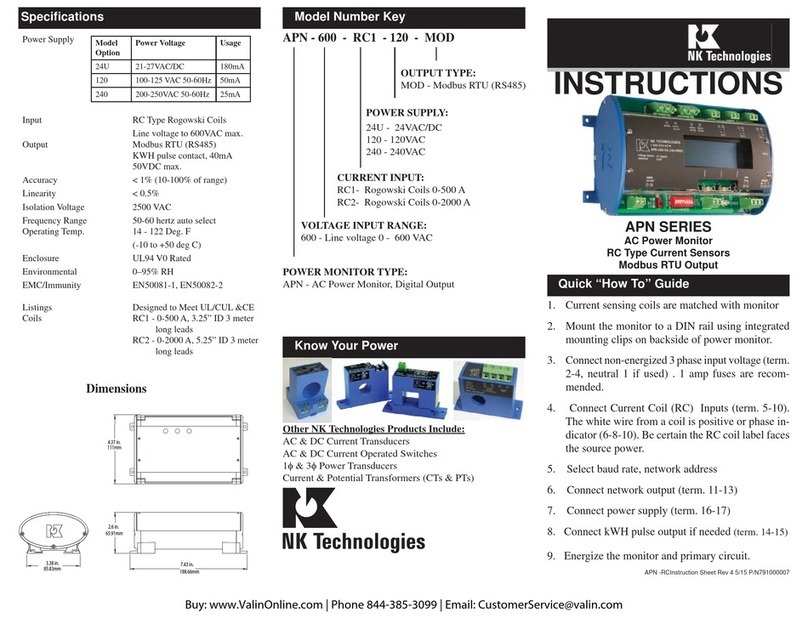

NK TECHNOLOGIES APN Series User manual

1. Ensure correct model was chosen for Current Input

Type: 5 amp or low-voltage 333mVAC.

2. Mount the monitor to a DIN rail using integrated

mounting clips on backside of power monitor.

3. Connect non-energized 3phase input voltage(term.

2-4,neutral 1if used). 1amp fusesare recommend-

ed. Tighten all terminals to 5-7 inch-pounds.

4. Connect Current Transformer Inputs (term. 5-10).

The white wire (or X1 terminal) from a CT is posi-

tive or phase indicator (6-8-10).

5. Select baud rate, network address

6. Connect network output (term. 11-13)

7. Connect power supply (term. 16-17)

8. Connect kWH pulse output if needed

9. Energize the monitor and primary circuit.

10. Set CT ratio and KWH type using buttons below

the display.

APN - 600 - MV - 120 - MOD

CURRENT INPUT:

5A - 5 amp secondary CT

MV - 0.333 VAC secondary (ProteCT)

VOLTAGE INPUT RANGE:

600 - Line voltage 100 - 600 VAC

POWER MONITOR TYPE:

APN - AC Power Monitor, Digital Output

Model Number KeySpecifications

Quick “How To” Guide

OUTPUT TYPE:

MOD - Modbus RTU (RS485)

POWER SUPPLY:

24U - 24VAC/DC

120 - 120VAC

240 - 240 VAC

3511 Charter Park Drive, San Jose, CA 95136

800-959-4014 or 408-871-7510 Phone

408-871-7515 FAX

Know Your Power

Other NK Technologies Products Include:

AC & DC Current Transducers

AC & DC Current Operated Switches

1φ& 3φ Power Transducers

Current & Potential Transformers (CTs & PTs)

Power Supply

Current Input 5 Amp secondary CT or

ProteCT (0.333VAC)

5A series: 50-3000A)

MV series: 5-1500A)

Voltage Input 347/600VAC 3-PhaseWye system

with earthed neutral, Measurement

Category III

600VAC 3-Phase Delta system,

Measurement Category III

Output Modbus RTU (RS485)

KWH pulse contact,

40mA and 50 VDC max.

Accuracy < 1%

Linearity < 0.5%

Isolation Voltage 2500 VAC

Frequency Range Auto. selects 50 or 60 hertz

Operating Temp. 14 - 122° F (-10º to +50° C)

Enclosure UL94 V0 Rated

Environmental 0–95% Relative Humidity non-

condensing

Altitude to 2000 meters

Pollution Degree 2

Indoor Use

EMC/Immunity EN50081-1, EN50082-2

Agency Approvals UL/cUL Listed

INSTRUCTIONS

APN SERIES

AC Power Monitor

Maximum 600 Volts

Modbus RTU Output

Model

Option Power Voltage Usage OVP Category

24U 24VAC/DC +/-10% (50-

60Hz AC power) 180mA II

120 120 VAC +/-10% 50-60Hz 50mA II

240 240VAC +/-10% 50-60Hz 25mA II

APN Power Monitors feature a 35mm wide DIN rail compatible

housing.Itshouldbe installedin aULlistedfire/electrical enclosure

certified under NRTL, or similar.

If the equipment is used in a manner not specified by Neilsen-

Kuljian, Inc., the protection provided by the equipment may be

impaired.

To mount on DIN rail: Orient transducer so that line voltage ter-

minals (1) neutral if used, (2) phase C, (3) phase B and (4) phaseA

are upright/at the top of unit and snap securely onto DIN rail.

To remove, pull the spring clipsaway from the rail onthe monitor underside,

on the left and right corners.

De-energize the monitored circuit. It is not recommended to

install the current sensors over an energized conductor. If unavoid-

able, adopt safe operating procedures when installing or removing

the current sensors.

Identify the monitored circuit phases asA, B and C, in no particu-

lar order. Connect the primary voltage using up to 10 AWG rated

75/90°C, to terminals 1-4,A to 4, B to 3, C to 2 and the neutral (if

used) to 1, and torque to 5-7 inch-pounds.Adding one amp fuses to

the voltage input leads will protect the power monitor. Equipment

can be used to monitor either Wye or Delta systems.

Install UL Listed Energy Monitoring Current Transformer (CT)

certified under category XOBAover each identified phase conduc-

tor. Connect CT secondary using 26-14 AWG wire (twisted pair

if ProteCT CT is used) Phase A to terminals 9-10, B to term. 7-8,

and C to term. 5-6. The CT terminal marked X1 or the white lead

connects to the positive and the black lead goes to negative. It is

essential that the phase relationships be matched. PhaseAvoltage

is connected to terminal 4, CT over phaseA connects to term. 9 &

10, and so on for all three phases as labeled.

The H1 side of the CT must face the source.

The output will not be correct if there are any mismatched

phases. Use a shorting block is highly recommended if 5 amp

secondary CTs are used.

The current sensors may not be installed in a panel where they

exceed 75% of the wiring space of any cross-sectional area of

the panel.

Separate Class 1 and non-Class 1 conductors per NEC.

Description

Installation

Input Wiring

APN Series Power Monitors are designed to monitorAC loads and

provide data points displaying line voltage, current, instantaneous

wattage, accumulated watt-hours and power factor. The APN is

available with a Modbus RTU (RS485) output as standard, and

also provides a configurable pulsed contact representing accumu-

lated watt hours.

Power Supply Wiring Connection

Connect correct power supply voltage to terminals 14 & 15 on

transducer using 22-14AWG copper wires rated 75/90°C and

tighten terminals to 5-7inch-pounds torque. Use 20Abranchcircuit

protection against the remote possibility of a short.

Modbus Address and Baud Rate

1 2 3 4 5 6 7 8

ADD VALUES

1 2 4 8 16 32 64 128

Edge of board

The node address is

set through a series

of eight dip-switches

allowing a possible

address range of1-247.

After converting your

decimal address to bi-

nary either by hand or

with a calculator you can set the dip-switches by flicking the

operating lever toward the edge of the board. As an example,

the illustration above shows the address set at the decimal

value of 23. Switch 1=1, 2=2, 3=4, 5=16. 1+2+4+16=23

Note that switch 8 has the largest value.

Cycle power to the unit after changing the network address.

The baud rate can be set for 9600 or 19200 bps by placing

the switch to the left of the node address block, in the ap-

propriate position.

9600

19200

Power

Supply Baud

Rate Network

Address KWh

Pulse

Modbus

Output

Programming

Buttons

LCDDisplay

4linesof20characters

Primary Voltage Inputs

A

B

CN

If Used

Current Transformer

Inputs

A

B

C

+ -

+ -

NKTech APN Monitor

v.1.00 3ph4W

Set Up Screens

When the field input connections have been made (current

transformers and voltage), and the monitor is powered up,

the LCD will display the following screen:

Product series, firmware version,

and meter configuration (three

phase, four wire).

After approximately two seconds, the display will show the

default data display screen:

Volts Amps Watts

128.8 27.5 2871

129.7 28.5 2997

127.8 27.5 2749

Voltage and current are RMS values, the watts displayed are

active power. The measurement is made with six, twenty four bit

analog to digital converters.

Press one of the three buttons below the display and the

display will change to:

select:

Setup Display Press the button below “Set-Up” and

the display will change:

select:

pick store kwhr

CT kwhr pulse

Press the button below “Pick CT” to

program the CT range value. The dis-

play will show the available ranges for

the type of current sensors appropriate

for the device (ProteCT or 5amp secondary)

select:

333mVCTs

5A Next 15A

Press the button below the matching

value of the current transformers you

have installed. Press “Next” to advance

through the available CT ranges.

select: Save?

333mVCTs

No Yes 15A

Press the button below “yes” to save

the CT range value. Selecting “No”

will return you to the data display

screen.

Display is 4 lines of

20 characters max.

+ -

+ -

Yellow

LED,

flashes

with

kWH-

pulse

select:

pick storeKWHr

ct KWHr pulse

Enter KWHr setup by pressing the button

to either “Store KWHr” to save and display

the accumulated watt hour value to flash

memory or “KWHr Pulse” to save and dis-

play accumulated value only while powered

on. Any change to the meter set-up will clear

the KWHr pulse.

Pressing “KWHr Pulse” before “Store

KWHr” will clear any previously ac-

cumulated watt hour value from flash

memory.

5-Amp Secondary CT

Ranges 333mV Secondary CT

Ranges

50 600 5 250

75 800 15 300

100 1000 30 400

150 1200 50 600

200 1500 70 800

250 1600 100 1000

300 2000 150 1200

400 2500 200 1500

500 3000

The APN can be used with many current trans-

formers, and it must be programmed for the

range you will be using. The ranges available

are:

Next select the rate at which the pulse con-

tact opens and closes. The options are 1/10,

1, or 10 KWH per pulse. The solid state no

voltage contact will open and close when

the selected watt hours have accumulated.

Note: Only the 10KWHr setting is available

with CT ranges of 1000 or higher.

select: Save?

KWHr Yes NO

Once the pulse rate has been selected, the

display will change to show the selected

rate on the left. Pressing the button below

“Yes” will save this value to memory.

Pressing the button below “No” will return

you to the Power Up ID.

After completing the set up programming, the

LCD display can be changed to show several data

points. Press any button, and the display selection

screen will be seen.

select:

Energy PwrFtr VAWatt

Press the button below “Energy” and

the display will change to show the

following:

Energy

sumWatts 3,480

KWHr 127

PwrFtr +0.68

Sum Watts shows the active power

being used at any time.

KWHr increases as kilowatt hours are

accumulated.

Pwr Ftr shows the average power fac-

tor of all three phases.

This is generally the last screen viewed, and will be the default screen

shown. Press any button to return to set up or display other values.

select:

Energy PwrFtr VAWatt

Press the button below “PwrFtr” to

display the power factor of each phase

PowerFactor

A +0.70

B +0.71

C +0.68

The power factor is shown with a (+)

positive notation for inductive loads,

and a (-) notation for loads which are

capacitive.. If the monitored load is in-

ductive, all three phases should show

power factor as positive. If one or

more phases are displayed as “0.01”,

the current transformer is facing the

wrong direction or the leads are re-

versed (X1 connected to negative).

select:

Energy PwrFtr VAWatt

Press the button below “VAWatt” to

display the voltage, current and watts

of each phase.

Volts Amps Watts

128.8 27.5 2871

129.7 28.5 2997

127.8 27.5 2749

About MODBUS and the APN Power Monitor

MODBUS® Protocol is a messaging structure, widely

used to establish master-slave communication between

intelligent devices. A MODBUS message sent from a

master to a slave contains the address of the slave, the

‘command’(e.g. ‘read register’), the data, and a check

sum (CRC). Since MODBUS protocol is just a messag-

ing structure, it is independent of the underlying physical

layer. The interface used by the Monitor is RS-485.

The Query

The function code in the query tells the addressed slave

device what kind of action to perform. The data bytes

contains any additional information that the slave will

need to perform the function. Only function code 03 HEX

(Read Holding Registers) is supported by the Monitor,

other codes will not be responded to and the red FAULT

LED will turn on. The Monitor will read the requested

registers and return their values. The data field will con-

tain the information telling the slave which registers to

read. The error check field (CRC) provides a method for

the slave to validate the integrity of the message contents.

The Response

If the slave detects a transmission error, the message

will not be acted upon, but the red FAULT LED will be

turned on. If the slave makes a normal response, the func-

tion code in the response is an echo of the function code

in the query. The data bytes contain the data collected by

the slave, with the reading of voltage, current, Watts and

Power Factor.

If an out of bounds register is requested , no register

or too many registers have been requested, the function

code is modified by adding 80 HEX to the function code

(returning 83 HEX) to indicate that the response is an

error response. There also will be 2 data bytes of zeros

returned. The error check field (CRC) allows the master to

confirm that the message contents are valid.

RTU Mode

When controllers are setup to communicate on a MOD-

BUS network using Remote Terminal Unit (RTU) mode,

each eight-bit byte in a message contains two four-bit

hexadecimal characters. Each message is transmitted in a

continuous stream.

Coding System

Consists of eight-bit binary, hexadecimal 0 ... 9, A ... F.

There are two hexadecimal (HEX) characters contained in

each eight-bit field of the message

Bits per Byte:

1 start bit

select:

10/KWH next 1/KWH

Press the button below the value you have

selected, or next to see other values.

Pulse Contact Connection

DC Power Source

Out to Controller 10K Pull Up Resistor

Use an external resistor

of 10K ohm from the DC

power to the pulse output

contact (+) and out to the

controller input. Ground

the (-) terminal of the pulse

contact. This will allow volt-

age to pass when the output

is open, and block when

closed. One kwh value is

represented with an open and

closed output cycle.

-+

Table 1 Register Map - Read Only

CT size or

ratio Multiply

data by

5 to 15A 1 (direct

reading)

30 to 200A 10

250 to 2000A 100

2500, 3000A 1000

Table 2 Scaling For Watts

Data

About MODBUS and the Monitor (continued)

8 data bits, with the least significant bit sent first

1 bit for even parity

1 stop bit

Errors that occur during a query, such as parity or CRC,

will flash the FAULT LED and no response will be sent.

RTU Framing

In RTU mode, messages start with a silent interval of at

least 3.5 character times. This time is scaled to BAUD rate

with the BAUD selection switch.

The first field then transmitted is the device address. The

allowable characters transmitted for all fields are hexadeci-

mal 0 ... 9, A ... F. The Monitor monitors the network bus

continuously, including during the silent intervals. When

the first field (the address field) is

received, the Monitor decodes

it to find out if it matches the

address set on the switch. If there

is a match the following bytes

are collected. Following the last

transmitted character, a similar

interval of at least 3.5 character

times, marks the end of the mes-

sage. The Monitor will collect the

data and respond to the master. A

new message will begin after this

interval

Troubleshooting

1. No Data shown on LCD Display

Recheck that all connections are made properly, and the

power supply to the unit is energized. Recheck line volt

age fuses to be sure they are conducting.

2. Negative Power Factor when monitoring an induc-

tive load.

One or more current transformers are reversed, either

the marked H1 side is not facing the power source or the

output leads are reversed. The X1 secondary must be con-

nected to the positive input terminal.

3. Modbus output is not being received at the Master

Check the slave (APN) network address setting to be

sure there are no conflicts with other network nodes. Also

recheck the baud rate settings to match the other equip-

ment.

Address Register Type Description

0 40001 Integer, 16 bit Volts RMS Phase A

1 40002 Integer, 16 bit Current RMS PhaseA

2 40003 Integer, 16 bit Watts (active) Phase A

3 40004 Integer, 16 bit Volts RMS Phase B

4 40005 Integer, 16 bit Current RMS Phase B

5 40006 Integer, 16 bit Watts (active) Phase B

6 40007 Integer, 16 bit Volts RMS Phase C

7 40008 Integer, 16 bit Current RMS Phase C

8 40009 Integer, 16 bit Watts (active) Phase C

9 40010 Integer, 16 bit Watts (active) sum

10 40011 Integer, 16 bit Energy (active) KWH, MSB, (see Note 1)

11 40012 Integer, 16 bit Energy (active) KWH, LSB

12 40013 Integer, 16 bit Power Factor, Phase A (see Note 2)

13 40014 Integer, 16 bit Power Factor, Phase B (see Note 2)

14 40015 Integer, 16 bit Power Factor, Phase C (see Note 2)

Notes:

1. Energy is saved in two registers (40011 and 40012) for a maximum

total of 4,294,967,295 kWHr. To combine the two registers, multiply

MSB by 65,536 and add to LSB

2. A power factor reading of 70 = +0.70 (inductive). A power factor

reading of 198 = -0.70 (capacitive). If the data shows readings greater

than 128, subtract 128 from the reading and change the sign to nega-

tive. In the case shown as an example, 198 - 128 = 70, but the sign

should be changed to negative to represent a leading power factor.

Other NK TECHNOLOGIES Monitor manuals