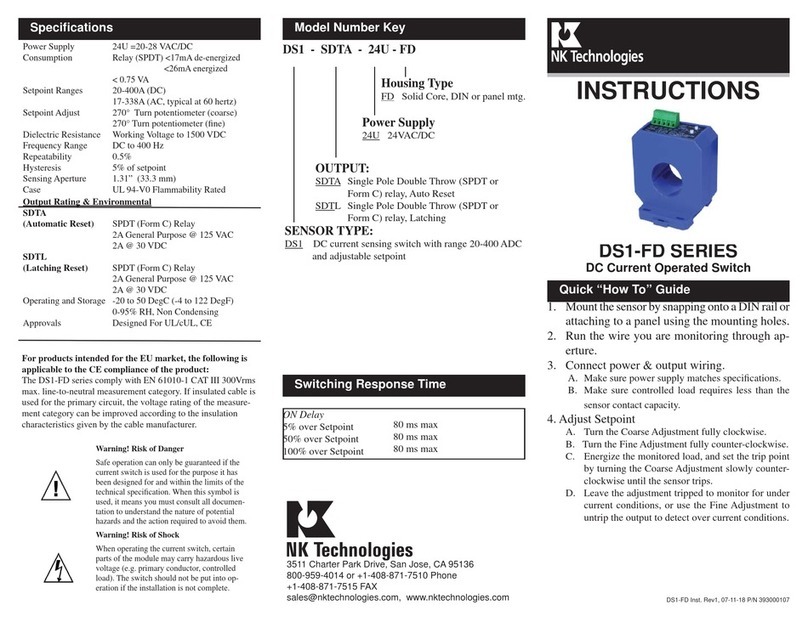

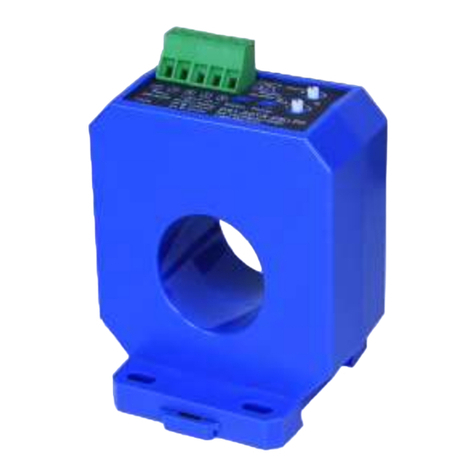

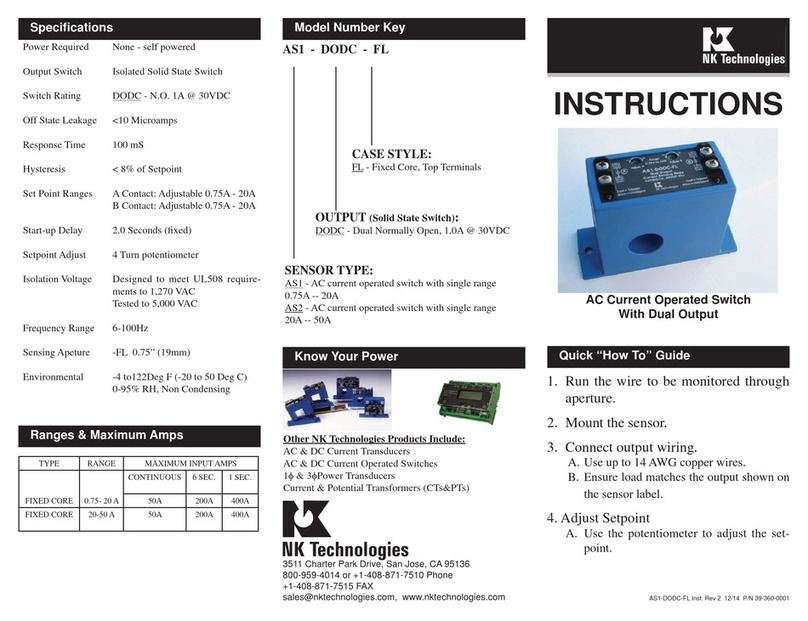

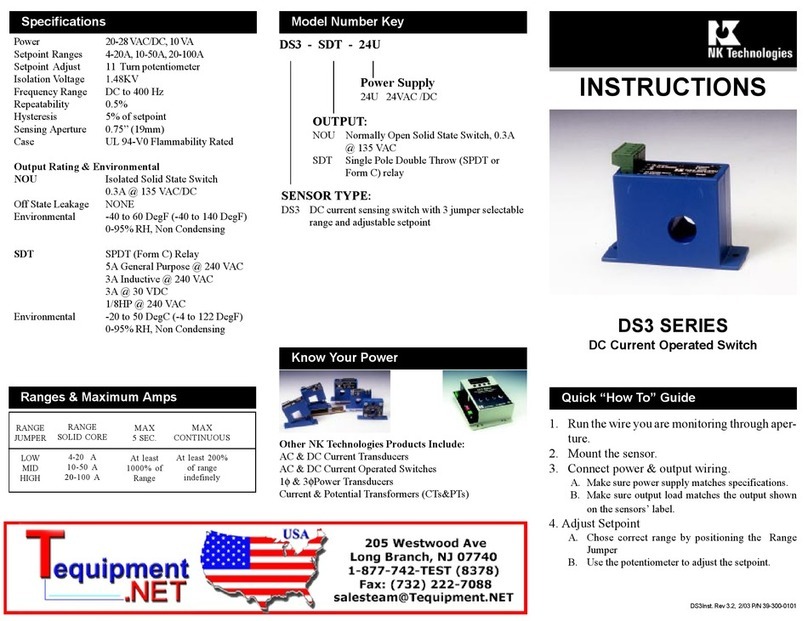

DS3 Series are DC current operated switches. They operate

(switch) when the current level through the hole exceeds the

adjustable setpoint. They accept 24VAC or 24VDC power.

The outputs areisolated from the input andthe power supply.

The sensor can be supplied with solid-state output (-NOU)

or with form C relay output (-SDT ).

Run wire to be monitored through opening in the sensor.

DS3switches work in the sameenvironmentas motors, con-

tactors, heaters, pull-boxes, and other electrical enclosures.

They can be mounted in any position or hung directly on

wires with a wire tie. Just leave at least one inch distance

between sensor and other magnetic devices.

Description

Installation

Setpoint Adjustment

Range & Setpoint

DS3 switches have two setpoint adjustment mechanisms:

1. Select the setpoint RANGE with the Range Jumper.

2. Fine tune the SETPOINT with the 11 turn potentiom-

eter (pot).

The 11 turn pot is shipped from the factory set fully counter

clockwise (CCW) to the lowest setpoint. Turning the pot

clockwise (CW) will increase the setpoint. The pot has a

slip-clutch to prevent damage at either end of its rotation.

To determine where theadjustment is, turn the pot atleast 11

times CCW. This will return it to the minimum setpoint.

Adjustment Notes:

1. NOU output contacts aresolid-state. Check output status

by applying a small load and reading the voltage drop

across the contacts. Anohmmeterwillgivemisleading

results.SDT output contacts are mechanical, and can be

tested with an ohmmeter.

2. We recommend adjusting setpoint to allow for normal

voltage variations.

3. Adaptive Hysteresis (deadband) is 5% of the setpoint.

This allows sensitivity at low setpoints while eliminating

dithering and output chattering at high setpoints.

Output LED

MONITORED

AMPS

OPEN

OPEN

CLOSED

CLOSED

CLOSED

OPEN

OUTPUT TYPE

N.O. N.C.

OFF

OFF

ON

None or below range

Below trip level

Above trip level

1. Sensor is always tripped

A. The jumper may be set in a range that is too low for

current being monitored. Move jumper to the correct

range.

B. The setpoint maybetoolow. Turn pot CWto increase

setpoint.

C. Switch has been overloaded and contacts are burned

out. Check the output load, remembering to include

inrush on inductive loads (coils, motors, ballasts)

Typical Adjustment

1. Make sure all wiring is correct, all terminals are tight and

that power is on (green power LED)

2. Move the jumper to the desired range. Turn the pot to

minimum setpoint (11 turns CCW).

3. Have normal operating current running through sen-

sor. The output should be tripped and red output LED

“ON”.

3. Turn the pot CW until the unit un-trips. This is indicated

by the LED going off and by the output switching.

4. Now turn the pot CCW slowly until the unit trips again.

It now set at the current level being monitored.

A. To Set UNDERLOAD - Turn the pot about 1/8 turn

further CCW.

B. To Set OVERLOAD - Turn the pot about 1/8 turn

further CW.

2. Sensor will not trip

A. Unit is not powered. Check power supply and power

wiring.

B. The jumper may be set in a range that is too high for

current being monitored. Move jumper to the correct

range.

B. The setpoint may be too high. Turn pot CCW to

decrease setpoint.

C. Switch has been overloaded and contacts are burned

out. Check the output load, remembering to include

inrush on inductive loads (coils, motors, ballasts).

Trouble Shooting

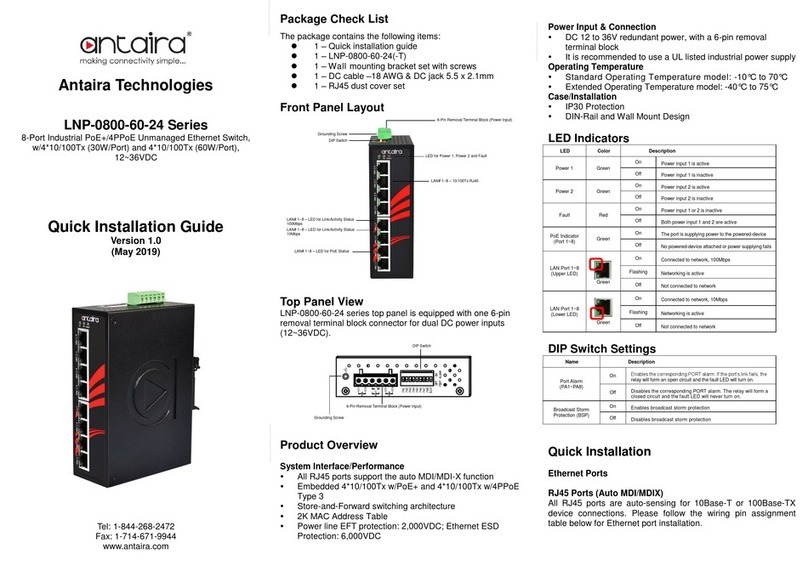

Power Wiring

Connect 24 VAC or 24 VDC (or 12 Volts depending on the

model) power to Terminals 1 and 2. Tighten to 4.5 In-Lb

torque. The connection is not polarity sensitive. Terminals

are removable to make wiring easier. Be sure to seat the

terminal properly in the location marked “Power”

Output Wiring

Connect control or monitoring wires to the sensor. Use

up to 12-22 AWG copper wire and tighten terminals to 4.5

In-Lb torque. Be sure the output load does not exceed the

switch rating.

Incandescent lamps can have “Cold Filament Inrush” cur-

rent of up to 10 times their rated amperage. Use caution

when switching lamps, especially with solid state output

sensors.

3 4

1 2

Power 3 4 5

G R

R

Partial View “-NOU”

Models

Isolated Solid State Output

(Shown De-Energized)

Power Supply

12 or 24VAC/DC

Isolated Relay Output

(Shown De-Energized)

Setpoint

- +

Top View “-SDT”

Models