NITTOH Power UP-35DX-IN User manual

ELECTRIC/HYDRAULIC PUMPS

UP-35DX-IN(L)

Operation and maintenance manual

NITTOH ZOHKI CO.,LTD.

102,4-10,2-Chome,Kamezawa,Sumida-ku,

Tokyo 130,Japan

Telephone.03-3625-6551

Facsimile. 03-3625-6553

1

INDEX

page

1

Safety information------------------------

2

2

Description of components-------------

4

3

Instructions before use------------------

4

4

Operation-----------------------------------

5

5

Maintenance-------------------------------

5

6

How to remove the cover---------------

9

7

Circuits--------------------------------------

10

8

Construction drawings-------------------

11

9

Parts lists-----------------------------------

12

10

Trouble shooting guide------------------

13

11

Warranty------------------------------------

14

2

1Safety Information

Three types of symbols are used in this instruction manual to ensure correct use of the

product and to prevent harm to you or others or damage to property. The symbols and their

meanings are as follows. Please read the text after understanding the contents carefully.

NITTOH ZOHKI is not responsible for any damage or injury resulting from unsafe use of the

product, lack of maintenance, or improper application of the system.

Cautions remarks used in this manual are classified as follows;

⚠DANGER

If this symbol is ignored and the product is handled improperly,

there is a high probability that the user will be killed or seriously

injured.

⚠WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury to the user.

⚠CAUTION

Indicates a potentially hazardous situation which, if not avoided,

could result in injury to the user or property damage.

Cautions when installed

⚠WARNING

■Install the unit stably.

Since this pump uses a sealed tank, it can be used in all directions (diagonal, upside down,

vertical, horizontal), but please do not place it on an unstable surface. However, do not place

it on an unstable surface, as it may fall and cause injury. When installing the product at an

angle, make sure to fix it firmly.

■Prepare the work environment.

Remove any objects (high temperature, fire, movable objects, sharp objects, corrosive

objects, etc.) around the work area where the pump is used that may cause injury or harm

to the user.

⚠CAUTION

■Avoid rain and moisture, and use the product in a place with as little dust as possible.

■Avoid direct sunlight in summer. The temperature of the hydraulic fluid may rise, causing

problems with processing and equipment.

■For outdoor use in extremely cold weather, replace with hydraulic fluid of the proper

viscosity. The viscosity of hydraulic fluid increases as the temperature of the fluid drops,

which may cause problems with processing and equipment.

3

Precautions for use

⚠WARNING

■Take safety measures.

Use protective equipment, work clothes, safety glasses, etc. to protect yourself when

operating hydraulic equipment.

■Pay attention to the allowable pressure of the hydraulic circuit.

Always work to ensure that the maximum permissible working pressure of the pump is

less than the permissible pressure of other hydraulic equipment connected to it and less

than the permissible load.

■Be careful of electric shock.

Do not pull out the power plug with wet hands. Always use the grounding clip on the power

plug to ground the unit when in use. Do not use this product near an electric welding

machine or on grounded materials or equipment.

⚠CAUTION

■The power supply is AC200-230V 50/60Hz single phase.

Use of the wrong voltage may cause burnout or heat generation.

Use of the product at a low voltage may result in burning or overheating. Be careful of

voltage drops, especially when using a generator.

■When unplugging the power plug from the outlet, be sure to grab the power plug and pull

it out. Pulling the cord and unplugging it from the outlet may cause disconnection or short

circuit.

■When using auxiliary cords, please use 1.25 ㎟or more thick cords so that the voltage will

not drop, and the length should be within 10m.

Specifications

Model,No

Electric motor

Hydraulic pump

Reservoir

Weight

UP-35DX

-IN (L)

Commutator

and open type,

0.35KW

200-230V

50/60Hz

single phase,

“E”insulation,

2000rpm

Max,

Work pressure

MPa

Flow Rate

L/min(50Hz)

Capacity

1.0L

(2.0L)

Usable

0.8L

(1.6L)

1L

10.5Kg

2L

(12Kg)

1st stage

2nd

stage

1st stage

2nd

stage

1

70

2.5

0.3

4

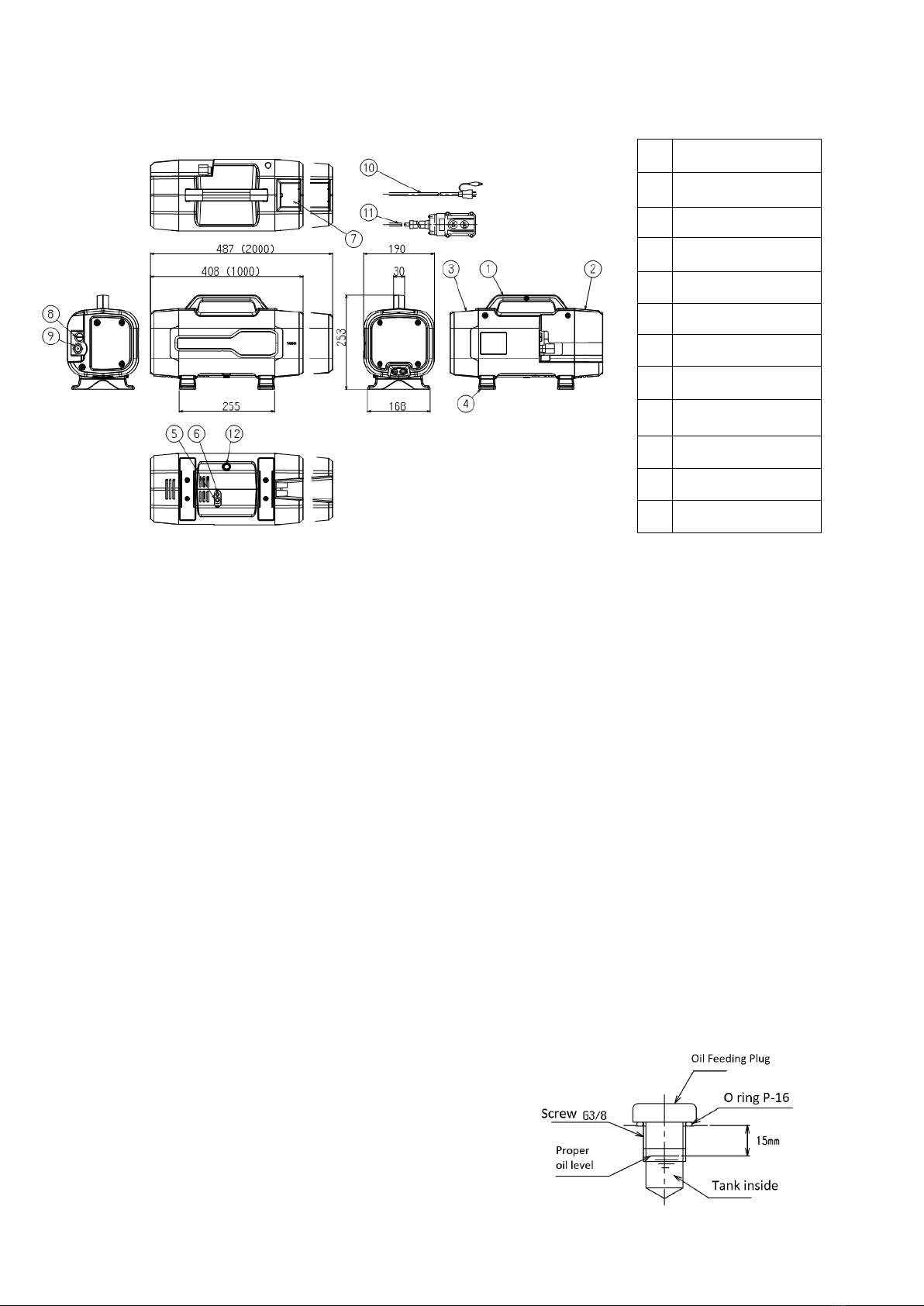

2 Description of components

3Instructions before use

3-1 Please make sure that there is no damage or oil leakage during transportation.

3-2 ⚠CAUTION Oil feeding plug

The tank (using a rubber tank) is a sealed type, so please use a sealed fueling plug. Also, be

sure to use a coupler with a check valve.

3-3 ⚠WARNING Check the power supply

The power supply is AC200-230V (50/60Hz) single phase. Be sure to ground the unit when

using it.

3-4 ⚠WARNING Check the hydraulic oil

To check the oil level, use the following method.

Always check the amount of oil in the pump with the cylinder of the connected equipment

fully returned before operation, and always use the correct amount. If oil is supplied when

the cylinder lot of the connected equipment is out, there will be no place for the oil in the

cylinder to return, and the oil will overflow, or high pressure will be generated in the tank,

which is dangerous.

(1) Turn the cylinders of the connected devices back on completely.

(2) Unplug the power supply.

(3) Stand the pump upright with the oil tank side

down.

(4) Turn the oil feeding plug with a flat-blade

screwdriver in the semi-clockwise direction to remove

it.

(5) Check the amount of oil from the removed oil

supply port.

1

Pump body

2

Back Cover

3

Tank Cover

4

Pump Feet

5

Relief Valve

6

Air Relief Valve

7

Storage Box

8

Oil Feeding Plug

9

Discharge Port

10

Power Cord

11

Operation Cord

12

Fuse

5

(6) If the oil fills up to the step in the oil supply cap, it is normal. (For the type of hydraulic

fluid to be used, refer to the section 5-1) Hydraulic fluid.)

(7) Turn the oil supply plug clockwise to tighten it. Be careful not to damage the O-ring.

4Operation

“UP-35DX-IN(L)”with 2-way normally closed solenoid valve, pressure holding and

inching type.

1. When you press the ON button on the two-point control switch, the motor turns and

oil is sent through the hose to the cylinder. When you release the switch button, the

motor stops, the oil stops flowing, and the cylinder stops.

2. When you press the OFF button on the two-point control switch, the solenoid valve is

activated and the oil in the cylinder returns to the tank. (The cylinder returns only

when the OFF control switch is pressed, and stops returning when the switch is

released. (An intermediate stop of return is possible.)

5Maintenance

5-1 Hydraulic oil

①Type of oil

As a general rule, use genuine oil NHO-32 (1 liter ). For urgent use, use high quality

hydraulic oil (equivalent to ISO standard #32 viscosity : 32 cSt @40℃).

②Oil temperature

The proper operating temperature for hydraulic fluid is 55℃or less. Stop working until

the temperature drops to the proper level.

③Oil change

⚠CAUTION

Since hydraulic fluid deteriorates, replace the entire amount periodically. The oil should

be replaced after 300 hours of operation or 3 months. To replace the oil, remove the oil

plug, turn the pump at an angle to remove the oil, and fill the pump to the top of the oil

plug, taking care not to let any impurities such as dust enter. The following are the

three points to keep in mind when replacing.

*Make sure that the cylinder is completely back in place.

*Never add different kinds of oil, even if it is only a small amount.

*When refilling the oil, be careful not to mix in any foreign matter.

④Other

⚠WARNING

If oil gets into your eyes, rinse thoroughly with clean water. Rinse thoroughly with

clean water and seek medical attention immediately. If oil gets into wounds or other

skin areas, rinse with soapy water, stop bleeding, and seek medical attention

immediately.

6

5-2 Pressure and piping

①Composition of hydraulic equipment system ⚠WARNING

When combining pumps, high-pressure hoses, cylinders, couplers, valves, etc. to form a

hydraulic system, make sure that the maximum working pressure of each device is the same.

If a pump with a lower maximum working pressure is used, the maximum working pressure

of the system should be adjusted to the lowest one.

②Pressure gauges

Install a pressure gauge to check the pressure at all times, or make it readily available.

③Piping ⚠CAUTION

Wrap sealing tape around the tapered pipe screw when connecting it to the hose piping or

to various valves and couplers. Refer to the taper screw tightening torque table below and

be careful not to over-tighten.

NPT,PT sizes

Tightening torque N-m(kgf-m)

1/8”

13-14 (1.3-1.4)

1/4”

30-40 (3.0-4.0)

3/8”

60-70 (6.0-7.0)

1/2”

100-110 (10.0-11.0)

Do not allow any scraps of sealing tape to enter the hydraulic equipment. Failure to do so

may result in damage.

5-3 High pressure hoses

①Hose installation ⚠WARNING

The high pressure hose will expand and contract slightly when pressurized, so allow

some room for expansion. Also, be careful not to rub against other hard objects.

Do not clamp the high pressure hose. The high pressure hose will stiffen and move to

straighten when pressure is applied. Clamping the hose, especially at the bent part,

may cause damage due to excessive force during pressurization. If the high-pressure

hose is not handled properly, its life will be extremely short. In particular, it is

susceptible to fire (high temperature), extreme bending, and twisting, so do not use it in

high temperature environments, below the minimum bending radius, or while twisted.

②Hose handling ⚠DANGER

Never drop objects into the high pressure hose. The impact of falling objects may cause

the high pressure hose to burst, resulting in a serious accident.

Do not pull the high pressure hose with strong force. Dragging or carrying the pump,

cylinder, etc. with the high pressure hose may cause damage to the high pressure hose,

resulting in a serious accident.

7

5-4 Coupler

①Connection

Before connecting the coupler, make sure that there is no dust, sand, etc. attached to

the connection part of the coupler. After connecting, pull the high-pressure hose to

confirm the connection.

②Handling ⚠WARNING

Do not pressurize the product with the coupler attached to the end of the

high-pressure hose without installing the cylinder. If the coupler is damaged, a

serious accident may result. If it is necessary to remove the coupler to check the

operation and pressurize, avoid working in a direction where the coupler may pop out.

Do not connect or disconnect the coupler while it is pressurized.

5-5 Air inclusion ⚠CAUTION

The UP-35DX series has a sealed structure with a rubber tank inside the tank cover.

When the tank is full of oil, there is no air ingress, but when a hose, cylinder, or other

pressure equipment is connected, the air in the hose, cylinder, or other equipment may

enter the pump. If air is mixed in the pump, the pressure will not rise, oil will not be

discharged, and other problems will occur. In this case, follow the procedure below to

restore the pump.

①Is the oil filled to the fullest level ?

Turn the pump upright (tank cover side down), open the oil supply valve, check the

amount of oil, and refill the tank to the full level. (For precautions, refer to "5-1) Replacing

the hydraulic fluid (3)".

②If the pump does not discharge or the pressure does not rise even after refilling with oil,

press the operation switch and the return switch about 10 to 11 times repeatedly with the

pump in the upright position.

③If the discharge or pressure still does not increase, loosen the air release valve (No. 5 on

page 3) at the bottom of the pump by about two turns, and press the operation switch and

the return switch repeatedly about 10 to 11 times. After that, tighten the air release valve

and operate the pump for confirmation.

④When the pump operates normally, be sure to refill the tank with oil to the full capacity.

This is because air in the hoses, cylinders, and other hydraulic equipment is in the tank of

the pump.

◎How does air accumulate in the pump (rubber tank) when hydraulic equipment is

connected together? Always make sure that the oil tank is full before use.

8

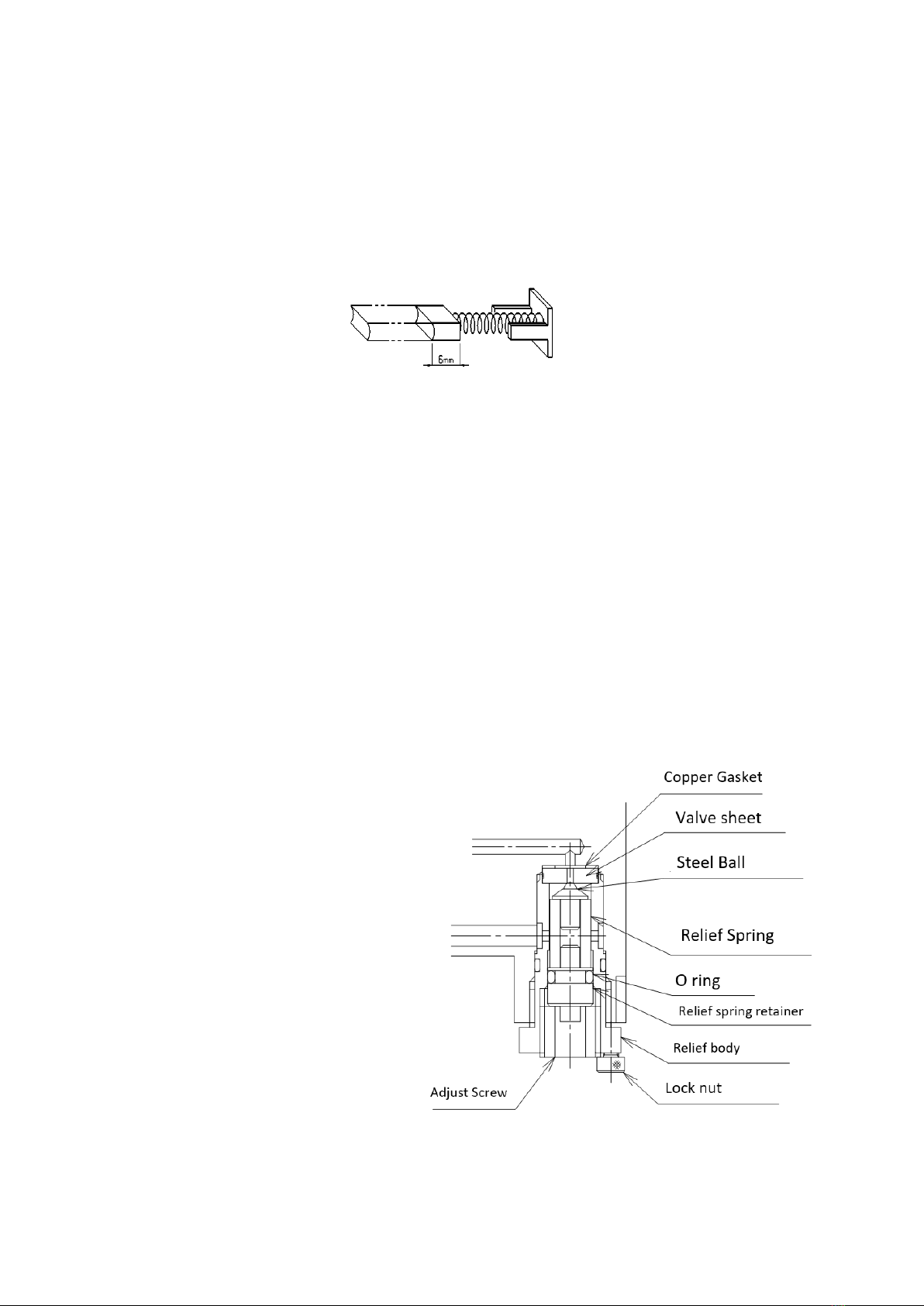

5-6 Carbon brushes

①Cautions for use ⚠WARNING

Always pay attention to the wear of the carbon brushes. When the carbon brush is worn

down to 6mm or when the motor has been running for more than 150 hours, replace it with a

new one. If worn brushes are used as they are, rectifying sparks will increase and cause

failure. The material of the carbon brush has a great influence on the performance and life of

the motor, so be sure to use a genuine carbon brush when replacing it.

①How to change

First, turn off the power; remove the two rubber caps, then loosen and remove the mounting

screws inside with a screwdriver to remove the carbon brush. Replace the brush with a new

one and fix the screws and rubber cap.

5-7 Relief valve adjustment

①Range of standard pressure adjustment available is form 58.8 to 68.6MPa. Loosen lock

screw on the high-pressure relief valve and turn the adjusting screw a few turns

counter-clockwise to decrease pressure setting to a lower desired pressure. Clockwise

rotation of the adjusting screw will increase pressure. After setting pressure, replace the

lock screw.

Different kind of a spring is needed to adjust and set at lower pressure than the standard.

Consult NITTOH authorized distributor.

Loosen the relief valve lock nut

(hexagon 2.5mm) and turn the adjust

screw (hexagon 6mm) to adjust the

pressure to the set value. Turning

the adjustment screw to the right

will increase the pressure, and

turning it to the left will decrease the

pressure.

However, the standard product can

be adjusted in the pressure range of

58.8 to 68.6 Mpa (600 to 700 kg/cm2).

If you want to use it at a pressure

lower than that, you will need to

replace the spring, so please contact

us.

Check the operation and tighten the

lock bolt. The pressure may change when the lock bolt is tightened, so please check the

set pressure again.

9

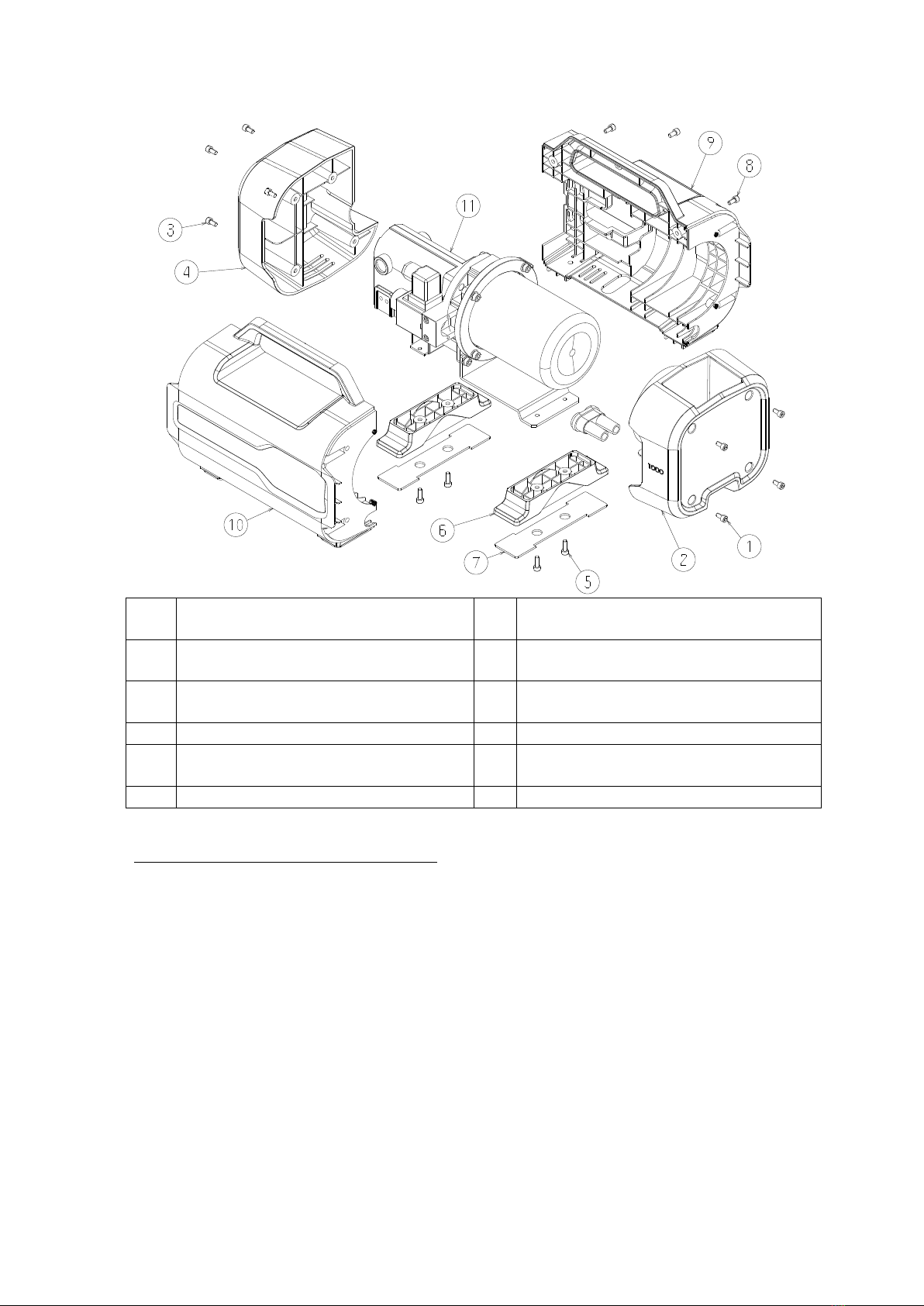

5-7 How to remove the cover

①

Fitting bolt M5×10 Hexagon socket

head screw

⑦

Rubber sheet

②

Tank Cover

⑧

Fitting bolt M5×10 Hexagon socket

head screw

③

Fitting bolt M5×10 Hexagon socket

head screw

⑨

Side cover 1

④

Back Cover

⑩

Side Cover 2

⑤

Fitting bolt M5×15 Hexagon socket

head screw

⑪

Pump body

⑥

Pump Feet

Disassembly procedure of the cover

The cover cannot be removed if the hose etc. are connected to the outlet.

1. Remove the 4 fitting bolts ①and ③, and then remove ②tank cover , and ④back

cover.

2. Lay the pump down so that ⑨the side cover 1 is on top.

3. Remove ⑤the fitting bolts, and remove ⑥the two pump feet. ⑦Rubber sheet

is glued.

4. Remove ⑧the 3 mounting bolts.

5. Lift up and remove ⑨the side cover 1.

6. Lift up and remove ⑪the pump body.

Note that there are some wires connected to the pump.

For installation, reverse the above procedure, paying attention to the pump alignment

and wiring.

10

6Circuits

Hydraulic Circuit

Electrical diagram

How to change the carbon brush

Relief valve & Air relief valve

1. Remove the back cover.

2. Remove the carbon

brush mounting screw

with a screwdriver.

3.Pull out the carbon

brush and insert a new

carbon brush.

4. Use the screw threads to

set it so that it is stuck in

the back.

5. Screw in the carbon brush mounting screw. If there is any

uncomfortable feeling when screwing in, do not screw it in but

remove it again. There is a possibility that the metal part of the

carbon brush will be deformed.

Lock screw

Relief Valve

Air Relief Valve

11

7 Construction drawings

12

8 Parts list

No.

Part No.

Description

Driving section

1-1

Base plate

1-2

AC0598A00

Oil seal

1-3

TLA1512Z

Bearing

1-4

Eccentric collar

1-5

RNAF273013

Bearing

1-6

φ4×28

Spring Pin

1-7

NTB1528

Thrust bearing

1-8

AS1528

Thrust Washer

1-9

Shaft

1-10

Second gear

1-11

Key

1-12

G-15

G ring

1-13

AS1528

Motor

1-14

M6×20CAP

Fitting bolt 1

1-15

PCB M6×15

Fitting bolt 2

1-16

M6

Washer

1-17

PT1/16

Plug

1-18

φ6

Steel ball

1-19

M8×6

Hollow set

1-20

MB700-050

Expander

1-21

MB700-040

Expander

Pump section

2-1

High pressure piston

2-2

Piston spring

2-3

Low pressure piston

2-4

Piston spring

2-5

Cupper packing

2-6

High pressure plug

2-7

Pushing screw

2-8

High pressure suction spring

2-9

φ6

Steel ball

2-10

Valve sheet

2-11

Pushing valve sheet

2-12

MSW12

Pushing screw

2-13

Valve sheet

2-14

φ5

Steel ball

2-15

WF5-10

High pressure check spring

2-16

Check retainer

2-17

P-7

O ring

2-18

P-7 bias

Back up ring

2-19

Low pressure suction holder

2-20

WF5-10

Low pressure suction spring

2-21

φ5

Steel ball

2-22

Valve sheet

2-23

Cupper packing

2-24

Suction retainer

2-25

MSW12-6

Pushing screw

2-26

MSWA20

Pushing screw

2-27

WF5-10

Low pressure check spring

2-28

φ5

Steel ball

2-29

Cupper packing

2-30

Retainer F

2-31

MSWAS12-6

Pushing screw

2-32

Low pressure suction filter

2-33

High pressure suction filter

Returning section

3-1

NW-22B

Solenoid

3-2

Base block

3-3

M5×45

Fitting bolt

3-4

M5

Spring washer

3-5

Push pin

3-6

φ3×8

Spring pin

3-7

Lever

3-8

MS3-25

Straight Pin

3-9

Lever support

3-10

M4×10 CAP

Fitting bolt

3-11

M4

Spring washer

3-12

Poppet

3-13

Sleeve

3-14

P-8

O ring

3-15

P-8 bias

Back up ring

3-16

P-5

O ring

3-17

P-5 bias

Back up ring

3-18

WH8-20

Spring

3-19

Valve sheet

3-20

P-9

O ring

3-21

P-9 bias

Back up ring

3-22

Valve sheet pushing screw

3-23

M4

Washer

3-24

M4.5×P0.75

Hexagon nut

3-25

M4

Tooth lock washer

3-26

-

-

3-27

-

-

3-28

-

-

3-29

Push pin holder

3-30

φ3×15.8

Push pin

3-31

Push pin spacer

3-32

P-3

O ring

3-33

P-3 endless

Back up ring

3-34

Stopper pin

3-35

WB6-10

Spring

3-36

MB700-040

Expander

3-37

P-5

O ring

3-38

M5×30

Fitting bolt

3-39

M5

Spring washer

Relief valve section

4-1

Cupper packing

4-2

Valve sheet

4-3

High pressure relief

4-4

S-12

O ring

4-5

φ2.5

Steel ball

4-6

Relief ball receiver

4-7

High pressure spring

4-8

Spring pushing

4-9

P-6

O ring

4-10

MSWA12

Pushing screw

13

4-11

M3×6

Lock screw

4-12

φ6

Steel ball

4-13

Ball pushing

4-14

P-4

O ring

Tank section

5-1

Rubber tank 1L

5-2

Fixed tank ring

5-3

M6×20

Fitting bolt

5-4

M6

Spring washer

5-5

Oil feeding plug

5-6

P-16

O ring

5-7

Discharge nipple

5-8

TSC-14

Coin filter

5-9

O-14

Snap ring

5-10

Pump stay tank side

5-11

M6×10

Fitting bolt

5-12

Pump stay motor side

5-13

M4×10

Firring bolt

9 Trouble shooting guide

⚠WARNING To avoid injury, repairs and troubleshooting should be performed

by qualified personnel familiar with this type of equipment. Use appropriate gauges and

equipment.

Problems

Possible Causes

Remedies

Motor does not run

⚠WARNING

Disconnect power

supply before

disassembly or repair.

(1) No supply voltage.

(2) Broken lead wire or defective

power cord plug.

(3) Defective switches.

(4) Worn carbon brushes.

(5) Defective motor.

(6) Defective remote switch.

(7) Unit is not plugged in.

(1)Check line voltage.

(2)Replace defective part.

(3)Check switches.

(4)Replace carbon brushes.

(5)Repair or replace motor.

(6)Repair or replace switch.

(7)Plug in unit.

Abnormal noise of

motor.

(1)Damage or pump or motor.

(2)Damage of ball bearings, etc.

(1) Repair or replace unit.

(2) Replace ball bearings.

Motor runs, but

cylinders do not

advance or retract.

(1)Damage of release valve.

(2)Oil level is too low.

(3)Air in system.

(4)Filter plugged or dirt in pump.

(5)Damage of pump body.

(6)Damage or out of adjustment

of relief valve.

(1) Repair or replace it.

(2) Fill reservoir to 1/2 of level

gauge with all cylinders

retracted.

(3) Bleed the system.

(4) Pump filter should be

cleaned and if necessary,

pump should be dismantled

and cleaned.

(5) Repair pump.

(6) Repair or readjust as needed.

Cylinders works, but

full pressure is not

built up.

(1) Damage of release valve.

(2) Air in system.

(3) Damage of pump body.

(4) Lowering of set pressure or

damage of relief valve.

(1)Repair or replace.

(2)Bleed the system.

(3)Repair pump.

(4)Readjustment of set pressure

or repair of relief valve.

Cylinders works, but

their speed too slow,

partially or erratically.

(1) Damage of release valve.

(2) Air in system.

(3) Unacceptable rise in oil

temperature.

(4) Damage of pump body.

(1)Repair or replace.

(2)Bleed the system.

(3)Stop operation or install oil

cooler. (max. 55℃)

(4)Repair pump.

Cylinders do not

retract.

(1) Damage of release valve.

(2) Damage of return springs of

cylinders or quick couplers.

(1) Repair or replace.

(2) Repair or replace springs or

couplers.

Oil leaks.

Damage seals, seats or steel

balls.

Replace them.

Short circuit.

(1)Damage cords.

(2)Bad insulation of electric

parts.

(1)Replace.

(2)Replace.

14

10 Warranty

10-1) Warranty period

For general defects and failures, 365 days from the last day of the month of

manufacture.

Example: If the pump was purchased on January 1, 2019, the warranty period will be

until January 31, 2020.

10-2) Warranty conditions

NITTOH products and components are warranted against damage to products and

components due to defects in materials and workmanship, with the following exceptions

This warranty provides for the repair and replacement of the product or component

parts at no charge. In the event of a malfunction within the warranty period, please

present this warranty card and contact your dealer or nearest Nittoh sales office.

10-3 Exceptions to the Warranty

Warranty claims will not be accepted for damage or malfunction caused by the following

reasons

Misuse or improper use, fair wear and tear, incorrect or careless operation, improper

storage, chemical or electrical effects, climatic or other effects that cannot be

specifically linked to manufacturing defects

We are not responsible for packing, springs, etc. and the following items.

Modification or processing of the product carried out by the purchaser without prior

notice or consent to us.

Harsh and very frequent use of the product deviating from its specifications.

Damage caused by incorrect installation or assembly by the purchaser or a third party.

Failure due to natural disasters.

Damage caused by fire, submersion, dropping, or other accidents.

This manual suits for next models

1

Table of contents

Other NITTOH Power Water Pump manuals

Popular Water Pump manuals by other brands

Blue-White

Blue-White Chem-Feed C-1100A operating manual

Ceco

Ceco Sethco 2500 Series Operation manual

MRC

MRC PP-D-720 Operation manual

ProMinent

ProMinent DULCO flex Control Original operating instructions

SPERONI

SPERONI HDM Series Operating instruction

Clarke

Clarke DWP400A Operation & maintenance instructions