Ku nst sto ffschwei ßtec hni k

Contents

30.07.12 Working Instructions WIDOS 10000 obile Page 4 of 52

1.

DESCRIPTION OF THE PRODUCT .................................................................................... 6

1.1.

Usage and purpose-oriented use ...................................................................................6

1.2.

Safety measures ..............................................................................................................6

1.3.

Conformity........................................................................................................................6

1.4.

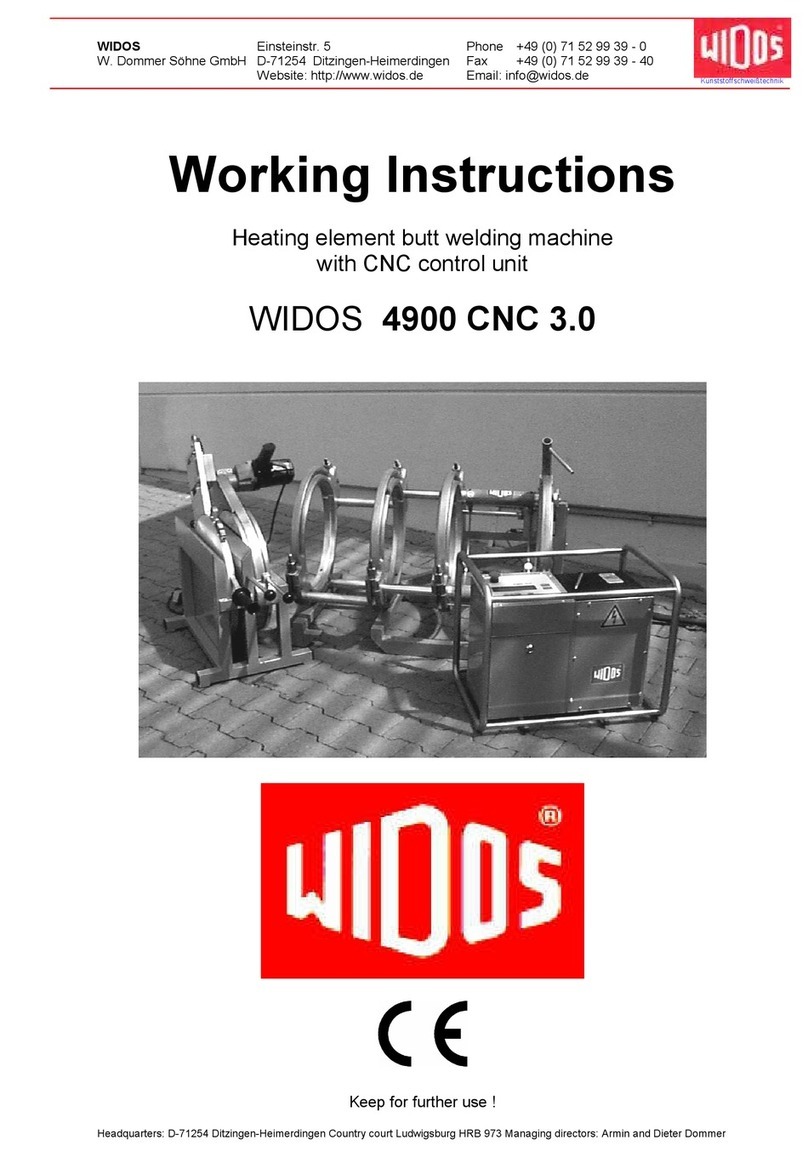

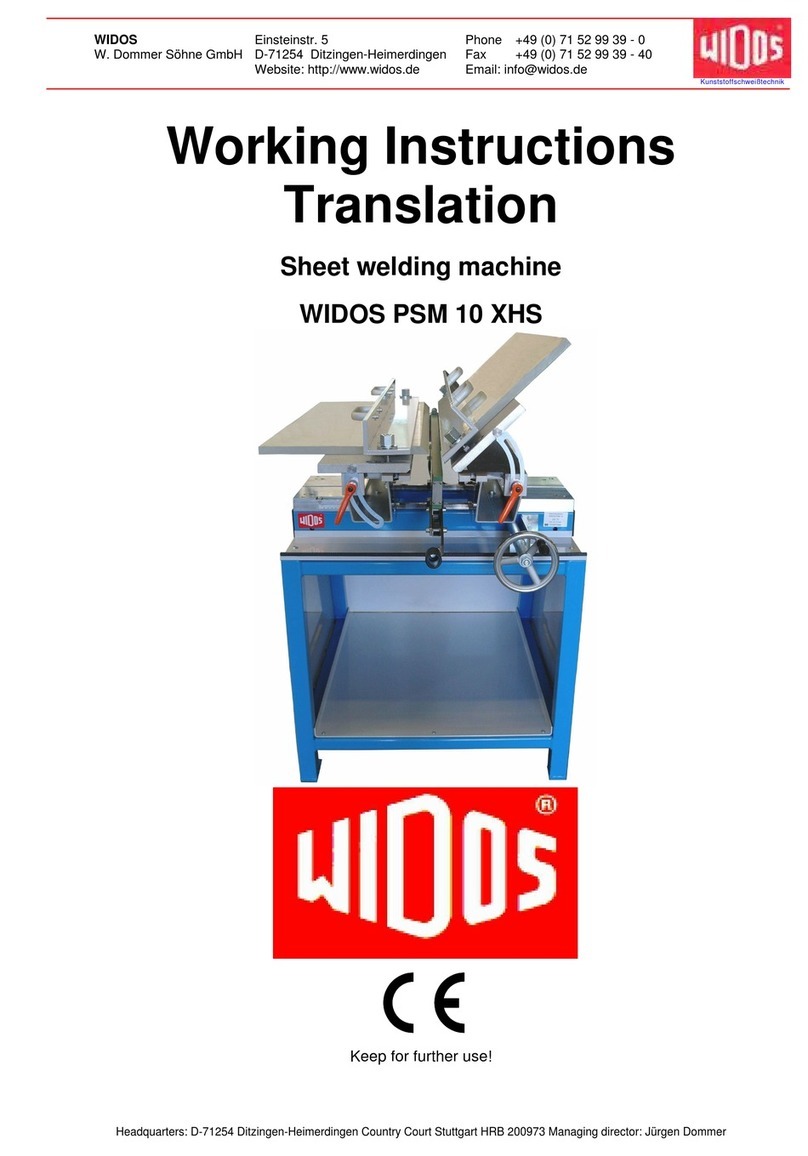

Machine overview............................................................................................................7

1.5.

Designation of the product..............................................................................................7

1.5.1.

Technical data................................................................................................................7

1.5.1.1.

WIDOS 10000 mobile General data.....................................................................8

1.5.1.2.

Basic fra e ...........................................................................................................8

1.5.1.3.

Hydraulic pu p ......................................................................................................8

1.5.1.4.

Heating ele ent.....................................................................................................9

1.5.1.5.

Planer....................................................................................................................9

1.6.

Tools and accessories ....................................................................................................9

1.7.

Verschleißteile .................................................................Fehler! Text arke nicht definiert.

2.

S FETY RULES................................................................................................................... 10

2.1.

Explanation of the symbols and indications ................................................................10

2.2.

Obligations of the owner................................................................................................11

2.3.

Obligations of the worker ..............................................................................................11

2.4.

Measures of organization..............................................................................................11

2.5.

Information about safety precautions ..........................................................................11

2.6.

Instructions for the staff................................................................................................11

2.7.

Maintenance and inspection, repair..............................................................................12

2.8.

Dangers while handling the machine............................................................................12

2.9.

Specific dangers ............................................................................................................12

2.9.1.

Danger of stu bling over electric wire..........................................................................12

2.9.2.

Dangers caused by electric energy ..............................................................................12

2.9.3.

Dangers caused by the hydraulics................................................................................13

2.9.4.

Danger of catching clothes by the planer......................................................................13

2.9.5.

Risk of injury by noise ..................................................................................................13

2.9.6.

Danger of co bustion by heating ele ent and welding area.........................................13

2.9.7.

Dangers by unsecured carriage ...................................................................................13

2.9.8.

Danger of crushing by cla ping devices and guideways ..............................................14

2.10.

Structural modifications on the machine .....................................................................14

2.11.

Warranty and liability .....................................................................................................14

3.

FUNCTION L DESCRIPTION............................................................................................ 15

4.

OPER TING ND INDIC TING ELEMENTS .................................................................. 16

4.1.

Machine ..........................................................................................................................16

4.2.

Portable operator panel.................................................................................................17

4.3.

Hydraulic control elements............................................................................................18

4.4.

Switch cabinet ................................................................................................................19

4.4.1.

Control la p oil te perature.........................................................................................19