Nippon Gases MICROTIG DC 162 PULSE Quick guide

MANUAL

MICROTIG DC 162PULSE

2719135

MICROTIG DC 202 PULSE

2719161

OPERATING AND SAFETY INSTRUCTIONS

Note: It is essential to read these operating instructions before starting up

the equipment. .

Otherwise, it could be dangerous.

The machines may only be used by personnel familiar with the relevant

safety regulations. The machines bear the mark of conformity and

therefore comply with the following regulations:

-EC Low Voltage Directive (73/23/EEC)

-EC EMC Directive (89/336/EEC)

(CE marking is only required in Member States) In accordance with

IEC60974, EN60974, VDE0544, the machines may be used in environments

with a high electrical risk.

Z

Rev.:

0 03 /2020

2

ES

PT

MICROTIG DC 162 / 202 PULSE

GENERAL TABLE OF CONTENTS

INSTRUCCIONES DE MANEJO Y SEGURIDAD (ESPAÑOL) ................................................3

INSTRUÇÕES DE USO E SEGURANÇA (PORTUGUES) ....................................................23

3

MICROTIG DC 162 / 202 PULSE

ES

PT

EU- DECLARACIÓN DE CONFORMIDAD

EU- CERTIFICADO DE CALIDAD

Nippon Gases España S.L.U. C/Orense, 11, 28020 Madrid

Producto Modelo Código

INVERTER PARA SOLDADURA MICROTIG DC 162 PULSE

MICROTIG DC 202 PULSE

2719135

2719161

NORMATIVA

NIPPON GASES ESPAÑA S.L.U., como empresa fabricante y distribuidora de máquinas, aparatos y artículos de

soldadura y corte, DECLARA que el producto suministrado cumple con los requisitos descritos en las Directivas y

Normas Comunitarias indicadas a continuación.

–Compatibilidad de Electromagnetismo (EMC): 2004/108/EC

–Bajo voltaje (LVD): 2006/95/EC

Pruebas EMC SCC(06)-206-10-EMC of 2008-10-16

Estándares de las pruebas: EN 60974-10:2007

Pruebas LVD 20081250 of 2008-09-24

Estándares de las pruebas: EN 60974-1:2005

INDICACIONES

La presente Declaración de Conformidad implica que:

–El equipo es seguro

–Es conforme para el uso al que está destinado

–Existen controles de fabricación que garantizan el mantenimiento de la calidad del producto.

–

Los componentes del equipo son apropiados para el uso al que están destinados y cumplen con las

correspondientes normas y directivas de aplicación.

Esta declaración no tendrá validez en el caso de cambios no autorizados, reparaciones inadecuadas o

modificaciones que no hayan sido expresamente aprobadas por NIPPON GASES ESPAÑA, S.L.U

Jefe de Producto

Product Manager

Madrid, 4 de noviembre, 2019

José Rivas

4

ES

PT

MICROTIG DC 162 / 202 PULSE

ÍNDICE ESPAÑOL

1. WARRANTY..........................................................................................................................5

2. SAFETY........................................................................................................................6

2.1 Emission reduction methods .......................................................................7

2.2. Electric safety.....................................................................................................8

2.3. Individual protection...................................................................................................8

3. TIG WELDING (Tungsten Inert Gas) ............................................................................. 11

4. MMA WELDING (electrodo revestido) ........................................................................ 12

5. CONTROL PANEL........................................................................................................ 13

6. CHARACTERISTICS .......................................................................................................... 14

7. INSTALLATION .................................................................................................................. 14

7.1. Connection to the power supply ............................................................................. 14

7.2 Connection........................................................................................................ 14

8. FUNCTIONS ...................................................................................................................... 15

8.1. MMA process welding(electrodo revestido) .......................................................... 15

8.2. TIG welding............................................................................................................ 16

8.3. SPOT welding mode ............................................................................................17

8.4. JOBS - Welding programmes ............................................................................... 18

9. ERROR DESCRIPTION............................................................................................. 18

10. WIRING DIAGRAM...................................................................................................... 19

11. LIST OF PARTS ............................................................................................................ 20

12. MAINTENANCE............................................................................................................ 22

12.1. Breakdown repairs ..............................................................................................22

5

MICROTIG DC 162 / 202 PULSE

ES

PT

1. WARRANTY

The purchase invoice guarantees your warranty. The number of this invoice must be indicated on

each warranty claim.

All materials are guaranteed for 12 months from the date of invoice, unless otherwise specified.

Defects or deterioration caused by natural wear and tear or by an external accident (incorrect

assembly, faulty maintenance, abnormal use...) or by a modification of the product not accepted in

writing by the seller, are excluded from the guarantee.

The guarantee only covers the free replacement of recognised defective spare parts (transport not

included).

(transport not included).

The workmanship carried out by the distributor is entirely at your expense. However, if you wish, the

labour may be carried out free of charge by NIPPON GASES S.L.U., in its establishments, provided that

the return transport is paid for by the distributor.

NIPPON GASES S.L.U. reserves the right to modify its equipment without prior notice. Illustrations,

descriptions and characteristics are not contractual and do not engage the responsibility of the

manufacturer.

Nippon Gases S.L.U. reserves the right to modify its equipment without prior

notice. Illustrations, descriptions and characteristics are not contractual and do

not engage the responsibility of the manufacturer.

6

ES

PT

MICROTIG DC 162 / 202 PULSE

2. SAFETY

This machine, in its design, component specification and production, is in accordance

with the regulations in force [EU directives, European (EN) and international (IEC)

standards. The European Directives "Electromagnetic Compatibility", "Low Voltage" and

"RoHS" as well as the IEC / EN 60974-1 and IEC / EN 60974-10 standards are applicable.

Electric shocks can be fatal.

-This machine must be connected to earthed sockets. Do not touch the live parts

of the machine.

-Before any intervention, disconnect the machine from the mains. Only qualified

personnel should work on these machines.

-Always check the condition of the power cable.

It is essential to protect the eyes from the radiation of the electric arc. Use a welding

shield with a suitable protective filter.

Use localised extraction. Smoke and fumes can damage the lungs and cause poisoning.

Risk of fire or explosion.

-Remove all explosive or flammable products from the welding area;

-Check that there is a sufficient number of fire extinguishers in the vicinity of the

welding area;

-Check that the sparks projected cannot cause a fire, remembering that these

sparks can reignite several hours after the end of welding.

Hot parts can cause burns. Workpiece, spatter and droplets are hot. Wear gloves,

aprons, safety shoes and other personal safety equipment.

Electromagnetic fields generated by welding machines may cause interference to other

devices. They may affect cardiac pacemakers.

Gas bottles can explode (MIG or TIG welding). It is essential to comply with all safety

regulations regarding gases.

Electromagnetic compatibility

If electromagnetic disturbances occur, it is the responsibility of the user to remedy the problem with

the manufacturer's technical support. In some cases, corrective action may be reduced to simply

grounding the welding circuit (see note below). In the opposite case, it may be necessary to build an

electromagnetic shield around the source and add input filters to this measure. In any case,

electromagnetic disturbances should be reduced until they do not disturb nearby welding equipment

or persons. The following situations should be taken into account:

-Power cables, control cables, display and telephone cables close to the welding equipment.

-Radio and television transmitters and receivers.

7

MICROTIG DC 162 / 202 PULSE

ES

PT

- Computers and other control equipment.

- Safety-critical equipment, in particular the monitoring of industrial equipment.

-Health of the people around, in particular those wearing cardiac stimulants and hearing aids.

-Equipment used for calibration.

-Immunity of other surrounding equipment. The user must ensure that these materials are

compatible. This may require additional protective measures.

-Time at which welding materials and other equipment operate.

2.1. Methods to reduce emissions

Power supply

The welding equipment must be connected to the mains according to the manufacturer's instructions.

Should interference occur, it may be necessary to take additional precautions such as filtering the

power supply. It is necessary to take into account the shielding of the power cables of welding

equipment permanently installed in metallic conduits or equivalent. Shielding must be carried out in

compliance with electrical continuity. The welding source must be connected in such a way that there

is always a good electrical contact.

Welding Cables

Welding cables should be as short as possible and in good serviceable condition (no splices), on or near

the ground.

Equipotential bonding

The links between all metallic components in and adjacent to the welding installation must be taken

into account. However, metallic components connected to the part being worked on increase the risk

of electric shock if the user touches the metallic components and the electrode at the same time. The

user must be isolated from all connected metallic components.

Earth connection

When the part to be welded is not earthed for electrical safety reasons or because of its size or position

(e.g. ship hull, steel mill), a connection of the part to earth may reduce emissions in some cases. Care

must however be taken to ensure that this connection does not increase the risk of injury to the user or

damage other electrical equipment. When necessary, the grounding of the part must be made by a

direct connection, but in some countries where this is not authorised, the connection must be made by

a capacitance resistor and according to national regulations.

Shielding and protection

Selective shielding and protection of other cables and materials in the surrounding area can limit

interference problems. Shielding of the entire welding installation may be considered for special

applications.

8

ES

PT

MICROTIG DC 162 / 202 PULSE

2.2. Electric safety

Connection to the power supply

Before connecting your appliance, check that:

-The electrical meter, the overcurrent protection device and the electrical installation are

compatible with the maximum power and supply voltage of your welding equipment (indicated

on the nameplate).

-The single-phase or three-phase earthed connection must be made on a basis appropriate to

the maximum current of the welding equipment.

-If the cable is connected to a fixed post, the earth, if provided, shall never be cut off by the

electric shock protection device.

-The welding power source switch, if provided, shall indicate "OFF".

Job position

The application of arc welding implies strict compliance with the safety conditions regarding electric

current (decree of 14.12.1988). It is necessary to ensure that no metallic part accessible to welders can

come into direct or indirect contact with a conductor of the power supply network. If there is any doubt

about this serious risk, a conductor of this metallic part shall be connected to earth with an electrical

cross-section at least equivalent to that of the largest phase conductor.

It is also necessary to ensure that a conductor connects any metallic part which the welder could

touch on an uninsulated part of the body (head, ungloved hand, bare arm, etc.) to earth of an electrical

cross-section at least equivalent to that of the largest power cable of the earth clamp or welding

torch. If several metal grounds are used, they shall be connected at one point, earthed under the same

conditions.

Welding and arc cutting shall be prohibited, except in very special cases in which stringent measures

shall be applied, in narrow conductive enclosures in which welding apparatus must be left outside.

Very serious safety measures shall be compulsory a priori for welding in poorly ventilated or damp

enclosures.

Risk of fire or explosion

Welding may involve risks of fire or explosion. Some precautions must be observed:

-Remove all explosive or flammable products from the welding area;

-Check that there is a sufficient number of fire extinguishers in the vicinity of the welding area;

-Check that the sparks projected cannot cause a fire, remembering that these sparks can

reignite several hours after the end of welding.

2.3. Individual protection

Risks of external injury

Electric arcs produce very bright infrared light and ultraviolet rays. These rays will damage your eyes

and burn your skin if not properly protected.

-The welder must be equipped and protected according to the difficulties of the work.

-They must be covered in such a way that no part of the welder's body can come into contact with

metal parts of the welding equipment, and also those which could come into contact with the

voltage of the mains supply.

9

MICROTIG DC 162 / 202 PULSE

ES

PT

-The welder must always wear individual insulating protection.

The welder's protection systems shall be as follows: gloves, aprons, safety shoes, etc. These offer

the additional advantage of protecting against burns caused by spatter and slag. Users must ensure

that these protective systems are in good condition and renew them if they deteriorate.

-It is essential to protect the eyes against arc flash (glare from the arc in visible light and infrared

and ultraviolet radiation).

-Hair and face against projections.

The welding shield, with or without helmet, is always provided with a protective filter specified in

relation to the current intensity of the welding arc (NS Standards S 77-104/A 88-221/A 88-222). The

coloured filter can be protected from shocks and projections by transparent glass.

The screen used must be used with a protective filter. It must be replaced by the same references

(opacity level number). See the table below for the level of protection recommended for the welding

method.

Persons in the vicinity of the welder must be protected by the interposition of UV protection screens

and, if necessary, by a welding screen provided with a suitable protective filter (NF S 77-104- por. A 1.5).

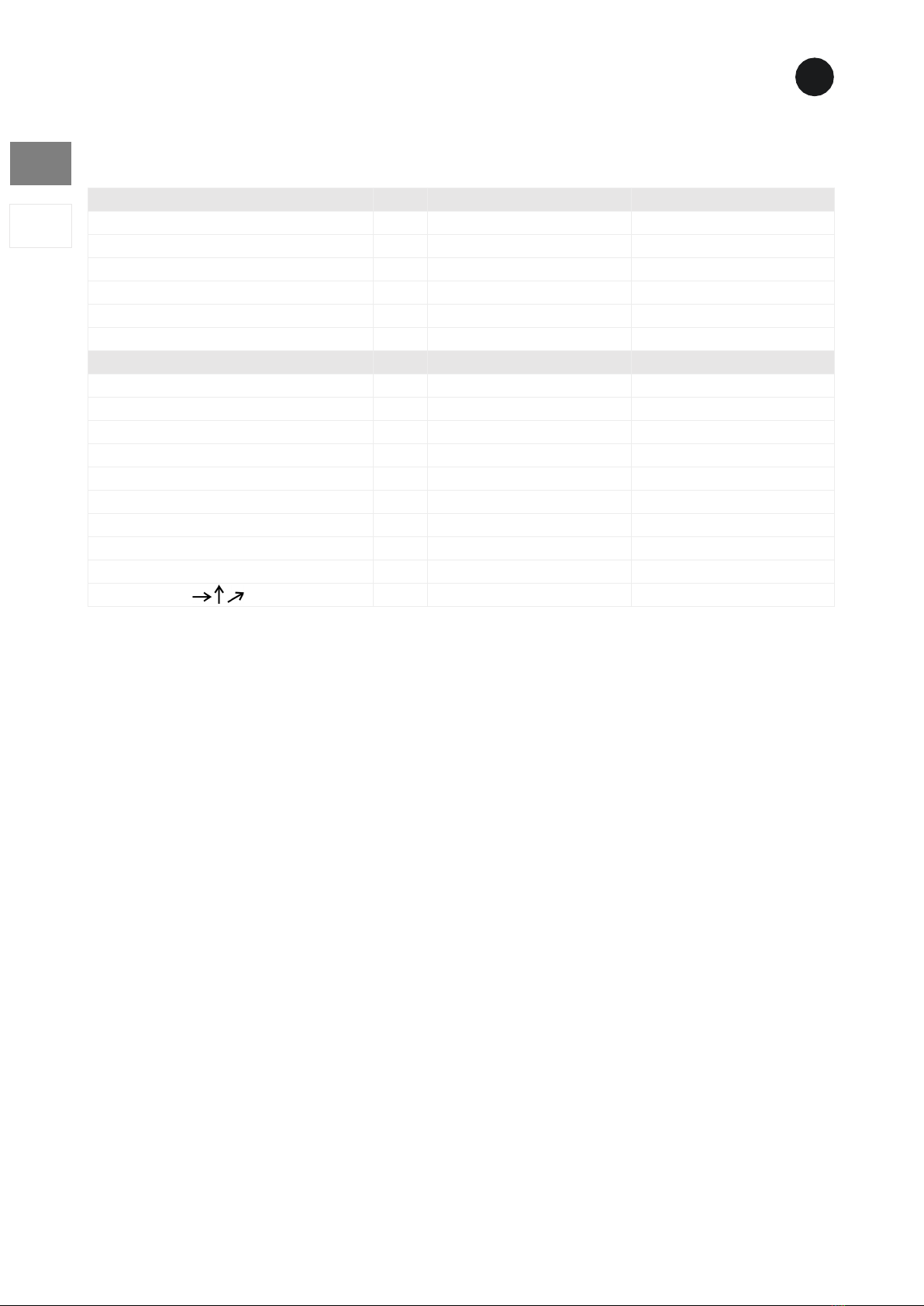

WELDING PROCESS NTENSITY OF CURRENT AMP.

0,5 2,5 10 20 40 80 125 175 225 275 350 450

1

5

15

30

60

100

150

200

250

300

400

500

Electrodes 9 10 11 12 13 14

MIG on metal 10 11 12 13 14

MIG on alloys 10 11 12 13 14 15

TIG on all metals 9 10 11 12 13 14

MAG 10 11 12 13 14 15

Arc/Air 10 11 12 13 14 15

Plasma Cutting 9 10 11 12 13

Depending on the conditions of use, it should be set to the nearest number.

The term "metal" means steels, copper and copper alloys.

The shaded area represents applications where the welding process is not normally used.

Risks of internal injuries

Safety against fumes and vapours, noxious and toxic gases

-Arc welding operations with electrodes must be carried out in suitably ventilated areas.

-Welding fumes emitted in workshops must be collected as they are produced, as close as

possible to their production and discharged directly to the outside. Fume extractors must be

installed for this purpose.

-Chlorinated solvents and their vapours, even at a distance, if affected by arc radiation, are

transformed into toxic gases.

10

ES

PT

MICROTIG DC 162 / 202 PULSE

Safety in the use of gases (TIG or MIG inert gas welding)

Compressed gas cylinders

Comply with the safety standards indicated by the gas supplier and in particular:

-Avoid knocks when holding the bottles.

-Avoid heating above 50 °C.

Pressure reducer

Make sure that the release screw is loosened before the connection is made on the cylinder.

Check the tightness of the connection before opening the cylinder valve. Open the bottle tap slowly.

In the event of a leak, never loosen a connection under pressure; close the bottle tap first.

Always use flexible hoses in good condition.

11

MICROTIG DC 162 / 202 PULSE

ES

PT

3. TIG WELDING (Tungsten Inert Gas)

It is an electric arc welding process under gaseous protection, using a torch with an infusible tungsten

electrode and can be performed with or without filler metal, in an inert gas atmosphere such as argon

and its mixtures.

The melting temperature of the tungsten electrode is 3400ºC higher than the metals to be welded so it

does not melt or release contaminating welding atoms.

Through this process you can weld with a very stable electric arc without spatter and slag which

guarantees a high mechanical strength of the welded joints.

TIG welding replaces oxyacetylene welding with advantages especially in the welding of mild steels and

stainless steel in direct current (DC) or aluminium and its alloys in alternating current (AC).

In specific cases, it can also be advantageous in connection with mainly MMA welding (fusible

electrode) or MIG welding that does not require the addition of metal or thin sheets in which the wires

are not visible.

Composición química de los electrodos

Código

Composición

Tipo

Color

Soldadura

WP

Tungsteno puro

W

Verde

AC – Aluminio, Magnesio

WT4

0,35-0,55% torio

Th

Azul

DC

Acero carbono, Acero inox,

Titanio

Cobre

WT10

0,80-1,20% torio

Amarillo

WT20

1,7-2,3% torio

Rojo

WT30

2,7-3,3% torio

Violeta

WT40

3,8-4,3% torio

Naranja

WZ3

0,15-0,50% zirconio

Zr

Marrón

Acero inox, Níquel,

Metales no ferrosos

WZ8

0,70-0,10% zirconio

Blanco

WL10

1,0-1,2% lantano

La

Negro

Todas aplicaciones TIG

WC20

1,9-2,3% cerio

Ce

Gris

Todas aplicaciones TIG

Tabla de diámetros y corrientes aplicables a los electrodos

∅

eléctrodo

(mm)

Amp. DC

Amp. AC

Negativo (-)

Positivo (+)

1,6 mm

40-130 A

10-20 A

45-90 A

2,0 mm

75-180 A

15-25 A

65-125 A

2,5 mm

130-230 A

17-30 A

80-140 A

3,2 mm

160-310 A

20-35 A

150-190 A

4,0 mm

275-450 A

35-50 A

180-260 A

5,0 mm

400-625 A

50-70 A

240-350 A

12

ES

PT

MICROTIG DC 162 / 202 PULSE

Shielding gases: Gases used in TIG welding contribute to:

-To involve the electric arc in an ionisable atmosphere.

-Avoid contamination of the weld by oxygen in the atmosphere.

-To cool the electrode.

Argon(Ar)

The most common gas used with a purity grade of 99.9%.

Helium (He)

Pure helium is used for copper welding mixed with argon in percentages varying between 10% and

75%.

Hydrogen (H)

It is an inert gas at room temperature and is used especially in copper soldering. It is not

recommended for soldering in enclosed spaces because it combines with oxygen to create an

unbreathable atmosphere.

4. MMA WELDING (coated electrode)

To establish a welding arc, a potential difference is induced between the electrode and the workpiece.

potential difference between the electrode and the workpiece.

The air between them is ionised and becomes conductive, so that the circuit is closed and creates the

electric arc. The heat of the arc partially melts the base material which is deposited creating a weld

pool. Arc welding is still very common due to the low cost of the equipment and consumables used in

this process.

An electric arc is formed between the electrode and the metal to be welded by means of an electric

current. The temperatures reached cause it to melt and deposit in the welded joint. Metal core

electrodes made of steel or other alloys are coated with a fluxing material which creates a protective

atmosphere that prevents oxidation of the molten metal and facilitates the welding operation.

In DC power sources (rectifiers) the polarity of the electric current affects the mode of metal transfer.

Typically, the electrode is connected to the positive (+) pole, although in welding very thin materials, it

may be connected to the negative (-) pole.

The most favourable welding position is horizontal, while welding can be carried out in any position.

Porta-electrodos

Electrodo revestido

Zona de soldadura

Transferencia

de metal

Atmosfera de

protección de arco

Pieza a soldar Pinza de masa

13

MICROTIG DC 162 / 202 PULSE

ES

PT

Tabla de parámetros de soldadura MMA:

Diámetro electrodo

Intensidad de corriente

Espesor de chapa

∅2,5 mm

40 – 125 A

> 2 mm

∅3,2 mm

105 – 250 A

> 3 mm

∅4,0 mm

75 – 185 A

> 6 mm

∅5,0 mm

140 – 305 A

> 9 mm

∅6,0 mm

210 – 430 A

> 9 mm

∅8,0 mm

275 – 450 A

> 9 mm

5. CONTROL PANEL

1

Welding mode selector: TIG HF (TIG welding with high frequency ignition), LIFTIG (TIG welding

with contact ignition), MMA welding, PULSE (when on with another mode also on, indicates

pulsed welding of the respective welding mode).

2

Indicator for machine switched on and under voltage

3

Overheat indicator - switches the machine off in case of overheating due to overloading

4

VRD - MMA VRD - No-load voltage reduction for use in environments with increased risk of

electric shocks

5

Selector 2T/4T and SPOT

6 Welding current and voltage display

7

Welding programs / welding current / welding voltage key - when pressed, allows selection

of welding programs and displays welding current or welding voltage on the digital display.

8

Parameter selection and setting - Allows selection of parameters by pressing / setting

of parameters by turning

9

Welding parameters - see description of these parameters in this instruction

manual.

14

ES

PT

MICROTIG DC 162 / 202 PULSE

6. CHARACTERISTICS

162

202

Single-phase power supply V** 1 x 230 V (-+10%) 1 x 230 V (-+10%)

Frequency Hz 50/60 50/60

Maximum primary current (MMA) A 34 43

Maximum primary current (TIG) A 24 30

Maximum power absorbed (MMA) KVA 7,8 9,9

Maximum absorbed power (TIG) KVA 5,5 6,9

SECONDARY

No-load voltage V 74 80

Welding current regulation A 10 - 160 10 - 200

40 % welding current A 160 200

60 % welding current A 135 160

100 % welding current A 105 125

Protection class IP 21S IP 21S

Insulation class H H

Standards IEC / EN 60974-1 IEC / EN 60974-1

Weight Kg 7 7,6

Dimensions cm 15 x 24 x 39 15 x 24 x 39

7. INSTALLATION

7.1. Connection to the power supply

The equipment must be supplied with 230V - 50 Hz/60 Hz single-phase + earth.

The power supply must be fitted with a device (fuse or circuit breaker) corresponding to the I1eff value

indicated on the nameplate of the equipment.

The installation of a differential protection device is not compulsory except for the safety of the users.

7.2. Connection

For the protection of the users, the equipment must be correctly connected to the earthing installation

(INTERNATIONAL SAFETY RULES).

It is essential to establish a good earth connection via the green/yellow conductor of the power cable in

order to avoid discharges due to accidental contact with live parts in contact with earth. If the earth

connection is not made, there is a risk of electric shock to the machine casing.

Avoid placing the device in rooms with high dust concentration, humidity or excessive ambient

temperatures.

15

MICROTIG DC 162 / 202 PULSE

ES

PT

8. FUNCTIONS

8.1. MMA process welding (stick welding)

-Make the connections to the mains and earth as indicated in the "Installation" chapter. Connect

the earth cable and electrode holder to the + (positive) and - (negative) quick connectors

according to the polarity of the electrode used and in accordance with the manufacturer's

instructions.

-Switch on the equipment with the ON/OFF switch located on the rear panel of the machine.

-The machine connected and under voltage indicator lights up, indicating that the machine is

under voltage.

-Select MMA (stick welding) or MMA PULSED welding (both indicators are lit).

-Set the current value (Fig.1 - 2), according to the following table:

Electrode diameter

(mm)

Ø2,0 Ø2,5 Ø3,2 Ø4,0 Ø5,0 Ø6,0

Welding current range

(A)

50 - 70 60 - 100 80 - 150 130 - 200 150 - 260 200 - 360

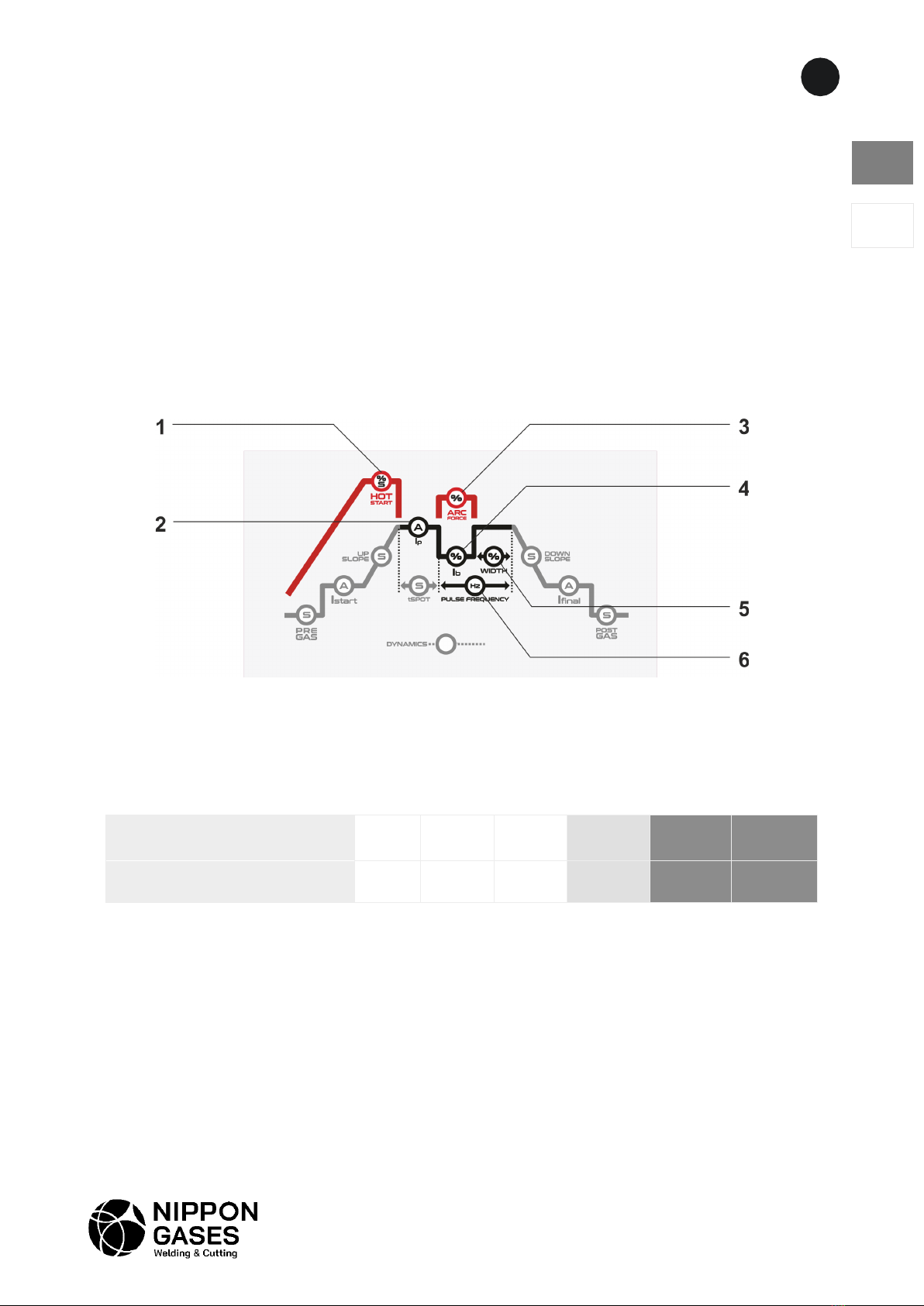

-Hot Start (Fig.1 - 1) - To improve arc starting, adjust the hot start percentage in relation to the

main current and/or time (seconds).

-Arc Force (Fig.1 - 3) - To prevent the electrode from being pulled into the workpiece during

welding, adjust the arc force percentage in relation to the main current.

Pulsed MMA welding - the welding current oscillates between a high and low value, for less thermal

delivery on thinner sheets and more control of the arc in the most demanding positions (vertical up).

-Ib (Fig.1 - 4) - set the base current as a percentage of the main current.

-WIDTH (Fig.1 - 5) - adjust the width of the peak (main) current from 10% to 90%.

-PULSE FREQUENCY (Fig. 1 - 6) - set the pulse frequency in Hertz.

-Start welding.

Fig. 1 – Parámetros MMA

16

ES

PT

MICROTIG DC 162 / 202 PULSE

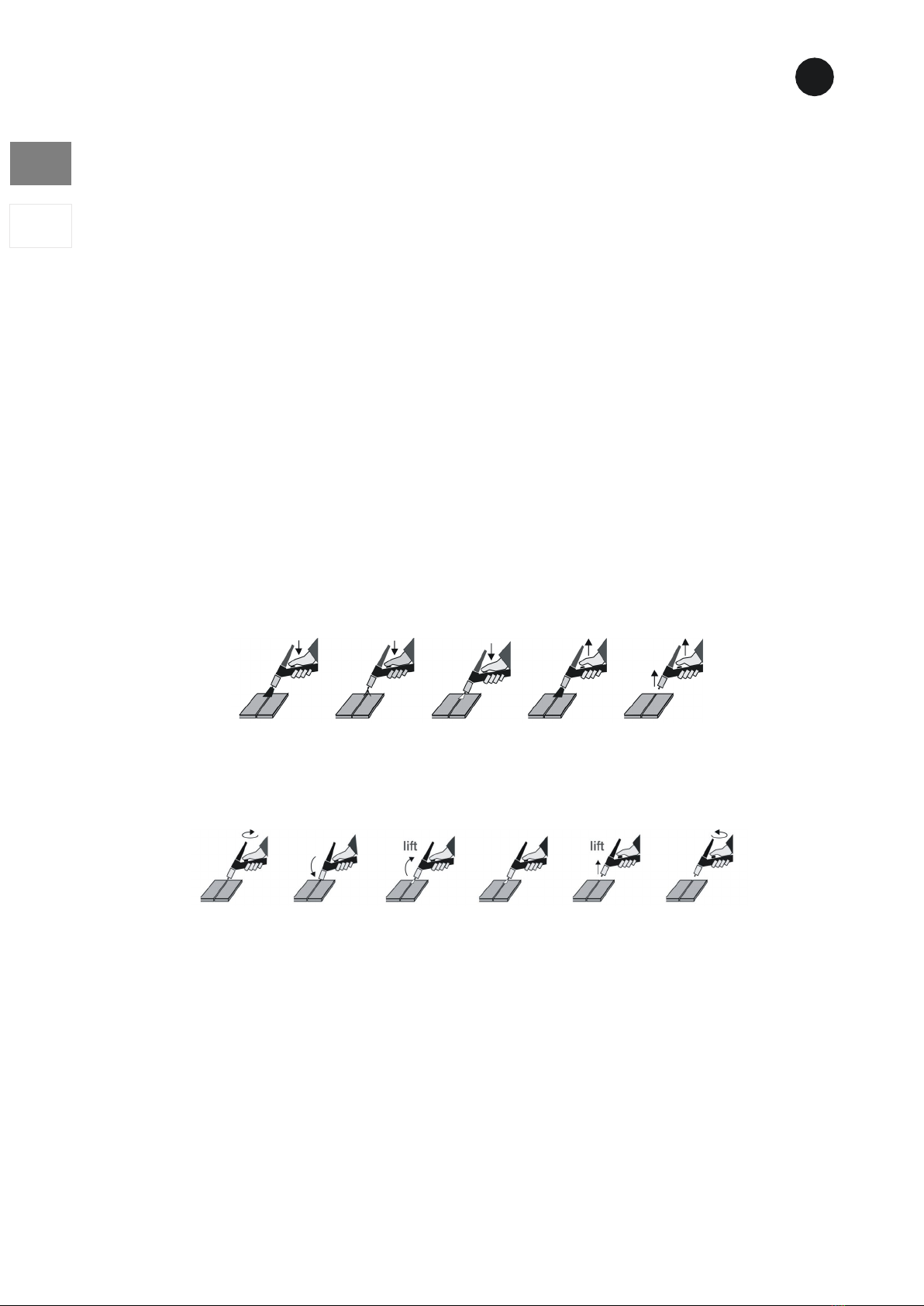

1-abrir gas 2-contact 3-cebado 4-soldadura 5-parar 6-cerrar gas

1-pré-gas 2-cebado HF 3-soldadura 4-post-gas 5-parar

8.2. TIG welding

- Make the mains and earth connections as described in the chapter "Installation".

- Connect the earth clamp cable to the positive socket by rolling it firmly to the right until a

perfect contact is ensured.

- Connect the power cable of the TIG torch to the negative socket by turning it firmly clockwise

until a perfect contact is ensured.

- Connect the gas hose of the TIG torch to the gas connection.

- Connect the torch control cable plug to the front panel connection.

- Connect the gas tube of the torch to the gas inlet on the rear panel and to the gas tube flow

meter. Check the gas content in the tube and, if necessary, change it.

- Regulate the gas flow through the pressure regulator of the flow meter 6 l/min and 12 l/min

depending on the current value.

- Apply the appropriate tungsten electrode to the TIG torch. The electrode must be sharpened

according to the selected welding mode - TIG DC sharpened on the tip.

- Switch on the machine by turning the main switch, located on the rear panel, to the ON position.

- The machine on and over voltage indicator lights up, indicating that the machine is over voltage.

- Select either TIG HF* (TIG welding with high frequency ignition) or LIFTIG** (TIG welding with

contact ignition). In both modes, there is a pulsed welding mode function - PULSED (both

indicators are lit respectively).

* TIG HF:

** LIFTIG:

This process is used in premises where the emission of high frequency waves may affect the operation

of sensitive electronic devices such as computers, hospital equipment, cardiac pacemakers, etc.

-Select 2T* (2-stroke) / 4T** (4-stroke) mode.

* 2T - Gas starts flowing according to the set PREGAS time when the torch trigger is pressed, and the

arc is established. The current rises according to the UPSLOPE time and the current IStart value for

the set Ip value. When the torch trigger is released, the current decreases according to the IFinal

current value. After the set DOWNSLOPE time, the arc is switched off and the POST GAS time starts.

17

MICROTIG DC 162 / 202 PULSE

ES

PT

** 4T - The gas starts to flow according to the set PREGAS time when the torch trigger is pressed.

When the torch trigger is released, the arc is automatically established. The current rises according to

the UPSLOPE time and the current IStart value for the set Ip value. When the torch trigger is pressed

and released, the current decreases according to the IFinal current value. After the set DOWNSLOPE

time, the arc is switched off and the POST GAS time starts.

-Adjust the welding parameters of the TIG cycle.

** DYNAMICS - Set ON or OFF by turning the parameter setting knob at the end of the TIG cycle

parameters to the left (OFF) or to the right (ON). Not available in PULSED mode.

-Start welding.

8.3. SPOT welding mode

-Follow the instructions for TIG mode but when selecting the 2T/4T/SPOT button, select SPOT.

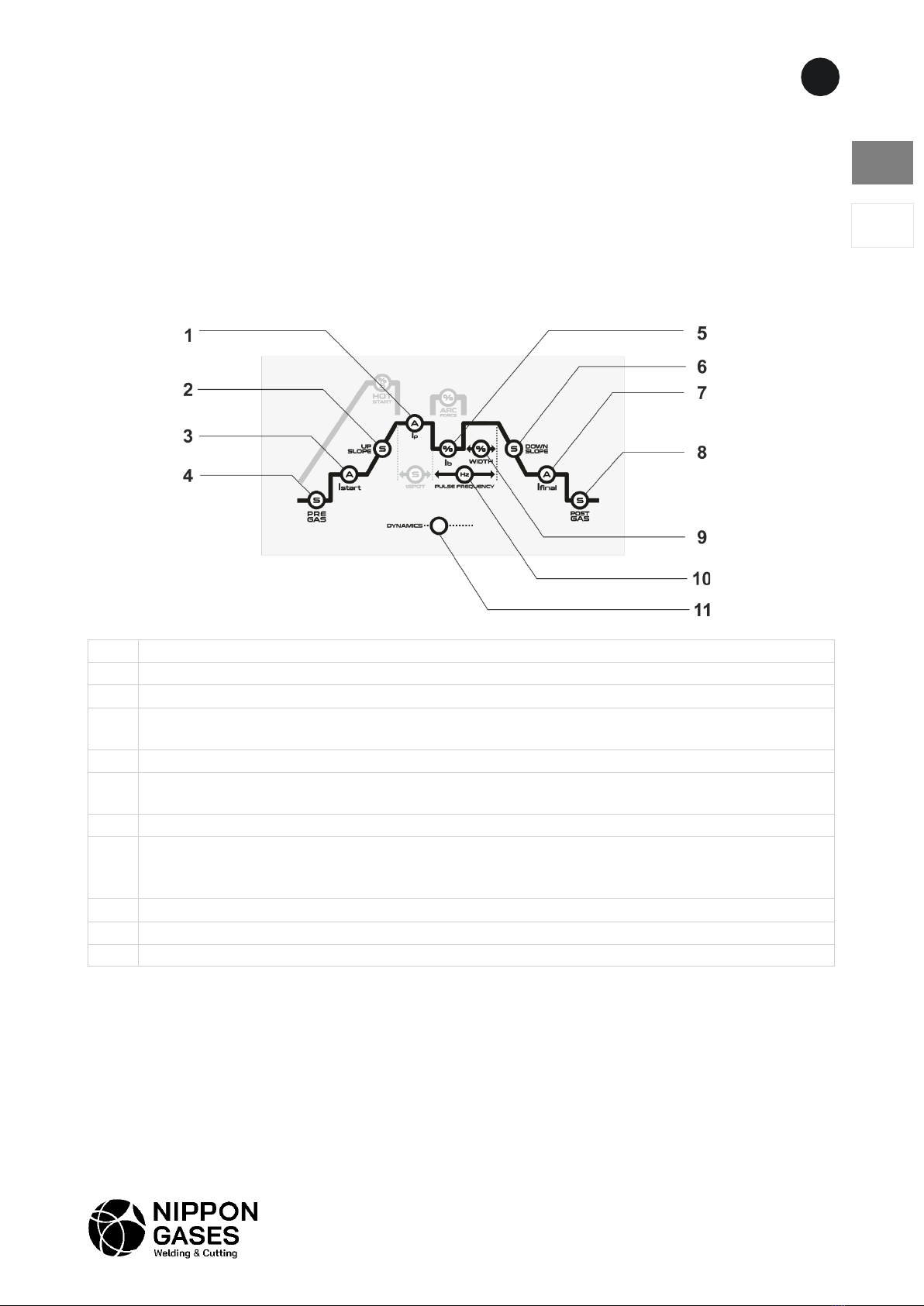

1 Welding current or, in pulsed mode, peak current

2

Up slope time in seconds from IStart to welding current (Ip)

3

IStart - Initial current in Amps

4

Pre-gas time in seconds - interval between gas flow and arc ignition. Allows welding to be

started with a shielding gas atmosphere.

5 Base current indicator (in pulsed mode).

6

Down slope time from the main stream to the final stream for crater treatment.

7

IFinal - Final current for crater treatment.

8

Post-gas time - interval after arc extinction to maintain the shielding gas at the end of

welding. Prevents the weld pool and tungsten electrode from oxidation.

9

Width - Length gives peak current from 10% to 90%.

10

Pulse frequency - set pulse frequency in Hertz

11

DYNAMICS - with arc length compensation for beginner welders*.

18

ES

PT

MICROTIG DC 162 / 202 PULSE

-Set the spot time (tSPOT) from 0.1 to 20 seconds.

-Start spot welding by pressing the torch trigger and continuing to press until the end of the set

TIG cycle.

8.4. JOBS - Welding programmes

This machine has 20 memories for storing and repeating your welding programmes.

- To save a welding programme, set the parameters and press the button (Fig.1 - 10) until the LED P

lights up. Then press the parameter selection/setting knob for 2 seconds until the digital display

shows P1. Then turn the parameter selection/setting knob to the desired programme number.

Finally, press the parameter selection/setting knob until the digital display shows MEM.

- To access a programme: Press the key (Fig. 1 - 10) until LED P lights up. Then turn the parameter

selection/setting knob to the desired programme number. Wait 2 seconds and your programme is

available.

- When you change the parameter values, the machine automatically switches to P0.

- After switching off the machine, your programmes will still be stored.

9. ERROR DESCRIPTION

Er1 - Overheating - Switches the machine off in case of overheating due to overloading

19

MICROTIG DC 162 / 202 PULSE

ES

PT

10.WIRING DIAGRAM

20

ES

PT

MICROTIG DC 162 / 202 PULSE

11. LIST OF PARTS

This manual suits for next models

3

Table of contents

Languages: