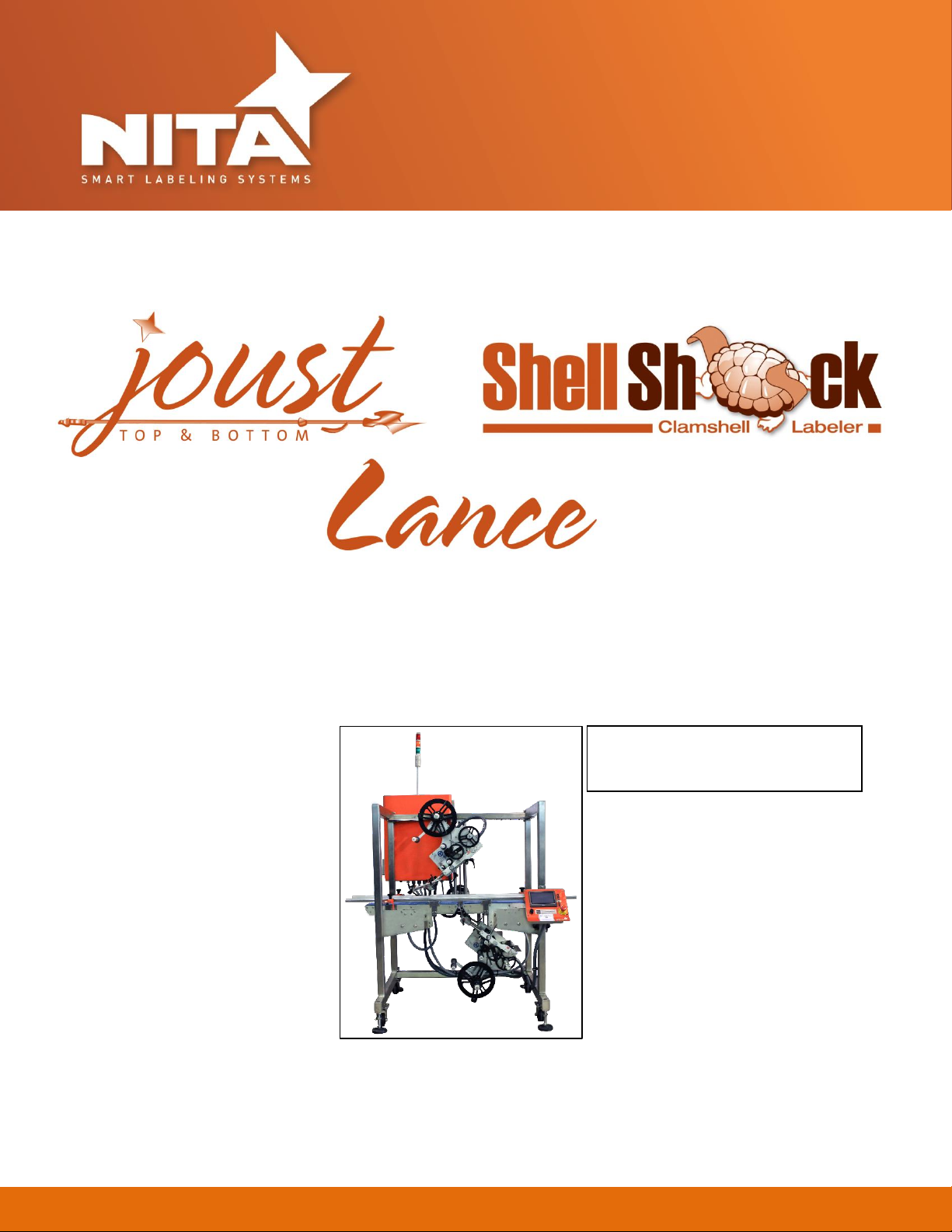

NITA Joust Product manual

Operator and parts manual - 2013

OPERATOR AND PARTS MANUAL

These systems are packaged to include one or several label heads as well

as a conveyor and may contain several options such as status light tower,

transparent label detectors, etc.

Some of the options described in this manual may not apply to your equipment.

HMI Password: 12345678

Adv. Settings: 222183600

Joust-Shellshock-Lance-Servo Labeling system

i

TABLE OF CONTENTS

1 MANUAL PREFACE –Machine identification......................................................................................................1

2 CERTIFICATION APPROVALS ...............................................................................................................................2

3 WARNINGS AND CAUTION INFORMATION ........................................................................................................3

4PRODUCT INTRODUCTION..................................................................................................................................5

4.1Joust 5

4.2Shellshock (SSK).............................................................................................................................................6

4.3Joust / Shellshock (Combo) ...........................................................................................................................7

4.4Lance top .......................................................................................................................................................8

4.5Lance bottom ................................................................................................................................................9

4.6Shellshock with servo closer 360 ................................................................................................................10

4.7This equipment is an assembly of 3 major components.............................................................................11

4.8Direction of travel .......................................................................................................................................11

5 SHIPMENT RECEPTION (uncrating)...................................................................................................................12

6 SYSTEM SETUP..................................................................................................................................................14

6.1MAIN CONTROL PANEL with HMI Touch Screen.........................................................................................14

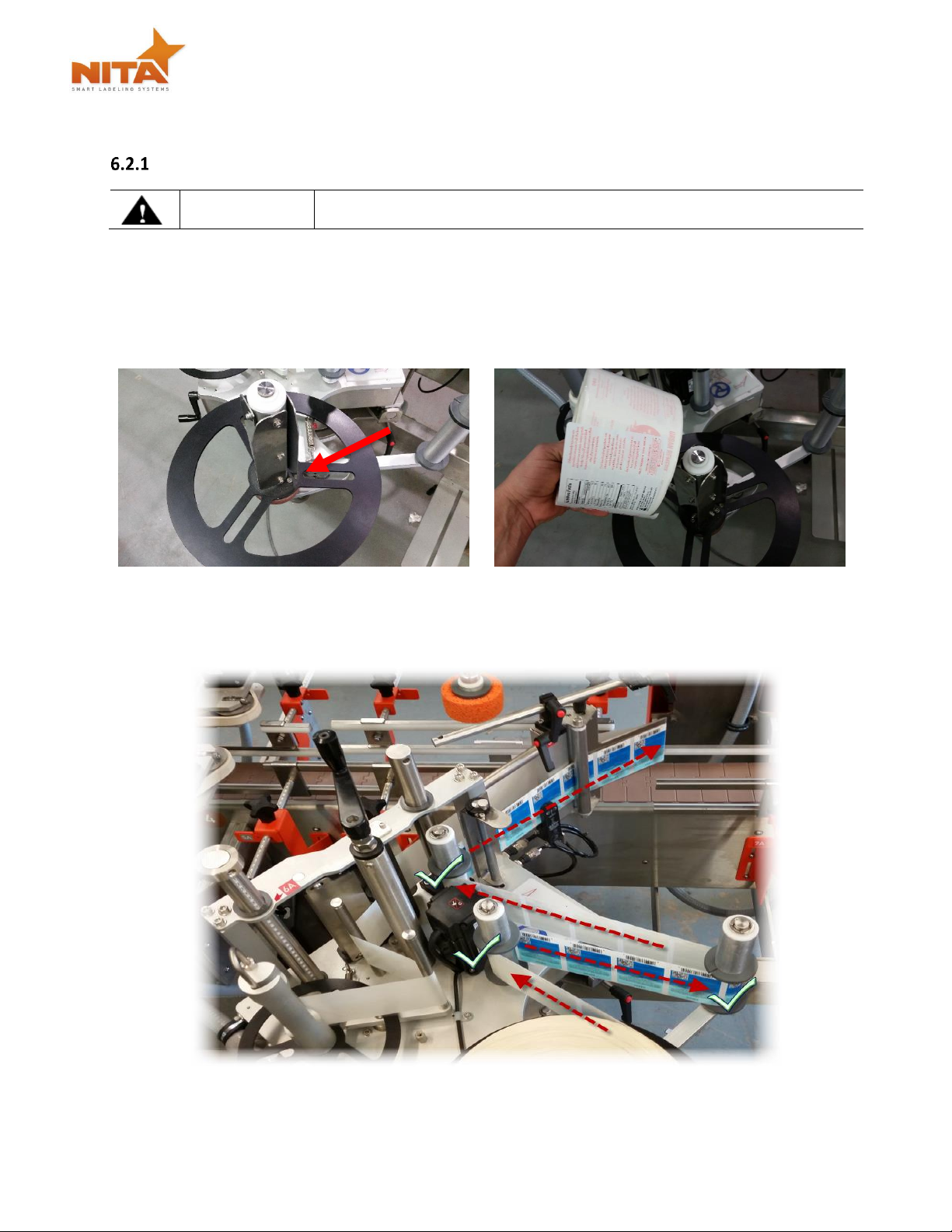

6.2Labeling Head:.............................................................................................................................................15

Loading & unloading the label stock roll .............................................................................15

Connectivity and labeler head manual feed control button ...............................................19

Setting the Label GAP sensor...............................................................................................20

Standard GAP sensor –for Opaque labels Tritronic model # LER ........................20

GAP sensor for transparent label Tritronic Model # CLS .....................................................21

GAP sensor for transparent label SICK Model # UF3............................................21

GAP Sensor calibration - Quick procedure –SICK Model UF3..............................23

GAP sensor calibration - CLEAR label - Quick procedure Di-Soric Model # KSSTI 1000

(Capacitive - Black)...............................................................................................................23

Filtering the Gap sensor trigger ...........................................................................................24

Product sensors ...................................................................................................................25

Labeling head POSITIONING adjustments and rulers..........................................................26

Vertical Up/Down adjustment..............................................................................26

Joust-Shellshock-Lance-Servo Labeling system

ii

Lateral adjustment................................................................................................27

Angle adjustments ................................................................................................28

Peel plate angle adjustments ...............................................................................29

6.3Side guide rails.............................................................................................................................................30

6.4Top retaining guides (skis)...........................................................................................................................30

6.5Shell Shock option (C-shaped application) adjustments.............................................................................31

6.6Shellshock with Servo closer 360 ................................................................................................................32

6.7Thermal Transfer coder...............................................................................................................................37

6.8Loose Loop printer: .....................................................................................................................................39

7 HMI –GETTING TO KNOW THE HMI TOUCH SCREEN –OPERATOR INTERFACE ..............................................40

7.1Start-up screen............................................................................................................................................42

7.2Main screen.................................................................................................................................................43

7.3TOP Labeler - Screen ...................................................................................................................................44

7.4Ruler values screen .....................................................................................................................................46

7.5Offset Setting for label application - Normal Mode....................................................................................47

Label flag (normal mode).....................................................................................................47

Label position on product....................................................................................................48

Product length (normal mode) ............................................................................................49

Gap sensor to peel plate (normal mode).............................................................................49

7.6Offset Setting for label application –3 Panels Mode..................................................................................49

Label flag (Tri-panel mode)..................................................................................................50

Label position on product (Tri-panel mode)........................................................................50

Product Length (Tri-panel mode).........................................................................................50

Gap sensor to peel plate (Tri-panel mode)..........................................................................50

7.7Production menu screen .............................................................................................................................51

7.8Conveyor screen..........................................................................................................................................51

7.9Recipe screen ..............................................................................................................................................52

Saving a recipe .....................................................................................................................53

Load an existing recipe: .......................................................................................................54

Erase a Recipe ......................................................................................................................55

Creating/Saving a new recipe ..............................................................................................56

Memory Stick.......................................................................................................................59

Joust-Shellshock-Lance-Servo Labeling system

iii

7.10 System configuration ........................................................................................................................61

7.11 Advanced setting screens .................................................................................................................62

CONVEYOR:.................................................................................. Erreur ! Signet non défini.

LABELER NODE 1: Corresponding to the Top Labeler.........................................................63

7.12 Alarm screen .....................................................................................................................................66

Temperature screen Alarm.................................................................................................66

Emergency screen:..............................................................................................................66

Label out: ............................................................................................................................67

8 INFORMATION..................................................................................................................................................69

9 MAINTENANCE .................................................................................................................................................70

10 TROUBLE SHOOTING –QUICK GUIDE...............................................................................................................75

11 WARRANTY .......................................................................................................................................................76

12 PARTS LIST ........................................................................................................................................................78

13 MANUFACTURER’S COORDINATES...................................................................................................................82

Joust-Shellshock-Lance-Servo Labeling system

1

1MANUAL PREFACE –Machine identification

GENERAL DESCRIPTION OF THE EQUIPMENT

Thank you for choosing NITA. We have designed and manufactured this equipment with the utmost pride and care

ensuring you the absolute best quality, maximum versatility and reliability.

The AE MKII labeling head guarantees constant precision and repeatability in a virtually maintenance-free operation.

Being built with high grade anodized aluminum and stainless steel ensures that it provides multiple long-lasting benefits

in a hostile and humid environment (please note: it is NOT considered a WASH DOWN-friendly system). Its open design,

controlled by a servo motor and drive as well as an HMI touch screen operator interface, offers great flexibility suited

to handling the most demanding labeling applications.

WHAT IS A LABELING SYSTEM?

Found in almost every sector of manufacturing, a labeling system is used to apply pressure sensitive labels onto boxes,

cartons and plastic and glass containers. A labeling system is generally a stand-alone machine and does not require the

use of a computer or label software program in order to perform its operations. It is typically built to automatically

dispense one label at a time. Using a variety of different media roll widths the NITA system can run to the maximum

dispensing speed of 1570 inches / minute and conveying speed of 130 feet/minute. Depending on the application the

system will typically receive a signal from a product sensor to allow the dispensing of a label onto a specific product.

This equipment is intended to be used only as described in this document. NITA Labeling Equipment Inc. cannot be held

responsible for the improper use or functioning of non-described functions of this machinery. Liability for any personal

injury, loss of production or revenues, or property damage occasioned by the use of this manual in effect maintenance;

operation, or repair of the equipment is in no way assumed by NITA Labeling Equipment Inc. Anyone using a procedure

not recommended by the end user should first completely satisfy himself/herself that personal safety and equipment

integrity will not be jeopardized in the method selected.

This manual will provide operating instructions, parts listing and schematics. The information contained in this manual

will help the user in his/her operations, troubleshooting and maintaining the machine in good operating conditions.

Information, illustrations and specifications contained in this manual are based on the latest product information

available at the time of this manual release. Nita Labeling Equipment Inc. reserves the right to alter and substitute

information contained herein at any time.

It is also possible that you have received a different variation of this equipment, with several different options. Some

pictures used in this manual may not totally reflect your configuration, although the labeling is completely the same.

All rights reserved

While every precaution has been taken in the preparation of this manual, Nita Labeling Equipment Inc. assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages, loss of production, or revenues

resulting from the use of the information contained herein.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 2

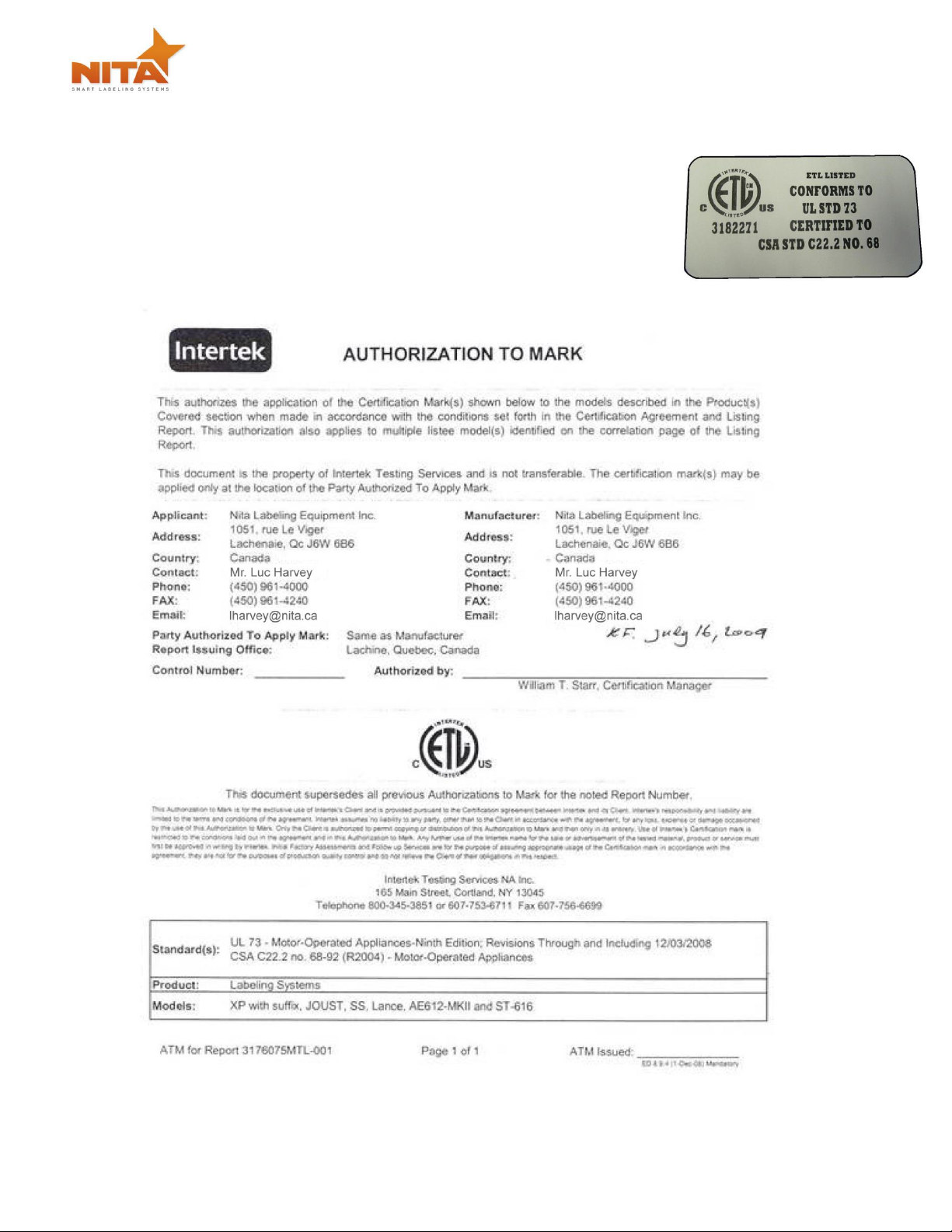

2CERTIFICATION APPROVALS

All the NITA systems mentioned in this manual conform to the following

certification ensuring quality standards.

Standard 73 from Underwriter’s Laboratory (UL) Standard C22.2 no 68 from

Canadian Standards Association, (CSA) Tests and certification have been

executed and allotted by UL and CSA mandated firm by the name of Intertek and

bare the certification markings ETL. FILE IDENTIFICATION NUMBER: 318227

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 3

3WARNINGS AND CAUTION INFORMATION

Machine use disclaimer

This equipment must NOT be used for the purposes other than for which it has been supplied to the customer

under the purchase agreement and reflected in the quotation provided to the distributor or end user prior to

purchase. Failure to use the equipment for the purpose described in this manual nullifies any warranty claim

or injury claim that could arise as a result.

Safety

Be certain that the operators and maintenance personnel read this manual before attempting to operate

perform maintenance or service to this equipment. Failure to follow these instructions could possibly result

in serious personal injury, and cause damage to the equipment, or its components. Recognize safety symbols,

words, and labels. Warning and Safety Instructions appearing in this manual are not meant to cover all

possible conditions and situations that can occur. Common sense, caution, and care must always be exercised

when installing, maintaining, servicing or operating this equipment.

The Joust / Lance / SSK are engineered to feed and apply labels on your products. In designing this device,

NITA valued personal safety; however we would like to draw your attention to the following safety

acknowledgments.

WARNING

Hazards or unsafe practices, which COULD result in severe personal injury or

death

CAUTION

Hazards or unsafe practices, which COULD result in minor injury

CAUTION

The presence of safety systems in these units does not exempt the operators

to act cautiously, avoiding behaviours that could endanger their health or the

equipment. These models are engineered to feed and apply labels on your

products. In designing this device, NITA valued personal safety; however we

would like to draw your attention to the following safety acknowledgments:

Operators should know the basic operations and setup procedures

before operating this equipment.

Safe operations should be maintained at all times.

Know the location of E-stops and power switches prior to operating

machinery such as this.

WARNING

To reduce risk of fire, electrocution or other personal injury when operating

or maintaining the Joust / Lance / SSK, follow basic safety precaution,

including the following:

This equipment must have an operator attending the machine at all

times to monitor the operations at all times. Do NOT leave this

equipment un-attended during maintenance or perform any

maintenance on the equipment unless the E-Stop condition has been

activated or power turned off.

The electrical power to this device is 240 Vac, 1 Phase, 60 HZ, and 10

Amps. While installing, make sure the electrical cord (supplied without

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 4

a connector plug) is properly configured and connected by a qualified

electrical technician.

Do not bypass any of the safety circuits or safety features designed into

this equipment.

ALWAYS turn off the power before performing any repairs.

The control box door must always be closed as well as the stainless steel

back panel cover of the label head. Do NOT remove this back cover

label when machine is under tension (plugged in).

The electrical connection must be done through the end user’s electrical

panel directly without using a quick-connect or twist lock plug.

CAUTION

To reduce risk of fire, electrocution or other personal injury when operating

or maintaining the Joust / Lance / SSK, follow basic safety precaution,

including the following:

This device is built to perform in humid conditions, but must not be

pressure washed. In case of wash down conditions, it is recommended

to cover with a plastic wrapping or Nita’s optional head cover. It is

always best to remove the system from the wash down environment

temporarily to return it afterwards. The use of compressed air and

wiping down the device is the recommended cleaning method.

This equipment is designed to function in automatic mode. Do NOT

stand, sit or allow any personnel to be within reach of tamp cylinder

activation (if so equipped).

Report any malfunctions, or problems with the equipment to qualified

maintenance personnel for repair or adjustments that may be required.

For devices equipped with a pneumatic air cylinder, you must first shut-

off the air supply to the device in order to change label roll (or perform

all set-up operations).

For systems containing conveyors, you must be vigilant with loose clothing or bodily parts as they can get

caught in the conveyor’s belt or chains as direct injury or death can incur. DO NOT use the conveyor as a

working platform or walkway.

TUCK IN ANY LOOSE CLOTHING. DO NOT WEAR TIES, PENDANTS, JEWLERY OR ANY OTHER ARTICLE OF

CLOTHING OR ACCESSORY THAT MAY GET CAUGHT ON ANY PORTION OF THE SYSTEM

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 5

4PRODUCT INTRODUCTION

4.1 Joust series

The JOUST system is a conveyor with two AE612-MKII labeling heads mounted in a top and bottom

configuration. Options can be packaged together to make the system more complete (you will see the

components described in each section of this manual). With the appropriate settings the JOUST can fulfill all

of your labeling requirements. The JOUST can accept flat cardboard, plastic, foam or clamshell containers as

well as parallel lipped shrink wrapped products. In its normal operation mode, the JOUST can apply labels on

the top or bottom in wipe-on fashion. The Joust is available with both a 5 and an 8 foot long conveyor.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 6

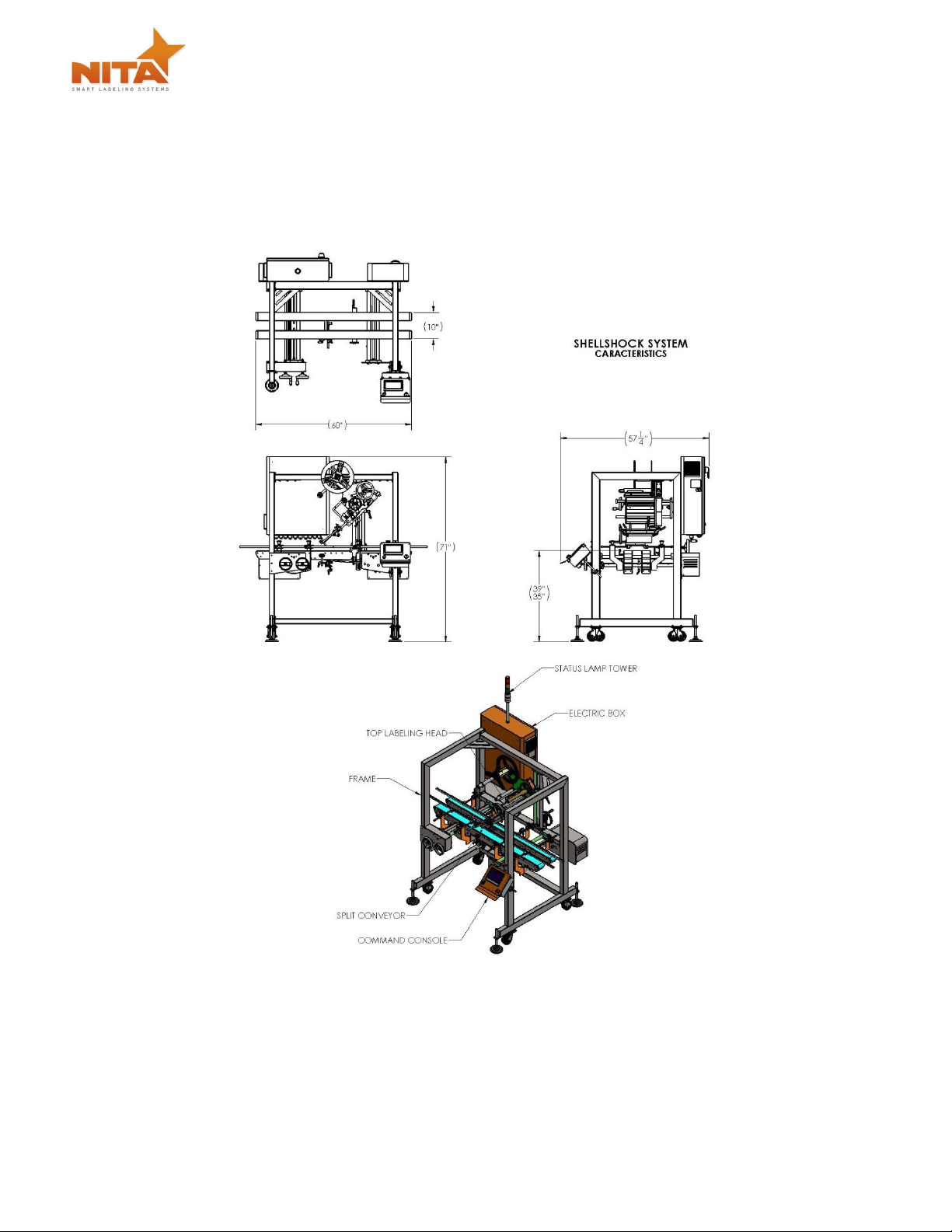

4.2 Shellshock (SSK)

The Shellshock system is a packaged system which a single head over the conveyor having a laterally split belt

configuration in order to allow the application of a label in a “c-shaped” tamper evident configuration (top,

front and under). Usually used for clamshells it is also suitable for foam trays and platters. The Shellshock is

available with a 5 foot conveyor.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 7

4.3 Joust/Shellshock (Combo)

This system is equipped with two labeling heads, one on the top and one on the bottom of the conveyor

which generally has a split belt configuration from side to side as well as on the front and back ends. These

belts are made of rubber and are used for both top and bottom labeling application as well as providing a “C-

shaped” tamper evident seal (with the top head only in tri-panel mode). The Joust / Shellshock are available

with both a 5 and an 8 foot long conveyor.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 8

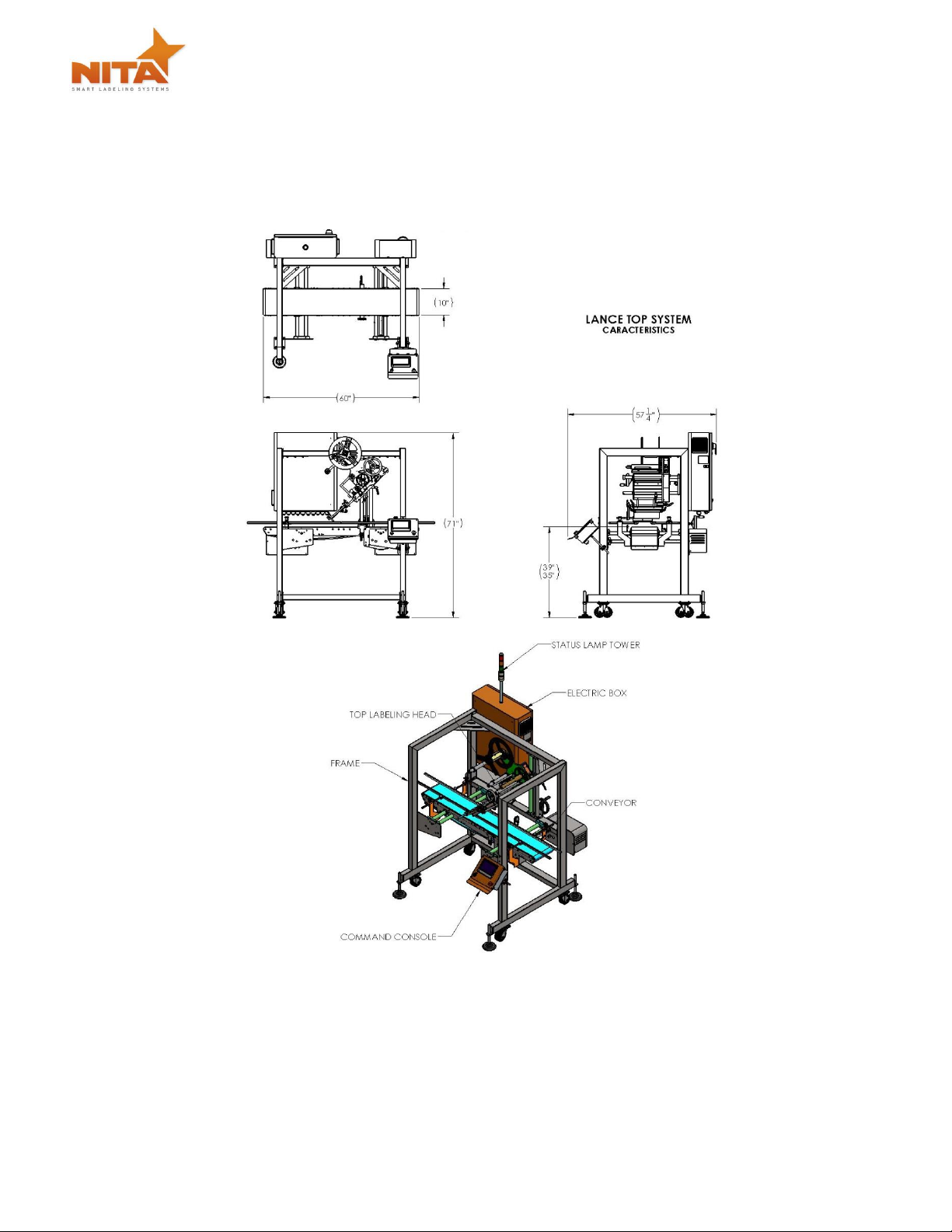

4.4 Lance top

The Lance is a system which combines an AE612-MKII labeling head with an automatic conveyor. The belt is

generally configured with a full width belt. It is built to simply place a label on the top of a package, container

or box. The Lance top is available with a 5 foot conveyor.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 9

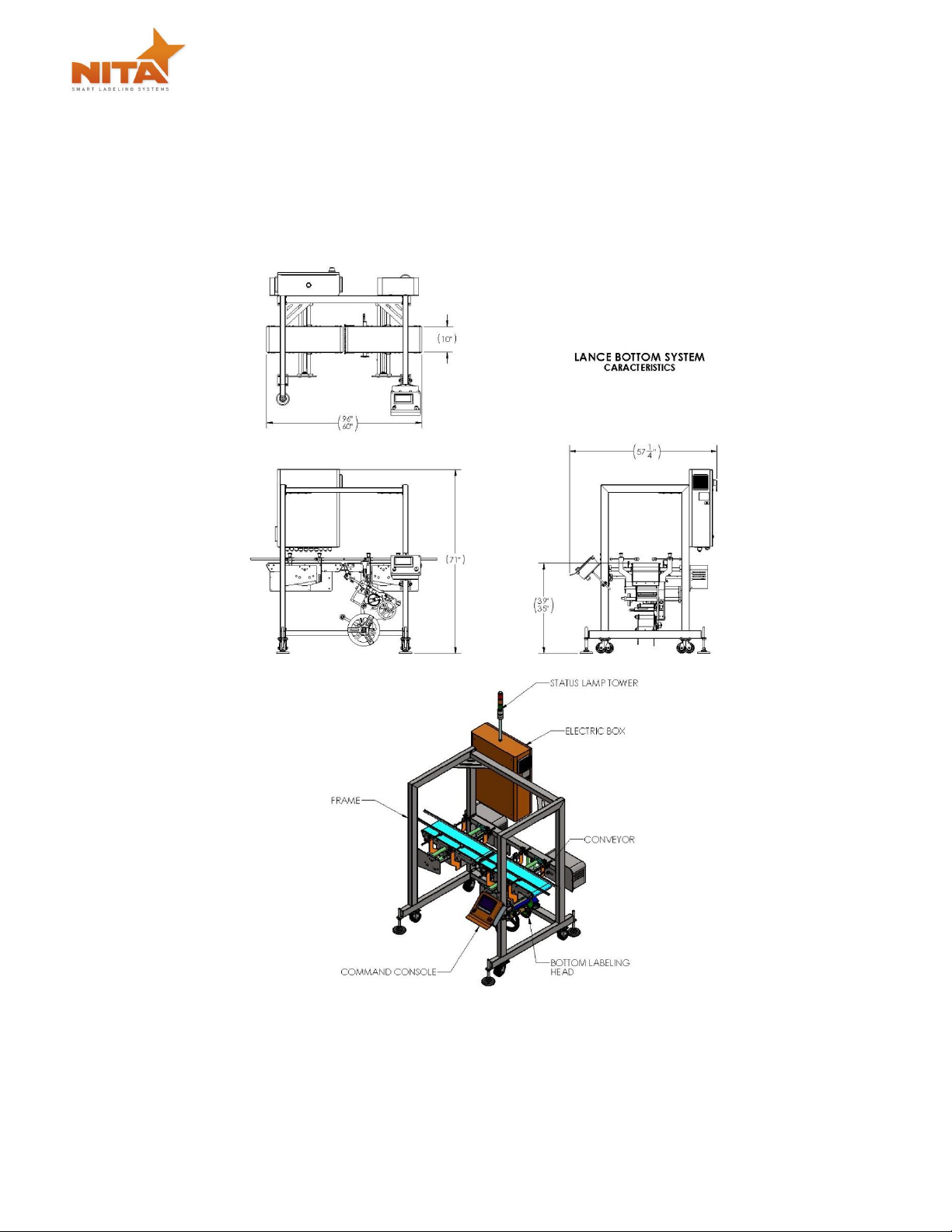

4.5 Lance bottom

The Lance is a system which combines an AE612-MKII labeling head with an automatic conveyor. The labeling

head is mounted through the bottom portion of the split belt. It is built to simply place a label on the bottom

of a package, container or box. The Lance bottom is available in 5 and 8 foot conveyor.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 10

4.6 Shellshock with servo closer 360

The Shellshock with servo closer system is a packaged system which a single head over the conveyor having

a laterally split belt configuration in order to allow the application of a label in a “band-shaped” tamper

evident configuration. Usually used for clamshells it is also suitable for foam trays and platters. The Shellshock

with servo closer is available with a 5 foot conveyor.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 11

4.7 This equipment is an assembly of 3 major components

Conveyor

1 or 2 Wipe-On AE612-MKII Servo driven label applicators

HMI touch screen control panel and electrical cabinet

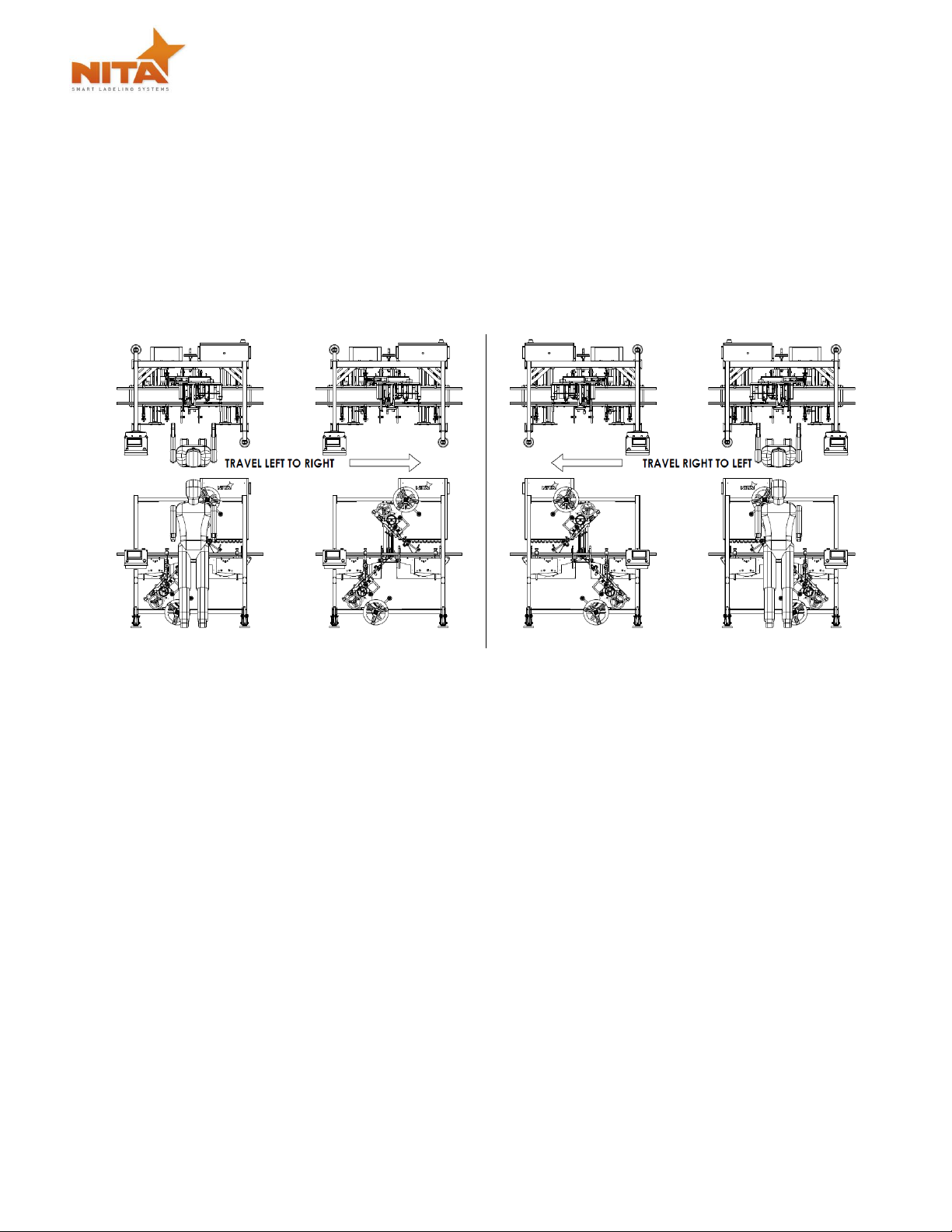

4.8 Direction of travel

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 12

5SHIPMENT RECEPTION (uncrating)

For shipping purposes, a half crate is used. This avoids any damage to the device as well as protects the

adjustment settings allowing for a very stable product once installed in its final destination.

The crate is generally pop-nailed together and can be taken apart by using a simple hammer or a nail crowbar.

Proceed in removing the side wood panels from the crate and work your way inward.

WARNING

Always be vigilant while using any tools as they can result in bodily injury.

The Joust / Lance / SSK was carefully packaged and protected prior to transportation. On reception of the

machine, a complete visual inspection should be done in order to detect any apparent damage before

proceeding with the equipment power up.

If any anomaly is detected, verify if the packaging/crating shows apparent damage. If it is the case, please

contact the transporter right away (it is always a good idea to take pictures of the damages).

After the visual inspection is done, proceed with the un-packaging of the Joust / Lance / SSK. The Joust /

Lance / SSK should be installed on a level floor with 200 - 240Vac, 1 phase, 60 Hz, 10 amps and compressed

air 80 PSI available in proximity.

Ensure the Joust / Lance / SSK is perfectly level to the ground. If necessary, the level of the Joust / Lance / SSK

can be adjusted with the adjustable legs located at the extremities of the frame.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 13

Once the Joust / Lance / SSK system is perfectly levelled, you can connect the power (200 - 240 vac, 1 phase)

and the compressed air (80 PSI).

To turn power ON or OFF, simply turn the main handle power switch on the electrical panel.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 14

6SYSTEM SETUP

This equipment can accommodate many variations of containers on the market. There are adjustable

components on this machine that allows the operator to effectively make changeovers. The proper

adjustments are described in the following pages.

6.1 MAIN CONTROL PANEL with HMI Touch Screen

The main control panel is a HMI (touch screen) controller and appears such as the picture below shown below.

The HMI panel allows the user to switch between manually and automatically controlling the speeds and all

peripheral functions of the equipment.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 15

6.2 Labeling Head:

Loading & unloading the label stock roll

CAUTION

To avoid injuries, you must keep the unit in MANUAL mode!

Look carefully at the diagram and follow the threading procedures indicated below.

You will also find the threading diagram directly on the Label applicator head as well as a quick reference

1) Place the label stock roll on the label support cylinder. Make sure that the stock roll is well secured

2) Pull approximately 36 inches of stock from label stock roll.

3) Follow the webbing diagram as shown in this manual or on the ID plate of the device itself.

Joust-Shellshock-Lance-Servo Labeling system

Operator and parts manual –2015 16

4) For different label widths, slide the guides on the rollers to avoid label swirling. Do not move the

guides closest to the main plate, these are the zero point.

5) Release the spring-loaded tension plate by gently pulling the lock.

This manual suits for next models

2

Table of contents