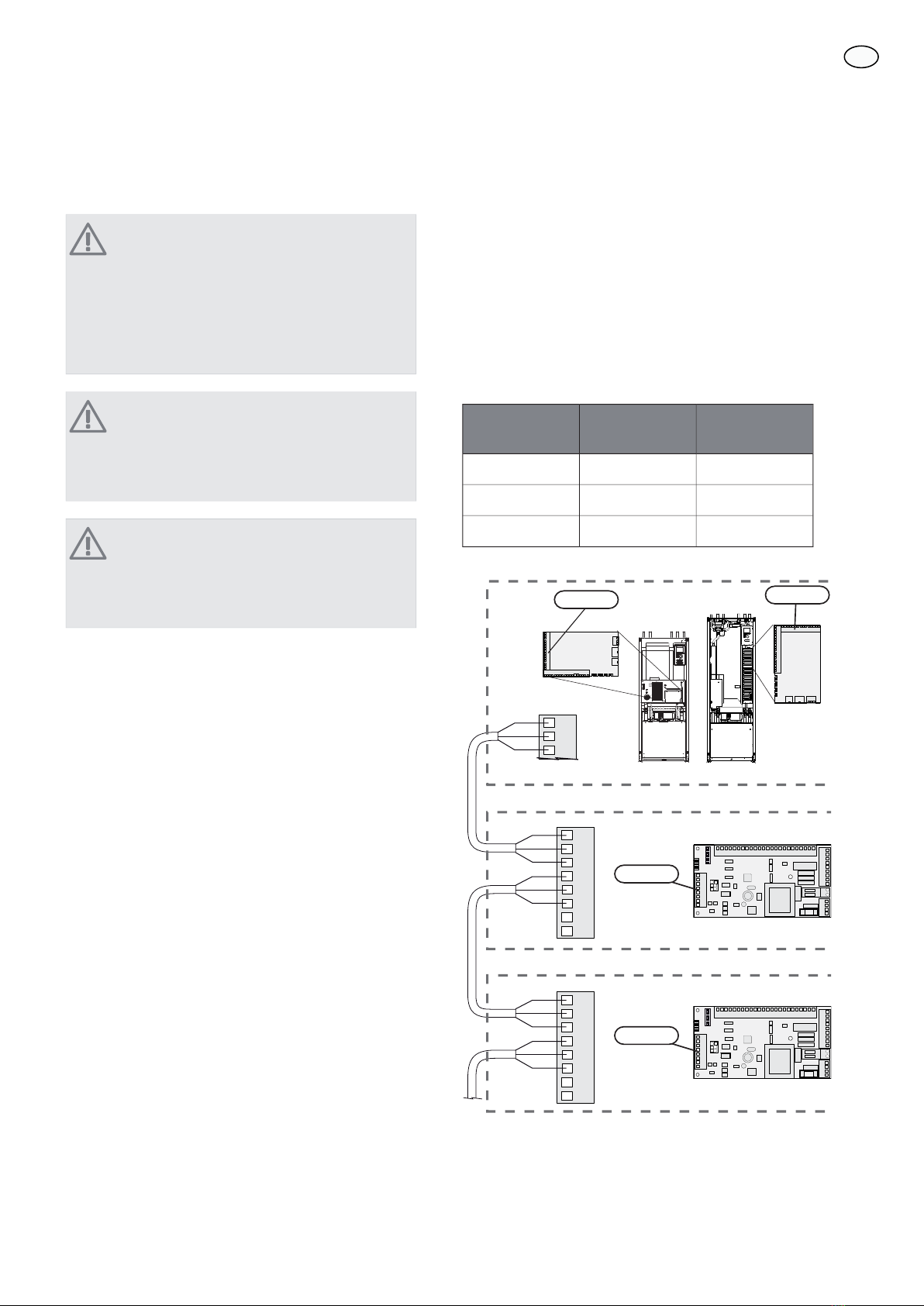

Expansion vessel

The brine circuit must be supplied with a pressure expan-

sion vessel (membrane type). If there is already a level

vessel installed this should be replaced.

The pressure expansion vessel should be dimensioned as

set out in the diagram, to prevent operating disturbances.

The pressure expansion vessel covers the temperature

range from -10 °C to +20 °C for the brine at a pre-pres-

sure of 0,5 bar and the safety valve's opening pressure

of 3 bar. The brine side must normally be pressurised to

at between 1,0 and 1,5 bar.

0

0100 200 300

10

20

30

40

50

400 500 600 700 800 900 1000

([SDQVLRQ YHVVHO

%ULQH YROXPH

Condensation insulation

Pipes and other cold surfaces must be insulated with dif-

fusion-proof material to prevent condensation.

Where the system may be operated at low temperatures,

any convection fan used must be fitted with a drip tray

and drain connection.

21

GB