4SI-Ethernet User Guide

Issue Number: 3

Contents

1 Safety information ..........................................................6

1.1 Warnings, cautions and notes .................................................................6

1.2 Important safety information. Hazards.

Competence of designers and installers .................................................6

1.3 Responsibility ..........................................................................................6

1.4 Compliance with regulations ...................................................................6

1.5 Electrical hazards ....................................................................................7

1.6 Stored electrical charge ...........................................................................7

1.7 Mechanical hazards ................................................................................7

1.8 Access to equipment ...............................................................................7

1.9 Environmental limits ................................................................................7

1.10 Hazardous environments ........................................................................8

1.11 Motor .......................................................................................................8

1.12 Mechanical brake control ........................................................................8

1.13 Adjusting parameters ..............................................................................8

1.14 Electromagnetic compatibility (EMC) ......................................................8

2 Introduction ....................................................................9

2.1 Products covered by this User Guide ......................................................9

2.2 Features ..................................................................................................9

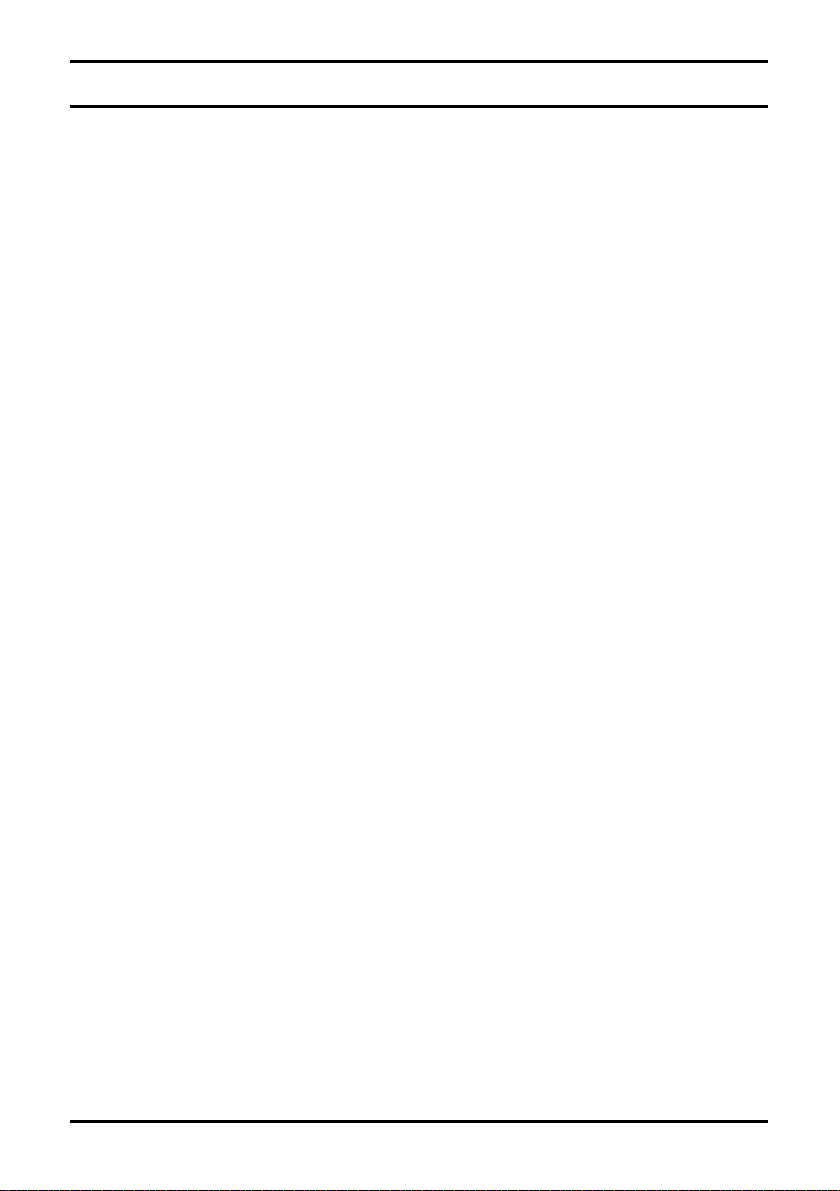

2.3 Option module identification ..................................................................10

2.4 Factory fit Ethernet interface identification ............................................11

2.5 Product conformance ............................................................................11

2.6 Conventions used in this guide .............................................................11

2.7 Firmware Statement ..............................................................................11

3 Mechanical installation ................................................12

4 Electrical installation ...................................................14

4.1 SI-Ethernet module information .............................................................14

4.2 Cabling considerations ..........................................................................14

4.3 Module grounding ..................................................................................14

4.4 Cable shield connections ......................................................................15

4.5 Cable .....................................................................................................15

4.6 Maximum network length ......................................................................15

4.7 Network topology ...................................................................................15

5 Getting started ..............................................................17

5.1 Network design considerations .............................................................17

5.2 Addressing ............................................................................................17

5.3 Where do IP addresses come from? .....................................................17

5.4 Addressing etiquette ..............................................................................17

5.5 Class types ............................................................................................18

5.6 Generating the complete address .........................................................18

5.7 DHCP considerations ............................................................................19

5.8 Basic principles of routing .....................................................................20

5.9 Set-up flow chart ...................................................................................21

5.10 Single line parameter descriptions ........................................................22