CONTENTS

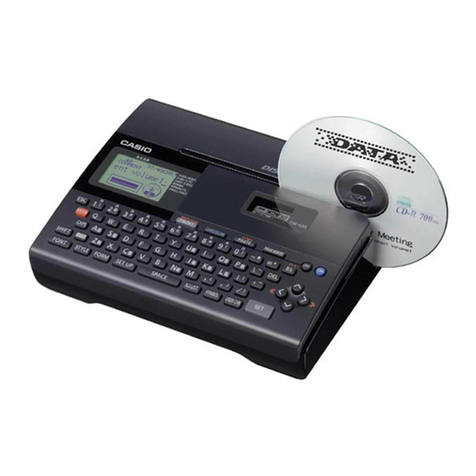

1. SPECIFICATIONS ..................................................................................................................... 1

2. CLEANING THE PRINTER........................................................................................................1

3. BLOCK DIAGRAM .................................................................................................................... 2

4. SCHEMATIC DIAGRAMS

4-1. Wiring Diagram.................................................................................................................. 3

4-2. Main PCB Z568-1 (1/2).......................................................................................................4

4-3. Main PCB Z568-1 (2/2).......................................................................................................5

4-4. Power PCB Z568-S1 ..........................................................................................................6

4-5. Sensor PCB Z568-2 ...........................................................................................................7

4-6. Cam sensor PCB Z568-S2 ................................................................................................8

4-7. Paper, Ribbon & Jam sensor PCB Z568-S3 ....................................................................8

4-8. Key Matrix Z568-E4 ...........................................................................................................8

5. CIRCUIT EXPLANATION

5-1. LSI PIN FUNCTION ............................................................................................................9

5-2. CIRCUIT EXPLANATION ................................................................................................. 11

6. SETTING THE THERMAL HEAD ............................................................................................12

7. SENSOR POSITION, PRINTING SPECIFICATION & OPERATION CHECK ........................ 14

7-1. SENSOR POSITION ......................................................................................................... 15

7-2. PRINTING SPECIFICATION.............................................................................................15

7-3. OPERATION CHECK .......................................................................................................17

8. TROUBLE SHOOTING............................................................................................................ 21

9. DISASSEMBLY........................................................................................................................ 25

10. PARTS LIST

10-1. Z568-1 ASS'Y, COMPONENTS & OTHERS...................................................................27

10-2. PRINTER UNIT ............................................................................................................... 31

10-3. CHASSIS UNIT............................................................................................................... 34

10-4. CHASSIS ASS'Y............................................................................................................. 37

10-5. HEAD HOLDER ASS'Y ..................................................................................................40

10-6. PLATEN ASS'Y .............................................................................................................. 43

10-7. CASSETTE CASE ASS'Y...............................................................................................45

10-8. MOTOR CHASSIS ASS'Y ..............................................................................................47

11. EXPLODED VIEW & DISASSEMBLY VIEW

11-1. EXPLODED VIEW (Z568-1 ASS'Y & COMPONENTS) ................................................. 30

11-2. DISASSEMBLY VIEW (PRINTER UNIT) ........................................................................32

11-3. DISASSEMBLY VIEW (CHASSIS UNIT)........................................................................35

11-4. DISASSEMBLY VIEW (CHASSIS ASS'Y)......................................................................38

11-5. DISASSEMBLY VIEW (HEAD HOLDER ASS'Y)............................................................41

11-6. DISASSEMBLY VIEW (PLATEN ASS'Y)........................................................................44

11-7. DISASSEMBLY VIEW (CASSETTE CASE ASS'Y)........................................................46

11-8. DISASSEMBLY VIEW (MOTOR CHASSIS ASS'Y)........................................................48