Nigos MC-3000 User manual

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 1

07:31:16 09M 2020ar M100%R84% - running -

G=2 R=45 S=0 E=10.0%

drying

7. -> 21.0%

45%

29%

100% 2:45'

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

6:32'' 1

2

1 .0 1

1 61.

EMC 1.90

%

1 . %0 0

1 . %0 0

NIGOS Elektronik Niš

TEMP

1

2

41.7

41 0.41.3C

º

42.4ºC

42.4ºC

1

5

2

6

3

7

4

8

1.00

%

19 4.

33 9.

17 5.

20 1.

19 2.

5.5

20 4.

20 6.

21.6

%

avg

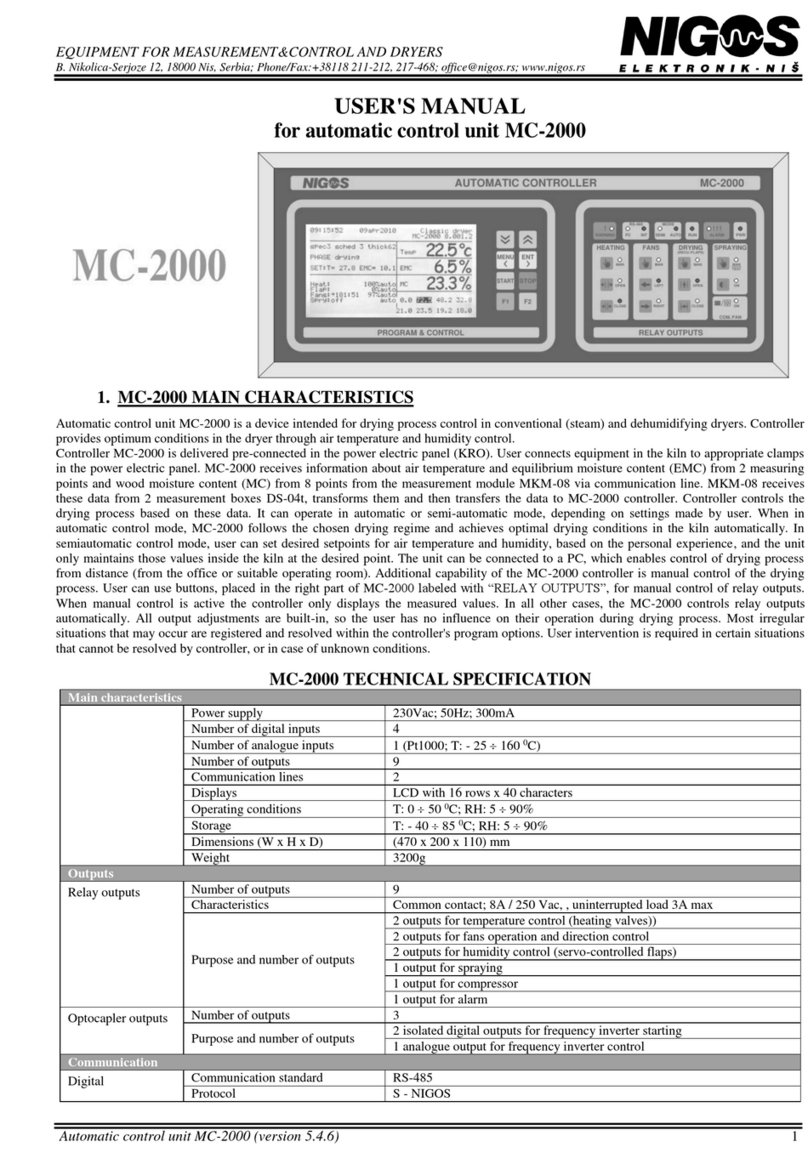

AUTOMATIC CONTROL UNIT

MC-3000

USER'S MANUAL

(translated from serbian to english)

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

2Automatic control unit MC-3000 (version 1.1.1)

TABLE OF CONTENTS

1. PURPOSE OF THIS INSTRUCTION................................................................................................................................................................................. 3

2. LITHIUM BATTERY REPLACEMENT IN MC-3000 PANEL.......................................................................................................................................5

3. INSTALLATION OF EQUIPMENT...................................................................................................................................................................................6

3.1. CONNECTION BETWEEN MC-3000, RB-3000 AND MKM....................................................................................................................................7

3.2. CONNECTING RB-3000 .............................................................................................................................................................................................8

3.2.1. Fuse replacement of relay board RB-3000 ......................................................................................................................................................................................10

3.3. INSTALLATION OF MEASURING & COMMUNICATION MODULE MKM .....................................................................................................11

3.3.1. Measuring module with wire probes MKM-08 ...............................................................................................................................................................................11

3.3.1.1. Position of MKM-08 and DS-04 boxes in the dryer chamber..................................................................................................................................................11

3.3.1.2. Connection scheme .................................................................................................................................................................................................................12

3.3.2. Measuring module with wireless probes MKM-RF ........................................................................................................................................................................13

3.3.2.1. Positions of MKM-RF, antenna and wireless probes in the dryer chamber .............................................................................................................................13

3.3.2.2. Connection scheme .................................................................................................................................................................................................................14

3.4. INSTALLATION OF PROBES IN DRYING CHAMBER........................................................................................................................................15

3.4.1. Installation of probes for measuring equilibrium moisture content in the dryer...............................................................................................................................15

3.4.2. Installation of probes for measuring wood moisture content ...........................................................................................................................................................15

3.5. WIRELESS PROBE BATTERIES .............................................................................................................................................................................18

3.5.1. Battery replacement in RF-MC1 .....................................................................................................................................................................................................18

3.5.2. Battery replacement in RF-EMC and RF-SHT................................................................................................................................................................................18

3.6. CONNECTING THE COMMUNICATION LINE.....................................................................................................................................................19

4. OPERATIONS OF AUTOMATIC CONTROLLER UNIT.............................................................................................................................................20

4.1. MAIN MENU ON PANEL OF MC-3000...................................................................................................................................................................20

4.2. HUMIDITY CALCULATOR.....................................................................................................................................................................................20

4.3. KILN VIEW ...............................................................................................................................................................................................................21

4.3.1. Status line of panel..........................................................................................................................................................................................................................21

4.3.2. Status and control of equipment in dryer.........................................................................................................................................................................................22

4.3.2.1. Adjusting drying parameters ...................................................................................................................................................................................................22

4.3.2.2. Operating mode of kiln ...........................................................................................................................................................................................................22

4.3.2.3. Heating ..........................................................................................................................................................................................................................22

4.3.2.4. Circulation pump ..............................................................................................................................................................................................................22

4.3.2.5. Drying ...............................................................................................................................................................................................................................22

4.3.2.6. Fans ................................................................................................................................................................................................................................22

4.3.2.7. Spraying .......................................................................................................................................................................................................................23

4.3.2.8. Extra drying ............................................................................................................................................................................................................................23

4.3.3. Measured values in dryer ................................................................................................................................................................................................................23

4.3.3.1. Information and field for the main menu screen......................................................................................................................................................................23

4.3.3.2. Temperature .....................................................................................................................................................................................................................23

4.3.3.3. Air humidity in dryer

.......................................................................................................................................................................................................24

4.3.3.4. Wood moisture content

............................................................................................................................................................................................24

4.4. DRYING HISTORY OVERVIEW.............................................................................................................................................................................24

4.5. DRYING REGIMES SETTINGS ...............................................................................................................................................................................25

4.5.1. Explanation and range of parameters values ...................................................................................................................................................................................26

4.5.2. Heating phase .................................................................................................................................................................................................................................26

4.5.3. Phase by segments 1 to 12 ..............................................................................................................................................................................................................26

4.5.4. Conditioning phase .........................................................................................................................................................................................................................26

4.5.5. Cooling phase .................................................................................................................................................................................................................................26

4.6. CONTROLLER UNIT SETTINGS ............................................................................................................................................................................27

4.6.1. Option: Drying parameters..........................................................................................................................................................................................................28

4.6.1.1. Parameter: Operating mode .................................................................................................................................................................................................28

4.6.1.2. Parameter: Timber group......................................................................................................................................................................................................29

4.6.1.3. Parameter: Schedule.............................................................................................................................................................................................................29

4.6.1.4. Parameter: Slowdown / acceleration ..................................................................................................................................................................................29

4.6.1.5. Parameter: Heat time............................................................................................................................................................................................................29

4.6.1.6. Parameter: Remaining time heating ....................................................................................................................................................................................29

4.6.1.7. Parameter: Final MC..............................................................................................................................................................................................................29

4.6.1.8. Parameter: Equalization........................................................................................................................................................................................................29

4.6.1.9. Parameter: Conditioning .......................................................................................................................................................................................................30

4.6.1.10. Parameter: Remaining time conditioning ...........................................................................................................................................................................30

4.6.1.11. Parameter: Way of drying .....................................................................................................................................................................................................30

4.6.1.12. Parameter: Oscillatory drying ...............................................................................................................................................................................................30

4.6.1.13. Parameter: Phase (visible only with user access).................................................................................................................................................................30

4.6.2. Option: Wood probe status .........................................................................................................................................................................................................30

4.6.3. Option: Air probe status ..............................................................................................................................................................................................................31

4.6.4. Option: Wireless probes (only for MKM-RF and with user level)...............................................................................................................................................31

4.6.5. Option: Display .............................................................................................................................................................................................................................32

4.6.6. Option: System (visible only with user access)............................................................................................................................................................................32

4.6.7. Option: Cooling (visible only with user access)............................................................................................................................................................................33

4.6.8. Option: Fans .................................................................................................................................................................................................................................34

4.6.9. Option: Spraying (visible only with user access)..........................................................................................................................................................................34

4.6.10. Option: Time/Date (visible only with user access).......................................................................................................................................................................35

4.6.11. Option: Communication (visible only with user access) .............................................................................................................................................................35

4.6.12. Option: Statistics .........................................................................................................................................................................................................................35

4.6.13. Option: Initialization.....................................................................................................................................................................................................................35

4.7. CHANGING ACCESS LEVEL..................................................................................................................................................................................36

4.8. OPERATING MODES ...............................................................................................................................................................................................37

4.8.1. Automatic, semiautomatic and manual operating mode ..................................................................................................................................................................37

4.8.1.1. Automatic mode......................................................................................................................................................................................................................37

4.8.1.2. Semiautomatic mode...............................................................................................................................................................................................................37

4.8.1.3. Changing of operating mode (auto to semiauto and vice versa) ..............................................................................................................................................37

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 3

4.8.1.4. Semiautomatic control of temperature and/or EMC in automatic mode ..................................................................................................................................37

4.8.1.5. Manual mode ..........................................................................................................................................................................................................................37

4.9. STARTING UP DRYING PROCESS.........................................................................................................................................................................38

4.10. STOPPING DRYING PROCESS ...............................................................................................................................................................................38

4.11. PAUSING DRYING PROCESS .................................................................................................................................................................................38

5. OPERATING PRINCIPLES (DRYING PRINCIPLE) ....................................................................................................................................................39

5.1. DRYING .....................................................................................................................................................................................................................39

5.1.1. PHASE: measurement ................................................................................................................................................................................................................39

5.1.2. PHASE: heating ...........................................................................................................................................................................................................................39

5.1.3. PHASE: core heating...................................................................................................................................................................................................................39

5.1.4. PHASE: drying..............................................................................................................................................................................................................................39

5.1.5. PHASE: equalization ...................................................................................................................................................................................................................40

5.1.6. PHASE: conditioning...................................................................................................................................................................................................................40

5.1.7. PHASE: cooling............................................................................................................................................................................................................................40

5.1.8. PHASE: stop.................................................................................................................................................................................................................................40

5.1.9. PHASE: pause..............................................................................................................................................................................................................................40

5.2. SET VALUES DEVIATIONS ....................................................................................................................................................................................41

5.3. POWER FAILURE DURING DRYING PROCESS...................................................................................................................................................41

6. DRYING REGIMES ...........................................................................................................................................................................................................42

7. DESCRIPTION OF ALARMS, INFORMATIONS AND WARNINGS ON MC-3000 UNIT .......................................................................................46

8. TECHNICAL CHARACTERISTICS OF DRYING SYSTEM........................................................................................................................................48

1. PURPOSE OF THIS INSTRUCTION

The MC-3000 user manual provides information for its safe use and is intended for qualified personnel.

To use the MC-3000 machine safely , read and follow these instructions. Plant it and pay special attention to the safety warnings and general

warnings. Always will keep this instruction manuals in or neerby power electric switch board (hereinafter referred to as KRO ) in which the

MC-3000 is built-in.

This manual is updated in accordance with hardware and software changes.

Date

Manual version

SW version

HW version

Description of recent changes

30.03.2021.

v.1.1.1

1.0.0.5

3.00

Humidity calculator is added

Unit MC-3000, installed by NIGOS-electronik personel, is used as an integral part of a conventional or dehumidifying dryers only in

industrial environments and in accordance with local laws and standards.

It is not allowed to use the controller unit for purposes that do not comply with the above operating conditions and environments..

Safety labels and notes

Explanation of the symbols in the instructions for use as well as on the labels of unit MC-3000 and relay board RB-3000:

Ground input connector.

L/+

AC phase input connector or DC hot end.

N/-

AC neutral input connection or DC mass.

Be sure to read the entire user manual before turning on the unit controller and before using.

Equipment containing electrical components must not be disposed of with household waste.

It must be collected separately, in accordance with local and current regulations.

Caution, warning of unsafe use that could result in personal injury, property damage and data loss.

Installation should to be carried by authorized persons, with appliance ofprotecting equipment and safety measures for work.

Installation of the unit is performed exclusively in KRO. Provide a dry, lighted and ventilated room for cabinet installation.

Be sure to conduct the earth wire to KRO, along with conducting of phase and neutral wire of voltage and correctly ground automate.

It is mandatory to bring 20 ÷ 24V ac / dc as written in the declaration and on the label of unit. Pay most of attention not to

connect high alternating voltage to digital nor analog inputs.

To avoid danger of fire or electrical shock, never exposed any unit nor KRO to influence or rain, snow or humidity. KRO

cabinet is transported wrapped in stretchable, waterproof foil. If any part of the machine is damaged or there is any doubt about its

correctness, use of KRO and drying system are prohibited.

Be sure to disconnect the unit from the power supply (term.clamp 2) before installing or opening the MC-3000 . All interventions

on the unit must be performed by persons authorized for service or trained technical personnel. Necessary replacements are made to

the original spare parts. For help, information and repair services, contact an authorized servicer or manufacturer NIGOS-elektronik.

Access is banned for children and unemployed persons!

Do not install the KRO cabinet near a device that produces strong electromagnetic or mechanical interference (except for

frequency regulators, which have to be electromagnetically compatible) , as is not in the areas with exploding atmosphere.

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

4Automatic control unit MC-3000 (version 1.1.1)

Additional security measures for correct and safe installation of system:

The HMI panel unit and the relay board are intended for installation on the KRO cabinet in a room with operating conditions

0 ÷ 50°C, without moisture and dust.

Pay attention to installation of other equipment in the KRO in order to avoid interference from mutual influence.

Measuring--communication module MKM is mounted outside, on the rear wall of the dryer, above the auxiliary door. As it is

exposed to external influences, it is mounted under the tin cover ( “roof”).

Installation of probes is described in section 3.4. INSTALLATION OF PROBES IN DRYING CHAMBER

To connect the measuring-communication module MKM, use communication cable with a shield that must not be placed in

parallel with power cables at a distance of less than 30 cm . An intersection at a right angle would be ideal.

Abbreviations and a list of symbols used on the display of unit MC-3000

Abbreviations

Temp

Temperature

EMC (UGL)

Equilibrium Moisture Content

RH

Relative Humidity

MC

Moisture Content

SHT

Sensor of relative humidity and temperature

KRO

Komandno-razvodni ormar

RB

Relay Board modul

MKM

Measure-communication module

RF

Radio frequency or communication unit that works inside of radio frequency range

Symbols

Temperature measurement

Equilibrium moisture measurement (EMC)

Measurement of moisture content in wood (MC)

Semi-automatic mode

Automatic mode

Manual mode

Heating valve

Electric heating (* only in dehumidifying dryers)

Circulation pump

Drying flaps (PI regulation)

Drying flaps (ON / OFF regulation)

Circulation fan

Sprayers

Recuperator (* only in classic dryers)

Compressor (* only in dehumidifying dryers)

M100%

R84%

Success of communication with measuring module / relay board

Communication with a PC

Access level

Wireless probe battery charge

RF signal strength of the wireless probe

Alarm

Warning

Information

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 5

2. LITHIUM BATTERY REPLACEMENT IN MC-3000 PANEL

Table 2. Battery technical specifications

MC-3000 unit contains a real-time clock circuit and a button battery, which provides the

necessary energy to provide this circuit independence of external power. Despite constant

work, consumption is low and battery life is about three years. If the drying system is often

shut down, it is advised to remove 3V battery and set the time and date for the next use of the

unit. It also advises replacing the battery every 3 years to avoid miscalculations of time and

errors in the history records.

Figure 2. Remove of metal cover on rear side of unit (up) and main printed circuit board of unit with 3V battery (down)

- Pull out both terminal clamps (K1 PC and K2 KILN/BUS) from the rear side of unit.

- Remove 4 screws from the rear side (one at each corner) and remove metal cover.

- Battery is located in a battery holder on the main PCB of unit.

- Push the flat screwdriver under the battery and remove the battery from the battery holder.

- Use lithium battery CR2032 of 3V only as replacement !

- Replace the battery with the suitable one. Pay attention to the poles !

- Put the cover back on and tighten all screws.

- Connect both terminal clamps (K1 and K2) with the automatic controller unit.

- Put the battery in adequate packaging to avoid short-docking and take the battery to the recycling service.

IEC battery label

CR2032

Type

Lithium

Rated voltage

3,0 V

Rated capacity

210 mAh

Working conditions

-20°C÷60°C

Weight

~ 3g

Dimensions

Ø20 x 3.2mm

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

6Automatic control unit MC-3000 (version 1.1.1)

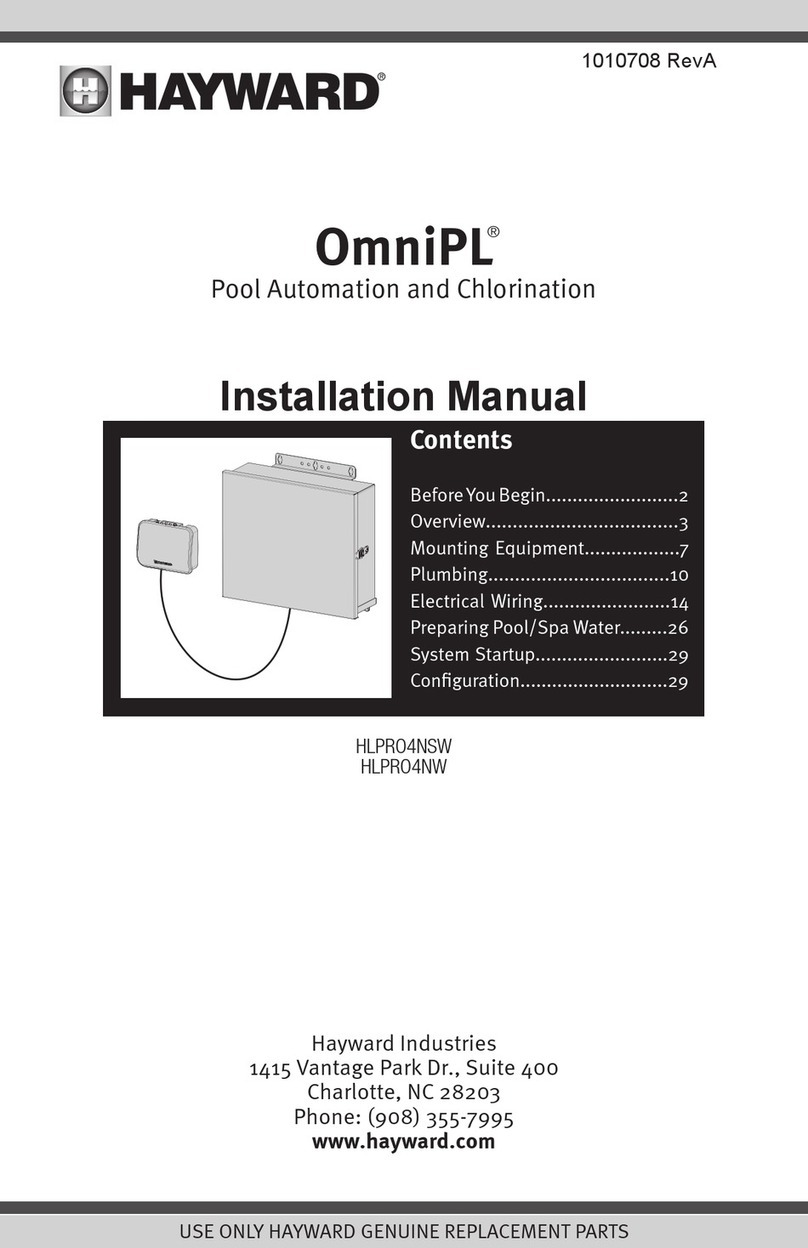

3. INSTALLATION OF EQUIPMENT

The control system for wood drying with controller unit MC-3000 consists of the following parts:

1) MC-3000 main unit with touchscreen, through which mediation is made between users and equipment in dryer,

2) RB-3000 relay board, over which equipment is managed in dryer,

3) MKM measuring-communication module could be type MKM-08 (with wire probes) or MKM-RF (with wireless

probes), provides measuring of temperature, equilibrium moisture content in the air and moisture content in the

wood, under which the drying process is conducted,

4) TR-RB isolating transformer for supplying RB block 230/20 V ac, 50/60 Hz, max 1.25 A,

5) probes for measuring temperature, EMC in the air and MC in wood,

6) USB-RS485 adapter for PC connection (optional),

7) communication cable S/FTP Cat.7 4P or LIYCY 5 x 0.34 mm2, for connecting MC-3000 and RB-3000 and

8) communication cable S/FTP Cat.6 4P, for connecting RB-3000 and MKM, as well as MC-3000 and PC.

MKM

kiln

KRO

MC-3000

RB-3000

24 VAC

PC

office

adapter

internet

RS-485

RS-485

S/FTP Cat.6

S/FTP Cat.6

S/FTP Cat.7

or

LiYCY 5x0.34

USB-A/USB-A

cable

Figure 3.1. Blok šema povezivanja sistema za sušenje sa automatom MC-3000

MC-3000 panel unit is designed for the installation of a closet (KRO) in which the rest of the equipment is installed.

Relay board RB-3000 is mounted on rail in KRO. It is connected to power supply and consists of command relays.

Measuring module MKM is mounted on the dryer chamber’s rear outer wall. Probes for temperature, EMC and

wood MC are placed inside chamber. For MKM with wired probes, the cables for connecting to the measuring

module are included. For MKM with wireless probes, an antenna is mounted inside chamber to receive signals.

Connection between MC-3000 and RB-3000 is cable S/FTP Cat.7 (NIGOS KRO) or LiYCY (other’s KRO) (item 7).

Connection between RB-3000 and MKM is cable S/FTP Cat.6 (item 8). Length of this cable could be up to 300 m.

Connection between MC-3000 and PC-a is cable S/FTP and adapter USB-RS485, which are optional and available

upon user’s request.

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 7

3.1. CONNECTION BETWEEN MC-3000, RB-3000 AND MKM

For connecting MC-3000 and RB-3000 use cable S/FTP Cat.7 4P or shielded cable LiYCY 5x0.34.

For connecting RB-3000 and any MKM use standard cable S/FTP Cat.6 4P.

SG

B

A

L +/

*

N -/

MKM

RB 3- 000

SG A BN -/L +/

654 7 8 9

K2 M K M

121110 13 14 15

K3 K IL N -B U S

SG A BN -/L +/

SG

A

B

N -/

L +/

654 7 8 9

K2 K IL N - B U S

A1

B1

C1

321

K1 PC

MC- 0003

BRO N/BR - E (L +)

W. WHIT /

GR GRE. WHIT /

EEN/ - E (N -)

SHIELD (GND)

O GE O WHIT

RAN / RAN.- E (SG)

BLUE-WHITE(B)

B UEL (A)

B UE WHIT

L - E (B)

B UEL (A)

O GE O AN WHIT

RAN / R .- E (SG)

SHIELD (GND)

GR GRE. WHIT /

EEN/ - E ( N -)

BRO N/BR - E (L +)

W. WHIT /

BLUE-WHITE (B)

B UEL (A)

O GE O AN WHIT (SG)

RAN / R .- E

SHIELD (GND)

GR GRE. WHIT ( N/-)

EEN/ - E

BRO N/BR - E (L +)

W. WHIT /

BRO N/BR - I E (L +)

W. WH T /

GR GRE. WH T /

EEN/ - I E ( N -)

SHIELD (GND)

O GE O AN WH T

RAN / R .- I E (SG)

B UEL (A)

B UE WHIT

L - E (B)

S/FTP Cat. 47 Pairs

S/FTP Cat. 46 Pairs

A1B1C1

321

PC

PE

X K c la m p

in K R O

SG

B

A

L +/

*

N -/

MKM

RB 3- 000

SG A BN -/L +/

654 7 8 9

K2 M K M

121110 13 14 15

K3 K IL N -B U S

SG A BN -/L +/

SG

A

B

N -/

L +/

654 7 8 9

K2 K IL N - B U S

A1

B1

C1

321

K1 PC

MC- 0003

BRO N/BR - E (L +)

W. WHIT /

GREEN/GRE.-WHITE (N/-)

SHIELD (GND)

O GE O WHIT

RAN / RAN.- E (SG)

BLUE-WHITE(B)

B UEL (A)

BLUE-WHITE (B)

B UEL (A)

O GE O AN. WHIT

RAN / R - E (SG)

SHIELD (GND)

GREEN/GREEN-WHITE ( N/-)

BRO N/BR - E (L +)

W. WHIT /

WHITE (B)

GREY (A)

YELLOW (SG)

SHIELD (GND)

GR /

EEN ( N -)

BRO N (L +)

W /

BRO N (L +)

W /

GR /

EEN ( N -)

SHIELD (GND)

YELLOW (SG)

GREY (A)

WHITE (B)

L YCY 0.34i 5X

S/FTP Cat. 46 Pairs

Figure 3.1. Connection diagram of MC-3000, RB-3000 and MKM

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

8Automatic control unit MC-3000 (version 1.1.1)

3.2. CONNECTING RB-3000

K9

32 33 34 35 36 37 38 39 40 41 42 43

K8

293031

K7

25 26 27 28

K6

22 23 24

K5

161718192021

KILN - BUS

MKM

DIGITAL INPUTS RECUPERATOR FANS

ANALOG

INPUTS RELAY OUTPUTS

COUNTERS HE ATFLAP SFANS

OPEN

ALARM

CIR .PUMPC

COMPRE SOR/S

FLAPS FAN

SPRAY

RIGHT

LEFT

CLOSE

OPEN

RELAY

COM ONM

CLOSE

COM.

CNT2

CNT1

RIGHT

COM.

SPEED

LEFT

COM.

SPEED

START

COM.

DIN1

DIN2

DIN3

DIN4

DIN5

POWER

READY

RUN

BASGN/-L/+SG BAN/-L/+

COM.

AIN2

AIN1

POWER

FUSE

RELAY FUSE

FUSE

FUSE

K4

L/+ N/-

K3

10 11 12 13 14 15

K2

4 5 6 7 8 9

K1

12 3

Figure 3.2.1. Overview RB-3000 clamps

Data cables and control signals inside the power electric switch board are connected to clamps marked with numbers 1 through 9 and plug into

the corresponding clamps of the RB-3000 relay board. The user connects the equipment in the dryer to the appropriate clamps of the power

electric switch board (KRO) according to given layouts and schematics.

Table 3.2. RB-3000 clamp connection layout

CLAMP

LABEL

NUMBER/

LABEL

CONNECTED TO CLAMP OF…

FUNCTION

…CONVENT. DRYER

…DEHUMIDIFY. DRYER

K1

Analog

inputs

1/com.

GND for temperature probes

Common contact for probes

2/Ain1

Temperature probe Pt-1000

Monitored temperature 1 and 2

3/Ain2

K2

MKM

4 / L/+

L+ on clamp inside MKM module

MKM module power supply

5/ N/-

N- on clamp inside MKM module

6/ GND

GND on clamp inside MKM module

MKM module grounding

7, 8, 9 / RS-485

RS-485 (B, A, SG) on clamp inside MKM module

Communication with MKM module

K3

KILN-BUS

10 / L/+

L+ on clamp of MC-3000 unit

MC-3000 unit power supply

11/ N/-

N- on clamp of MC-3000 unit

12/ GND

GND on clamp of MC-3000 unit

Grounding for MC-3000 unit

13, 14, 15 / RS-485

RS-485 (B, A, SG) on clamp of MC-3000 unit

Communication with MC-3000 unit

K4

Power supply

24V AC/DC

GND

GND for isolating transformer

GND for RB-3000

N/-

Neutral for isolating transformer

RB-3000 power supply

L/+

Phase for isolating transformer

K5

Digital

inputs

16/com.

GND for digital inputs

Common contact for digital inputs

17/Din1

Voltage-free contact on switch for flow fan

Flow fan’s failure alarm

18/Din2

/

… switch for fan on Ther.Pump

Thermal Pump’s fan control

19/Din3

Voltage-free contact on circulation pump

Circulation pump’s heating alarm

20/Din4

…switch for recuperator

… switch for TP’s compressor

Recuper.control

TP’s compress.

21/Din5

Voltage-free contact on switch for optional user’s device

Defined by user

K6

Recuperator

22/com.

Frequency regulator for

recuperator

/

DC freq. reg. grounding

/

23/Speed

DC freq. reg. speed input

/

24/Start

DC freq. reg. start input

/

K7

Fans

25/com.

Frequency regulator for flow (air circulation) fan

DC freq. reg. grounding

26/Speed

DC freq. reg. speed input

27/Right

DC freq. reg. start CW input

28/Left

DC freq. reg. start CCW input

K8

CNT

29/com.

GND for counter inputs

Common contact for counters

30/CNT1

Measuring electricity consumption

Electric meter output

31/CNT2

Measuring thermal energy consumption

Calorimeter output

K9

Relay

outputs

32/Alarm

Alarm signal

Alarm

33/Circ.pump

Circulation pump start

Circulation pump

34/Compressor/

Flaps fan

Switch for recuperator

Switch for compressor

Recuperator ON

Compressor ON.

35/Spray

Spraying valve

Spraying valve open

36/Fans_Right

Switch for CW (right) direction of flow fans (in KRO)

Right direction of fans

37/Fans_Left

Switch for CCW (left) direction of flow fans (in KRO)

Left direction of fans

38/Flaps_Close

Servo drive on flap

Servo flap closing

39/Flaps_Open

Servo drive on flap

Servo flap opening

40/Heat_Close

Heating valve

Electrical heating switch

Heating valve close

Heater ON

41/Heat_Open

Heating valve

Water heating valve

Heating valve open

Aux. relay

42, 43/Relay common

Control voltage from power electric switch board (KRO)

Control voltage

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 9

K9 RELAY OUTPUTS

32 33 34 35 36 37 38 39 40 41 42 43

K8 CNT

293031

FANSK7

25 26 27 28

REC.K6

22 23 24

DIGITAL IN.K5

161718192021

24V /ac dc

K4

L/+ N/-

KILN-BUS

K3

10 11 12 13 14 15

L/+

N/-

SG

A

B

K2 MKM

4 5 6 7 8 9

L/+

N/-

SG

A

B

K1 A.IN

1 2 3

L

N

Single-phase transformer

230Vac/24Vac

MKM-RF

www.nigos.rs

07:31:16 09ožu2020 M100%

R84% sušenje u t ijeku

G=3 R= S=0 E=12.0%53

su š enje

2. -> 50. 0%

0%

0%

9 0% 2 :5 "1

53:02''

K1= 16°

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

1

2

15.7

16.0

EMC 15.9

%

1 . %5 615. %6

kondenzaciona

TEMP

1

2

36.7

37.2 37.0C

º

3 . ºC7 3

37.3 ºC

1

5

2

6

3

7

4

8

12.0

%

50. 4

51.4

46.3

48.4

42.2

45.0

43.6

44.3

46.5

%

control temperature 2

control temperature 1

job detection

fan

frequency

regulator

CW +24 Vdc

0 10 Vdc

÷

gnd

CCW +24 Vdc

measuring of thermal energy

measuring of electrical energy

close

open

close

open

counterclockwise

clockwise

spraying valve

recuperator relay

circulation pump relay

audible/light signaling

Automatic fase

2 A

~ 230 V ac, 50 Hz

RB-3000

calorimeter

electric meter

recuperator

frequency

regulator

start +24 Vdc

0 10 Vdc

÷

gnd

Figure 3.2.2.Block schematics of connecting equipment of conventional dryer to RB-3000 relay board

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

10 Automatic control unit MC-3000 (version 1.1.1)

OPEN

REL AY

CO M ONM

41 42 43

POWE R

FUSE

FUSE

POWER

FUSE

RELAY FUSE

K9 RELAY OUTPUTS

32 33 34 35 36 37 38 39 40 41 42 43

K8 CNT

293031

FANSK7

25 26 27 28

REC.K6

22 23 24

DIGITAL IN.K5

161718192021

24V /ac dc

K4

L/+ N/-

KILN-BUS

K3

10 11 12 13 14 15

L/+

N/-

SG

A

B

K2 MKM

4 5 6 7 8 9

L/+

N/-

SG

A

B

K1 A.IN

1 2 3

L

N

Single-phase transformer

230Vac/24Vac

MKM-RF

www.nigos.rs

07:31:16 09mar2020 M100%

R84% sušenje u t oku

G=3 R= S=0 E=12.0%53

su š enje

2. -> 50. 0%

0%

0%

9 0% 2 :5 "1

53:02''

K1= 16°

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

1

2

15.7

16.0

EMC 15.9

%

1 . %5 615. %6

kondenzaciona

TEMP

1

2

36.7

37.2 37.0C

º

3 . ºC7 3

37.3 ºC

1

5

2

6

3

7

4

8

12.0

%

50. 4

51.4

46.3

48.4

42.2

45.0

43.6

44.3

46.5

%

control temperature 2

control temperature 1

job detection

thermal pump fan

fan

frequency

regulator

CW +24 Vdc

0 10 Vdc

÷

gnd

CCW +24 Vdc

measuring of thermal energy

measuring of electrical energy

close

open

close

open

counterclockwise

clockwise

spraying valve

compressor relay

circulation pump relay

audible/light signaling

Automatic fuse

2 A

~ 230 V ac, 50 Hz

RB-3000

calorimeter

electric meter

Figure 3.2.3. Block schematics of connecting equipment of dehumidifying dryer to RB-3000 relay board

NOTE: Figures represent examples of connection of output devices, directly connected to 230 Vac power supply. The user can use

devices with different power. It is recommended that user use voltage-free contacts for work with output devices !

3.2.1. Fuse replacement of relay board RB-3000

In case that RB-3000 is connected to power supply, but POWER LED does not glow, fuse marked with POWER FUSE needs to be replaced.

In case that RB-3000 can not turn on output devices, but their LED glow, fuse marked with RELAY FUSE needs to be replaced.

- Only a trained person (electrician) can replace the fuses !

- It is mandatory to pull out clamps: K4 (power supply) and K9 (relay outputs) before any replacement !

- Insert a flat screwdriver into the slot under the FUSE sign, press it and turn it to the left for about 60°.

- The fuse carrier's loose. Pull the carrier up from RB-3000 and pull the fuse out of the carrier.

- Discard old fuse, replace it with suitable one, which is given together with RB-3000 in certain quantity.

- Use T3,15A/250V fuses only as replacement! Be sure that the same type is given with RB-3000.

- Put a new fuse in the fuse carrier and return the carrier back in the fuse case in RB-3000.

- With a flat screwdriver, press the carrier into fuse case and turn it to the right for about 60°.

- Re-connect loosed clamps back to RB-3000.

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 11

3.3. INSTALLATION OF MEASURING & COMMUNICATION MODULE MKM

There are 2 types of MKM measuring-communication modules: MKM-08 with wire probes and MKM-RF with wireless probe.

3.3.1. Measuring module with wire probes MKM-08

Following equipment with MKM-08 are:

-1 measuring-communication module MKM-08,

-2 measurement boxes DS-04t,

-2 EMC paper holders,

-1 box of EMC papers (made of special hygroscopic material), sufficient for exploitation in period of 1 to 2 years,

-8 wood MC probes attachment cables, different lengths (10 m, 8 m and 6 m),

-1 box of prochrome (inox) probes for wood, shorter and longer and

-1 tool for probe extraction from dried wood.

3.3.1.1. Position of MKM-08 and DS-04 boxes in the dryer chamber

Measuring module MKM-08 performs temperature and moisture measurements in the chamber and transfers that informations to MC-3000 by

communication line. MKM-08 is mounted on the outside rear wall of the chamber. DS-04t boxes are mounted inside, arranged diagonally.

These boxes carry on them one probe for measuring temperature, one EMC paper holder and 4 cable connections to plug in the wood moisture

content measuring probes.

DRYING CHAMBER

MKM-08

Pt1 000

DS-04t EMC

Pt1000

EMC

DS-04t

Figure 3.3.1. Position of MKM-08 and DS-04 boxes in the dryer chamber

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

12 Automatic control unit MC-3000 (version 1.1.1)

3.3.1.2. Connection scheme

DS-04t boxes are connected by multi-wire cable (LI6YC6Y 8x 0.34 mm2) to the MKM-08 terminal clamp according to the scheme provided in

figure 3.3.2. The colors layout is standard for cables delivered by NIGOS-elektronik and should be adhered to whenever possible.

DRYING CHAMBER

30m max

GREY (S8)

YELLOW (S7)

BROWN (S6)

WHITE (S5)

RED (CD)

YELLOW- GREEN (GND)

GREY (S4)

YELLOW (S3)

BROWN (S2)

WHITE (S1)

RED (CD)

YELLOW- GREEN (GND)

Vd8

Vd7

Vd6

Vd5

COM

GND

Vd3

Vd4

Vd2

Vd1

COM

GND

BLACK (T2)

BLACK (T1)

GREEN (COM)

BLUE (V2)

GREEN (COM)

BLUE (V1)

T2

T1

COM

V2

COM

V1

MKM-08

Pt1000

DS-04t( )2

W o prob so d e

S2

S1

S3

S4

CD

BRO NW

WHITE

GREY

RED

YELLOW

EMC

GREEN

BUEL

Pt1000

SHIELD

BLACK

Pt1000

DS-04t(1)

W o probeso d

S2

S1

S3

S4

CD

BRO NW

WHITE

GREY

RED

YELLOW

EMC

GREEN

BUEL

Pt1000

SHIELD

BLACK

L 6YC6Y 0.34i 8X

A

B

SG

L +/

*

N -/

MKM clamps

on RB-3000

BROWN/B -WHITE (L +)

R. /

GREEN/GRE.-WHITE (N -)/

SHIELD ( GND)

ORANGE/ORAN.-WHITE (SG)

BLUE-WHITE (B)

BLUE (A)

BLUE WHIT- E (B )

B U EL (A )

O GE ORAN. WHIT

RAN / - E (SG)

SHIEL D (GND )

GR GRE. WHITE /

EEN/ - (N -)

BRO N/BR - E (L + )

W. WHIT /

SG A BN -/L +/

654 7 8 9

K2 M K M

Figure 3.3.2. Connection scheme of measuring boxes DS-04t and MKM-08

EMC is measured over paper samples placed in the holder. Replace fresh new paper before each new drying cycle.

Wood MC is measured over nails hammered into the wood and they are connected via cables with crimp connectors on both sides to DS-04.

Sen ors

Pt1000

Wood MC probes

attachment cables (6 - 10 m)

EMC pape r

h ldero

LI6YC6Y

x0.34mm8 2

FEP/SILICON

2x0.75mm 2

DS-04t

EMC

MC1

MC2

MC4

MC3

Temp

17 ÷ 25 mm

30 mm÷ 35

50 m m

Wo MC probeod

minimal 7 0 mm

Figure 3.3.3. Connection of measuring elements to DS-04t box: wood MC probes, sensor Pt1000 and EMC paper holder

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 13

3.3.2. Measuring module with wireless probes MKM-RF

Following equipment with MKM-RF are:

-1 measuring-communication module MKM-RF,

-1 RF-antenna which receives signals from probes,

-2 RF-EMC probes - or - 2 RF-SHT probes,

-2 EMC paper holders (with RF-EMC probes only!),

-1 box of EMC papers (with RF-EMC probes only!),

-8 wireless wood MC probes RF-MC1, with built-in batteries,

-1 box of prochrome (inox) probes for wood, shorter and longer and,

-1 tool for probes extraction from dried wood.

MKM-RF module "listens" to probes that are in the chamber and receive measured temperature and moisture values and transmits these

informations to MC-3000 by communication. MKM-RF is mounted on the outside rear wall of the chamber, and the antenna inside the dryer

chamber. Probes are deployed in chamber on various spots for the best space covering and the best signal strength to MKM-RF.

3.3.2.1. Positions of MKM-RF, antenna and wireless probes in the dryer chamber

DRYING CHA BEM R

Pt1000

RF-EMC

EMC

Pt1000

RF-EMC

EMC

(***)

RF-MC1

RF-MC1

RF-MC1

RF-MC1

RF-MC1

RF-MC 1

RF-MC1

RF-MC1

MKM-RF

ANTEN AN

Figure 3.3.4. Position of MKM-RF, antenna and wireless probes RF-MC1 and RF-EMC

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

14 Automatic control unit MC-3000 (version 1.1.1)

3.3.2.2. Connection scheme

ANTEN AN

MKM-RF

L+

*

N-

SG

B

A

MKM clamps

on RB-3000

BRO N/B - E(L +)

W R. WHIT /

GRE GRE. WHIT /

EN/ - E(N -)

SHIELD (GND)

O GEORA . WHIT

RAN / N - E(SG)

B UE WHIT

L - E(B)

BLUE(A)

B UE WHIT

L - E (B)

B UEL (A)

O GEORAN. WHIT

RAN / - E (SG)

SHIELD (GND)

GR GRE. WHIT /

EEN/ - E(N -)

BRO N/BR - E(L +)

W. WHIT /

SG A BN -/L +/

654 7 8 9

K2 M K M

Figure 3.3.5. Connection scheme of measuring module MKM-RF

RF-EMC probes have 1 temperature probe and 1 paper holder to measure EMC. EMC paper has to be renewed before each new drying cycle.

RF -SHT probes have a combined temperature and EMC probe located in a tube with an air passing filter. This filter should be cleaned every 6

months or when it is observed to be clogged.

Sen ors

Pt1000

EMC paper

holder

RF-EMC

EMC

Temp

Sen ors

SHT 31

RF-SHT

EMC + Temp

Figure 3.3.6. RF-EMC probe mounted on the dryer wall, with measuring elements Pt1000 sensor and sample holder (left)

and RF-SHT probe mounted on the dryer wall, with capacitive sensor as measuring element (right)

RF-MC1 probes are connected to the nails in wood (wood MC probes) via attachment cables with crimp connectors on both sides.

17 ÷ 25 mm

30 ÷ 35 mm

50 mm

w o probeo d FEP/SILICON 2x0.75mm 2

RF 1-MC

minimum 500 mm

Figure 3.3.7. Connection of wood probes to RF-MC1 probe

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 15

3.4. INSTALLATION OF PROBES IN DRYING CHAMBER

3.4.1. Installation of probes for measuring equilibrium moisture content in the dryer

This probe is placed in DS-04t and RF-EMC boxes. The paper holder is made of aluminum and is mounted on it according to the instructions

given (Figure 3.4.1). The measuring sample has rectangular shape and it is made of hygroscopic paper.

Placement of EMC paper into holder: Unwind 4 nuts on the sample holder so that the springs become free. The sample is placed between 2

sets of plates. Wind up rolls tighten so that the tiles are well attached to the sample and the make contact between them.

NOTE:

This sample is used for ONLY ONE drying cycle. After each drying cycle, the paper is thrown away and renewed as written above.

In case of RF-SHT probe instead of RF-EMC, no need for papers, since built-in SHT sensor unifies temperature and EMC se.

EMC paper

connectors

nuts

springs

plates

Figure 3.4.1.EMC paper holder

3.4.2. Installation of probes for measuring wood moisture content

The whole process of drying sawn lumber is conducted on the basis of the measured average moisture in the wood, which was obtained from

eight measuring spots (probes). That is why it is extremely important to properly place and arrange the probes in the lumber stock. The same

stainless steel probes are used to connect to the DS-04t boxes as for the RF-MC1 probes. Sometimes it is necessary to use stainless steel

screws instead of stainless steel nails, for thin wooden materials (eg. lamellas).

The probes are made of INOX (rust-proof, stainless steel). After drying, the probes are removed with special tool and will be used for next

drying. The recommended dimensions of the nails for measuring wood MC are:

30 mm for lumber up to 40 mm thick (thinner lumber) and

45 mm for lumber over 40 mm thick (thicker lumber)

90°

min.70mm

min.500mm

.2 mmø 3

1/2

lumber

tickness

1/2

lumber

tickness

Figure 3.4.2. Proper drilling of holes and hammering of INOX probes into the lumber

One pair of probes is used for one wood MC measuring spot.

First at all, drill two holes in a wood board with Ø 3.2 drill bit (3 ÷ 3.5 mm), up to half the lumber thickness.

Further, the probes are hammered into prepared holes, where the depth of penetration must not be less than 1/3 thickness of the lumber, and it

is best to be up to 1/2 thick of lumber.

Probes are placed cross-board at a distance of 30 to 35 mm (ideally 32 mm). Thinner and softer lumber does life is minimal twonot need

drilling, but probes can be hammered directly.

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

16 Automatic control unit MC-3000 (version 1.1.1)

> 5 0 mm0

> 70 mm

3mm

2

> 20 mm

> 20 mm

Figure 3.4.3. Probes placement in boards wider than 70 mm (top view)

NOTE: In lumber elements shorter than 103 cm, the probes are placed around the middle of the element.

<70mm

min.500mm

.2 mmø 3

32mm

1/2

lumber

tickness

> 5 0 mm0

< 70 mm

3 mm2

> 20 mm

> 20 mm

Figure 3.4.4. Probes placement in elements narrower than 70 mm (top view)

>500mm

< 25 mm

32mm

> 5 0 mm0

< 25 mm

3 mm2

longer probes only (45 mm)

Figure 3.4.5. Probes placement in boards thinner than 25 mm (side view)

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 17

A pair of stainless steel screws are used to measure the moisture in the lamella as shown in the following figure, with the recommended

dimensions of the screws 4.8 x 13 mm. The screws are placed transversely on the lamella at a distance of 30 mm to 35 mm (ideally 32 mm). .

A couple of holes are first drilled in the board with a Ø 3.2 mm drill bit. A nickel-plated ring pedal (Ø 4.8 - 1mm2) is placed on the screw as

an adapter for connecting the probe cable. Then, a rubber 3 ÷ 5 mm thick, 15 ÷ 20 mm in diameter is placed (sealing plumbing rubber rings are

used). After that, the screws are screwed into the prepared holes until the rubber is slightly sunken. With thinner and softer material, you do

not need to drill holes, but the screws are screwed directly into the material. The following figure gives an example of placing probes. After

drying, the screws have to be removed and a new pair of screws is needed for the next drying.

>500mm

< 25 mm

3.2 mmø

32mm

Figure 3.4.6. Placement of stainless steel screws in the lamella

wood probe attachment cable

FEP/SILICON

2x0.75mm2

crimp connector

probe adapter

made of stainless steel

lamella

plumbing

rubber

stainless steel screw

4.8 x 13 mmø

Figure 3.4.7. Connecting stainless steel screw

After installing the probes, connect the wood probe attachment cable by plugging the crimps at one end of the cable into the holes located at

the top of the wood MC probes. The crimps on the other end of the cable are connected to the DS-04t junction box or to the RF-MC1 probe.

Figure 3.4.8. Extraction of INOX nails with a special tool after drying (left) and removing INOX screws (right)

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

18 Automatic control unit MC-3000 (version 1.1.1)

3.5. WIRELESS PROBE BATTERIES

Additional safety warnings for non-rechargeable batteries:

Don't open the batteries.

Do not store batteries at a temperature higher than 40 °C, do not heat them or expose them to flames.

Empty and damaged batteries store under WEEE directive and local laws.

Under extreme conditions, there may be a leak of electrolytes from the battery. In that case, wipe the battery and the interior of

probe with dry cloth, while avoiding contact with the skin.

The battery meets the standards IEC60086-4, IEC60079-11, UL1642 and directives RoHS and REACH.

Table 3.6. Battery technical specifications

Wireless probes run on batteries at all times and send measurements to MKM-RF. Despite

constant work, consumption is low and battery life is minimal two years. If the probe has not

been used for a long time, it is advised to remove the batteries from the probes. It also advises

replacing batteries every two years to avoid miscalculation results.

It is preferable to replace batteries before drying process starts, but if the battery runs out or leaks

during drying, passivise probe on controller screen. A more detailed description follows.

Disconnect RF-MC1 probe from the silicon cables or disconnect RF-EMC and RF-SHT probes

from the chamber wall. Remove a cover and replace a battery (see below for more details). Close

the cover and restore the silicone cables to the RF-MC1 probe or return RF-EMC and RF-SHT to the wall. Activate probes on MC-3000 unit

and check measures after a few minutes. Put the batteries in adequate packaging to avoid short-docking and take them to the recycling service.

3.5.1. Battery replacement in RF-MC1

- Pull out 2 silicone cables from the side of RF-

MC1.

- Remove 8 screws from the top of probe and

remove cover.

- Use a sharp tool to press the tooth in each white

battery contact holder to release the contact.

- Replace the battery with a suitable one, paying

attention to the poles, using a sharp tool.

- Return upper cover, making sure that the silicone

rubber is well fitted and that the opening on the

cover matches LED from PCB and tighten screws.

- Connect 2 silicone cables.

- Return RF-MC1 on the wood, if the battery is

changed during drying process.

3.5.2. Battery replacement in RF-EMC and RF-SHT

-Remove probe from a wall of the dryer chamber.

-Remove 4 screws on the back of the box and remove

front cover.

-Replace battery with suitable one, paying attention to the

poles.

-Return front cover, tighten the screws on the back.

-Return the probe on the wall of the dryer chamber.

IEC battery label

Saft LS 1xx00

Type

Li-SOCl2

Rated voltage

3,6 V

Rated capacity

1.2Ah ÷17Ah

Working conditions

-60°C÷150°C

Weight

~ 10g

Dimensions

Ø12 x 40mm

+

BATTERY

-

+

-

RF-MC1

WIRELESS

WOOD PROBE

www.nigos.rs

RF_MC1_V2.1

+BATTERY -

+BATTERY - -

+

+

BATTERY

-

+

-

RF_EMC_V2.00

RF_SHT_V2.1

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

Automatic control unit MC-3000 (version 1.1.1) 19

SG

A

B

N -/

L+/

654 7 8 9

K2 K IL N - B U S

A1

B1

C1

321

K1 PC

MC- 0003

WHITE (B)

BLUE (A)

ORANGE-WHITE

ORANGE (G)

GAB

BLUE 1(A )

WHITE 1(B )

ORANGE-WHITE

ORANGE C1( )

SHIELD

S/FTP Cat.6 4P

G A B

USB Tx Rx

Rx Tx

USB-RS485

adapter

3.6. CONNECTING THE COMMUNICATION LINE

The communication of the machine with a PC allows monitoring and control of the drying process via a computer. Supplied as an option at the

request of the customer.

Communication between the computer (PC) and the control unit is performed by the communication standard RS - 485. The drying process

control unit and the computer are connected with an S / FTP CAT7 cable. The length of this cable can be up to 1000 m.

This equipment is used not only to connect the machine to the computer but also to connect communication boxes, frequency regulators,

sterilization boxes, etc ... The last device on the line must have a terminating resistor between communication connections A1 and B1 or A and

B. A resistor of 120 is used Ω. The devices supplied by NIGOS-elektronik have terminals for communication with the factory-mounted

resistor. If the controller unit is connected somewhere in the middle of the cable, the resistor is removed. If the controller unit is located at the

end of the cable, the resistor must remain connected between A1 and B1.

Figure 3.6. shows the connection method where the MC-3000 unit is placed first on the master (and on the slave) line and the resistor is

removed, the next controller unit continues on it and so on. Terminal resistor lefts on the last unit.

As for grounding, it is enough to connect the shield to the ground only at one end of the cable. Cable shield connects only to the ground of the

PC (housing), and no need to connect with other devices on the line, just passes through the cable. At the cable break point, the shield is short-

circuited as shown in the cable joining scheme between the two MC-3000 units.

USB - RS485

adapter PC

B(L-)

A(L+)

GND D+

D-

VCC

USB 2.0

MC-3000

(1st unit on the line)

KILN BUSPC

SG

N-

B1

C1

B

L+

A1

A

PC Grounding

MC-3000

(2nd unit on the line)

RS-485

line

GND

Terminal resistor

120 Ω

KILN BUSPC

SG

N-

B1

C1

B

L+

A1

A

MC-3000

(the last unit on the line)

KILN BUSPC

SG

N-

B1

C1

B

L+

A1

A

Figure 3.6. Scheme of connection of communication cables between the units with a PC

The standard used by Nigos-elektronik in color selection for S / FTP cable:

A1 and A - blue,

B1 and B –blue-white,

C1 and GND - orange and orange-white.

EQUIPMENT FOR MEASUREMENT&CONTROL AND DRYERS

Borislava Nikolića - Serjože 12, 18000 Niš, Serbia; Tel./Fax. (018) 211-212, 217-468; office@nigos.rs; www.nigos.rs

20 Automatic control unit MC-3000 (version 1.1.1)

4. OPERATIONS OF AUTOMATIC CONTROLLER UNIT

After switching on the machine to the power supply, the software first automatically performs an internal memory check, resets the equipment

in the dryer and displays the home screen - main menu.

4.1. MAIN MENU ON PANEL OF MC-3000

The MC-3000 is equipped with a touch screen. All settings are made by a short and light touch on the field with the desired symbol or the

desired text displayed on the screen. In case of damage on the sensitive layer, the contoller can no longer be used.

From the main menu, selectables are: graphic view , textual view , history , regimes , settings and access level .

07:31:16 09Mar2020 M100%R84% - drying -

Humidity

calculator Kiln History

Regimes Settings Access

Figure 4.1. Main menu on the panel of automatic controller unit MC-3000

4.2. HUMIDITY CALCULATOR

Touching the field "Humidity calculator" opens new pop-up windows on the center of

main menu, as presented on figure on the left. Main function of the calculator is

conversion of psychonometric values, relative humidity and equilibrium moisture content

in the air. This can help the user to create new drying regimes or to translate older regimes

based on psychonometric measurements.

Each of the 4 sizes (dry probe temperature, wet probe temperature, relative humidity and

mixed humidity) has its own sliders to change the value. By changing one, the other

values are calculated automatically. The fifth slider, at the bottom of the window, is used

to change the temperature scale from Celsius to Fahrenheit and vice versa.

To exit the humidity calculator, touch one of the 4 visible fields of the main menu screen,

beside the calculator.

Humidity calculator

Access level icon

Kiln view

Drying regimes settings

Drying history overview

Controller unit settings

Access level

Humidi y calculatt or

| | | | | | | | | | |

EMC = 6.0%

| | | | | | | | | | |

RH = 39.0%

| | | | | | | | | | |

W = 49.4T °

| | | | | | | | | | |

DT °= 67.2

C°F°

Table of contents

Other Nigos Control Unit manuals

Popular Control Unit manuals by other brands

Argo-Hytos

Argo-Hytos SR1A-B2 INSTRUCTIONS FOR PRODUCT USE

Sandpiper

Sandpiper G Series Service & operating manual

YASKAWA

YASKAWA DO-A3 installation manual

Cornelius

Cornelius UF-1 Operator's manual

Pentair

Pentair Anderson Greenwood 93 Series Installation and maintenance instructions

CALEFFI

CALEFFI 200000 manual

powersoft

powersoft LiteMod quick guide

Moxa Technologies

Moxa Technologies NPort Z2150 Quick installation guide

Graco

Graco SDM8 Series instructions

Lutron Electronics

Lutron Electronics QSGRK-6D Quick installation and operation guide

M-system

M-system R3-NMW1F instruction manual

Centrometal

Centrometal CM2K Technical instructions